It is not only possible to use pellets and Euro wood as fuel in ordinary stoves (stove stoves, bulleryan, Russian, etc.) and boilers, but, on the contrary, is only welcome. Still, the characteristics of Eurowood are much superior to those of ordinary firewood.

It is imperative to remember that the calorific value of euro wood is 4-5 times higher than that of ordinary firewood (natural moisture) and 2-3 times than that of kiln-dried firewood. Therefore, you need to lay briquettes following the above. If, for example, you used to heat your stove with ordinary wood, then it is advisable to put 2-3 times less briquettes in the firebox. So you will avoid quick burnout of firewood and accelerated (forced) heating and overheating of the oven walls.

The temperature of the walls of a Russian stove after the furnace is usually no more than 70C. In very rare cases, they heat up to 900C. With this in mind, the furnace is designed. But, if you often overheat the walls of the stove, then cracks will begin to form on them and you may have to completely sort out the stove masonry. Therefore, it is worth not shifting the firewood and, it is better to add fuel once again than to use a forced furnace, which can lead to the complete destruction of the furnace or even to a fire hazard. Before the firebox itself, it is imperative to clean the stove from old ash. If there is a blower, be sure to clean it too. After cleaning, you need to put some paper, wood chips, bark, cones - any material on the grate for a better ignition. Briquettes are already stacked on top. They should be laid neatly, but not tightly, so that there is room for air.

If the stove does not have space for lining additional fuel, be sure to leave a little space at the beginning, placing the briquettes at a distance of about 15-20 cm from the door. After that, we simply open the blower door, fix it, and set fire to the paper or other material that we put. The firebox must be closed, but the fire must be monitored from time to time. After the briquettes are burned out, you can put new ones. You should not stir up the wood during the combustion process, they themselves burn evenly and burn completely.

Recently, the trend of a return to old traditions has become clearer, at least in the household sphere. Each owner wants to have a stove or fireplace in his home, which he identifies with the hearth. The warmth, coziness and comfort that stoves and fireplaces can give us are incomparable with anything. In addition, in private houses, a heating system is often already established, therefore, a stove or fireplace is more of a decorative tool designed to bring peace, peace and joy.

To light a stove or fireplace, we can use ordinary firewood, or we can resort to the help of innovative fuels. In this article, we would like to talk about how to heat the stove with fuel briquettes, a modern alternative to classic wood.

General information

Fuel briquettes, or as they are also called eurowood, are made from pressed natural materials, most often sawdust, sometimes peat or straw, rarely from seeds or nut shells. During the pressing process, most of the moisture comes out of the wood, which allows obtaining high calorific characteristics. Unlike firewood, whose maximum dryness is determined by 20% moisture, the same parameter for fuel briquettes is 8-9%.

The version of the briquettes can be different:

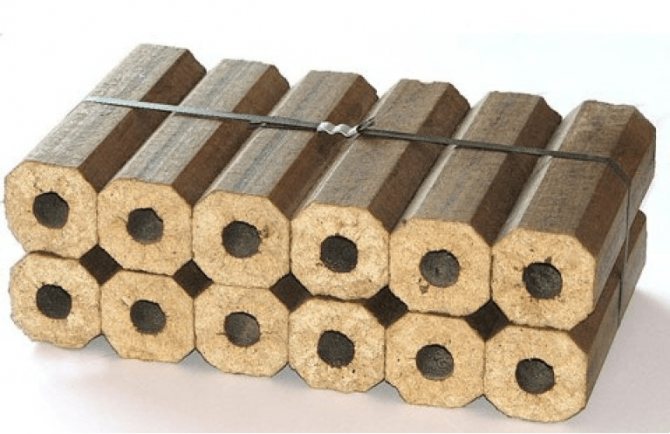

- Eurobriquettes RUF - made exclusively by pressing without additional processing.

- Eurobriquettes Nestro are compressed briquettes with a cylindrical shape, sometimes with a hole in the middle.

- Pini-Cay Eurobriquettes are compressed sawdust fired with a gas-air mixture to create a more durable shape, which increases storage time and protection from moisture.

Production of home briquettes for the firebox

Independent production of fuel briquettes is practically similar to the technological process organized in an industrial environment. The initial stage provides for preliminary grinding and drying of consumable raw materials, the optimum moisture level of which should be 10%.

Important! The initial raw material for the manufacture of Eurowood can be various wastes - husks, husks, straw, paper, cardboard, leaves, sawdust and coal dust.

The main production stage is the pressing of prepared raw materials. To reduce the cost of producing solid fuels, raw materials can be pressed using a hand-assembled unit assembled at home.

Homemade briquette press

To make quality rectangular or round briquettes, DIYers use simple hand-operated machines.

The assembly of the hand press is carried out according to a previously prepared drawing indicating the dimensions of the main parts and mechanisms. The main construction mechanism can be:

- Mechanical jack.

- The drive is hydraulic.

- Manual drive.

The manual press consists of a welded frame made of a shaped metal tube and installed on a vertical surface. A shape of various configurations is fixed to the bottom of the frame. The best option is a rectangular shape. In the upper part of the frame, a hand lever is mounted on hinges, connected to a pressure piece, which is designed for pressing raw materials.

The lever can be replaced with a jack or a hydraulic drive, which makes it possible to obtain more technological and accurate equipment. To remove residual liquid from the press, the bottom of the mold is perforated.

For home production of briquettes, the following composition is used: 1 part of clay and 10 parts of sawdust (any other material), soaked cardboard or wallpaper paste. The resulting mixture is poured into a mold, which is operated by a manual drive from above.

The finished briquette is removed from the mold and laid out for natural drying in the open air.

Important! This technology provides for preliminary soaking of raw materials in water to increase the density of the fuel material.

Kindling a bath

Euro briquettes are a universal fuel, they can be used to heat all types of furnaces and boilers. They can be used in outdoor grills and home fireplaces. At the same time, the consumption of fuel briquettes is always significantly less than that of ordinary firewood.

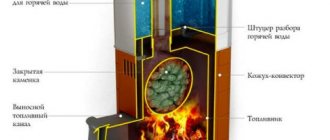

Many people are interested in whether it is possible to heat the stove with fuel briquettes if it is made of steel, an ordinary stove? This question is quite logical, since such stoves have restrictions on the calorific value of the fuel, you cannot heat a steel bath stove with black coal, which emits 4900 kcal / kg of heat. But in the case of Euro briquettes, less heat is released, which means that you can heat the stove in the bath with them.

For a bath, not only the heat generated is important, but also the duration of burning of wood or alternative fuel. The longer the wood burns with maximum heat release, the better for the sauna stove and the sauna itself.

It is not very easy to light fuel briquettes, the fire does not catch immediately, but after they catch fire, they will burn and smolder for a couple of hours, which is much longer than the combustion of ordinary firewood. Such a long combustion time of fuel briquettes is due to their high density and low moisture content.

A large amount of heat generated and a long burning time suggests that the consumption of fuel briquettes for heating a house is much less than that required for ordinary firewood.

Note that, according to the reviews of people, it is not necessary to completely fill the furnace of a sauna stove with euro-wood, so as not to quickly reach the maximum values of heat transfer.

An interesting point with Euro briquettes is the residues after their combustion. Possessing increased density characteristics, this fuel burns out almost completely, there is not a large amount of ash left from it, only a small pile of ash. Ash from fuel blocks smells unpleasant, but is an excellent fertilizer.

When burning Euro briquettes, practically no smoke is emitted, which is very valuable for maintaining the cleanliness of furnaces, boilers, and chimneys. According to experts, the least amount of tar is in briquettes of linden fuel, therefore, when using such fuel, chimneys and boiler nozzles are the least affected.

Fuel briquettes are an excellent option for lighting a sauna in a black way. As we have already said, this fuel is environmentally friendly, it does not emit smoke, it gives enough heat, and phytoncides appear in the heated air, which have a beneficial effect on the human body and improve immunity. Using the same linden euro briquettes, you will feel how your body heals, inhaling the pleasant aromas of flowers, honey and trees.

Advantages and disadvantages

Heating with alternative fuels has its positive and negative sides.

Pros:

- High calorific value and heat transfer. These figures are significantly higher for alternative fuels than for conventional logs.

- Long burning time. Therefore, their consumption is much less than that of firewood or coal.

- Uniform burning. Briquettes burn without unnecessary noise and smoke. And ashes form less than coal or wood. This makes it easier to clean the oven after use.

- Slight release of resinous substances. Thanks to this, the chimney is not clogged.

- Long shelf life. Briquettes can be stored from 1 to 5 years (depending on the manufacture).

- Environmental friendliness. The product is natural, without various impurities. Safe for people and the environment.

Minuses:

- Briquette fuel prices are higher. Firewood is much cheaper. But thanks to the economical consumption, the costs pay off.

- The purchase of such a product in some cities or towns is difficult.

- Store products in accordance with the instructions. Therefore, prepare a clean and dry place.

- Ash gives off a harsh odor.

House heating

For heating a house, fuel briquettes are perhaps ideal. The ability to light the stove once and maintain the fire and heat for a long time without additional throwing, allows us to speak about the good characteristics of Euro briquettes. Consider how to heat a brick stove with fuel briquettes within the house.

Of course, the pressed bricks will not immediately burn, so we will figure out how to ignite the fuel briquettes. It is quite simple to do this, the first thing to do is to put tree bark, wood chips, some dry newspapers into the oven, and on top of it, install alternative firewood. During kindling, while the chips are actively lighting up, adjust the blowing. As soon as the fire on the first briquettes started playing, the rest can be reported.

Another option is to heat the stove with fuel briquettes after the first batch of firewood has burned and decent coals have appeared. In such a furnace, quickly grab the fire on Euro briquettes.

Depending on the needs, we choose the tactics of filling the furnace with fuel:

- If you fold the fuel briquettes loosely, at a short distance from each other, then the fire in the stove will be quite intense, there will be a lot of heat, which will allow you to quickly heat the house.

- If you fold the alternative firewood tightly to each other and cover the blower, the firewood will smolder for a longer time, which is perfect for heating the house at night. At the same time, the consumption of fuel briquettes per day will be several times less firewood.

To roughly understand how many Euro briquettes will be required for heating a house, several experiments should be carried out, each time figuring out this parameter in practice. There are too many nuances in this matter.

It is worth noting that fuel briquettes have a specific purpose - to create warmth, while firewood can be viewed in order to create a comfortable and cozy environment. For example, is it possible to heat the fireplace with fuel briquettes - well, of course, yes, but they will not create such an atmosphere as firewood with its pleasant crackling and uneven fire. By the way, the smell from burning wood is stronger and more pleasant.

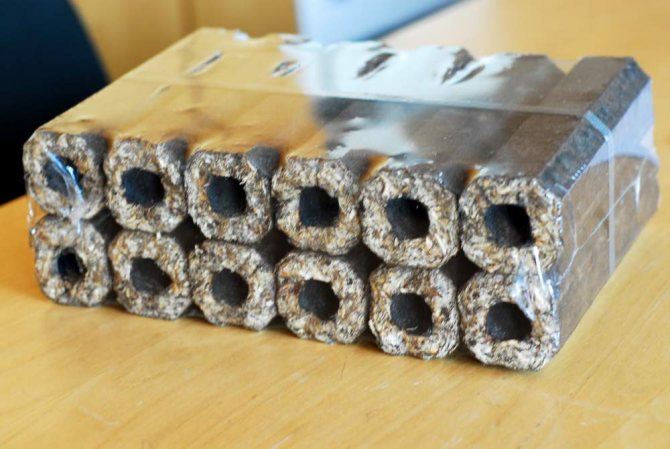

In conclusion, I would like to say a little about the storage of Euro briquettes and compare it with the preparation and storage of firewood. Fuel briquettes are sold in separate packages wrapped in cellophane. In this state, they are not afraid of moisture, which means they can be put in a utility room, in an attic, in a basement or a shed. Euro briquettes look like bricks or tubes, all of the same shape, which is very convenient for storage. In addition, they take up much less space, since they will need several times less than firewood for the winter.

If we remember what difficulties await us when preparing firewood, there is room for thought when choosing the right fuel. Euro briquettes do not need to be sawed, chopped, stored and dried throughout the year, they are already ready for use.

Solid fuel stoves are used to heat a bathhouse or a summer residence in a private house. The most common fuels have long been wood and coal. But now more and more people are using their alternative - briquettes.

Briquettes are made from various wastes of wood production (sawdust), straw, peat, husk of seeds of cereal plants. With the help of a press and high pressure, small homogeneous particles are held together, then cut into rectangles or cylinders. The heat transfer of this type of fuel is much higher than that of conventional firewood.

Types of briquettes

Classification of Eurodrops:

By material

Alternative fuels are produced from different raw materials, which significantly affects such indicators as:

- Calorie content;

- Ash content - indicates the presence of a large amount of minerals in the composition that do not burn or have a very low energy value. The greater their number, the lower the heat transfer of the material;

- Soot number;

- Burning rate.

Indicators of different materials for eurodrops are shown in the table:

| Material | Ash content,% | Humidity,% | Caloric content, kcal / kg | Density, g / cm3 |

| Straw | 7,3 | 7,8 | 3754-4740 | 1,08 |

| 4,86 | 9,3 | 3742-4097 | – | |

| Husk of sunflower seeds | 3,6 | 2,7 | 4480-5161 | 1,15 |

| 2,92 | 8,51 | – | – | |

| Tyrsa | 0,7 | 7,5 | 4200-4400 | 1,37 |

| Rice husk | 20,2 | 7,1 | 3161-3458 | 1,16 |

| Wood sawdust | 0,8 | 4 | – | – |

| 1,1 | 10,3 | 3985-4341 | – | |

| 1,16 | 4,1 | 4502-5043 | 0,79 |

Material type and characteristics:

- Husk from seeds. Briquettes have a high calorific value (5151 kcal / kg), as well as a low ash content (2.9-3.6%) due to the presence of oil among the components of the material. It burns well, emits heat well, but significantly pollutes the smoke passage.

- Wood sawdust. The second place in terms of calorific value belongs to euro wood from sawdust (4341-5043 kcal / kg). The ash content is exactly the same as when burning wood (0.5-2.5%).

- Straw. The third place is taken by straw with a heat transfer rate of 4740 kcal / kg. The ash content is in the range of 4.8-7.3%.

- Tyrsa. It has good heat transfer (4400 kcal / kg) despite its low ash content (0.7%).

- Rice husks. The ash content is within 20%, which is evidenced by the low heat transfer (3458 kcal / kg).

Most often used for the production of briquettes:

- Coal - one of the types of solid fuels of artificial origin, which is created from screenings and the corresponding binders. The material emits about 5000 kcal / kg of heat energy. Advantages of Eurodrops:

- safe for the environment;

- easy to transport;

- convenient to store;

- does not emit carbon monoxide;

- Peat Is a great alternative to wood. It has a high heat transfer rate. It has a long burning period (for example, one load in a boiler can smolder for about 12 hours). Manufacturing process.Well-dried, crushed material is heated to a certain temperature and then pressed into small bricks that are convenient to transport or store. It is used for fires and various types of boilers using solid fuels. A characteristic feature of peat products is that the resulting ash does not need to be disposed of, it can be used as fertilizer.

- Wood. Eurowood is created from wood waste, for example:

- not a format;

- sawdust;

- dead wood;

- shavings.

The advantages of compressed waste over natural wood:

- The density is the same everywhere, and the structure is homogeneous (in 1m3 there are about 1200 kg of briquettes);

- Higher heat transfer rate (4400 kcal / kg);

- Much lower humidity level (up to 10%);

- A small amount of ash about 1-3%.

- There is no characteristic crackling in the boiler;

- Releases less carbon dioxide into the air.

One tab maintains the same temperature for about 3-4 hours.

Coal briquettes

By form

Depending on the method of processing raw materials, several forms are distinguished:

- Nestro is shaped like a cylinder, for their production only large sawdust is used, which is tightly compacted mechanically

Рini-kay - a high-tech version of the Eurodrops presented. It has excellent density (1.08-1.40 g / cm3). Sectional shape in the form of a square or hexagon with a round hole through the center. Internal distribution of air flows allows to achieve perfect uniform combustion. Pini-kay is used for fireplaces because of its aesthetic appearance and the creation of a beautiful uniform fire. - RUF - differ in relatively small size, low density (0.75-08 g / cm3). In shape, they can be rectangular or square, resemble a brick. Small particles as well as dust can be used to create them. Benefits of the RUF form:

- convenient to use;

easy to store and store;

- there are no harmful components in the composition;

- have a high degree of thermal conductivity;

- smolder for a long time.

- Nestro - Eurowood with a density of 1-1.15 g / cm3. They resemble a cylinder in shape. For their production, only large sawdust is used, which is tightly compacted mechanically. Since the production process does not require additional equipment, they have the lowest cost. They have a number of disadvantages:

- They keep their shape poorly. If the rules are not followed, the transportation quickly crumbles.

Storage is required only in dry rooms with a good ventilation system.

- Burn out too quickly.

- Pellets - special granules several centimeters long. Various types of waste from wood are used for manufacturing. The material is used in special boilers with a long burning period. For a standard boiler, they are completely unsuitable, because due to the uncontrolled air flow, the pellets quickly burn out.

Used for classic boilers. They can be stored even in damp rooms, due to their density they retain their shape well. They have a high price, but the cost per unit of heat produced is lower than that of all other types.

They can be similar in shape to Pini-kay, but they are not made under the influence of high temperatures, therefore they are incapable of burning for a long time, and most importantly, evenly.

How to properly heat with briquettes?

To achieve maximum results, the stove should be properly heated with fuel briquettes.

Sauna oven

Heating a sauna room requires fuel, which not only generates a large amount of heat, but also burns out longer. This will ensure a stable temperature over a long period of time. These are the properties that briquettes have.

When firing up the stove and its firebox, you should adhere to the following tips:

- thoroughly clean the furnace from ash and other fuel residues from the previous furnace;

- put some wood chips, paper, bark or other flammable materials on the grate;

- then put a small amount of Euro wood and light the firebox.

This type of fuel is very good for use in saunas. The smell of essential oils from environmentally friendly wood materials fills the entire room and has a beneficial effect on the health of visitors.

Furnace for home heating

It is convenient to use fuel briquettes for the stove in the house. They can be ignited and nothing else can be thrown over for a long time. There are two ways to ignite eurowood in a home oven:

- The first one is similar to the ignition of fuel in a bath: briquetted fuel is placed on dry chips or paper. The fire is regulated by blowing.

Ignition with firewood

Ash from burning wood briquettes can be used as fertilizer in any garden plot.

After several fireboxes with briquettes, you will be able to assess their efficiency and find out the consumption. In the future, you can compare the number of required briquettes and the amount of firewood for heating your particular house.

The process of firing the oven with briquettes

Briquettes are intended for heating stoves, solid fuel boilers and fireplaces, so they can be kindled similarly to firewood from various breeds.

For ignition, quickly flammable materials are used: paper, cardboard, twigs, wood chips and dry alcohol tablets.

Long burning boiler

The boiler firing process is organized as follows. The first batch of briquettes is loaded into the fuel compartment, evenly distributed and ignited. As they burn out, the next batch is reloaded.

Loading and ignition of fuel in boilers with an upper combustion type is carried out immediately, therefore additional additional loading is not required.

What kind of stoves can be fired with briquettes?

Briquettes are distinguished by their versatility. They can be used in all types of ovens, including brick ovens. They emit about four and a half kcal per kg, which is quite acceptable for a heating device with refractory bricks. The main advantage of briquettes in comparison with ordinary logs is that they burn out several times slower.

Such fuel is economical and cheap. Regular logs need to be sawed, chopped, trimmed and dried. And Eurowood does not require long-term procurement: it is enough to purchase and store them in a dry room in a film or original packaging.

The fact that the fuel burns slowly is a disadvantage in some rooms. It will take several hours to warm up the house in winter. The heat from such fuel is much less. And after the briquettes are burned, the ash has a characteristic pungent smell.

Feedback on use

Wood briquettes reviews:

Alexey, Syktyvkar. I use two types of boilers for heating: an electric boiler and a solid fuel boiler. Previously, I used only firewood, and at night I turned on an electric boiler. I bought briquettes because they burn much longer, although they cost twice as much. Two bookmarks are enough for heating: in the morning and in the evening. Saved on electricity.

Valery, city of Lysva. Because of these briquettes, the kindling stove burned out, which only served three years. It was comfortable to melt the bathhouse with them, but a little expensive.

Timur, Yekaterinburg. I don’t use briquettes all the time, but I often started buying them in order to facilitate the heating process. One pack is enough for two bookmarks. What density, I have no idea, but an ordinary brick stove heats up twice as long. The weight of such a brick is greater than that of a log of the same size. As soon as finances allow, I will probably switch to them completely.

Lilia, Mirny. From an economic point of view, it is more expedient to use briquettes. The firewood is romantic, however, there is a lot of garbage from them by the fireplace.

Peat and coal briquettes for the furnace reviews:

Vladimir, Ufa. I have a house of about 100 m2. It is heated by a boiler with an upper load version Karakan 15kW.I used firewood, as well as coal, but coal bricks are much better. They burn just like coal, ashes are the same, and most importantly, there is order in the room. I like it, I also want to try sawdust, but their price bites.

Andrey, Kaluga region I use 80 mm peat briquettes with different lengths for the 20 kW Virbel Eco boiler. 25 kg of raw materials is enough for a day for a house of 75 squares without insulation. The product is super, and after the tree it is just a fairy tale. There is not much ash in comparison with firewood. The only negative is the cost.

Output

Thanks to modern technologies, we can use an alternative fuel - briquettes. These are compressed particles of various materials. The most common are sawdust briquettes, but a similar product can be purchased from straw, peat or coal.

With the help of fuel briquettes, you can heat a bathhouse, a summer cottage and a private house. Their main advantages are environmental friendliness and high heat transfer at an affordable price. The disadvantages include the long time it takes to ignite the fuel, and uncharacteristic firewood, a pungent smell of ash.

Recommendations for the selection of fuel briquettes

In order for fuel products to burn well, the following principles should be adhered to when choosing:

- It is best to use sawdust briquettes. The oil, which is part of the fuel raw material from seed husks, contributes to the contamination of heating devices.

- Due to the resin in the composition of coniferous briquettes, chimneys are polluted.

- When buying fuel, you should first familiarize yourself with the documents containing the characteristics of the product.

- It is recommended to choose Eurowood with the maximum density. The duration and uniformity of combustion depends on this.

- If you need a large amount of fuel, for a start it is better to purchase 10-20 kg of raw materials for a sample in different places. Poor briquette quality can be identified by its appearance, for example, if it crumbles. The samples should be burned separately, checking the duration and efficiency of the combustion. It is worth paying attention to the remaining coals, which may decay or keep their shape. Experiments like this will help you choose a quality fuel.

What are fuel briquettes

Fuel briquettes are a relatively new type of solid fuel. They are made by pressing fine-grained raw materials of natural origin. As such raw materials, sawdust, wheat, rice or buckwheat husks, sunflower husks can be used. In addition, fuel briquettes are pressed from leaves, straw, reeds, tree bark, and pine needles. Pellets are also made from reeds.

In the process of pressing, strong pressure is exerted on the raw materials from which wood fuel briquettes are made, as a result of which a special substance is released - lignin. It acts as a connecting component. Thus, in the production of wood pellets, no additional chemicals are used, which makes such fuel environmentally friendly.

Various types of raw materials can be used for the production of fuel briquettes.

The release of lignin is possible only in those cases when significant pressure is exerted on the raw material from which the wood briquettes are made. It is quite difficult to fulfill this condition when making fuel briquettes with your own hands using home-made equipment, therefore, in such cases, binders are added to the raw mixture. Clay, wallpaper glue, soaked paper or cardboard can be used as the latter.

Pressed briquettes for a furnace can differ not only in the material of manufacture and the degree of density of the internal structure, but also in their geometric parameters, in particular, in shape and size.

Diagram of the technological process of briquetting production