Protherm skat error codes

| The code | Value | Elimination |

| F.00 | Temperature sensor error (NTC) |

|

| F.10 | ||

| F.13 | ||

| F.19 | ||

| F.20 | Safety shutdown: safety temperature limiter |

If the boiler starts up again, replace the high limit safety cut-out.

|

| F.22 | Dry start |

|

| F.41 | Stuck Relay (HDO) |

|

| F.55 | Stuck contactor or relay |

|

| F.63 | Communication failure with EEPROM | - Return the product settings to the factory settings (D.096). |

| F.73 | Water pressure sensor signal out of range (too low) |

Replace the faulty wire to the water pressure sensor.

|

| F.74 | ||

| F.85 | The water in the reservoir is frozen | When the temperature at the NTC sensor drops below 3 ° C and there are no pressure surges, the boiler is automatically switched off. When the temperature rises above 4 ° C, the boiler automatically switches on again. |

| F.86 | The external water heater is frozen | If the temperature in the external storage tank falls below 3 ° C, the boiler will automatically shut down. When the temperature rises above 4 ° C, the boiler automatically switches on again. Indication If the external water heater is not activated, the error is not displayed. |

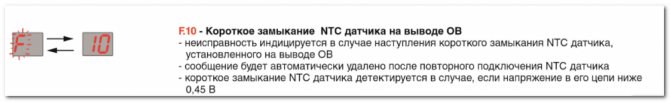

F.10 - Short circuit of the NTC sensor at the extract air

- - a malfunction is indicated in the event of a short circuit of the NTC sensor installed on the OB terminal

- - the message will be automatically deleted after reconnecting the NTC sensor

- - a short circuit of the NTC sensor is detected if the voltage in its circuit is below 0.45 V

- In this case, the sensor shows a deliberately incorrect value in comparison with the one indicated in the table.

RECOMMENDATIONS

- Check sensor connection

- Check sensor cables

- Check sensor Resistance (replace if necessary)

Problems with sensors

The codes indicate that from the sensing element of the circuit, the signal does not go to the electronic board. This can be in two cases: a malfunction in the sensor circuit or in itself. For convenience, the causes of Proterm Cheetah errors are indicated by a fraction. Read: circuit / sensor.

Where to looking for

F0 / F10 - heating circuit (supply).

F1 / F11 - similarly, but on the return line (inlet to the boiler).

F2 / F12 - DHW system.

F3 / F13 - boiler.

F4 / F14 - collector (if connected).

F5 / F15 - measurement of the temperature of the exhaust gases.

F6 / F16 - chimney draft.

F7 / F17 - solar collector return thermostat.

F8 / F18 - boiler grounding.

F9 / F19 - boiler exhaust.

The rest of the Proterm Cheetah errors are caused by malfunctions of the electronic board or a violation of the reliability of the connections of the wires suitable to it. What can be done?

- Check the contacts (for oxidation, the tightness of the plugs in the sockets).

- Dry the board. Boiler errors, as already noted, are often caused by condensation. It is necessary to remove the covers from Proterm Cheetah and direct the flow of hot air inward. A few minutes are enough for the problem to be leveled.

If the measures taken do not bring results, you need to contact the service center.

F.13 - Short circuit of the NTC sensor of the external DHW storage tank

- the malfunction is initiated on the boiler display in the event of a short circuit in the NTC sensor of the external DHW storage tank

- the message will be automatically deleted after reconnecting the NTC sensor

- a short circuit of the NTC sensor is detected if the voltage in its circuit is below 0.45 V

RECOMMENDATIONS

- Check sensor connection

- Check sensor cables

- Check sensor Resistance (replace if necessary)

Electric boilers Protherm: characteristics

Heat generators Proterm are deservedly considered to be high quality systems, which are combined with an acceptable cost.

This equipment is perfect for use in heating systems of private houses, office, industrial, warehouse and other premises.

This equipment has the following characteristics:

- single-circuit boiler has the ability to connect an additional boiler in order to provide hot water supply;

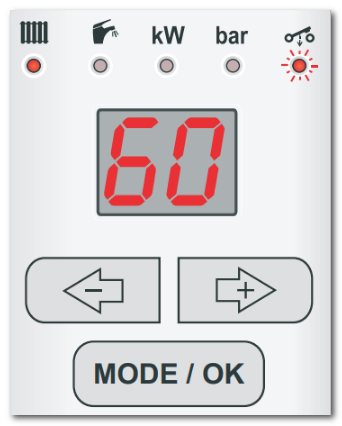

- the presence of a liquid crystal display;

- touch control of the device;

- stepwise power-on with a time delay (this is necessary to protect the device from possible sudden surges in the power grid);

- overvoltage control;

- water heating at a rate of up to 15.3 liters per minute in an additionally installed boiler;

- cascade connection of several electric boilers is allowed;

- the ability to operate with weather-dependent automation;

- built-in circulation pump with anti-blocking function and automatic air vent;

For the first time on the Russian market - an electric wall-mounted heating boiler from Vaillant!

Electric boilers galant, read here.

- built-in expansion tank with a volume of 10 liters;

- the ability to automatically diagnose the operation of an electric boiler;

- work in an electric network with a voltage of 380 V;

- the ability to connect a room temperature controller to the device;

- the device is protected from freezing and overheating.

These boilers are designed for permanent connection to a three-phase stationary electrical distribution network. Since there is a large power consumption, it is required to select the necessary fuses when connecting the device.

F.19 - Short circuit outside temperature sensor

- malfunction is indicated in case of short circuit of the outside temperature sensor

- the message will be automatically deleted after reconnecting the NTC sensor

- a short circuit of the NTC sensor is detected if the voltage in its circuit falls below 0.45 V

- error is not indicated in case of inactive equithermal regulation function (E-)

- in this case, the boiler continues to work in normal heating mode (without equithermal regulation)

RECOMMENDATIONS

- Check sensor connection

- Check sensor cables

- Check circuit voltage

- Check sensor Resistance (replace if necessary)

PROTHERM Pantera. Single-circuit wall gas boilers PROTHERM Panther

Description

| Single-circuit boilers PROTHERM Panther are designed for heating with the possibility of heating DHW in a separate boiler. Equipment: copper heat exchanger, modulating burner, expansion tank 5 l, circulation pump, safety group, the possibility of equithermal regulation, the boiler can be converted to liquefied gas. |

Specifications

| A type | 25 KOO | 25 KTO | 12 CTO | |

| Fuel, inlet pressure | natural gas, 13 mbar / LPG, 30 mbar | |||

| Boiler power, kW | 9.3 — 25 | 9.3 — 25 | 3.4 — 11.5 | |

| Gas consumption, m3 / hour | 1.2 — 2.7 | 1.2 — 2.7 | 0.45 — 1.34 | |

| Combustion products removal | into the chimney | turbo | ||

| Chimney diameter, mm | 130 | 60 / 100 | ||

| Boiler efficiency | 90 % | 90 % | 91 % | |

| Boiler weight without coolant, kg | 31 | 34 | 30 | |

| Gas connection | G 3/4 ″ | |||

| Heating circuit connection | G 3/4 ″ | |||

| Dimensions, H x W x D, mm | 740 x 410 x 320 | 740 x 410 x 320 | ||

Error f20 on the Proterm Scat boiler

- malfunction is indicated in case of activation of the emergency thermostat as a result of boiler overheating

- the message will be automatically deleted after manually resetting the emergency thermostat

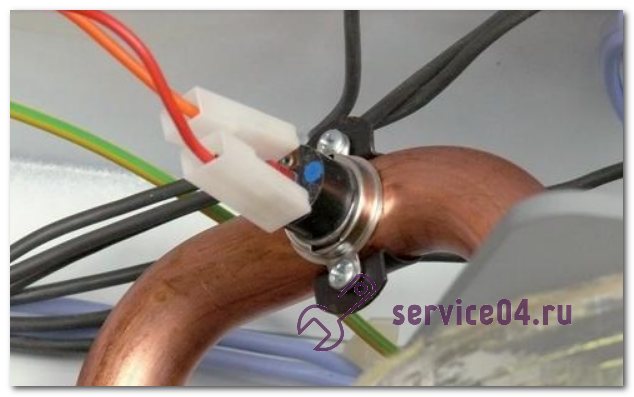

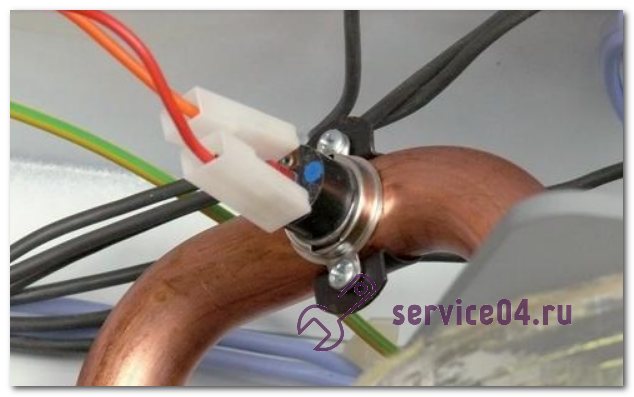

This emergency thermostat should also be installed in the copper pipe.

This thermostat is installed in older versions of the boiler, in boilers that come after 2012 this thermostat is not

there is a thermostat on the heat exchanger

- remove the protective rubber sheath from it

-in the middle you will see a small red button, press it and collect everything in reverse order. But find the cause of the overheating.

Not only press, but also identify the cause of overheating, why it happened. !!!

There is no circulation, the pump and the air in the system should be checked. , there may be air in the heat exchanger, etc. To check the pump, unscrew the air bleed plug (you can see it visually or touch it with a screwdriver) The pump is Wilo. If it is broken and does not rotate, replace it. So that it would be more economical to buy one head, and not the entire pump assembly

Overheating just doesn't happen.

RECOMMENDATIONS

- air in the boiler heat exchanger

- Check the heating pump (no flow through the unit)

- Check the overheat thermostat

Service of PROTHERM boilers

is a trade and service partner of the PROTHERM brand on the territory of St. Petersburg and the Leningrad region since 2000. Our company represents on the market the entire range of PROTHERM boilers of industrial and household series. We provide a full range of services from the selection of equipment to its installation and commissioning. The company employs certified commissioning engineers trained at PROTHERM service centers, which allows for warranty and service maintenance of any PROTHERM boilers, as well as the supply of spare parts for them. We accept for servicing PROTHERM boilers sold by other organizations. Carrying out repair and maintenance of PROTHERM boilers for over 16 years, we have accumulated extensive experience in solving various technical problems. We will be glad to see you among our clients!

PROTHERM Service Center Certificate | VAILLANT Service Center Certificate |

|

|

F.22 - Loss of water - insufficient water pressure in the heating system

- a malfunction is indicated if the water pressure in the heating system drops below 0.6 bar

- the message will be automatically deleted after the heating water pressure in the system rises above 0.6 bar

- as a result of adding water to the heating system

- an error message will not appear in the event of a pressure sensor malfunction

The pressure sensor is used to determine the water pressure in the boiler (heating system). In the event of a lack of heating water in the boiler, the pressure sensor will transmit information to the boiler control board, which will give a command to stop it.

Operating principle

As the water pressure rises, the volume of the membrane carrying the magnet will increase. Opposite the magnet there is a Gall sensor, which changes the input voltage on the boiler control board, depending on the change in the parameters of the magnetic field. The change in the parameters of the magnetic field depends on the change in the distance of the Gall sensor in relation to the position of the magnet Measurement points

Pressure sensor input voltage:

Measuring points 1 and 2 = 5 V DC Test values: Measuring points 1 and 3 At 1 bar / 1.7 V DC At 1.5 bar / 2 V DC At 2 bar / 2.3 V DC

RECOMMENDATIONS

- Water pressure too low 0.3 bar. When filling the boiler with water, in this case it is not necessary to press the RESET button.

- Faulty water pressure sensor. Replace.

- Check for leaks in the boiler and heating system.

- Check if the pump is working properly. It is possible that the pump may be blocked. disassemble it and check for proper operation and cleanliness.

Conclusions and useful video on the topic

The nuances of connecting a turbocharged boiler Protherm are described in detail by a professional master in a short and clear video:

The heating system with boilers Proterm is reliable and durable. The wall-mounted equipment has an attractive design and is intuitive to operate: all information is displayed on the display, thanks to which you can easily control each stage of the equipment operation. A gas boiler installed by specialists, subject to operational standards, will delight its owners with stable operation and a comfortable microclimate.

Would you like to supplement our material with useful tips for installing a boiler? Or tell about the problems you faced when deciding to independently connect gas-using equipment? Write about your experience, participate in discussions - the comment block is located below.

F.41 - "Sticky" relay Proterm skat

- - this message will appear in the case of a 5-fold unhurried attempt of the boiler to "unstuck" the relay

In such cases, a LED will flash on the boiler control panel. The boiler will try to break the relay, and in case of failure, the display will show the error message F41. The boiler will run at minimum heat. After switching off and on again, the boiler will start working in operating mode, but the LED will continue to flash on the display. Contact a specialized service organization.

- the message will disappear after the boiler is switched on and off again

- the presence of a problem with the "sticky" relay after restarting the boiler continues to be signaled by the blinking of the HDO LED

- the message will disappear after updating the boiler factory settings stored in the EEPROM (code d.96)

- the error image is eliminated by switching off and

turning on the boiler

- when switched on again, the boiler signals a sticking relay

flashing HDO LED

Verification:

- When the command to heat the heating water is canceled - at the end of the heating water cycle (opening the RT circuit) or hot water supply (the water temperature in the storage tank has reached the set value).

When the "programmable temperature limiter" is activated, i.e. if the set temperature is exceeded by 5 ° C. Note: This function is activated when the boiler is in "standby" mode (ie there are no commands). The function starts when the detector is activated. If the boiler operates with a jumper and an external temperature sensor without heating the hot water supply, then a similar problem with the relay can be ignored until the temperature of the water in the system calculated by the equithermal regulation unit is exceeded by 5 ° C. Relay sticking test does not depend on the boiler operating mode. It is linked to the current state of the heating function. While the latter is disconnected, and the relay status is checked. The boiler is in a similar state whenever the heating elements stop working, i.e.: 1. after canceling the commands for heating the heating water and preparing the hot water supply, activating the anti-frost protection system - heating. 2. when activating the programmable temperature limiter - setpoint + 5 ° C Note: In case of a detector triggering (for example, in case of accidental closure of a relay contact), the function is activated (that is, similar to the one described in point 1). In addition, the function is activated in the following cases: DHW: cases 1 and 2 RH may occur: room thermostat - 1 and 2 RH: jumper + external temperature sensor

Selection of boilers

When choosing a boiler, do not forget to calculate the area of the room that will be heated before doing this. To make heating economical, make sure that the area corresponds to the heat losses from the room.

Also pay attention to the boiler output. If there is a lack of it, the room will not warm up properly; if there is an excess of it, resin and condensate will form inside the solid fuel boiler.

If the volume of the expansion tank built into the boiler is insufficient, install an additional external tank. Calculate the hydraulic resistance of the heating system and its quantitative and qualitative relationship with the pump head.

Using the scheme given by us above, you will solve your problems regarding the safety and economy of heating your country house without connecting to the gas main.

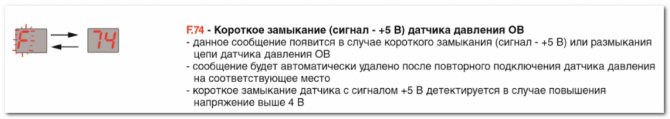

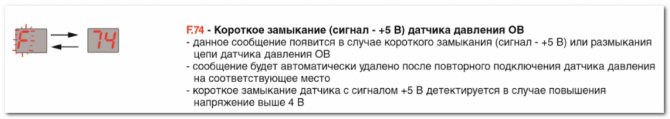

F.74 - Short circuit (signal - +5 V) of the extract air pressure sensor

- this message will appear in the event of a short circuit (signal - +5 V) or an open circuit of the extract air pressure sensor

- the message will be automatically deleted after reconnecting the pressure sensor to the appropriate place

- a short circuit of the sensor with a +5 V signal is detected if the voltage rises above 4 V

RECOMMENDATIONS

- Check sensor connector

- Check the sensor

- Press RESET of the boiler. If the error persists, replace the pressure sensor

PROTHERM Lynx (PROTERM Lynx) - wall-hung gas condensing boilers

Description

| PROTHERM Lynx - practically unparalleled wall-mounted gas boiler with built-in boiler. This solution allows you to save space when installing the boiler (you do not need to look for a place where to put the boiler) and at the same time do not experience a shortage of hot water during peak water withdrawal, which often happens with traditional double-circuit boilers. Boilers PROTHERM Lynx are equipped with a unique system (SPIN) for preparing hot water supply, which allows you to simultaneously heat almost the same amount of hot water as conventional boilers for 80-100 liters. The basic boiler configuration includes: copper heat exchanger, boiler 45 l, modulating burner, expansion tank 6 l, boiler and boiler safety group, 3-way valve. The boiler can be converted to liquefied gas, and external temperature regulators can also be connected. |

Specifications

| A type | 18/25 MKV | 25/30 MKV | 25 MKO | 30 MKO |

| Fuel, inlet pressure | natural gas, 13 - 20 mbar / LPG, 37 mbar | |||

| Boiler type | Double-circuit (heating + hot water supply) | Single-circuit (heating) | ||

| Boiler power (heating), kW | 5,0 — 18,1 | 6,0 — 25,0 | 6,0 — 25,0 | 7,1 — 30,0 |

| Boiler power (DHW), kW | 5,1 — 25,7 | 6,1 — 30,6 | 6,1 — 30,6 | 7,2 — 35,7 |

| DHW productivity (dT = 30 deg C), lit / min | 12.1 | 14,2 | — | — |

| Combustion products removal | turbo | |||

| Chimney diameter, mm | 60 / 100 (80 / 125) | |||

| Max natural gas consumption, m3 / h | 2,7 | 3,2 | 3,2 | 3,8 |

| Boiler weight without coolant, kg | 35 | 37 | 36 | 36 |

| Gas connection | G 1/2 ″ | |||

| Connection of heating / water circuits | G 3/4 ″ / G 3/4 ″ | |||

| Dimensions, H x W x D, mm | 700 x 390 x 280 | |||