The autonomous gas heating system from the Korean manufacturer Navien is quite in demand among consumers, it is installed both in country houses and in apartments.

Navien units gained their popularity due to their good technical characteristics, ease of use and installation. Like all household appliances, the Navien gas heating system also has its own faults.

Of course, the manufacturer gives a guarantee for his device and claims that the probability of breakdowns is practically zero, given the high quality of the equipment. But if this happens, then with a competent and timely approach, they can be quickly eliminated.

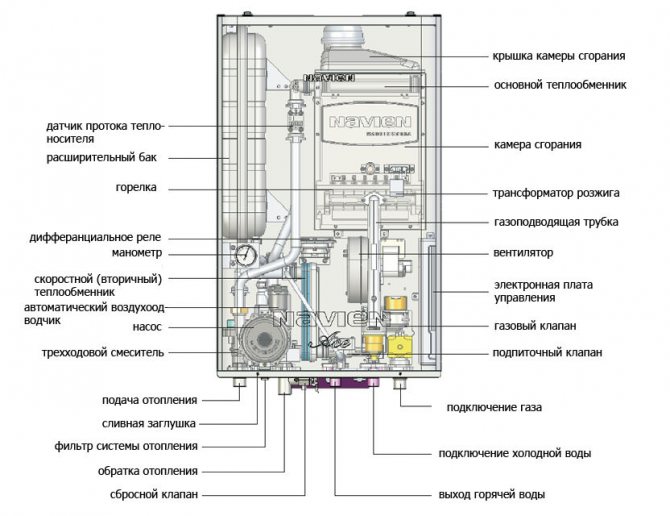

Design features

Boiler device

To attract the attention of buyers, the Korean manufacturer has developed a perfect design of the gas unit, minimized the number of breakdowns and released its product at a relatively low price. One of the advantages of a gas unit is an understandable and detailed instruction manual, which greatly simplifies the setting of the selected mode.

The company adheres to the same principles in the installation of the electronic control system, in the regulation of other parameters.

The versatility of a gas boiler can be judged by its working abilities:

- Adjustment circuit with microprocessor chip allows you to both protect and smooth out voltage surges in the power supply network. In the event of changes in the current parameters, the electronic system is able to maintain a mode for the full functioning of all components of the unit, which has a positive effect on the operational life of the device. And also the adjustment scheme allows you to avoid possible malfunctions with false switching on of the sensors. This feature of the electronic system is of particular importance for the operation of the equipment, given the instability of the voltage in the power grid and its deviations in a wide range.

- The design of the gas boiler is designed with a possible fall water pressure indicator up to 0.1 bar. This makes it possible to minimize blocking actions and breakdowns of the device, which is ideal for its installation on the upper floors of a building.

- The Navien boiler is able to neutralize possible malfunctionscaused by a decrease in supply pressure to 4 mbar, which is critical for the normal functioning of many modern systems equipped with electronic controls.

- Due to the design features of the Navien gas appliance, the heating system will not freeze even when the gas supply is cut off. In order to prevent the activation of the emergency mode when the temperature of the coolant drops below 5 degrees, as well as the impossibility of igniting the burner, a built-in pump was provided for forced and continuous circulation of water.

- There is a double heat exchanger for separate heating of hot water and heat carrier, which is very convenient (you can optionally adjust the preheating of water). The easy-to-use electronics allow you to precisely set the correct mode.

Error 02

Error 02 reports that the Navien boiler has a low coolant level. Or there is a problem with the flow sensor. As a rule, when the Navien boiler gives an error 02, boiling water comes from the hot water tap for the first seconds, and then cold water. That is, the water temperature sharply becomes maximum and also drops sharply.

How to fix error 02

1. Adjust the pressure in the heating system. 2. If there is excess air, bleed it through the special valve. 3.If the problem is due to a closed control valve, open it. 4. Check the functionality of the flow sensor.

Types of boilers

On the market you can find goods from Navien in a fairly wide range, where the following models are especially popular:

Wall mounted equipment made in two variations

The devices are normally able to function even with an unstable supply of electricity and gas. The units are equipped with a turbocharger and an anti-freeze protection system.

Floor standing units

Ideal for installation in private homes. They provide the room with hot water and heat. Advantages: compactness, simplicity of design, ease of use. The power indicator can vary from 11 to 34 kW.

Condensing products

High power rating and economical energy consumption. The boiler passport of this type indicates the efficiency level of 108%. The main advantage: the unit can significantly reduce the cost of heating the room.

Frequent malfunctions

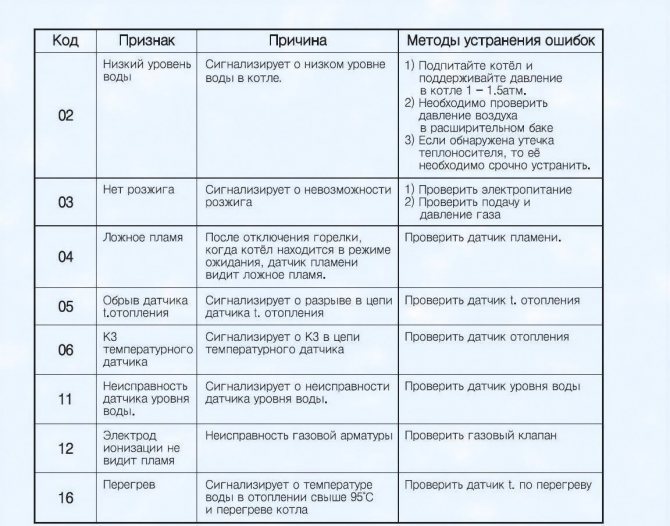

Gas boilers Navien, although they are distinguished by high quality components, correct assembly, can fail. Each breakdown has its own code, which is displayed on the device display.

Common problems include:

- An increase in temperature, leading to overheating of the equipment (01E).

- Insufficient level of coolant in the system, and also the circuit of the flow measuring device (02E) is damaged.

- Flame signal missing (03E).

- Invalid warning about the presence of fire or short circuit of the sensor circuit (04E).

- Open circuit in the heating water temperature meter (05E).

- Short circuit of a circuit in the temperature sensor (06E).

- Damaged circuit in the hot water temperature sensor (07E).

- Violation of a circuit in the hot water temperature sensor (08E).

- Fan faults (09E).

- Difficulty eliminating smoke (10E).

- In the process of work, the fire (12E) went out.

- A short circuit has occurred in the heating flow meter (13E).

- No gas supply (14E).

- There is a problem with the control board (15E).

- Unit (16E) overheated.

- DIP switch (17E) has failed.

- Overheating of the fume extraction meter (18E).

- There is a problem with the air pressure sensor (27E).

- The presence of noise and buzzing without displaying an error on the displays, which happens when the passage of water is obstructed by scale in the pipes, when overheating or boiling.

- There is no hot water supply, indicating a problem with the 3-way valve (it needs to be replaced).

Error codes

The Arderia gas boiler is generally stable. But this does not mean that the technique does not need care. Accumulation of scale, debris, soot leads to system malfunctions. Sometimes the causes of malfunctions are external factors: pressure drops in the line, voltage surges in the network.

As soon as you notice the fault code on the display, take a look at the instructions. The first thing the manufacturer recommends is to reboot. If after switching on the error is highlighted again, look for its value in our table.

| Error codes | What do they mean | How to fix it yourself |

| A1 | The pressure sensor has shorted. Problems with the removal of combustion products. |

|

| A2 | Traction has disappeared. |

|

| A3 | The head sensor was triggered before the pump started. |

|

| A4 | The safety thermostat has tripped.Boiler overheating. | How to restore work:

|

| A5 | The pressure in the heating system drops. |

|

| A6 | Ignition problems. | How to repair:

|

| A7 | The relay is closed, the fuel valve is out of order. | Check for serviceability of the valve, relay, contacts. Defective electronic board. |

| A8 | The flame in the burner is not extinguished, although the supply valve is closed. | Examine the valve diaphragm. If deformed or damaged, install a new element. Contact a specialist to replace the Control Unit. |

| A9 | The system signals that the temperature drops to 5 degrees. | If it does not start automatically, turn on the device yourself. |

| AA | Overheating of the coolant. The reading has exceeded 100 degrees. |

|

| AND YOU | The thermostat is out of order. | Ringing the sensor contacts for short circuit, open circuit. Installing a work piece. |

| AE | The chimney is blocked. | Remove foreign objects from the pipe. If the pipe is deformed, it is necessary to install a new structure. |

Causes of malfunctions and their elimination

To understand how to eliminate a particular malfunction in the gas unit, you need to know the causes of the malfunctions:

- Code 01E indicates an increase in the temperature regime in the device. This is possible due to a blockage in the ducts, which provoked their narrowing, or there were problems with the circulation pump.

- Code 02E indicates the presence of air, insufficient water, damage to the impeller in the circulation pump, closed control valve, or the flow sensor has become unusable.

- Code 03E lights up as a result of problems with the ionization sensor, lack of gas supply, ignition, with the tap closed, with improper grounding of the boiler.

- Code 05E indicates poor contact between the temperature sensor and the controller, or the presence of a short circuit in the same area.

- Code 10E is displayed on the screen in case of fan failure, as well as in case of improper connection of the sensor tubes directly to the fan. In addition, a clogged chimney, a strong gust of wind can also cause device malfunctions.

- Code 11E, as a rule, is displayed on European-made boilers (with appropriate sensors).

- Code 13E indicates a short circuit in the heating water flow meter.

- Noise generation and hum is possible with a poor coolant.

- The reason for the lack of hot water is the valvewhich has fallen into disrepair. Optimum valve life is 4 years.

How to fix:

- Error 01E: carefully inspect the impeller in the circulation pump to detect various malfunctions; check the resistance in the pump coil itself; examine the heating system for the presence of air (excessive venting).

- Error 02E: deflate; check the pressure, resistance in the coil; whether a closure has occurred; open the valve (control valve); check the resistance in the flow meter; remove the sensor housing and clean the flag.

- Error 03E: clean the flame sensor from debris (you can use fine-grained emery paper to get rid of gray deposits on the electrode).

- Error 05E: examine the circuit from the controller to the sensor. If there is a problem, the sensor should be replaced with a new one. The connectors of the meter and controller must first be disconnected and then reconnected.

- Error 10E: repair the fan or replace it; check the connections on the pipes of the measuring device; clean the chimney from all kinds of debris.

- Error 13E: replace the sensor.

You can get rid of noise and hum if you disassemble the product and clean the heat exchanger. If the problem persists, the part must be replaced. Inspect the taps, they should be open as much as possible. Reduce water temperature.

Other malfunctions

Consider what to do in case of malfunctions when an error is not displayed on the screen:

- If you feel a clear smell of gas, immediately turn off the boiler, all electrical appliances and close the gas valve. After that, call the gas service, which will have to check the gas pipeline and the boiler itself. Be sure to open a window and listen carefully to yourself, as there is a danger of carbon monoxide poisoning.

- After turning on the device, the fan starts working, and the flame does not appear in the burner. The mains voltage may be too low. You can check this with a voltmeter. To eliminate this problem, install an additional voltage regulator.

It is also important to inspect the chimney for blockages and foreign objects. This is also caused by a malfunction of the air pressure switch and a lack of tightness in the combustion chamber. - If the flame is red or yellow during operation, the burner is most likely clogged. It is necessary to disassemble the body and clean the nozzles. This effect also occurs when the gas valve is incorrectly set.

- If warm water does not flow from the tap for a long time, this does not always mean a malfunction of the hot water supply. Since in the absence of a water draw-off, the water in the system cools down, in any case, time must pass before heating.

- When the boiler often shuts off by itself while using hot water, this may be due to the fact that initially there is too little pressure in the water supply system. The minimum pressure required for the correct operation of the equipment is 1.5 bar.

Each model of the Arderia gas boiler has its own personal characteristics. To avoid most problems during operation, carefully read the instructions for your particular equipment.

Recommendations for operation and repair

- So that the equipment works for a long time and efficiently you can install a voltage stabilizer, filters (gas and water), a magnetic or polyphosphate water converter, etc.

- The gas boiler must be installed strictly in accordance with the requirementsspecified in the passport.

- To eliminate the causes of malfunctions you need to carefully study the instructions and act according to it.

Gas boilers from the Navien company are the perfect combination of price and quality.

Error 16

The Navien boiler issues error 16 when the heating equipment overheats. The sensor responds to overheating and blocks the operation of the boiler. Perhaps the problem is a malfunction of the sensor itself.

How to fix error 16

1. Let the boiler cool down and restart it. 2. If the problem is a lack of water in the heating system, add it. 3. If the sensor itself is faulty, replace it. 4. Check the operation of the three-way valve. In case of malfunction, replace the tap. 5. Restart the boiler. Perhaps the matter is in the control board. It may be necessary to replace the board.