Home / Boiler automation

Back to

Published: 20.06.2019

Reading time: 5 min

0

987

In order for an autonomous heating system to work correctly and economically, it is necessary to install a heat accumulator for boilers. This allows you to significantly reduce the cost of not only fuel, but also it becomes more profitable to maintain a house.

Before choosing the necessary heat accumulator for your heating system, you need to study the principle of operation, where it can be installed and which heat accumulator is suitable, because they are of different types.

Photo: stovesonline.co.uk

- 1 What is a heat accumulator

- 2 Principle of operation

- 3 Varieties of accumulating models

- 4 When you need a heat storage

- 5 Where to install in the heating system

- 6 Is it possible to do it yourself

- 7 Top 5 best heat accumulators

- 8 Rules for safe operation

What is a heat accumulator

A heat accumulator is a buffer device that accumulates excess resource, equipped with nozzles for connecting heat generation circuits. What he saved is then used in the heating system during the interval of the planned main fuel loads.

If you have correctly selected and connected the device, then this makes it possible to significantly reduce the cost of purchasing fuel (up to 50 percent), so you can switch instead of 2 downloads per day to 1.

The buffer device, in addition to having the function of accumulating heat, also protects the cast-iron boiler from possible cracks when the temperature drops in the water supply system.

Calculation of the buffer capacity for the boiler

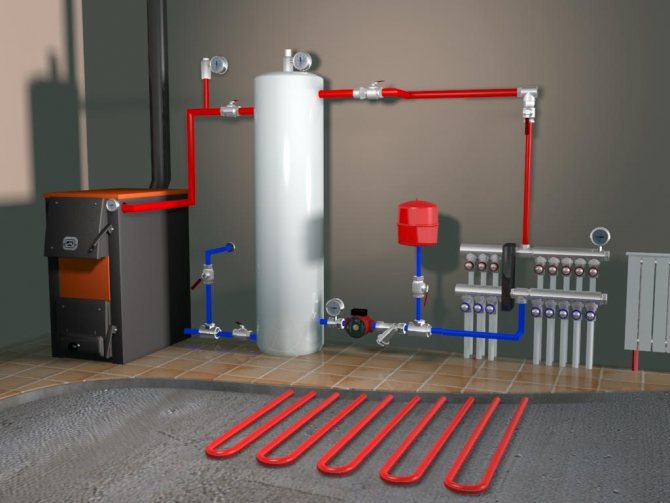

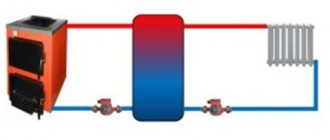

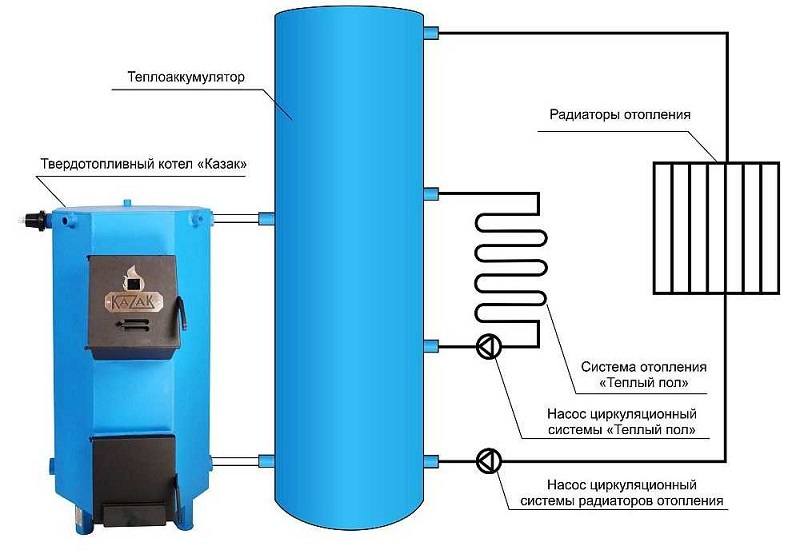

The role of the heat accumulator in the general heating scheme is as follows: during the operation of the boiler in normal mode, accumulate thermal energy, and after the firebox decays, give it to the radiators for a certain period of time. Structurally, a heat accumulator for a solid fuel boiler is an insulated water tank with an estimated capacity. It can be installed both in the combustion room and in a separate room of the house. It makes no sense to put such a tank on the street, since the water in it will cool down much faster than inside the building.

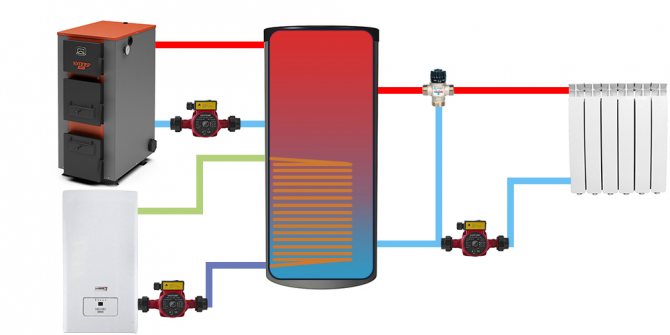

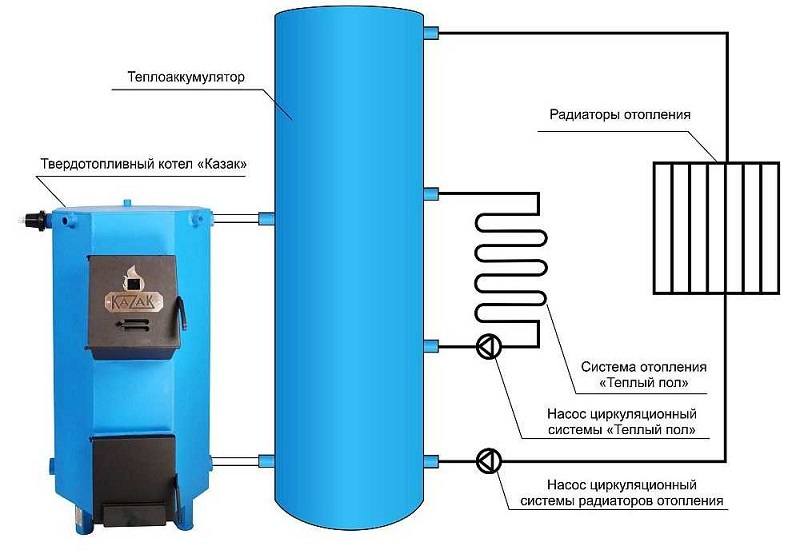

Connecting a heat accumulator to a solid fuel boiler

Given the availability of free space in the house, the calculation of the heat accumulator for a solid fuel boiler in practice is done as follows: the capacity of the tank is taken from the ratio of 25-50 liters of water per 1 kW of power required to heat the house... For a more accurate calculation of the buffer capacity for the boiler, it is assumed that the water in the tank heats up during the operation of the boiler plant to 90 ⁰С, and after turning off the latter, it will give off heat and cool down to 50 ⁰С. For a temperature difference of 40 ° C, the values of the heat given off for different tank volumes are presented in the table.

Table of values of the given heat for different tank volumes

| Heat accumulator volume, m3 | 0.35 | 0.5 | 0.8 | 1 | 1.5 | 2 | 3 | 3.5 |

| The amount of heat given off at a temperature difference of 40 ⁰С, kW / h | 20 | 30 | 45 | 58 | 85 | 115 | 170 | 210 |

Even if there is room for a large capacity in a building, this does not always make sense. It should be remembered that a large amount of water will need to be heated, then the power of the boiler itself should initially be 2 times more than is needed to heat the dwelling. A tank that is too small will not perform its function, since it will not be able to accumulate enough heat.

Operating principle

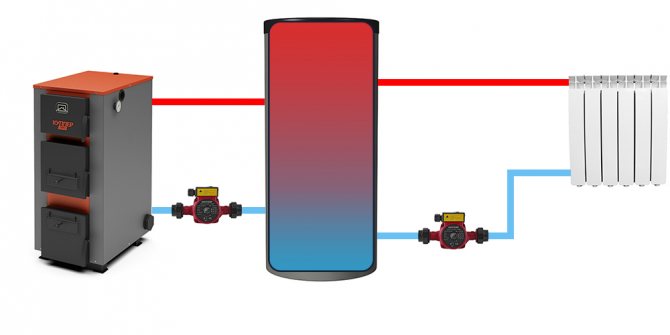

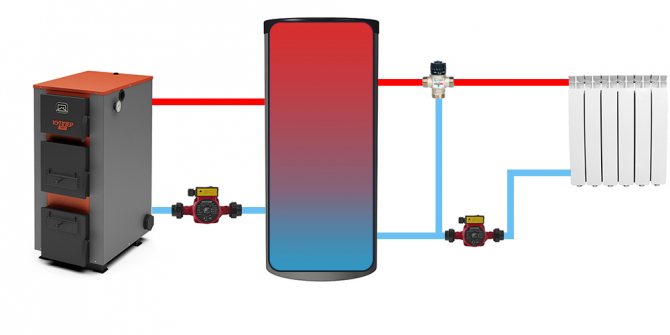

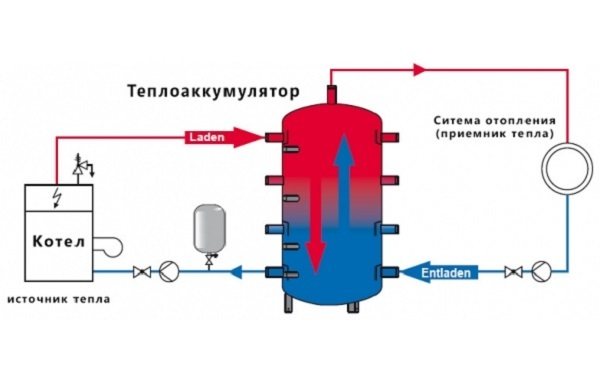

The heat accumulator for boilers has a simple operation scheme. From the unit of any type of fuel, a pipe is brought to the upper part of the device, through which hot water enters the storage tank.

When the water cools down, it goes down to the ring pump, which feeds it back into the main pipe, and the water returns to the heating device for the next cycle.

If you install a heat accumulator, this will prevent overheating of the water when the unit is operating at maximum power, will provide heat exchange and economical fuel consumption. Therefore, the load on the heating system decreases, and its service life increases.

The boiler with any type of fuel has a stepwise operation, from time to time it turns on and off, reaching the required temperature. The work stops, the heat carrier being in the tank is replaced by a hot liquid.

It has not cooled down because there is a heat accumulator for the heating boiler. If it happens that the boiler turns off and becomes inactive until the next fuel loading, then the radiators will still be hot for some time, and the water in the tap will also be warm.

Reviews of household heat accumulators for boilers: advantages and disadvantages

| Benefits | disadvantages |

| Much more efficient use of solid fuels, resulting in increased savings | The system is only justified with constant use. In case of intermittent residence in the house and kindling, for example, only on weekends, the system takes time to warm up. In the case of short-term work, the effectiveness will be questionable. |

| Extending cycle times and reducing the frequency of solid fuel filling | The system requires forced circulation, which is provided by a circulation pump. Accordingly, such a system is volatile. |

| Increased comfort due to more stable and customizable heating system operation | Additional funds are required to equip a heating system using an indirect heating boiler. The cost of inexpensive buffer tanks starts from 25 thousand rubles + security costs (a generator in case of a power outage and a voltage stabilizer, otherwise, in the absence of coolant circulation, at best, overheating and burnout of the boiler may occur). |

| Possibility of providing hot water supply | The buffer tank, especially for 750 liters or more, is of considerable size and requires an additional 2-4 m2 of space in the boiler room. |

| The ability to connect several heat sources, the ability to differentiate the coolant | To ensure maximum efficiency, the boiler must have at least 40-60% more power than the minimum required to heat the house. |

| Connecting a buffer tank is a simple process, it can be done without the involvement of specialists |

Varieties of accumulating models

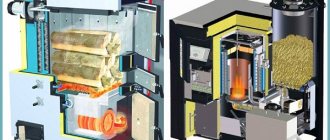

The storage devices function in the same way, but differ in their design, therefore, the following types of storage device are distinguished:

- hollow (does not have an internal heat exchanger);

- with 1 or 2 heat exchangers (ensures correct operation of the unit);

- with built-in small diameter boiler.

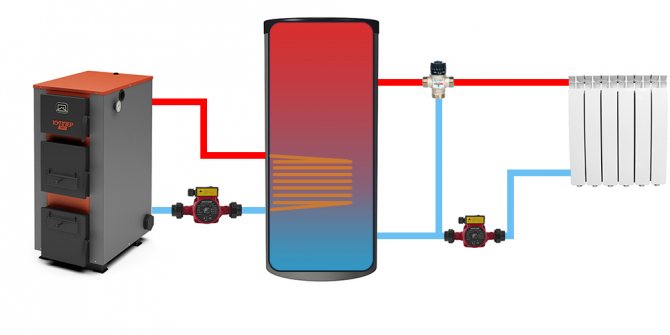

Hollow heat accumulators are the simplest ones and have a low cost. They can be connected to one or more units. It is also possible to install an additional heating element that operates on electricity. The heat accumulator guarantees good heating of the living space, reduces the likelihood of overheating of the heat carrier and ensures the safe operation of the system. The heat storage unit with one or two coils is an advanced type of device with a wide range of uses. The heat exchanger, which is located at the top, collects heat energy. The one at the bottom intensively heats up the buffer tank.

A thermal buffer unit is much more expensive than a hollow one, but this is fully justified. The device significantly increases the functionality and efficiency of the system. An accumulator with a built-in tank accumulates the excess heat generated and supplies hot water.

When you need a heat storage

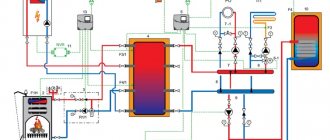

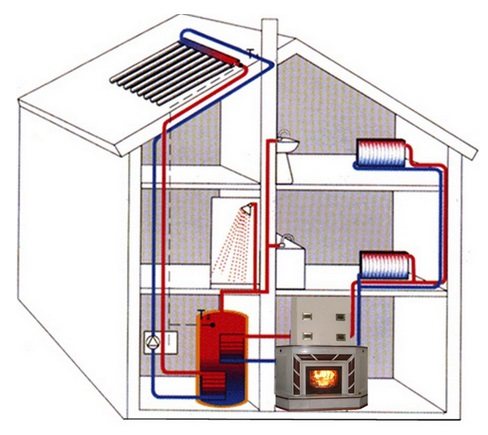

The heat accumulator is applicable to different types of boilers.Basically, it is used in the solar system, with solid fuel and electric boilers. The system with collectors allows you to use the energy of the sun every day at home If you do not use a heat accumulator, then the complex will not work fully, because the energy from the sun is supplied unevenly.

Photo: termocom-spb.ru

Accumulators are used in heating systems with solid fuel boilers. The buffer device allows you to provide heat at the moment the unit goes into passive mode. The tank must be large in order to store a significant amount of heat, and then use it rationally.

When working with electrical equipment, the tank must be placed in the immediate vicinity of the boiler. It is worth noting that this heating option takes up a lot of space, it requires a separate room and is very costly - it can pay off only in 2-5 years.

Significant energy costs can be reduced if the buffer tank has good capacity, using the equipment at night or on weekends.

TOP-7: HAJDU AQ PT 1000 C

Description

The tank of this heat accumulator is designed for 1000 liters. The device is designed to work together with a solar collector and a solid fuel boiler.

The buffer structure, in addition to storing excess heat generated by a solid fuel boiler or any other alternative energy source, can redirect it to a heat accumulator.

Among such additional sources, solar panels are actively gaining popularity, the cost of which is not as high as it might seem.

Their advantage is that they supply almost free heat all year round, even with low lighting. Even in cloudy weather, the heating system can receive tens of kilowatts of energy from them.

Design

Inside the Hajdu AQ PT 1000 C tank there is a coil-shaped heat exchanger. Its area is 4.2 square meters. The heat carrier heated by the sun's rays, flowing through the coil, gives off its heat, which is directed to the heating system for heating.

The coolant is supplied and discharged through the nozzles, which are located on the same vertical line, which is important, since the space of the boiler room is saved.

The dimensions of the device allow it to function in tandem with a solid fuel boiler, which has a power of 25-35 kW.

Important: a system that ensures the accumulation of heat by a buffer tank is only capable of functioning in a heating system with a forced cycle, and is not suitable for a gravitational one.

The designers of the Hoydu brand did not limit themselves to the described function of the device, i.e. the ability to accumulate heat. Therefore, they provided for a technological hole, which makes it possible to install 2, 3, 6, 9 - kilowatt heating elements. The importance of this decision is in the ability to increase the time between downloads. This was appreciated by those living in country cottages and summer cottages.

We recommend:

- Portable chargers for phones: advantages, features, price - TOP-7

- Heat accumulators: purpose, features, price - TOP-6

- TOP-6: inexpensive solar collectors for heating and heating pools, prices and where to buy

Now they can load cheap heat, i.e. load the energy storage device at a reduced price. At the same time, an insert into the heating system of the electric boiler is not needed, because the heating elements heat the storage device directly, giving the heat accumulated during the night to the system during the day.

In order for the price of the heat accumulator to be available to a wide audience of users, the developer does not complete it with external insulation, which can always be ordered as an option, like heating elements.

Inner surface

On the inner side, the walls do not have an enamel coating, like boilers with indirect heating water heaters, so heat accumulators are not recommended to use hot water supply.

Buy

| Where can one buy | Price in rubles |

| https://avangardteplo.ru/products/name/teplonakopitelj_hajdu_aq_pt_1000_c?_openstat=bWFya2V0LnlhbmRleC5ydTv/ | 40030 |

| https: //xn—-7sbcqc4aneonsmco5krb.xn--p1ai/products/bufer-emkost-hajdu-aq-pt-1000-c | on call |

| https://vsegdateplo.ru/vodonagrevateli/teploakkumulyatory/hajdu/hajdu-aq-pt-1000-c-bez-izolyatsii / | 42725 |

| https://nasos-kotel.ru/bufernyy-nakopitel-hajdu-aq-pt-1000-c/ | 40030 |

| https://mrklimat.ru/teploakkumulyatory/teploakkumulyator-hajdu-aq-pt-1000-c.html | 40030 |

Can I do it myself

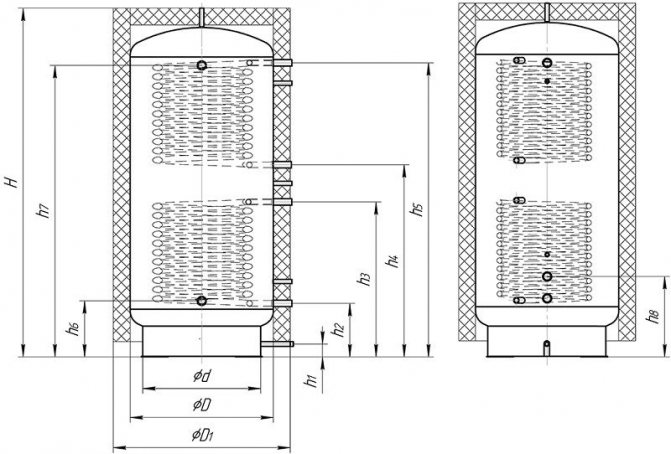

You can assemble a heat accumulator for heating boilers with your own hands. To do this, you need to take a steel tank or purchase stainless steel sheets with a thickness of more than 2 mm, weld a container in the form of a cylinder (vertical tank).

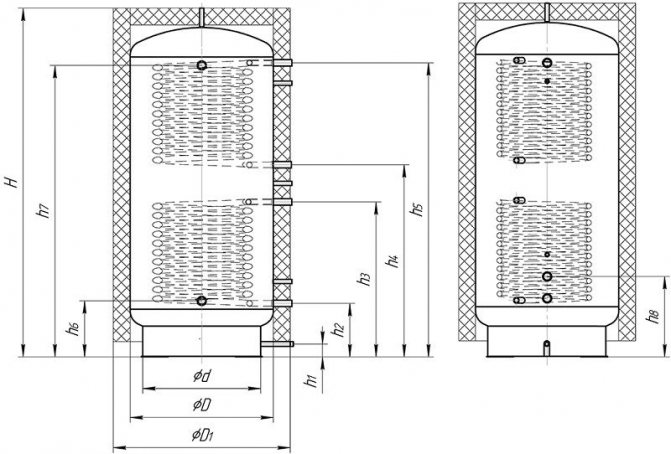

Battery drawing

A copper pipe with a diameter of 2-3 cm and a length of 8-15 m is required. It must be bent in the form of a spiral and placed inside the tank. Here, the battery is the top of the container. Connections for outgoing hot water and incoming cold water are installed in the tank.

Photo: builditsolar.com

For an open heating system, a cube-shaped steel tank is suitable.

It is imperative to check the tightness of the container by filling it with water or lubricating the welded seams with kerosene. If everything is fine, then it is necessary to insulate the home-made device, which will allow the liquid in the container to be hot for as long as possible.

The unit is insulated as follows:

- The outer surface of the container must be well cleaned and degreased, covered with anti-corrosion agents.

- Provide thermal insulation. You can wrap the container in foil film.

- Provide openings for branch pipes and connect the container.

- A thermometer, a pressure gauge and an explosion valve must be installed on the buffer tank.

It is better not to use polystyrene for insulation. In cold weather, mice start up in them, looking for a place for wintering.

Top 5 best heat accumulators

______________________________________________________________________________________

| Model | Characteristic | Benefits |

| S-TANK АТ PRESTIGE - 500 (Belarus) | Weight - 105 kg. Diameter - 78 cm. Height - 157 cm. The volume of the tank is 500 liters. | · Ease of maintenance and easy installation; · Water heats up quickly; · Protected from overheating; · Multifunctionality; · Compatible with different sources of heat supply. |

| HAJDU PT 300 (Hungary) | Height - 1595 mm. Weight - 87 kg. The volume of the tank is 300 liters. | · Works in a closed system, with pumps, heat and solar panels; · You can install heating elements; · Simple installation, construction and maintenance; · Good thermal insulation. |

| HAJDU AQ PT 1000 (Hungary) | The volume of the tank is 750 liters. Weight - 93 kg. Diameter - 79 cm. Height - 191 cm. | · Ergonomics; · The presence of thermal insulation; · Removable insulation and casing; · Compatibility with various boilers; · Long-term operation. |

| S-TANK АТ AT-1000 (Belarus) | Weight - 131 kg. Height - 2035 mm. Diameter - 92 cm. The volume of the tank is 1000 liters. | · The device is thermally insulated on top (70 mm); · For convenient connection, the branch pipes are turned at an angle of 90 ° and are located at different heights; · There are 4 holes of 0.5 inches for temperature control pressure gauges and sensors. |

| S-Tank AT 300 (Belarus) | Weight - 65 kg. Height - 1545 mm. Diameter - 500 mm. The volume of the tank is 300 liters. | · Goes well with any type of boilers; · Insulation has high fire resistance; The tank is protected from the outside by a casing (plastic or cloth, · The top of the tank is painted with heat-resistant paint. |

______________________________________________________________________________________ Heat accumulators for heating boilers of Russian production have proven themselves well in the market. They are not inferior to foreign counterparts, they also have high quality and long service life, and the price is much lower. Famous models of protective devices are produced by brands: "Prometey", "Vodosystem", "BTS", "Gorynya", LLC "RVS-engineering", "Teplodar".

Advantages of heat accumulators

The mechanism of operation of the heat accumulator

The heat accumulator can fully replace the hot water boiler. Moreover, both devices are comparable in cost.

However, the heat accumulator will not only provide hot water supply, but also solve a whole range of additional tasks. Using a solid fuel boiler with a heat accumulator, you can get many advantages:

- the service life of heating equipment increases several times;

- the boiler will never operate at maximum load or idle;

- the temperature of the heat supply at home is leveled. In the case when the water in the boiler does not have time to heat up, the hot coolant is automatically supplied from the reserve tank.Conversely, the excess temperature of the carrier will be taken away and accumulated;

- a properly selected container continues to take heat from the boiler even with complete combustion of the fuel;

- resource saving reaches 30%.

The advantages of batteries have been appreciated by many manufacturers of solid fuel boilers. And now they only provide their equipment warranties if additional tanks are installed.