Old technology problems

Many people know that boilers without connected pumps are often directly connected to the collector, and it is instead of this option that such a hydraulic arrow with a collector is most often used (manufacturing diagram below). These devices were simply removed from boilers with pumps, as a result of which they were installed on each separate heating circuit, but in fact, this option can not be used in all situations, since if at the moment there is still a guarantee on the boiler, then in In this case, it will not be possible to remove the pumps from it, and if we are talking about a cast-iron boiler, then in the case of such a dismantling of its components, when the heating is first turned on, even individual sections of the boiler may burst, unable to withstand such a temperature difference.

What this technology gives

To get rid of all this, today a specialized hydraulic arrow with a manifold is used (the manufacturing scheme is presented in the article). This device is intended to separate the hydraulics, and more precisely, it divides the boiler directly from the rest of the heating system. Thus, for example, a hydraulic arrow with a manifold (the manufacturing diagram is illustrated) can provide a single pump in the boiler, while several more such units of different capacities are installed in the system.

How does it work

The device of such equipment is extremely simple. At the moment, we will not disassemble any high-tech devices, but consider only the main options for implementing such a technology.

In principle, it is enough to use a standard piece of pipe from which the hydraulic gun (hydraulic separator) is made. The calculation of the hydraulic arrow will allow you to understand what basic characteristics such a device should have and what materials are best used for its manufacture.

What is its purpose

First of all, the designers try to proceed from the fact that the arrow is intended specifically to separate the hydraulics. In the overwhelming majority of cases, manufacturers today are trying to produce boilers equipped with their own pumps, and such devices are quite powerful.

For example, there are boilers with a closed combustion chamber in which built-in pumps are installed. The power of such devices can be approximately 300 watts, but in fact it will not be enough to completely push through the heating system if it is required to provide an object for 1000 m2, namely, such equipment is approximately designed for such an average heating area.

In this regard, it is necessary to install additional pumps, as well as use combined systems. It is in such a situation that, instead of help, the pump that is initially used in the boiler will simply interfere, and it is in such cases that a hydraulic arrow can be used (purpose, calculation, manufacturing - more on this later in the article). At the same time, it is worth noting the fact that such high-power equipment in the majority of cases is initially supplied with a factory hydraulic arrow in the kit, or at least there is a fairly accurate instruction on how to connect it.

If you take smaller boilers, then basically the same story is with them, but in this case you will have to make your own.

Appointment of the device

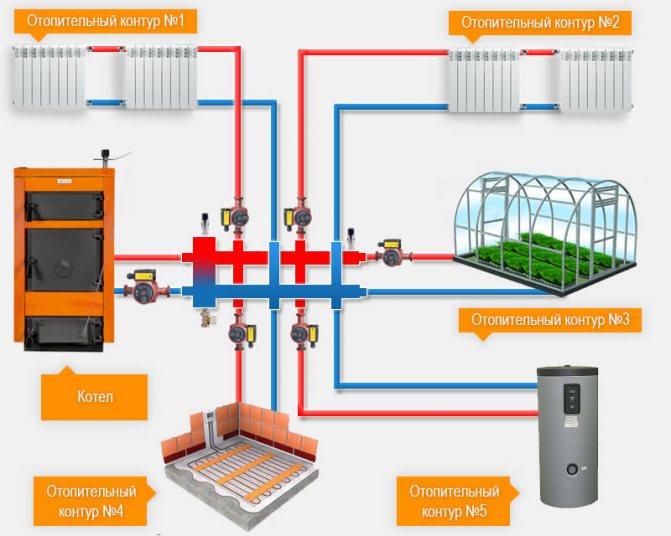

The expediency of using a hydraulic separator is justified in large houses where there are 2 or more heating circuits.

The hydraulic arrow described here is necessary to balance the pressure level in the entire boiler system when the indicators in the main circuit change. TThis device easily regulates the three-circuit version of the system, in which both a water heater, a heating radiator, and even a warm floor are turned on at once.

When all the rules of hydrodynamics are observed, stable operation in normal mode is ensured.

Worth knowing: most of the hydraulic switches are installed in a strictly vertical position, so that air is removed from the system completely automatically.

Also, a hydraulic separator is a kind of sump, in which various formations are removed from the coolant, be it scale or corrosion. But this happens again if all hydromechanical standards are observed.

It is worth noting that such a function of the hydraulic arrow, made of both stainless steel and other materials, increases the service life of many parts in the heating system. Such a device also removes the air formed in the coolant, which reduces the oxidation process in the metal parts.

You may be interested in the article on the condensing gas boiler. You can read about how to choose a gas boiler in this article.

You may also find useful an article on how to make a waste oil boiler with your own hands.

In the classic version of the design, which provides for the presence of only one circuit, if several branches are disconnected, then the heat consumption in the system is reduced. Therefore, the temperature of the coolant after passing the entire path decreases slightly. Hydrostrelka, on the other hand, allows you to maintain a stable level of heat consumption, thereby ensuring stable circulation in the system.

Where is it installed

The hydraulic arrow is installed on floor-standing boilers without a built-in pump to ensure effective protection of the boiler against large temperature differences during the first start of the heating system. For example, using this equipment, standard steel boilers can be protected from the generated condensate, while cast iron devices can be protected from the possibility of failure of individual sections.

To exclude such unpleasant situations, a specialized hydraulic arrow is used. The drawing and diagram of the boiler room in this case play an important role, since depending on the characteristics of the heated object, you need to choose the appropriate equipment. The only thing worth noting is that you also need to use an additional pump for various floor standing boilers.

Example

Initially, a person in his house wants to get an almost ideal heating system, having spent reasonable money on it, and in this case it all starts with the boiler. For a small private house, you can choose a standard double-circuit boiler with a closed chamber, which will be mounted on the wall. At the same time, you need to correctly understand that in the overwhelming majority of cases, to ensure the normal distribution of the coolant in this system, it may be necessary to individually manufacture the heating manifold for the hydraulic arrow. In such a situation, a completely standard question arises: will their pumps be used and what needs to be done with the device in the boiler?

It is quite natural that many people in such situations prefer to simply dismantle the pump from the boiler so that it does not spoil the installed hydraulics of the system, but in fact, the design of some devices is made in such a way that it is unlikely to be possible to do this procedure.It is in such situations that the connection of the hydraulic arrow boiler and the collector becomes the ideal solution.

Why do you need such a thing?

Heating a private house provides for the mandatory presence of balancing devices. Otherwise, the user will have to suffer with the setting, and this is not the worst thing. The absence of an optimizer in the system can lead to boiler breakdown, which will be very expensive to restore. Add to this

1. Fluid pressure drops on the lines (most of the carrier goes to the circuit with a more powerful pump)

2. Air pockets (increased air content leads to rust formation)

3. Harmful impurities (mechanical dirt from friction and twisting of internal parts, sludge walking through the pipes clogs the exits, which inevitably leads to unplanned stops of the carrier and disables the fittings)

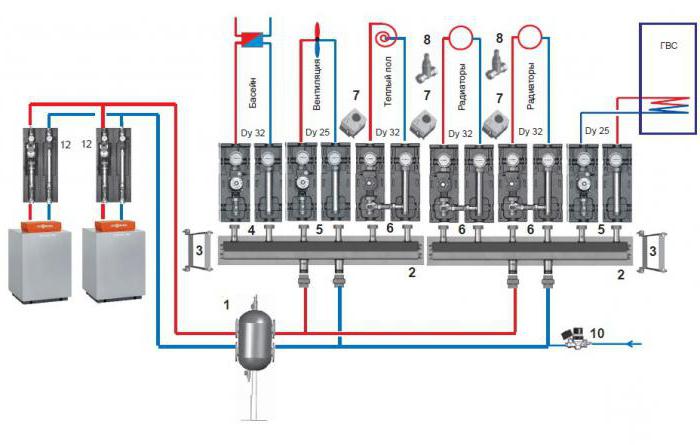

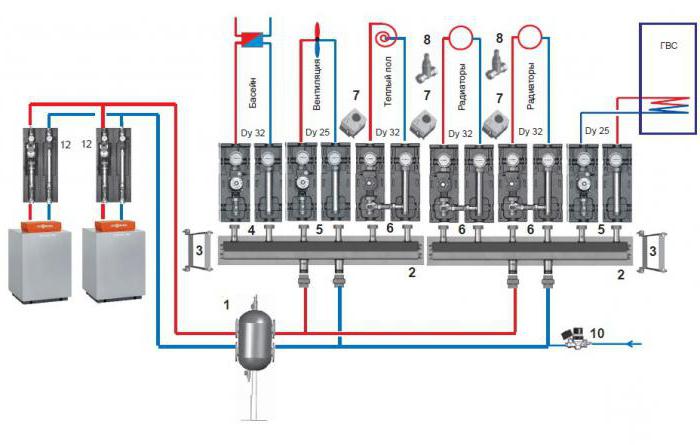

To prevent such force majeure from happening to your system, it is necessary to install a low loss header paired with distribution manifolds. Why with them? The coolant needs to flow somewhere. Through the collector pipes, it will go directly to the consumer, and each will have its own supply and return lines. This is very convenient, especially when you are assembling a module and want to combine all the liners in one place. The manifold with a hydraulic arrow will become a reliable base to which all equipment is quickly connected. And if you choose the right mixers, thermostatic valves, actuators and other automation, then the benefits will increase at least twice. The verified temperature regime significantly reduces energy consumption, which in turn allows you to save on electricity.

How is the installation carried out in such a situation?

Initially, a distribution manifold diagram is drawn. As an example, consider the following situation:

- Two contours of underfloor heating.

- The system will use an indirect heating boiler circuit, two spare circuits for a heat pump or a separate electric boiler, as well as a hydraulic arrow circuit, that is, 5 circuits.

In this case, there is nothing difficult in how to draw a collector diagram - it is enough to have at least some understanding of how such a system works.

Types of collectors in heating systems

According to the specifics of functioning, the product range is divided into 3 types - solar and distribution collectors, hydraulic arrows. The second position has the greatest coverage of consumers.

Solar collectors

They are intended mainly for solving economic problems; in the southern regions, all processes related to heating can be safely entrusted to them. In middle latitude with insufficient solar radiation, such collectors are used to provide hot water supply during those periods when the heating boiler is idle.

The collector of solar panels consists of registers placed in vacuum tubes, they interact with a closed circuit operating on the basis of a liquid agent. As it evaporates, the agent rises to the heat exchanger and heats the working medium. When it cools, the substance sinks, thereby laying the cycle of the process.

Hydrostrel - thermohydraulic distributor

The device is used to balance the heating system: it equalizes the temperature and pressure of the liquid working medium in different heating circuits. This element creates an optimal difference in characteristics between the two flow directions - supply and return, controls the degree of mixing. Hydrostrelka not only provides a stable microclimate in the rooms, but also creates gentle conditions for the use of boiler equipment.

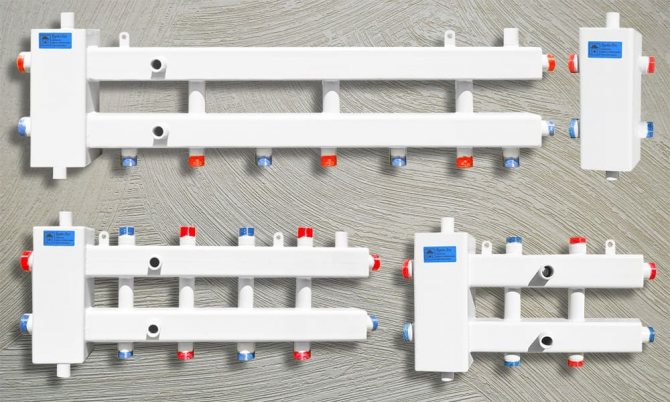

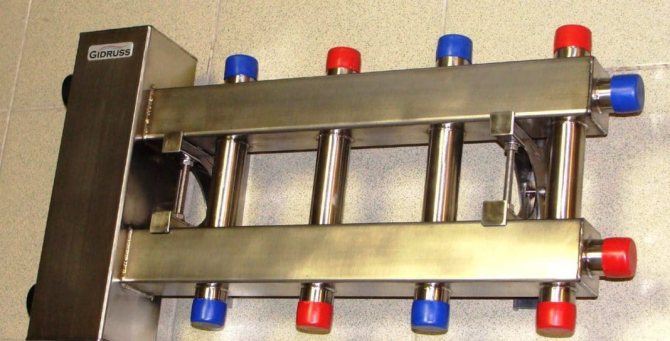

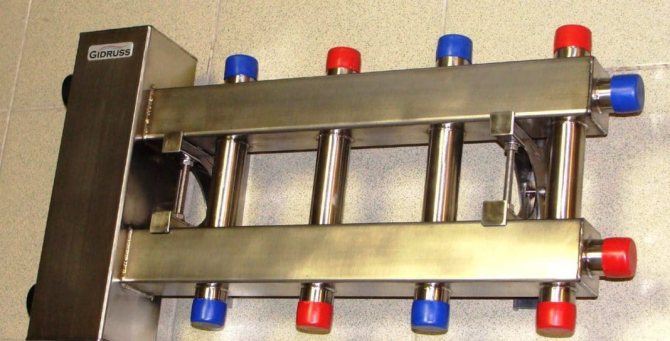

In the photo, a hydraulic arrow with a stainless steel manifold

The hydraulic separator is actively used in complex heating circuits based on several heating circuits; it combines a boiler with radiators, hot water supply, and underfloor heating. Factory models of devices include flow separators, as well as mechanisms that remove air and contaminants from the system.

To optimize heating, it is advisable to equip each circuit with its own pump. Hydrostrelka is a special category of collector, it is distinguished by the ability to work with large pipe diameters, it is mounted in a boiler room in a vertical plane.

Distribution manifolds for the heating system

They carry the flow of the working medium directly to the heating devices. Structurally, the product consists of a pair of combs, the first is necessary to deliver the coolant to the heating points, the second is used to drain water back to the boiler room. In the end part of each distributor, connections to the mains are provided, directly along the body you can see fittings for specific devices, in particular, for underfloor heating circuits, heating batteries.

Arrangement of radiator heating using a distribution manifold, in comparison with traditional 1-2-pipe schemes, is carried out in parallel, and not, as everyone is used to, sequentially. The coolant, bred in all branches, has the same temperature. The characteristics of each radiator or group within the same circuit can be set in accordance with requests, and you can not be afraid of their mutual influence.

For underfloor heating, the use of combs is the only feasible option to ensure smooth operation of the system. If necessary, the collector can be mounted discreetly, disguised with a special cabinet placed in a niche.

Manufacturing and calculation

It is worth noting the fact that you can independently adjust the power that your hydraulic arrow will have. How to calculate the power, you need to proceed directly from the characteristics of your room and the devices used.

If you do not need the power of the device you purchased, then in this case it will be possible to reduce the threads in diameter, but at the same time make a longer arrow. In some situations, it is advisable to reduce the total power of the purchased equipment in power by up to two times, since, for example, 80 kW devices are not needed in every home, and in such cases it would be quite optimal to leave equipment with a capacity of 40 kW or more.

How to arrange it

Some who use the scheme for making a hydraulic arrow with their own hands prefer to install it in the immediate vicinity of the boiler, but many experts say that mounting this device on a manifold is also a good option, which ultimately allows you to achieve a complete and harmonious design that will further easy to use, check and maintain.

In this case, the boiler can be installed approximately three meters before the installation point of the arrow, while the boiler supply and return lines can be mounted through the floor if there is a floor heating cake in the house. Otherwise, there are no fundamental differences in where your arrow will be mounted, and the main thing in this case is the installation of equipment with a suitable power and always in a vertical state. If you are making a hydraulic arrow for a heating system (diagram / calculation above), in which a boiler is installed without a safety valve, then it is recommended to weld an inch thread to the top of the device for mounting a special safety group.

It is also recommended to weld a small thread in the lower part to ensure proper drainage and filling of the arrow. An obligatory practical condition is the insertion of specialized couplings for mounting thermometers into the system "boiler, hydraulic arrow and collector".In the process of further operation, this can make your life easier, as it will allow you to easily monitor the state of the heating system.

What hydraulic processes take place in a hydraulic gun?

In order to understand the reasons for installing a hydraulic separator in the heating system of a house, it is necessary to understand what happens to the water during its passage in the cavity of the hydraulic arrow. For these purposes, it is imperative to understand the essence of the main parameters of the functioning of a correctly designed two or more circuit autonomous heating systems using a hydraulic separator.

- After completing the installation work, welding all butt joints in the pipes, the heating system is filled with cool water, as a rule, within 5 - 15 degrees.

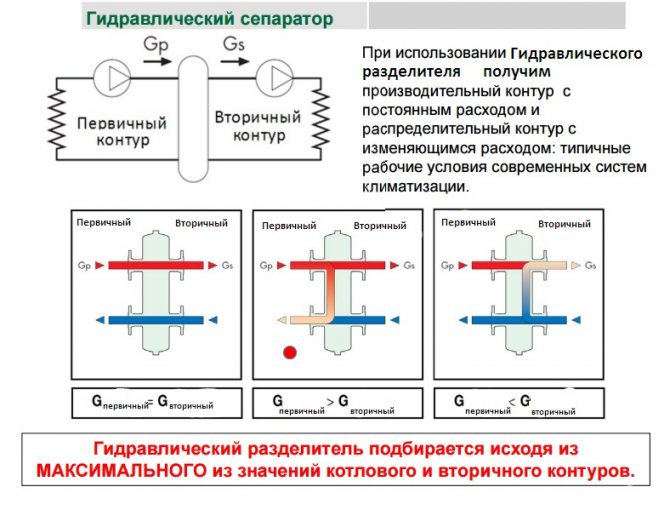

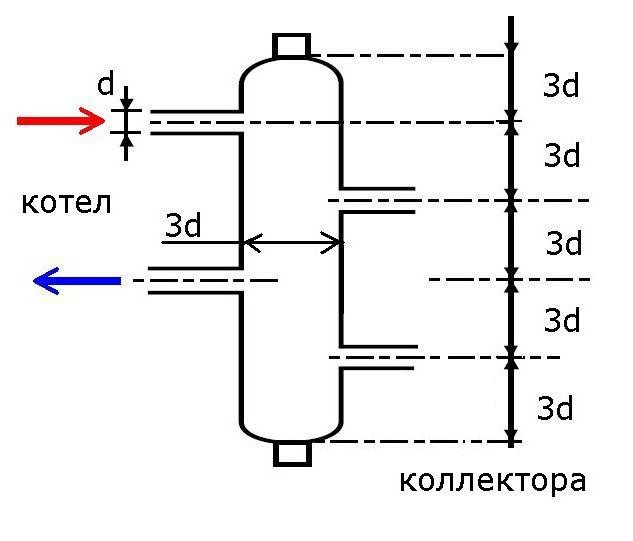

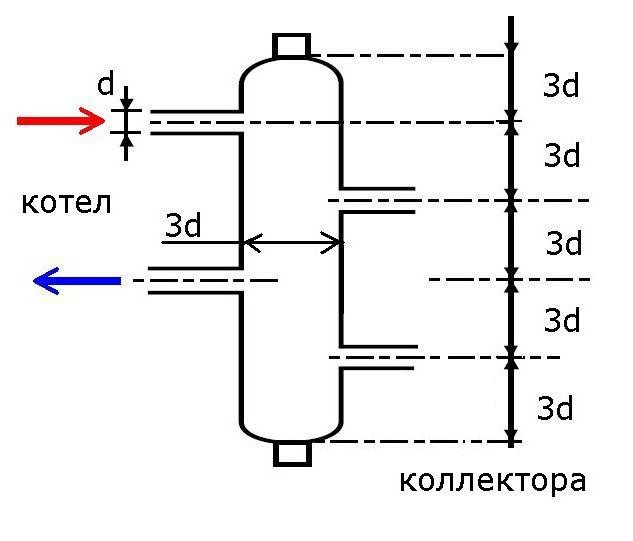

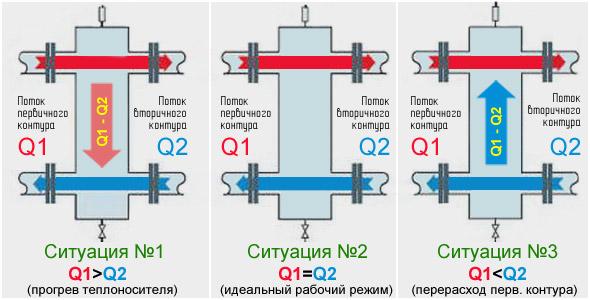

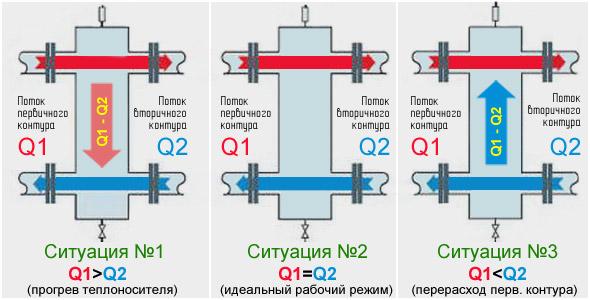

- When the boiler is turned on, the automation connects the circulation pump of the main circuit and the burner is fired up, since the coolant has not yet reached the temperature set by the program, the pumps of the secondary circuits do not turn on and the coolant moves only along the primary circuit. Thus, the entire flow will be directed down the hydraulic arrow, as shown in the diagram (Situation No. 1).

- Immediately after the coolant reaches the set temperature level, an equivalent extraction of the secondary circuit of the water flow begins. In an exceptional manner, equal water flows, the main and secondary circuits, the hydraulic arrow functions only as an air vent and a dirt-fuel oil trap, that is, as already mentioned above in points 3 and 4. Thus, a standard heating process and hot water heating occurs for the needs of your home (on the diagram, this is Situation No. 2). It is imperative to pay attention to the fact that it is practically impossible to achieve absolute equality of water flows Q1 = Q2 in all circuits of the heating system in practical application. That is why, without fail, it is necessary to install a hydraulic arrow in the heating system of the house.

- Further, the automation will regulate the flow rate in the secondary circuit, for example, when the water in the hot water supply reaches the set temperature, the hot water supply pump turns off; in conditions where the thermal heads of the radiators close the flow due to the overheating of the room on the sunny side, thereby increasing the hydraulic resistance in this heating circuit, the automatic adaptive pump is triggered, reducing their performance and reducing the flow Q2. Through this, the flow Q1-Q2 begins to move up the hydraulic arrow (Situation No. 3 on the diagram). If there is no hydraulic arrow in the heating system, at least the circulation pumps would fail due to significant hydraulic skew.

- When the boiler automation stops the pump of the main heating circuit, the flow of the coolant in the hydraulic arrow tends to go up (Situation No. 3 in the diagram). But this situation is very rare.

Let's summarize briefly. Considering the above, we can say that installing a hydraulic arrow in the heating system of your house is vital if you have 2 or more heating circuits and the boiler has a cast iron heat exchanger.

How to make it

If you have a standard welding machine and experience with such equipment, then in this case there is nothing difficult in welding a full-fledged hydraulic arrow yourself. However, at the same time, you need to correctly understand the fact that in the process of performing this work, you need to take into account a large number of subtleties.

Nowadays, there is nothing difficult in finding a drawing of a hydraulic arrow, but at the same time you need to correctly understand that all such drawings are different, and there is no specific template. Each specialist sees the structure of a hydraulic arrow differently, but there are certain rules that are followed by absolutely everyone.

The arrow itself is a certain metal container, to which the pipes are welded, designed to connect to the boiler and provide supply and return. Also, consumer pipes are built into the system.

Optionally, you can use the branch pipes intended for the automatic air vent in the upper part of the installed arrow. In the lower part, a tap pipe is installed to ensure the removal of various sludge and dirt. Among other things, in some place you can also put a pipe for making up water in the system.

How does a water gun work

Hydraulic arrow device diagram

The genius of this device is that all the processes of mixing cold and hot flows in it occur naturally, only according to the laws of physics. And also the fact that it performs its main functions only when the system is started and any nuances that have arisen during operation. The rest of the time, it serves only as a store of excess air and harmful deposits. True, in most cases, the so-called quiet mode of operation can be observed not so often. It is quite difficult to achieve the same heating of all circuits, so the presence of a hydraulic valve is more than justified.

To make it clear, we will give an example of the work of a do-it-yourself hydraulic arrow for heating, during the first start of the system. After starting the heating boiler, cold water begins to circulate in the pipes, driven by circulation pumps. Getting into the water gun, warmer water rises up, and cold water goes down to the boiler, where it heats up and is sent back to the system. Agree, everything is quite simple and quite understandable. But for all this simplicity, the device provides the system with the following advantages:

- Correct system pressure.

- Automatic distribution of temperature flows in the desired direction.

- Smoothing water hammer.

- Disconnection of one circuit independently of the others.

- The efficiency of the heating boiler is increased, which leads to fuel savings.

Well, and the already mentioned air valve and waste drain valve.

First rule

The most important rule that must always be followed is the so-called "rule of three diameters", that is, the diameter of the hydraulic arrow you installed should be three times larger than this parameter for the nozzles. If you want the hydraulic separator to be able to fully perform its main functions, that is:

- separate sludge from the system;

- remove gases;

- equalize the hydraulic difference;

- supply heated water to the boiler in order to ensure its greater durability.

Many people prefer to save money and make their own hydraulic arrows from polypropylene, but in fact this is an absolutely wrong decision, taken mainly by people who have little understanding of the features of the operation of such equipment.

It is for this reason that it is worth using only full-fledged metal pipes, which allow you to fully realize the potential of such a technology and will really show themselves effectively throughout the entire service life of such a system.

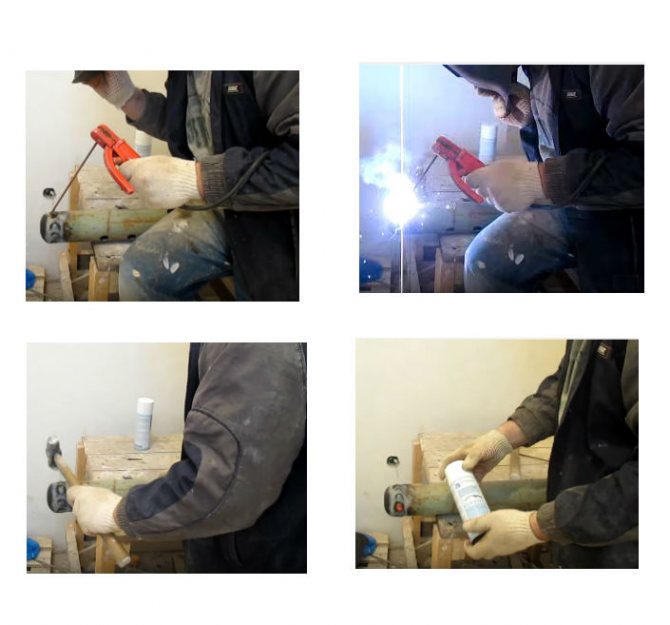

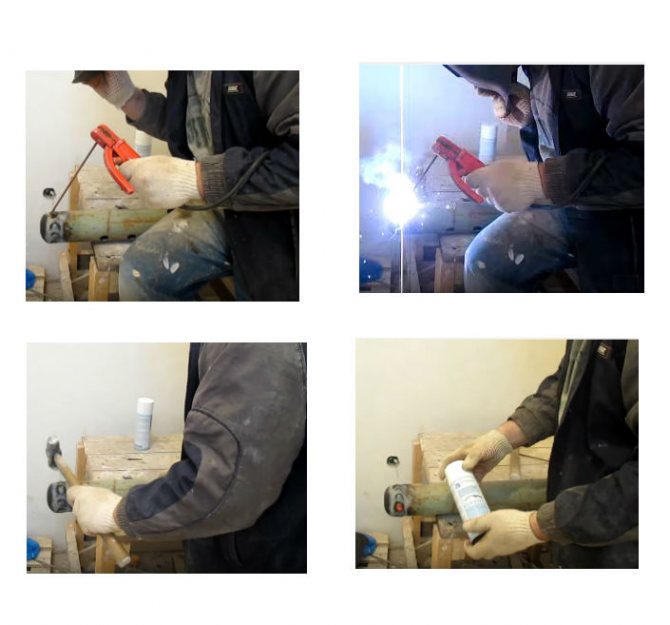

Do-it-yourself water gun made of steel

To make a hydraulic arrow from steel according to the found scheme is, let's say, not easy. Working with metal requires certain knowledge and training. The challenge starts with choosing the right steel grade. Many craftsmen think that any piece of pipe that is lying around in the garage or closet will do. This is not true. Indeed, the service life of the hydraulic arrow and its appearance depend on how high-quality the base will be. It is best to take stainless steel or structural steel. Both brands are sold in sheets, it is quite difficult for a novice craftsman to work with them, so we recommend that you pay attention to steel pipes.Many installers choose them as a basis. For example, the famous video blogger and repairman Vitaly Luzhetsky from Rostov-on-Don cooked a water gun from a metal pipe.

A pipe with a diameter of 76 mm along the inner circumference was taken as a basis.

After the inspection, Vitaly proceeded to drill the holes to which the thread will be welded in the future.

There were eight outputs in total: two for connecting the boiler and three for supply and return

The author welded the water gun on his own, because he could not find a finished product in his city that was suitable for the given parameters. The fact is that the house already had a double-circuit boiler, the performance of which was not enough, they decided to install an indirect heating boiler. It cannot be connected directly to the boiler, so we made an "intermediary".

Next, we lay out the components. Threads or "nipples" DN 20 3/4 ″ with inner rims for welding to inlets and outlets and plugs for end holes.

A 1/2 ″ thread is also installed on top of the plug for connecting an automatic air vent

Then welding is started. First, they work with caps.

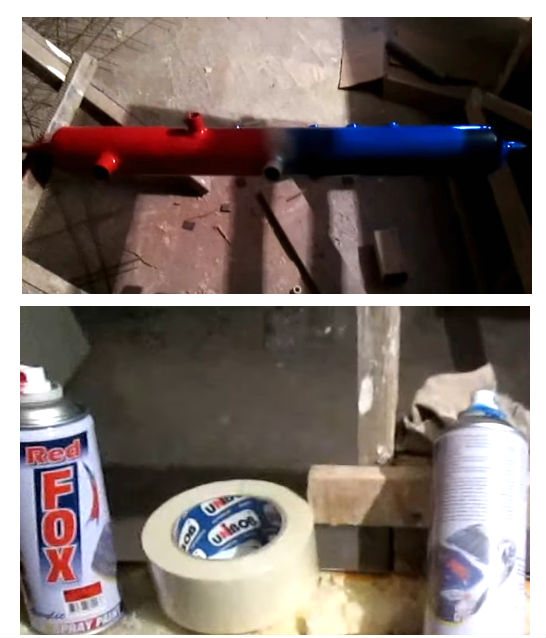

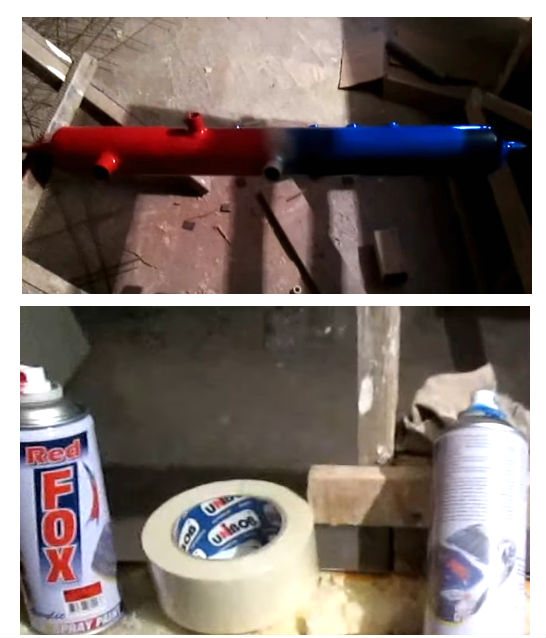

The unevenness of the seams is cleaned or grinded with a grinder. A special compound is sprayed onto the seam, which reduces the electrification of the metal.

The photo on the left is a rough version. on the right - intermediate (the junction is turned)

The next stage of welding involves the installation and connection of the threads. Here you need to pay attention to the accuracy of the diameters.

Rough welding does not look very aesthetically pleasing, but all flaws can be eliminated at the grinding stage. Particular attention is paid to the joints (transition areas). If there are many irregularities, puttying is additionally carried out. The body of the product is preliminarily primed and allowed to dry for several hours.

Also, do not forget about crimping. Usually the arrow is checked even before finishing, the allowable range is 10-16 atmospheres. The final painting is carried out only after all the preparatory work has been completed. The spray paint was applied at intervals of 15 minutes. There are only three layers.

The cost of the product was about 2 thousand rubles.