Roda Brenner Classic BCR-04

- Power, kWt:

23.3 - Number of circuits:

1 - A type:

floor

Advantages:

- thermal insulation

- fuel versatility

- the presence of a thermometer and manometer

- high efficiency

- price

Disadvantages:

- not

Choosing a heating boiler, the first item that the buyer pays attention to is the type of fuel used in the work. The reason lies not only in the significant difference between the price tag, for example, for gas and electricity, but also in the availability of this or that energy carrier.

Both problems are sometimes completely, sometimes partially solved by a combined heating boiler designed to operate with several types of fuel.

Features of heating with combined boilers

The main advantage of the combi boiler lies in its name. This device can operate with several types of fuel, which allows you to adjust energy costs directly during the operation of this equipment.

As an example, we can cite a situation when at some period it is much more profitable to heat a house with wood than with a diesel engine. This can happen with electricity and with liquefied gas.

Important! Combined heating boilers are mostly non-volatile, that is, they are able to continue normal operation during a power outage. In their design, as a rule, two combustion chambers are provided, each of which is designed to burn its own type of fuel. Some of the models are additionally equipped with heating elements, which insure the equipment operability.

The obvious advantages of multi-fuel boilers include the following points:

- Independence from the presence of one energy source.

- The ability to use exactly the currently available type of fuel.

- Possibility to equip several segments of the heating network, including underfloor heating, if the boiler is equipped with several heating circuits.

- Cost savings due to the use of the most profitable fuel at the moment.

- One combi boiler with several furnaces takes up less space than several mono-fuel units.

Some combined boilers are equipped with automation capable of independently switching equipment between types of fuel when the supply of one of them stops for any reason. For a private house, such a solution is extremely useful, since it removes the need for the owner to participate in the operation of the heating system.

Naturally, like any heating boiler, multi-fuel equipment has a number of disadvantages, which must be taken into account when deciding whether to install it:

- The cost... It is noticeably higher compared to mono-fuel boilers.

- Necessity organization of storage places of the solid or liquid fuel used.

- Necessity organization of a separate boiler room... Although it can be said about combined boilers that they are compact, they still surpass electric or gas units in size. In addition, work on the same coal or diesel fuel is too “dirty” to place the heat generator not in a separate boiler room.

- Overall design complexity, which, in fact, has a direct impact on the cost, and also complicates maintenance.

Important! Combined boilers also include models with only one combustion chamber. To convert them to alternative fuels, the burner needs to be replaced.Considering that such devices are often also equipped with heating elements, without replacing the burner, it is possible to work on electricity.

Conclusions - which combination boiler is better

When choosing, you should take into account the type of main fuel - working on this fuel, the boiler must deliver maximum power. The type of reserve fuel determines the final choice of the model. The final decision is made based on the financial capabilities and desires of the buyer. For a country house, cheaper and more reliable domestic models are preferable.

A Few Tips

- The most massive and dimensional boilers are those that can use the maximum number of types of fuel. This does not apply to boilers for electricity and wood, the dimensions of which hardly change. The heating element in such boilers turns on when combustion in the furnace stops and the temperature of the coolant falls below a critical level.

- The cost of wood-electricity boilers, as well as coal-electricity, is almost the same as for wood-fired boilers. The dimensions of the boilers are also the same, since they differ only in that the electric boiler has a small heater. Electric heating provides only one third of the boiler's output. It is impossible to fully heat the house on electricity, but the temperature will be sufficient to prevent the system from defrosting.

- The coal boiler can be fired with wood, because the combustion temperature of coal is much higher than that of wood. The volume of the coal boiler firebox is small, so it will be inconvenient to use it constantly for firewood. It is categorically impossible to lay coal in the firebox of a wood-burning boiler - high temperatures can destroy the unit.

Varieties of combined boilers for heating a private house

Among the combined boilers for heating a private house, you can choose models that meet the needs of even demanding buyers, of course, within reason.

Depending on the design features, multi-fuel heat generators are divided into several types, which allows you to choose an option without overpayment for specific operating conditions.

Single and double-circuit boilers

Heating of the house can be organized by combined boilers with a different number of circuits:

- Single-circuit boilers - designed for heating only.

- Double-circuit models - with an additional circuit providing hot water supply.

Models that operate only on a heating circuit are usually more reliable due to a simplified design. Because of this, they are also cheaper. On the other hand, when an indirect heating boiler is connected, heating is combined with DHW. True, such a bunch is more expensive than the cost of two-circuit models.

Combined boilers with two heating circuits are equipped with either a coil or a storage tank. In the first case, hot water taps receive rapid heating of water for domestic needs, but with limited capacity, depending on power.

In the case of a storage tank, it provides household supply without temperature fluctuations in the case when hot water is used by more than 2 - 3 consumers.

Some models, regardless of the number of circuits, are equipped with a cooking hob. Additional fuel is not consumed to warm it up, and therefore, you can warm up breakfast, roughly speaking, for free.

Fuel types

The combined boiler for the home can be dual-fuel and triple-fuel. The first group includes models with the following main fuel bundles:

- Gas-solid fuel... An electric wood-burning boiler is a prime example here, since it is believed that firewood itself is a cheap source of energy. However, this is true if they are mined on their own. Coal and pellets can also be used as solid fuel. This design is usually poorly automated.

- Gas-electricity - relatively compact, the main fuel is cheap gas. The heating element is connected to work either for rapid heating of water, or when the main heat carrier is turned off. Among the advantages, variability should be noted. It is also necessary to pay attention to the fact that in most of these models, electricity is spent not on heating the coolant, but on maintaining its temperature.

- Solid fuel-electricity - is popular in non-gasified regions. By design, this is a classic solid fuel boiler, but equipped with a heating element, which is capable of operating simultaneously with the firebox, or even independently, maintaining the nominal operating mode of the heat generator. Heating a house with an electric wood boiler is especially beneficial in non-gasified regions with wooded areas.

Three-fuel combined units are less popular, but among all the options, you can pick up quite interesting models that are easy to use:

- Gas-liquid fuel-solid fuel... The best models are structurally uncomplicated and have two fireboxes. In the first, either gas or liquid fuel is burned, which depends on the installed burner (it can be changed), and in the second only solid fuel.

- Gas-solid fuel-electricity - are considered the most versatile, since they use three energy carriers that are completely different in terms of availability, reliability, and cost.

It should also be noted that combined boilers can have both separate fireboxes, each of which operates on its own heating circuit, and one common combustion chamber. True, the latter option is typical mainly for home-made heat generators and constantly receives rather conflicting reviews.

Boilers with open or closed combustion chamber

The type of combustion chamber is another criterion by which the combined boilers are divided into subspecies:

- Open chamber models... Here, combustion products are removed by natural draft in the chimney. The air for fuel combustion is also sucked in without auxiliary devices directly from the boiler room.

- Equipment with a closed combustion chamber - works exactly the opposite. Combustion products are forcibly removed, as well as air is taken in to support the combustion process. It should be noted here that the air mass is supplied from the street, that is, oxygen is not burned in the room.

The operation of a closed chamber in any case depends on the electricity that powers the fan, so in terms of autonomy, it may not be the best choice.

Combined gas boilers

The only combined type of boilers that can be recommended for installation are double-circuit gas boilers, which allow you to use the boiler for both heating and hot water supply.

Every homeowner who decides to buy a double-circuit gas boiler and equip his home with it will be able to save by:

- no need to purchase an additional boiler. Each of the models on the market is capable of simultaneously heating not only the coolant in an autonomous space heating system, but also the water entering the draw-off currents;

- gradual heating of water and the absence of a hot water tank, which is in any boiler, allows you to consume exactly as much hot water as you need. Due to this, you save yourself from the loss of heat, which is inevitable, because over time, the accumulated hot water cools down due to which its additional heating is turned on;

- small size saves the area required for equipping the combustion room. The wall-mounted design of a double-circuit gas heating unit will make it possible to do without the purchase of additional equipment, for example, a centrifugal pump, since it is already in the design of the unit.This will also save usable floor space and reduce the load on the power grid;

- no need to equip a special chimney. Turbocharged double-circuit gas boilers do not require the arrangement of a complex chimney, brick or concrete base and breaking through the roof to supply air and remove combustion products;

- more accurate regulation by systems of automatic control of operating parameters. Depending on the climatic situation and the degree of thermal insulation of your home, such a system will automatically reduce or increase the degree of heating, it will make it possible both to save money on "warm" winter days, and to set the air temperature parameters depending on the presence of your family members in the house.

In addition to the above advantages of such heating installations, modern models are capable of operating at almost any gas pressure in the pipeline, which increases their operational characteristics.

As for the cost of double-circuit gas boilers, if there is one, it is not much higher than that of other heating units. If we take into account the significant service life and the above advantages of the heating system, then we can conclude that the purchase and installation of a double-circuit heating unit is the most optimal way to provide yourself and your own family with hot water and maintain a comfortable temperature in a private house during the winter months.

Recommendations when choosing a boiler

Studying any rating of combined boilers for a private house, you will notice that each model has its own characteristics, both in terms of operation and in physical dimensions and design. In fact, on sale you can find units working with four, and even with five types of fuel. It is from the availability and cost of the energy carrier that one should build on when buying.

Important! Combined boilers, designed for unequal use of energy resources, when switching from the main type of fuel to the reserve one, can therefore have a serious spread in efficiency. The planned costs for the season are also taken into account when choosing. When gas is available, questions usually do not arise, since it remains the cheapest. It is enough to purchase a model of the gas-electricity type, thereby ensuring uninterrupted and efficient heating.

Based on the costs of the heating season, the list from the cheapest energy source to the most expensive is as follows:

- Natural gas.

- Pellets.

- Firewood.

- Coal.

- Liquefied gas.

- Diesel.

- Electricity.

The location of the items in the list may vary depending on the actual cost of the energy carrier in a particular region.

Combined universal boiler TT-gas

To convert a solid fuel combi boiler into a gas one, you need to buy a burner separately. It is built into the heater's furnace and a central gas pipeline or a supply from a gas holder is connected to it. When choosing a burner, you need to pay attention not only to the configuration. It is important to consider two factors:

- thermal power;

- type of energy carrier.

It is impossible to make a warm floor from polypropylene pipes.

The disadvantage of installing a film underfloor heating is the lack of grounding.

The fact is that not all burners can operate on both natural and liquefied gas. The heater must be connected by a specialist with the appropriate level of approval. Under no circumstances should you supply gas on your own.

Combined boiler capacity calculation

In theory for heating 10 sq.m. area, you need to spend 1 kW of thermal energy. However, such a calculation is highly simplified and conditional, it is adjusted based on the following factors:

- Thermal insulation of the building as a whole... It takes into account not only the material of the walls, but the number of openings, which doors and windows are installed.

- Climatic features of the region... If winter is characterized by severe frosts, the difference between the ambient temperature and the mark to be reached increases. This means that the equipment should be more powerful.

- Number of floors and ceiling heights... In fact, it will not be necessary to heat the area of the house, but the volume of the contained air.

Thus, the power surcharge for a multi-circuit combi boiler can be 25 - 30%. Detailed calculations are carried out by specialists.

How to choose a combined boiler unit

The choice of heating boilers for wood and electricity is limited, since they are all very similar floor structures with a steel heat exchanger. When choosing, you should pay attention only to:

- Number of contours... Single-circuit models are used only for heating. Double-circuit ones also heat water in the DHW circuit, the sanitary water of which does not mix with the technical one in the heating circuit. Double-circuit models are 10-30% more expensive, but this is still the cheapest way to organize hot water supply.

- Burned fuel... Usually, such boilers are designed to burn not only firewood, but also coal, peat, pellets - this information is always indicated in the product description or operating instructions. However, there are exclusively dual-fuel models (wood-fired with built-in electric heaters) that are not intended for burning coal.

- Operating pressure... In view of the steel heat exchanger, many models are characterized by a maximum allowable working pressure of only 1 bar. This means that they can only be used in an open heating system with natural circulation, since in closed systems the operating pressure is usually in the range of 1.5-2 bar.

- Efficiency... Despite the fact that this is an indicator of efficiency, in this case it is possible to pay attention to it only in the last turn, since it depends very much on the quality of the fuel. The manufacturer's declared 75% when using too damp wood or ash non-heating coal can turn into 60 and even 50%. Nevertheless, an excellent indicator - 80% or more, testifies to a successful and efficient boiler design.

Minimum required power

For a standard non-insulated or slightly insulated house in the climatic zone of the Moscow region, with 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated using a simple formula: 1 kW for every 10 m 2 of area. We also recommend setting a power reserve of 20-30%.

For example, for the above-described average house with an area of 120 m 2, the minimum required heat output of heating equipment is 120/10 * 1.2 (20% of the stock) = 14.4 kW, that is, 15 kW.

If the boiler is double-circuit, it is advisable to add another 10-15% of the reserve so that the heating of the water does not affect the heating. If the house is located in the south or north of the country, it is well insulated, has high ceilings or a large glazing area, correction factors are taken into account, which change the result by 5-30% up or down.

Is it profitable to heat the house with a combined boiler

Variability is the main trump card of the combined boiler. With the correct selection of a heat generator for specific operating conditions, heating costs are reduced. In addition, if there is a shortage of one of the types of fuel, you can always switch to another. It all depends on the price tag for the energy carrier and its availability.

In non-gasified coal-mining regions, it makes sense to install combined boilers, in which coal is the main fuel. Usually the price tag for this energy carrier in such an area is below average. If there is access to gas, the situation becomes even more simplified, and solid fuel goes into the reserve category.

In the case of installing a multi-tariff meter, at night, when the cost of electricity is noticeably lower, it makes sense to use electricity to maintain the temperature in the rooms. The above options for operating a multi-fuel boiler are nothing more than examples of situational savings.

Combined boilers "electricity - solid fuel"

Heating boilers operating on solid fuel and electricity will not allow your fuel system and house to freeze if there is no one to throw firewood on.

Combined boilers "electricity - solid fuel" are often used to heat country houses and summer cottages.... They are built on the same principle as gas and solid fuel boilers. However, instead of a gas burner, heating elements of various capacities are installed in them. The largest part of these combined devices is the firebox into which the wood is loaded. The boilers themselves are made of steel or cast iron, the type of installation is floor-standing.

Most often, combined heating boilers "electricity - solid fuel" run on wood. This is a relatively cheap fuel that is sold in settlements that are not connected to gas mains. By purchasing a truck of firewood, you can provide yourself with warmth for the whole winter. As for the heating elements, they play an auxiliary role, maintaining heat in the absence of firewood.

The system works like this: the required amount of firewood is loaded into the firebox, the boiler begins to heat the premises. As soon as they burn out and the temperature begins to drop, the heating element will turn on. It maintains the desired temperature in the heating system, not allowing the coolant to cool down. If you throw firewood (or pellets) into the firebox and set them on fire, the heating element will turn off after a certain time.

Advantages of combined heating boilers "electricity - wood":

- the ability to save on electricity when working on wood;

- use of any type of solid fuel;

- the presence of an anti-freeze mode.

Freezing water tends to expand, which can lead to rupture of the heating pipe in winter.

The latter mode will become relevant for those who use their country house to stay on weekends or on holidays. By turning on anti-freezing, you can safely go to the city, and the boiler will automatically maintain a positive temperature in the system. This reduces the likelihood of pipe rupture as a result of freezing of the coolant. The main thing is that in cold weather the electricity does not disappear, which happens in small settlements and dacha associations.

Heating universal boilers "electricity - solid fuel" will help reduce the cost of heating premises... Solid fuel has a minimal cost, and in some cases it is completely free. For example, in rural areas, straw and other plant waste can be burned in such boilers. If there is no money to buy firewood, they can be cut in the nearest forest - here only labor costs are needed for felling the forest.

If firewood is not available, the equipment will operate from the electrical network. But you shouldn't get carried away with this mode of operation - high power consumption will come back to haunt with gigantic figures in electricity bills. Instead of firewood, you can use any other types of solid fuels, for example, coal, pellets, briquetted peat and much more. The main disadvantage of such boilers is their large dimensions.

The initial price for combined heating boilers "wood - electricity" varies between 20-22 thousand rubles (as of the end of May 2016).

Installation Requirements

Almost all combi boilers are floor standing and require a separately equipped boiler room. In addition, when installing them, it is imperative to comply with a number of fire and electrical safety requirements, as well as compliance with SNiPs. Below are the main features of the installation.

Premises

- The presence of a reinforced individual foundation for the installation of boiler equipment.

- Compliance with fire safety standards.

- Dryness in the boiler room, protection against moisture penetration.

- Non-combustible wall material.

- The minimum distance between the boiler and any wall is 300 mm.

Chimney

- Tightness of joints.

- No cracks or other mechanical damage.

- Thermal insulation that prevents the formation of condensation and ice, which can lead to the blockage of the chimney duct.

- The head is at least 500 mm high.

Electricity grid

Here it is important to eliminate the likelihood of contact with water of any current-carrying elements, if any. Also a mandatory requirement is the correct selection of the cross-section of the supply wiring, which is calculated on the basis of the total power of the supplied equipment, the strength of the consumed current.

How to heat a combi boiler

Yes, solid fuels involve constant approaches to stowing firewood. This is the minus of a solid fuel wood boiler.

However, in order for you to sleep peacefully at night, such a boiler has a heating element built into the water jacket of the boiler, which heats the coolant all night.

During the day, you add firewood every 2-4 hours. The time between filling depends on the type of boiler. And at night you do not put any firewood at all and sleep peacefully until the morning.

In the morning, you turn off the heating element and continue to heat the boiler with wood.

Top manufacturers

Combined heating boiler ratings can include dozens of models from a wide variety of manufacturers. Among them there are those that are especially popular with buyers and are rightfully considered one of the best.

Protherm

This European manufacturer of heating boilers is distinguished by a wide range of products with more than 90 products, including heat generators of almost any kind, including innovative condensing models. Products are delivered to more than 25 countries from Europe, Asia and Africa, where they have earned the trust of consumers.

Protherm boilers are certified according to ISO 9001, have an affordable price for a wide range of buyers and a rich model range. In addition, the manufacturer provides professional service both through its own services and through partner companies, whose employees must undergo special training.

Roda

The products of the German manufacturer Røda are represented on the domestic market by electric, gas, solid fuel and, of course, combined boilers. Roda is a climatic equipment of European quality with service throughout the Russian Federation and a wide network of dealers.

Roda solid fuel boilers all have natural draft, and the combustion intensity is regulated by means of a thermomechanical regulator. On the other hand, the heat generator can be retrofitted with automation. It is also possible to install a control unit and a forced air intake fan.

ZOTA

The domestic manufacturer ZOTA offers customers, among other things, combined heating boilers for wood and coal with the ability to connect heating elements as an option.

They differ in an affordable price tag, there are models with a burner. Some solid fuel heat generators fully provide long-term combustion, which, depending on the type of energy carrier, is 8 - 12 hours.

Teplodar

Another domestic manufacturer that offers customers not only boilers, but also stoves, and even fireplaces. Teplodar has been working in the field of heating for 20 years and has more than 50 patents for unique developments.

High-quality materials are used in the production, and the reliability of the products is confirmed by various certificates. The model range includes horizontal heat generators of the Uyut series with a spacious firebox designed for firewood up to 50 cm long.

© 2020 All rights reserved

Connecting wood and electricity boilers

Without a doubt, the purchase, installation and piping of two separate units will cost you more than one combined heat generator. But, by implementing this option, you get full heating with two energy sources, effectively operating in automatic mode.

Reference.In non-gasified private houses of the Russian Federation, the joint operation of a solid fuel and electric boiler is used quite often, since this is the most convenient way to heat a home with wood. The combination of gas and wood is no less common, and the third place is occupied by the so-called multi-fuel boilers, which we will discuss in a separate article.

In our pair of heat sources, a wood (coal) boiler is the main one, and an electric one is an auxiliary unit. As the latter, you can use any of the three types of electric boilers on the market:

- traditional heating element with built-in circulation pump and control unit;

- electrode with a remote control panel;

- induction with a separate control panel.

We will not analyze the advantages and disadvantages of each type of electric boilers, this is a topic for another article. Here we will show in diagrams how to connect boilers with wood and electricity, so that the second one would insure the first one in automatic mode. Let's start with the joint piping of the wood-burning and heating element heating unit:

Connection diagram for 2 boilers - on electricity and wood. Thermostats provide automatic start of the electric boiler after stopping the wood-burning boiler and vice versa.

Reference. The presented diagram can be used for joint connection with a gas wall-mounted boiler, which is put in place of the heating element.

The system operation algorithm looks like this:

- The TT boiler is inactive and its circulation pump is off. The heating devices receive heat from the electric boiler, which is guided by the room thermostat, where you have set the desired temperature. To prevent the coolant from moving in a circle through a parallel ring, 2 check valves are involved in the circuit.

- You melted a solid fuel plant. For a while, it will begin to gain temperature, and the water will circulate in a small circle, guided by a three-way valve with a thermal head. The pump will turn on at the command of the overhead thermostat installed on the supply pipeline.

- When the coolant in the small ring heats up to 55 ° C, the temperature sensor of the thermal head, which is on the return line, will be triggered. The three-way valve will open slightly and the heat will go to the heating system.

- The electric boiler will turn off heating at the signal from the room thermostat and go into standby mode.

- After the solid fuel burns out, the water in the system, and behind it the air in the rooms, will begin to cool down. The overhead thermostat of the TT-boiler will “see” that the coolant has cooled down and will stop the pump.

- When the temperature in the house drops to the value set by you, the room thermostat will re-activate the electric boiler.

Important! Since the internal circulation pump of the wall-mounted heat generator cannot be turned off, a more powerful unit must be selected for a solid fuel heat source. As a rule, a pump with a pressure of 0.6 bar is sufficient (in an electric boiler it usually costs 0.5 bar). The second moment: put all overhead sensors and thermostats on metal pipes, they will lie on metal-plastic or polypropylene.

Our expert Vladimir Sukhorukov will tell you in detail how to properly connect an electric and solid fuel boiler in his video:

Induction and electrode heat generators are not equipped with their own filter and circulation pump, so the latter will have to be purchased and installed separately. This is the whole difference in the wiring diagram for heaters of this type, only the pumping unit must be connected to the network through the control cabinet so that the room thermostat turns it off together with the electric boiler, as shown in the diagram:

In this scheme, the circulation pump of the electric boiler will be turned off with it thanks to a separate control cabinet

If the heating system of a private house consists of several circuits (radiators on different floors, underfloor heating and an indirect heating boiler), then for joint operation, a wood-burning and an electric boiler is connected by the method of primary and secondary rings. The principle of operation of this type of strapping is described here.

Connecting an electric and solid fuel boiler to the heating system using the method of primary and secondary rings

Types of boilers

One of the main parameters by which combined heat generators are classified are the types of fuel used.

This is usually reflected in the marking, which consists of several letters meaning:

- T - solid fuel (firewood, coal, pellets, peat, etc.);

- G - gas;

- E - electricity;

- W - liquid fuels (fuel oil, kerosene, waste engine oil, diesel fuel, etc.).

For example. the combination of the letters "TG" in the name of the heat generator means that it can operate on solid fuel and gas, and the design will use a scheme with two combustion chambers. If necessary, you can buy a multi-fuel unit, in the name of which there are four letters "TGEZH". Such heat generators are the most versatile devices, however, the complexity of the design and the high price do not in the best way affect their prevalence among consumers.

The most optimal solutions for private houses are devices using two types of fuel.

Gas / electricity combination

Electric gas equipment is usually used in gasified areas where there are interruptions in the supply of pipeline gas. Considering that the cost of electricity is about three times higher than the cost of gas, in combined units of this type gas is used as the main source of heat, and electricity is used as a backup. Compared to solid fuel heaters, gas-electric heaters are more compact and are often mounted on the walls of residential premises, significantly saving space.

Combination firewood / gas

Firewood-gas heat generators are widely represented on the heat equipment market. They are popular in gasified areas with harsh climates, in which the use of two types of fuel during an extended period of cold weather can reduce overall heating costs.

Prices for combi boilers ZOTA

combined boilers ZOTA

There are two types of solid fuel-gas installations:

- Units in which gas is used as the main fuel and firewood is used as an alternative fuel. The transition from one type of fuel to another requires a small upgrade.

- Universal heat generators, in which the gas turns on automatically when the wood burns out.

This type of equipment usually has two combustion chambers with a common chimney. In one chamber, grates are installed, and in the other, a gas burner.

Combination firewood / electricity

In those regions where the cost of firewood is low and there are no gas mains, combined firewood-electricity installations remain the most preferred and in demand. Two sources of thermal energy allow not only to minimize heating costs, but also increase the overall stability of the system. The heating circuit is inertial. The constant maintenance of the required temperature of the coolant by electric heaters reduces the consumption of firewood for heating it during ignition, which makes it possible to get by with fewer of them.

Multi-fuel plants

The prevalence of multi-fuel installations in private homes is hampered by two main factors: high cost and complexity of maintenance. The use of fuels with different physical properties in one unit requires the installation of a larger number of burners, pumps, nozzles and other elements.This leads to a more complex control automation and a decrease in overall reliability.

For private households, a maximum of three combinations of fuels are usually used, including wood, gas and electricity. Pellet / oil / gas combinations are very rare.

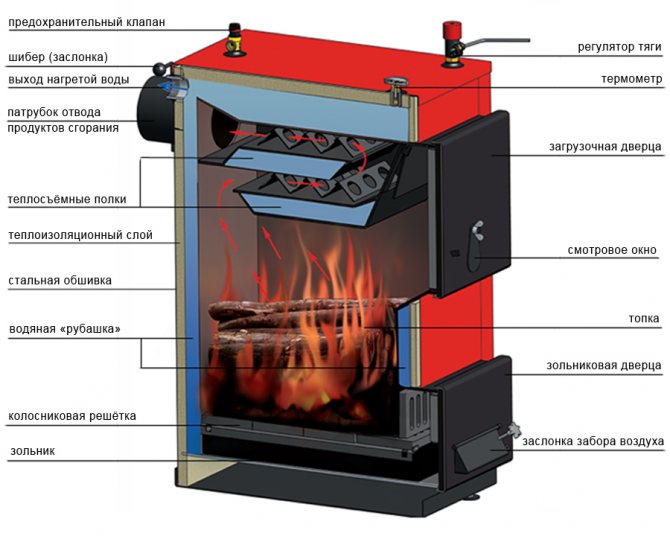

Electric fire boiler device

The device of multi-fuel heat generators uses a combination of elements capable of converting energy received from various sources into heat. Electric wood-burning units in their design practically do not differ from conventional boilers operating on wood and coal.

Structurally, they consist of:

- a casing, inside which a water jacket or heat exchanger of heat or water tube type is located;

- a combustion chamber with an air supply and chimney system;

- ash chamber for accumulation and removal of solid combustion products;

- TENA (tubular electric heater) or a block of heating elements;

- control equipment.

Depending on the chosen method of controlling the air supply to maintain combustion, heat generators operating on solid fuels can be equipped with either a mechanical draft regulator or an electric blower fan.

Principle of operation

The operation of the combined firewood-electricity heat generator is based on the principle of automatic or manual transition from solid fuel to electricity. At the moment when the firewood laid in the combustion chamber burns out, electric heaters come into operation, maintaining the temperature of the coolant within the specified limits. The switching on and off of the heating element or the heating element unit is carried out by a switching device when it receives a signal from a temperature sensor installed in the heating circuit.

Benefits of using

The presence of an electrical component in a solid fuel boiler can significantly increase the reliability of the entire heating system and the convenience of its use.

The relatively small complication of the combined unit design during operation allows:

- maintain a comfortable temperature when heating the house both during the day and at night;

- avoid defrosting the heating circuit of a country house, cottage or summer cottage in case of a long trip;

- use electricity in the absence of firewood or coal as a backup source of heat.

The cost of combined boilers of different types

The cost of combined units depends on many factors, including:

- brand awareness;

- boiler power;

- the number of types of fuel used;

- equipment.

Standard dual fuel boilers remain the most affordable today.

Universal equipment using 3 or more types of fuel is the most expensive due to the complexity of the design. The wider the functionality, the more elements are involved for its implementation.

Excessive costs for expensive multi-fuel models are not always justified, and during operation it turns out that many functions are simply not used. Simple and reliable equipment with a combination of wood-electricity in most cases perfectly copes with the tasks of heating private houses. What is better stone wool or mineral wool, see the link.

Criteria for choosing a firewood / electricity boiler

When choosing reliable heating equipment, it is not enough to be guided only by the availability of a certain amount of money and personal preferences. The main thing in this complex matter is the technical parameters that ensure the efficiency of the entire system.

When choosing a boiler, the following must be taken into account:

- thermal power and area of heated premises;

- the type of fuel to be used;

- the ability to connect to gas mains and power grids;

- the presence of special rooms for the installation of equipment, equipped with ventilation and a system for removing combustion products;

- type of heating circuit (open or closed);

- the need for coordination with licensing technical authorities.

An ideal option before purchasing any type of heat generator would be to develop a project with an accurate professional calculation of all system parameters. Errors at this stage can lead not only to the fact that the already assembled system will not provide the necessary heat, but also to its complete failure.