Have you decided to make a private house your permanent residence? Or maybe the summer season lasts in your family all year round and winter weekends outside the city are a common thing for you? Then the question of heating your nest is extremely relevant. Today, perhaps the most popular among all heating systems for private houses is water heating. The principle of its operation is quite simple and straightforward: heat is generated in a special boiler and already from it through a closed circuit, hot water is supplied through pipes to heating devices.

But this is a general principle. Depending on the heating method (gas, electricity, etc.), the circulation method, the heating systems used, as well as other characteristics, water heating is divided into many types. It is this topic that we will cover in detail in our article.

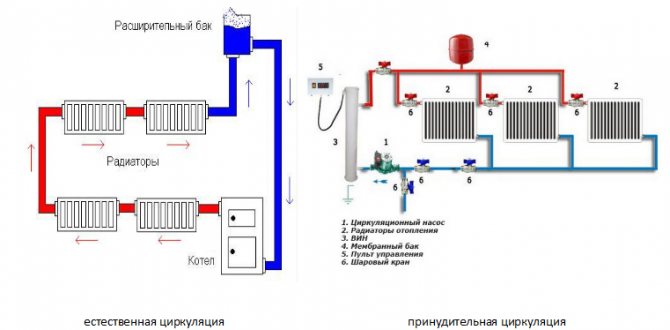

All water heating systems at home can be divided into two groups: using natural or forced circulation of water.

Natural circulation heating

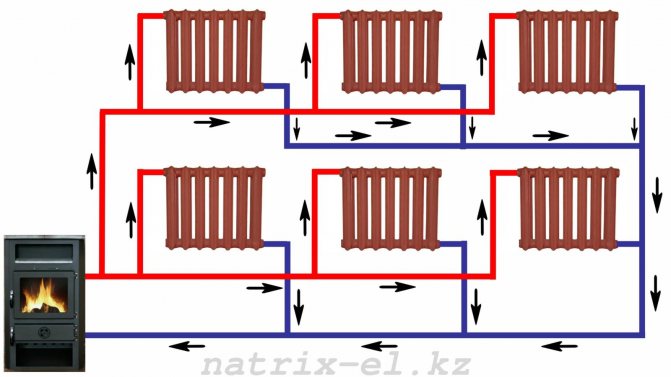

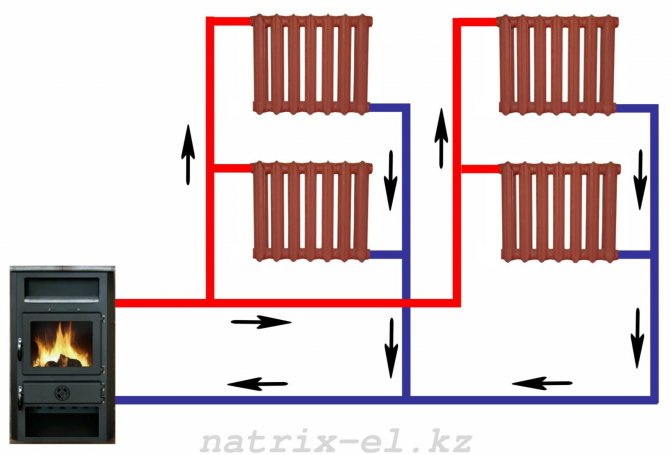

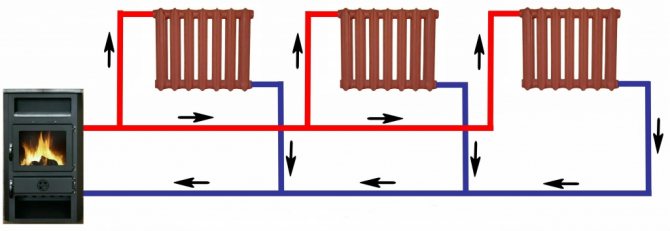

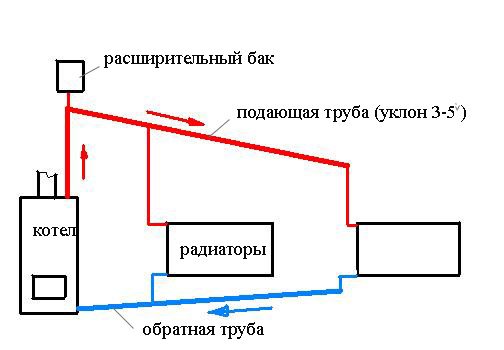

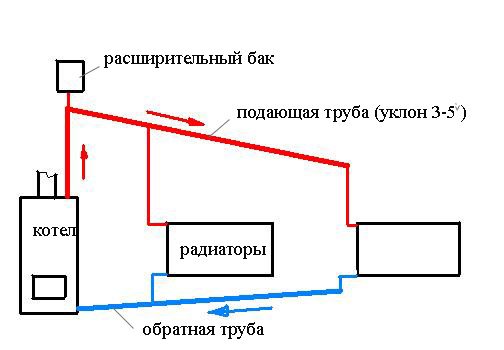

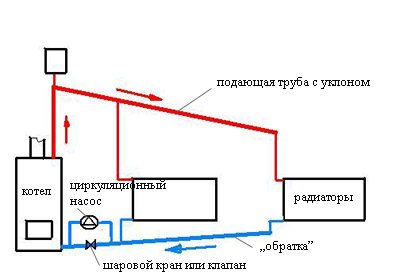

An example of a one-pipe system with natural circulation

Systems with natural circulation, or as they are also called gravity, have been used for a long time. From the name itself, we understand that they work without the help of special devices (pumps), and their work occurs due to natural physical laws.

We all probably remember from school physics lessons that a heated liquid or gas always moves upward. This is the principle behind such heating. Heating up in the boiler, the water begins its movement up the pipes. Having reached the farthest heater, it begins to descend back to the boiler, where it heats up again and circulates upward. When installing a self-circulation system, a slope is necessarily created in the water return section. And at the supply of the coolant, at the highest point of the system, it is required to install an expansion tank, which will act as a buffer that compensates for the increase in the volume of liquid.

Benefits of gravity heating

As already noted, gravity water heating systems at home have been used for a long time and have managed to recommend themselves, as they have certain advantages:

- Cheapness. After all, this system does not require installation of additional equipment.

- Ease of installation and repair (it is even possible to build a heating system in your own house with your own hands).

- Work in the absence of electricity. For a while, until the boiler temperature drops below 50 degrees, the liquid will continue to circulate through the system.

- Almost complete noiseless operation, again due to the absence of a pump.

Disadvantages of gravity heating

But with all the above advantages, self-circulation heating systems have many disadvantages that make it impractical to use this method of heating a house today.

- The inability to use this type of system for large rooms. Even for a two-story private house, the circulation of water will be difficult.

- The temperature difference in heating devices. The farther the room is from the boiler, the colder it will be. Moreover, the difference can sometimes be significant - up to 5 degrees.

- The regulation of heating is complicated. Firstly, the system will start working only when the boiler heats up to 50 degrees, respectively, you will not be able to make the heating power in the house below this mark.Secondly, even when installing heat regulators, the temperature error will be from 3 to 5 degrees, which is quite significant.

Such systems are gradually losing their relevance and every year they are replaced by more modern compulsory systems. We recommend that you do water heating from natural circulation only if you want everything simpler.

DIY water heating installation

Before deciding to install the system with your own hands, it is important to consider the following:

- Since the work on the arrangement of water heating directly relates to the whole house and its utilities, it is advisable to combine these activities with a major overhaul.

- If the boiler is to be installed on the floor, a separate room will be required for its installation.

- The place for the boiler room is selected taking into account the requirements of current standards - it is well heated and has effective ventilation.

The generally accepted procedure for installing a heating system, as well as connecting it to boiler equipment, takes into account many related factors that require separate consideration.

Forced circulation heating

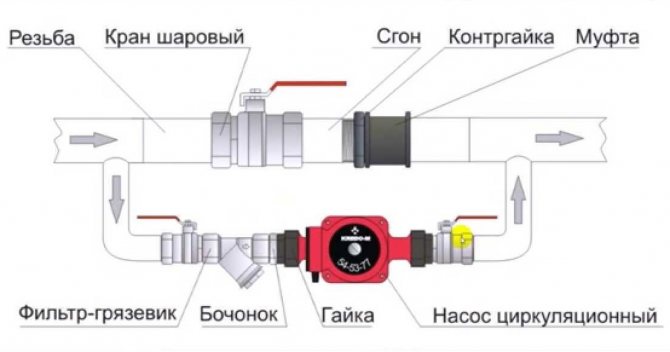

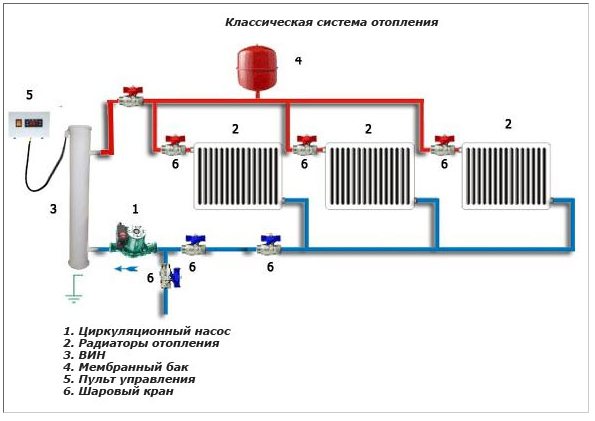

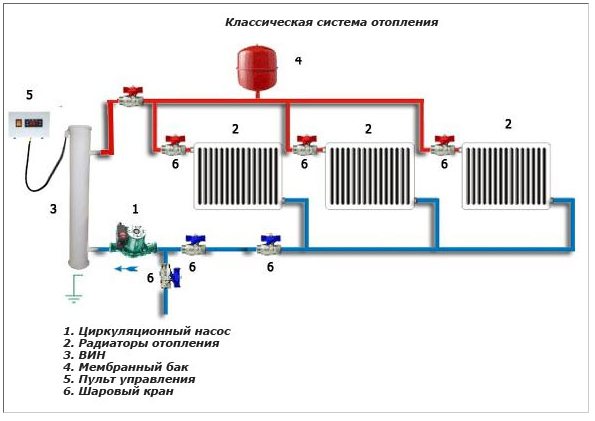

So, we see that systems with natural fluid circulation have a number of rather significant disadvantages. An alternative to them are systems with forced circulation, in which additional equipment is used to increase the supply of coolant in the system. Namely, the circulation pump.

Yes, this type of water heating at home will be more costly and difficult, but you get many advantages:

- The ability to heat a large room. We have already said that natural circulation is not good for large houses. If you are the owner of just this, then your option is only a forced circulation system.

- Complication of the system. By installing a pump, you do not depend on such an indicator as pressure. Therefore, what was an obstacle in a gravity system is not a problem in a forced system. So, for example, you can now increase the number of pipe bends if your home layout requires it.

- Use of smaller pipes. Agree, the neat appearance of the heating system is not the last indicator that you should pay attention to.

- Less dependence of heating quality on the presence of air in the system. With self-circulation, the ingress of air into the system would greatly complicate the transportation of the coolant through the pipes. The forced system solves this problem, but in the case of installing metal pipes, special expansion tanks with air deflectors and fuses should be used in order to avoid system corrosion.

- Possibility of using more durable and lightweight plastic pipes.

- Possibly concealed pipe installation. You can easily hide pipes in the screed and walls

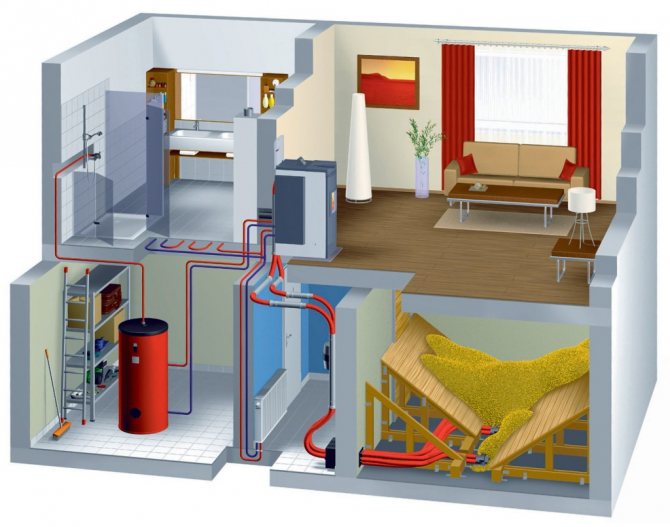

Efficient hot water heating in a private house

Water heating can be carried out in a private house with your own hands, although it is advisable that professionals who clearly know all the stages of the work carried out do this. In addition, they will be able to offer the most suitable option in this case for the layout and arrangement of pipes.

How to carry out water heating:

- First, you need to decide on a place for the boiler and heating workshop. A pedestal is placed under the boiler, and the heating device itself is connected to the chimney, and the joints are covered with clay.

- Further, the type of wiring and the location of batteries, risers and other elements necessary for the functioning of the system are determined. By the way, if the system will be with natural circulation, the expansion tank should be installed at the highest point of the system.

- After that, you can start laying pipes and installing batteries. The pipes are led to the radiators, after which all the necessary connectors, inputs and outputs are connected.Also, do not forget about the installation of a special tap, which will make it possible to remove air from the system.

- The entire heating circuit must be closed in the same place where it began - on the boiler. At its inlet, a filter is installed to purify the liquid and a circulation pump (if the system is forced).

- At the lowest point of the system, it is necessary to equip a drainage unit, with which it will be possible to drain the liquid if necessary.

You also need to remember that in the room where the boiler is located, there must be good ventilation - forced or natural.

It is only necessary to tie the boiler with metal pipes.

Types of water heating systems

Now let's look at the options for installing water heating. As in the case of the circulation method, we have a simpler and cheaper option, inferior in technical characteristics to the more complicated and costly one.

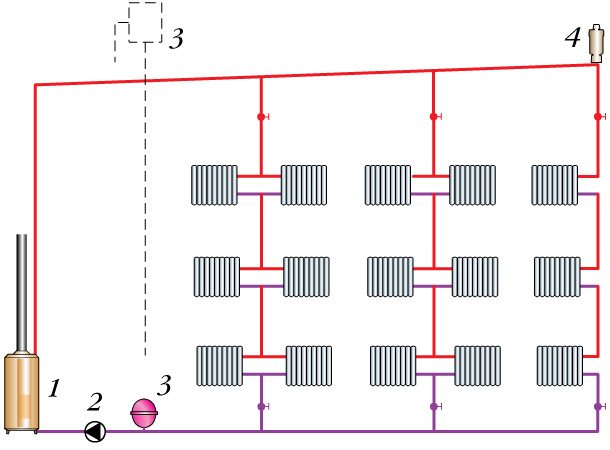

One-pipe heating systems

The first - simple and cheap - is a one-pipe water heating system at home, in which the liquid will pass sequentially through all pipes, radiators and other heating devices, if they are in the chain, and return to the boiler through the return pipe. This option is better suited, again, for a small room.

The disadvantage of such systems is the impossibility of their competent balancing. The first appliance is always hot, the last one is always warm.

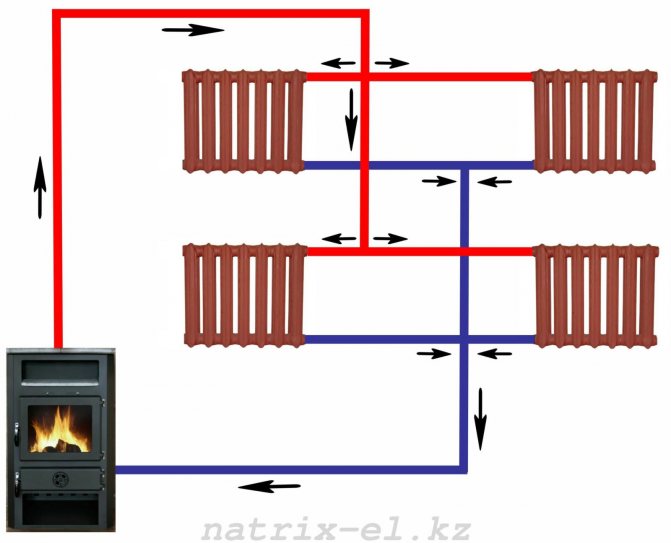

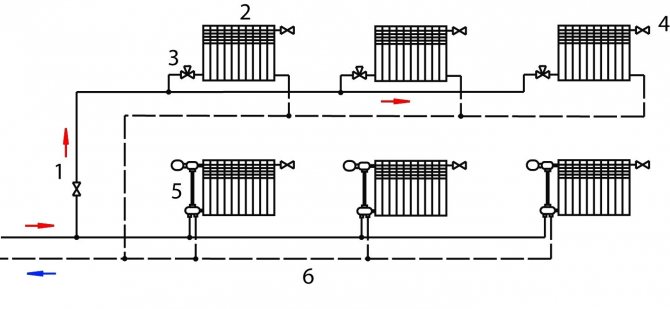

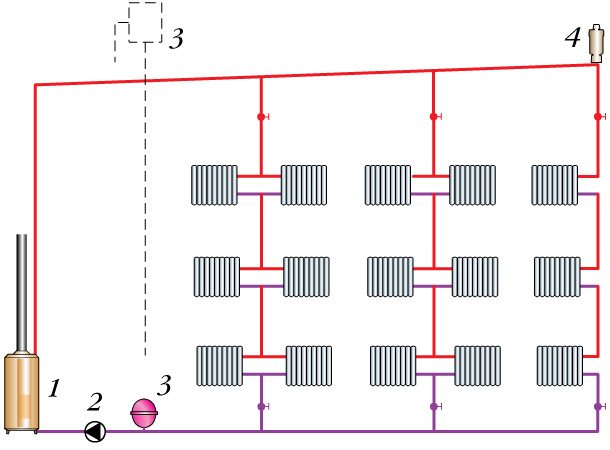

Two-pipe heating systems

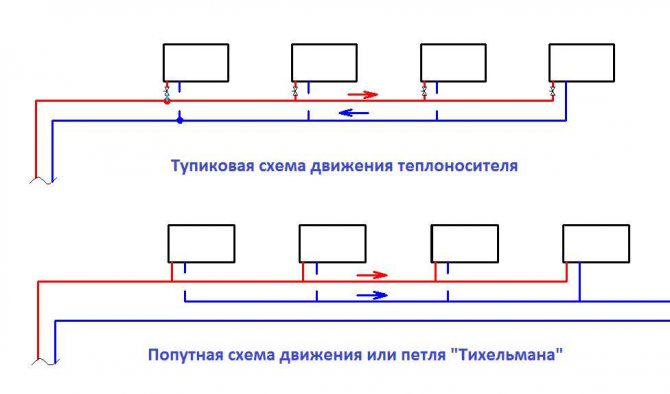

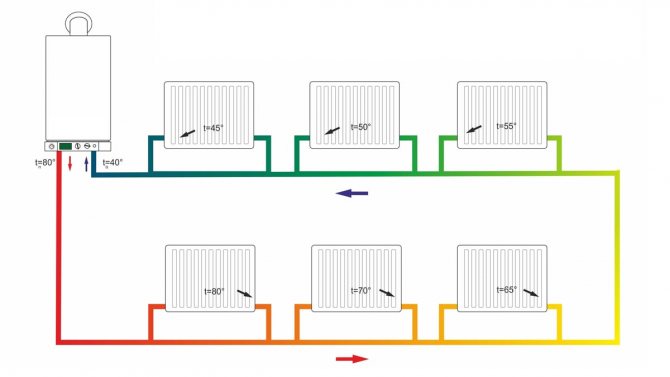

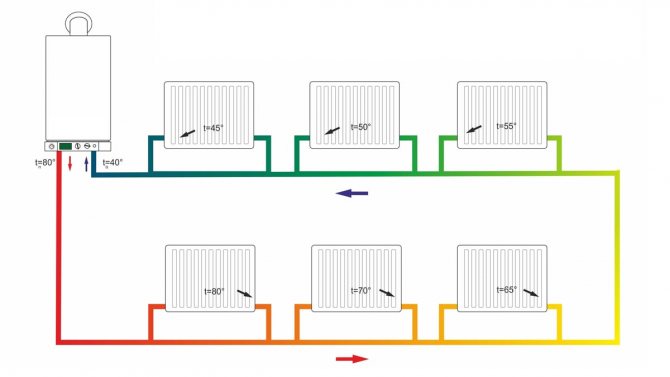

For rooms with a larger area, it is better to opt for a more advanced two-pipe system. In this case, the bottom connection of the radiators will be used. But such a heating gasket will really be perfect if you connect a circulation pump. Otherwise, it will be difficult to heat distant rooms.

In addition, it is possible to reduce the rate of liquid cooling in the system by installing special bypasses for each of the batteries, as well as regulators of the liquid supply to a separate radiator.

The difference between a two-pipe water heating system is the laying of a solid pipe to the furthest of the radiators, from which branching is made to intermediate heating devices. Thus, having passed through the entire heating system, the coolant returns to the boiler through a special return pipe, which makes it possible to evenly distribute heat transfer throughout the room.

Of course, the main disadvantage of such heating is its high cost and complexity of installation, but the comfort that you get in return is worth it.

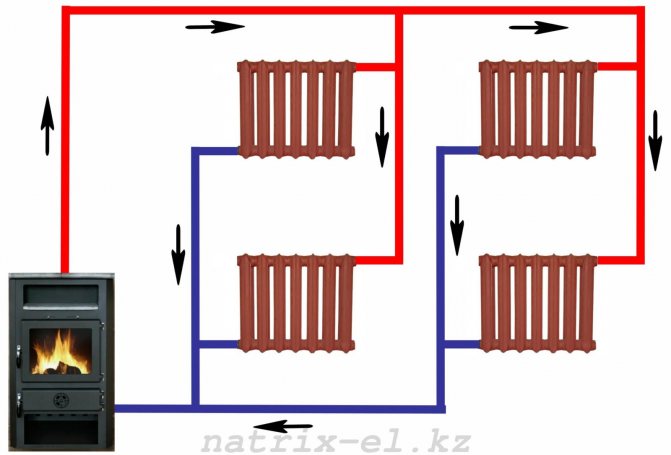

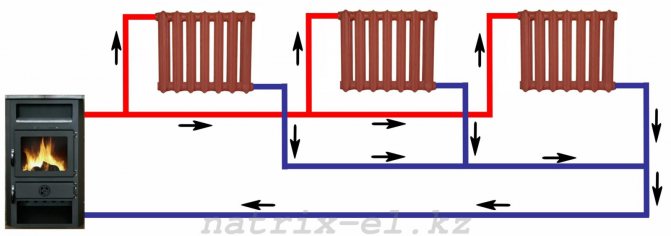

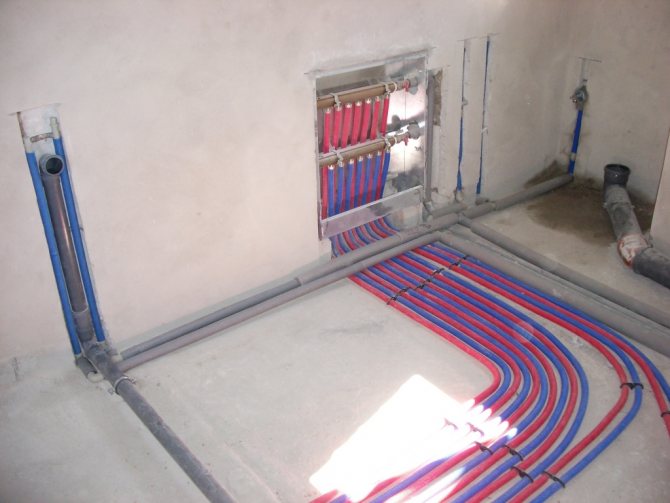

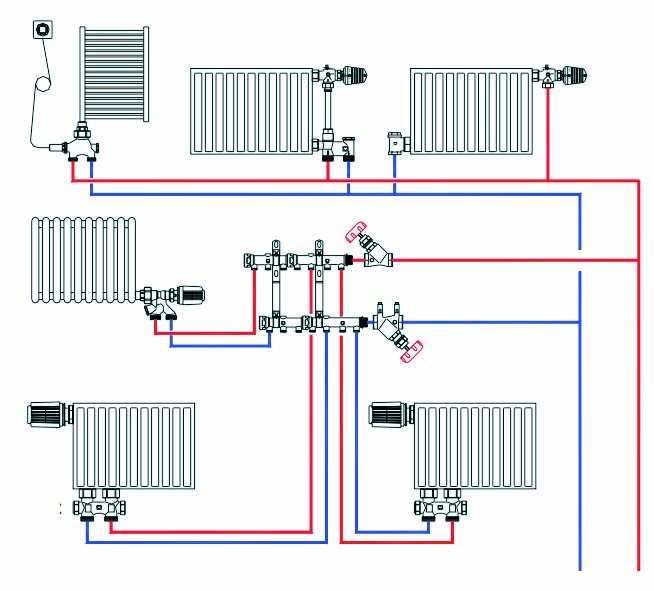

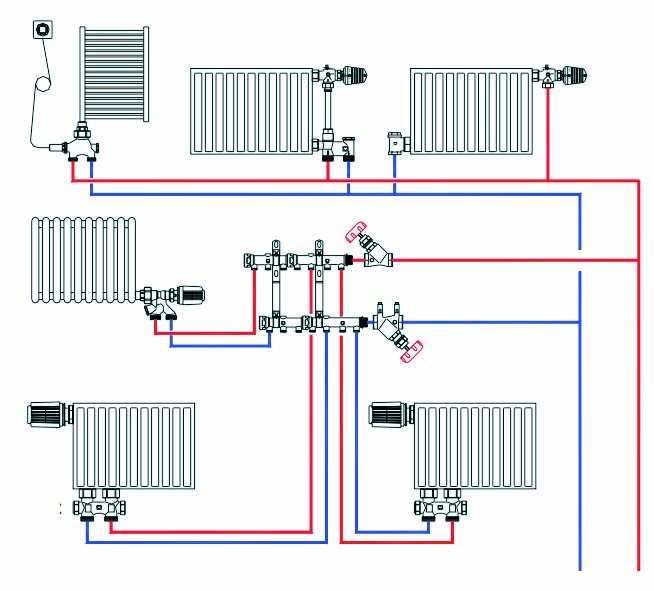

Radiant heating system

Radiation heating system diagram

The two above-described types of laying heating pipes are representatives of the perimeter method. But there is an alternative - ray. With such a laying, pipes are supplied separately to each radiator: one, through which the coolant enters the heater, the other is reverse. Such a system allows you to adjust a comfortable temperature regime in each of the premises of the house. In addition, if one of the radiators or pipes breaks down, there is no need to turn off all heating, it is enough to do this only in the desired area.

In view of the large number of pipes during the installation of the beam system, all communications are mounted directly into the floor or walls, which has a beneficial effect on the interior of the house.

It is most optimal to use the pump circulation of the coolant when radial laying.

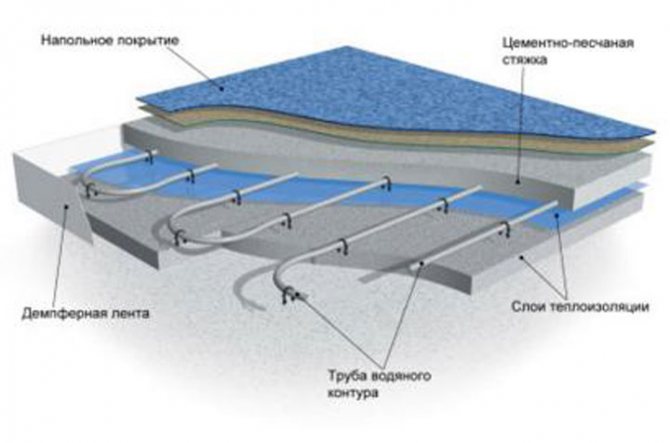

Underfloor heating

The most optimal way to evenly warm up the entire room is to lay water-heated floors in the house. It is possible to use only this system, and it is possible to combine it with other heating devices. For example, when radiators are installed in the rooms, and underfloor heating in the corridors, bathroom and toilet. That is, underfloor heating will be especially relevant for rooms with tiled or marble surfaces.

The use of the "warm floor" system is possible with forced circulation of the coolant.

Of the advantages that water heating gives with underfloor heating, one can single out:

- Uniform heating of the room. The screed, which gives off heat by radiation, gives it off in equal proportions in every square of the room.

- Rational distribution of heat. Heat moves from bottom to top.

- Comfort and microclimate.

- Lack of heating devices on the walls in most cases

Heat sources, circulation schemes and wiring

Depending on the type of elements with which the room is heated, water heating systems can be:

- radiator - the most common, at present, their type, the role of heating devices in which radiators (batteries) of various types perform;

- in the form of water "warm floors" with heating elements made of pipes, which are located at the base of the floor covering and through which the heated coolant circulates - a more modern, but even less common type.

Main elements

In addition, any such heating system consists of the following basic elements:

- heat generator (boiler, furnace);

- pipes through which the coolant (water) circulates and which can also serve as a heating element (for example, in a water-heated floor system);

- radiators providing room heating - in water-based radiator heating systems.

In addition, such systems, as a rule, include additional elements, such as an expansion tank (open or diaphragm), shut-off and control valves, control and safety equipment, and others, depending on the type and complexity of the system.

Generators or sources of thermal energy

The source of thermal energy for hot water heating can be boilers using various types of fuel:

- gas;

- electrical;

- solid fuel;

- liquid fuel;

- heat pumps;

- solar power plants.

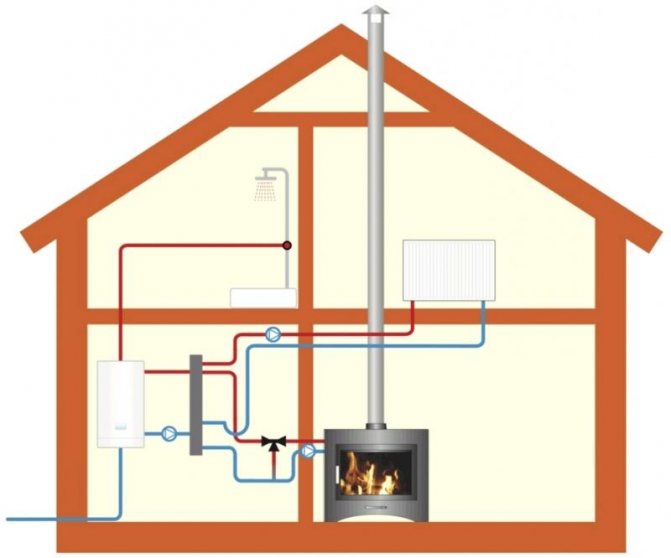

In addition, hot water heating can be combined with a traditional heating or heating-cooking stove, as well as with a stove or fireplace. At the same time, heat exchangers of various designs (coils, registers) made of pipes or sheet steel are included in the design of these heating devices. Thus, you can increase the efficiency of a stove, stove or fireplace and use a water circuit to heat several rooms or the whole house at once.

Even a combined version is possible, when several heat generators are connected in parallel to one heating system. For example: solid fuel and gas or solid fuel and electric. In this case, one of the types of heating will be the main one, and the other or others will be additional or backup. Moreover, water heating for different boilers practically does not differ, although it has some features, which we will consider below.

Very often, water heating is called steam. But they are not the same thing. Although water is also used as a heat carrier in steam heating, it heats up there to a state of steam. For this, special steam generators are used. Such installations are very rarely used in everyday life.

Closed and open systems

The hot water heating system can be open or closed. In the first case, it includes an expansion tank, which is placed as high as possible (under the ceiling or in the attic). Such a tank provides some excess pressure in the system, venting air from it and the function of a safety device if the water suddenly boils. In addition, it is often used to add water to the system during operation.

Open water heating system

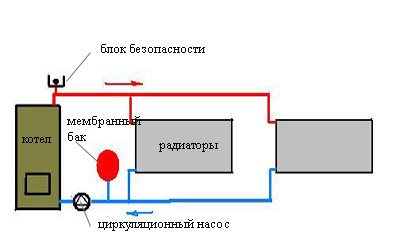

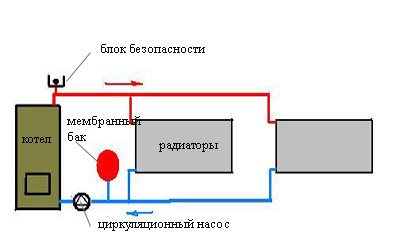

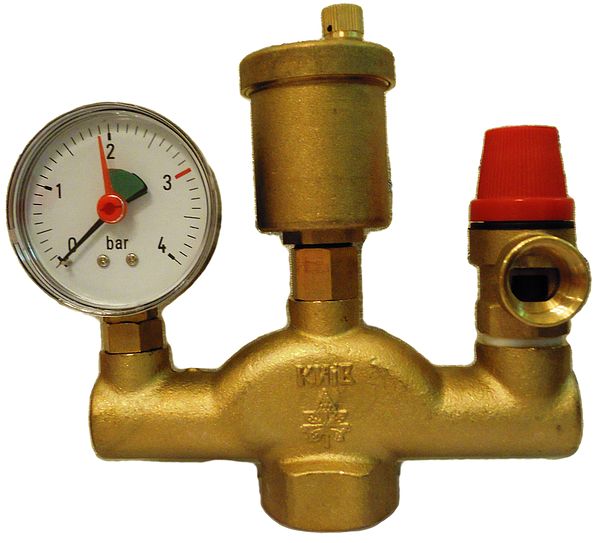

In closed systems, the expansion function is performed by a membrane pressure storage tank. In such systems, an overpressure is usually established in the range of 1.5 atm.(bar), and for control and safety, a special block is used, which includes a pressure gauge, air and safety valves.

Closed water heating system

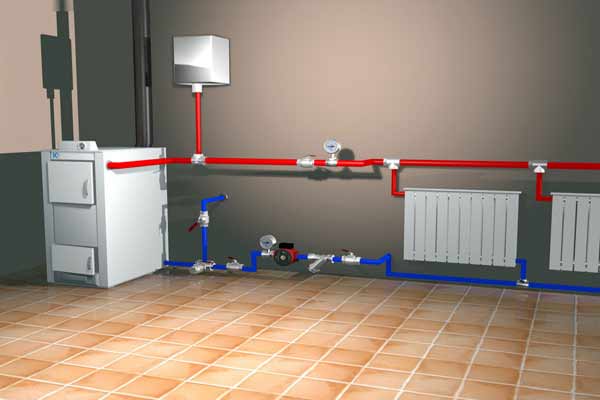

In order for the water heating system to function, it is necessary to ensure the circulation of the coolant in it - water or other liquid. Such circulation can be natural, forced or combined.

Coolant circulation: natural or gravitational

This type of circulation in water heating has been used since the very beginning of its existence. Such circulation is based on the fact that the density of heated water is less than that of cold water. Therefore, when heated, it rises up, displaced by a denser - cold one, it is fed through pipes to radiators, where it gives off its heat (cools) and, already cooled, goes back to the boiler or furnace. Everything is very simple and there is no need for any additional devices. This type of circulation does not depend on the availability of electricity and is most often used for heating with solid fuel.

Fig. 1 Water heating with natural circulation

But to ensure natural or, as it is also called, gravitational circulation, it is necessary that the pipes delivering water to the radiators and outgoing it be laid with a slope of at least 1/10 (3-5 °): the supply pipes are towards the radiators, and the "return »- towards the boiler. In the absence of such slopes, water will not naturally circulate.

The easiest way is to maintain the angle of inclination when installing such a water heating system from metal pipes, due to their rigidity. You can also use for this and, currently quite popular, polypropylene pipes. But to ensure correct slopes, it will be necessary to ensure their more frequent fastening to the wall according to preliminary marking or laying in inclined niches or "grooves".

To ensure natural circulation, the diameter of the water heating pipes is also important. It should be maximum near the boiler and gradually decrease until the last connection point (radiator). This applies to both the supply pipe and the "return". The maximum pipe diameter must match the diameter of the boiler inlet and outlet.

In addition, the boiler must be installed in such a way that the point of entry into it of the "return" is located as low as possible. The best option for ensuring natural circulation may be to locate the boiler in a basement or basement room. If this is not possible, then a so-called acceleration collector is arranged on the supply pipe: after the boiler, it first rises up by 1-1.5 m, and then drops down, providing a slope towards the radiators.

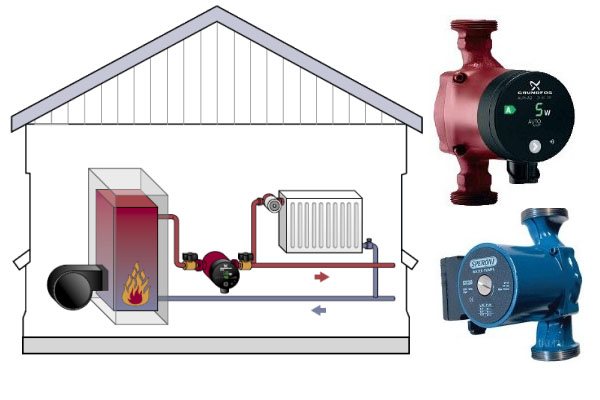

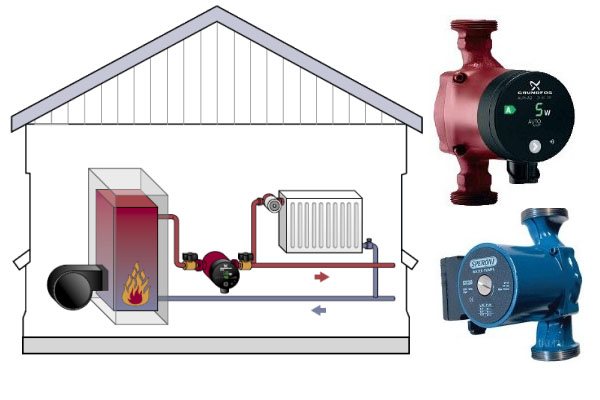

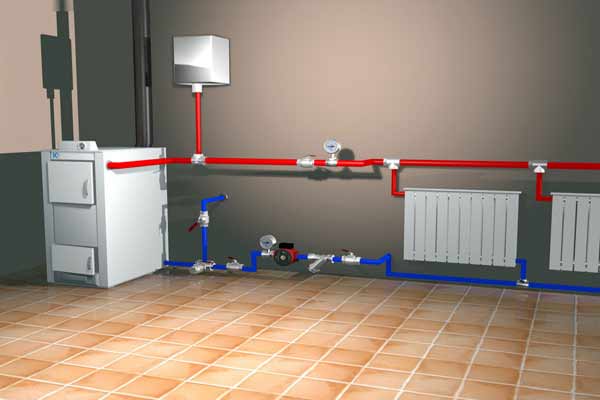

Forced circulation

Water heating with forced circulation allows you to increase the efficiency of the system by at least 20%. To provide it, a circulation pump is turned on in the heating system. In this case, the circulation is practically independent of the position of the boiler and the angle of inclination of the pipes. In addition, smaller diameter pipes can be used. But such water heating turns out to be volatile: in case of a power outage, the circulation pump does not work and the circulation stops. Therefore, forced circulation is justified in a combination of boilers, which are automatically switched off in the event of a power outage, for example: electric boilers.

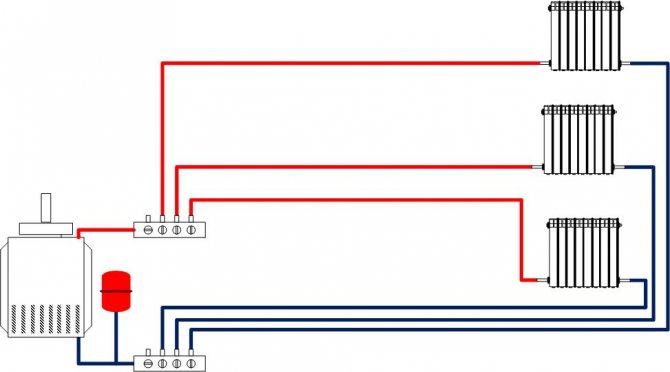

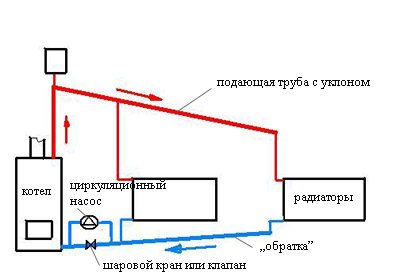

Fig. 2 Scheme of water heating with forced circulation of the heat carrier

Forced circulation hot water heating systems can be either open or closed. The pipes that are used for the distribution of such systems can be metal, plastic or metal-plastic.The circulation pump can be installed on the "return" or on the supply pipe, on its horizontal or vertical section, in the immediate vicinity of the boiler. Sometimes such systems include several circulation pumps - their own, for each separate branch of the wiring. In order for the pump to be changed if necessary, shut-off valves are installed before and after it. And in order to prevent its premature wear, a filter for mechanical cleaning of the coolant is installed in front of it. Some boiler designs are already equipped with a circulation pump.

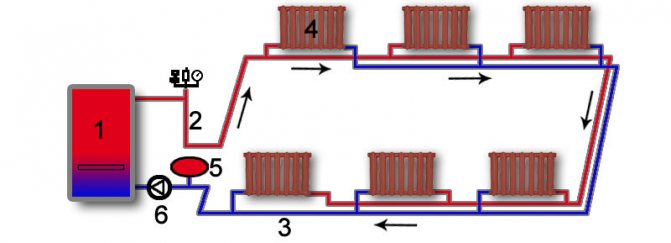

Combined or combined circulation

Water heating with this type of circulation combines the advantages of natural and forced and, if necessary, can be switched from one mode to another.

This is important for boilers, which cannot be stopped immediately in the event of a power outage. An example is a solid fuel boiler or a stove with a heat exchanger. Such a system, in this case, simply switches from forced to natural circulation. And for this, it is initially mounted with all the necessary slopes, but a circulation pump is installed in it with the help of a bypass. It, together with the piping (shut-off valves, filter, and sometimes an air valve), is mounted on a parallel branch of the pipe, and a ball valve is installed on the central pipe, which opens for natural circulation and closes when the pump is running.

Fig. 3 Diagram of a hot water heating system with combined (combined) circulation of the coolant

Pipe routing diagrams

The piping layout for water heating can be:

- one-pipe;

- two-pipe;

- collector (beam).

Single pipe the wiring assumes that the same pipe is used to supply the heated water and return the chilled water, which is a closed loop. The entrance and exit of the radiators are connected to it. Thus, after the first radiator, the water in the main pipe will have a lower temperature and each subsequent radiator will receive less heat energy. This is the main disadvantage of one-pipe hot water heating systems. But they allow you to save on pipes. In addition, one pipe is easier to fit into the interior of the room.

Two-pipe the scheme (shown in Fig. 1, 2, 3) assumes the presence of two main pipes: one for supplying heated water, the other (the so-called "return") - for returning cooled water back to the boiler. With such a system, heat is more evenly distributed between the radiators, but this increases the consumption of pipes and the amount of work on their installation. Two-pipe water heating systems can be with lower and upper piping. In the first case, the supply pipe is laid below the radiators, next to the "return", and in the second - above them.

Collector or, as it is sometimes called, beam wiring, in fact, is a kind of two-pipe. With such a wiring, heated water is first supplied to the distribution manifold (comb), and from there to each radiator with a separate pipe. The same is with the "return" - chilled water from each radiator is supplied to its own collector and further to the boiler. This method of wiring requires the largest number of pipes, but it also allows you to distribute heat as evenly as possible between the radiators and, if necessary, easily adjust its supply.

Heating pipes

Separately, you should consider the issue of the types of pipes used for heating private houses. Each material definitely has both positive and negative sides. Let's see which of the options is the most optimal.

Heating with metal pipes

Metal pipes include steel and copper pipes.

Wiring water heating of a steel house will cost you relatively inexpensively (and this is the main advantage of this material). This metal is quite versatile, suitable for both steam and water heating. Withstands great pressure. The main disadvantage of steel pipes is that they corrode quickly. This is reflected not so much in the quality of heating as in the appearance of your home - rusty pipes are not the best interior decoration.

Copper pipes have more advantages: they are extremely durable, keep temperature well, and do not corrode. Another advantage of copper pipes is the smoothness of their inner surface, which provides a high speed of movement of liquid through the heating system. The main disadvantage of copper is its high price.

It should be noted that both steel and copper pipes are only suitable for open heating systems and cannot be installed in walls or floors. Therefore, as we can see, their universality has a limit.

Heating a house with polypropylene pipes

The main advantage of polypropylene pipes is their resistance to external environmental factors: corrosion, decay, bacteria and chemical compounds.

Also one of the big advantages of this material is its lightness. Hence, other advantages follow: such pipes are easier to install, they are suitable both for use on the supporting wall and on the interior wall.

Heating made of polypropylene allows you to save fuel consumption (gas or electricity) used to heat the boiler due to the low coefficient of friction, since the coolant easily passes through the heating system. But the difference is insignificant.

In addition, polypropylene pipes are quite plastic, have different modifications with many joints, and are also supplemented by a huge selection of various components, which allows the installation of complex heating systems.

And finally, heating with polypropylene pipes can be done both in open and closed systems, when all pipes are hidden in the floor or walls.

With all the visible pluses, these pipes have minuses. Firstly, with a fairly high resistance to chemical attack, such pipes are easily amenable to mechanical action (you can cut it with an ordinary kitchen knife). Secondly, polypropylene is not suitable for all types of heating systems. It categorically cannot be used in combination with a steam generator, but they are excellent for the water heating we are considering. Also, water heating with polypropylene implies the presence of a large number of joints, which greatly affects the reliability of the system.

Heating with metal-plastic pipes

If we talk about the advantages of metal-plastic pipes, then we can highlight the same advantages as those of polypropylene counterparts. But it is worth highlighting that they are able to keep a higher temperature. And also, and this is their main distinguishing feature, metal-plastic bends perfectly. However, you can not be afraid of damaging it. And this fact makes this type of pipes an ideal option for the "warm floor" system.

Among the disadvantages is a higher price in comparison with polypropylene analogues.

Advantages and disadvantages of a water-heated floor

Benefits of a warm water floor

- When using this type of heating system, the principle of radiation will be involved, not conversion. In this regard, several important advantages of water-heated floors appear at once: active circulation of dust when moving air masses is excluded.

- The absence of areas of increased dampness, and therefore, a decrease in the likelihood of fungus.

- Many users, among the advantages of water heating, point out that it does not require additional maintenance, there is no difficulty in removing dust, unlike radiators.

- An important advantage of warm water floors over radiators is complete safety, eliminating the likelihood of burns even with prolonged contact with a heated surface.

- The heating system makes it possible to completely remove the equipment from the line of sight.

- An important advantage of a warm water floor is its compatibility with any other types of systems, which allows you to find an individual solution in each case.

- The savings in heating costs when using such a system is in the range of 20-30% in comparison with a radiator.

- All types of water underfloor heating in terms of their service life are limited only by the time of use of the pipes used in the formation of this system.

- During the operation of the system, self-regulation of the process of heat exchange in the room occurs: heat transfer depends entirely on the temperature in the room.

- With the use of a water-heated floor, no health disadvantages or any negative consequences were found.

Disadvantages of a water-heated floor

- There is no possibility of effective use of technology in rooms where a large area is occupied by stairs. You will need to use a warm floor in conjunction with radiators.

- There is a widespread misconception that the advantage of a water-heated floor is that it slightly reduces the level of humidity in the room. In fact, such a system dries the air much more than a traditional radiator system, so buying a humidifier will become a necessity.

- Installation of a water system in apartment buildings is not allowed due to a significant increase in hydraulic resistance.

- Installation is quite complicated, it can only be performed during a major overhaul in the room.

- When choosing between a water or infrared floor heating, it is important to consider that using the first option always leads to a significant increase in the floor level. For the installation of infrared systems, a polyester film cloth with a thickness of 100 microns is used.

- There is a possibility of a leak, which will require a rather complicated repair.

Heating with water skirting board

At the end of our article, we want to tell you about the "last word" in the field of water heating systems. If you want to make the heat in your home invisible in the truest sense of the word, then skirting board heating is your option.

Such a heating device is a body that looks like a regular plinth, inside which there is a heating element - special tubes. First they heat up, then the body, then the heat is distributed along the walls.

This type of heating is an ideal solution for our strip, where mold often forms on the walls due to dampness. In addition, as already mentioned, neither pipes nor radiators will spoil your interior.

But this system also has its drawbacks:

- it cannot be used on the walls along which the furniture is installed

- for large rooms, it will be necessary to install 2-3 buildings, since the maximum length of the heating circuit is 15 meters.

Main elements

What does a hot water heating system consist of in a private house? If in a city apartment we move, as a rule, into housing with already functioning heating, then here we will have to draw up a project from scratch.

Boiler

A heat source that converts the energy of fuel combustion or electricity into heat energy transported by the coolant. The list of the main types of boilers looks like this:

- Gas-fueled ones currently provide the lowest operating costs. Of course, when operating on main gas: balloon gas will increase the cost of a kilowatt-hour of heat several times.

Modern gas boiler.

- Solid fuel boilers are in second place for the cheapest heating. Firewood, coal, peat, sawdust, etc. are used as fuel.The main problem is the need for frequent loading of fuel.

- Solar boilers can operate in a fully automatic mode; however, solarium is very expensive and continues to rise in value.

- Finally, electricity is the most convenient, safe and ... expensive way to heat your home.

In addition: the very idea of using a coolant in this case seems strange. Individual electric radiators or convectors seem to be a much more sensible solution.

Pipes

Black steel pipes are still used in the installation of central heating; however, when independently transferring radiators and designing heating systems for cottages, the stake is usually placed on other materials.

- Galvanized steel has the strength of black steel pipes and is devoid of their main drawback - susceptibility to corrosion.

- Corrugated stainless steel, in addition to strength, also bends easily. The connections are made with fittings with silicone seals, without threads, which makes assembly quick and easy.

- Polypropylene pipes are cheap and are installed using the simplest low-temperature soldering iron. Usually pipes reinforced with aluminum or fiber are used for hot water and heating: they are stronger and have a much lower coefficient of thermal expansion.

- XLPE is an excellent material for screed beam routing. Temperature resistance and tensile strength combined with flexibility and the possibility of purchasing in coils up to 500 meters long.

The wiring from the manifolds is made with cross-linked polyethylene.

Armature

- If you need to shut off water, the best tool for this is a modern ball valve. Reliability is combined with ease of use and low hydraulic resistance when open.

- Chokes are used to manually adjust the heat transfer of heating devices and to balance them.

- After calibration, thermostatic heads are able to adjust the throughput in such a way that the set temperature is maintained in the room with an acceptable accuracy.

- For air extraction, automatic air vents are most convenient. However, instead of them, both Mayevsky taps and conventional valves and even water taps can be used.

Safety

It is provided by devices that are called so - a security group:

- Expansion tank compensates for the increase in the volume of the coolant during heating. Water is practically incompressible and can simply break pipes or radiators; but the air, separated from water by a rubber membrane, is easily compressed. The volume of the membrane tank is taken to be approximately equal to 10% of the amount of heat carrier in the system.

- Safety valve it is needed in case, if the capacity of the expansion tank is not enough with strong heating. When a critical pressure is reached, it dumps excess water.

- Pressure gauge allows you to control the current pressure in the system.

Pressure gauge, air vent and safety valve are often sold as one piece.

Heating devices

- Cast iron radiators quite heat-resistant and non-corrosive. The sections have a large internal volume and, due to the slow movement of the coolant, they easily silt up in them when connected to the side.

- Steel heaters are divided into several types: plate, tubular, convectors and registers. The design of non-corrosive steels makes them vulnerable to rust, and the thin walls of plate radiators are still extremely fragile mechanically.

- Aluminum radiators are cheap and have excellent heat transfer, but they are afraid of overpressure and galvanic processes, which are caused by the combination of different metals (in particular, aluminum and copper) in one circuit.

- Bimetallic heating devices - these are aluminum radiators with steel cores that increase tensile strength, and copper-aluminum convectors. The second is a copper tube with aluminum plates pressed to increase heat transfer.

Unlike aluminum, bimetallic radiators can be connected with a copper pipe.

Heating with water convectors

You probably managed to collide with electric convectors. There are the same, only water. They are connected in water heating according to the same rules as radiators. And they are essentially the same radiators, only with a different principle of heat transfer.

Water convectors work according to the convection principle. Cold air comes in from below, warm air comes out from above. Due to this, the room heats up very quickly.

The disadvantages of such water heating devices include their high cost, compared to conventional radiators.

If you carefully studied our article, you saw what a variety of solutions for carrying out water heating in a private house the modern market of heating equipment is represented. You just have to choose the best option based on the parameters of your own home and material capabilities. Peace and warmth to your home!

The principle of operation of autonomous heating

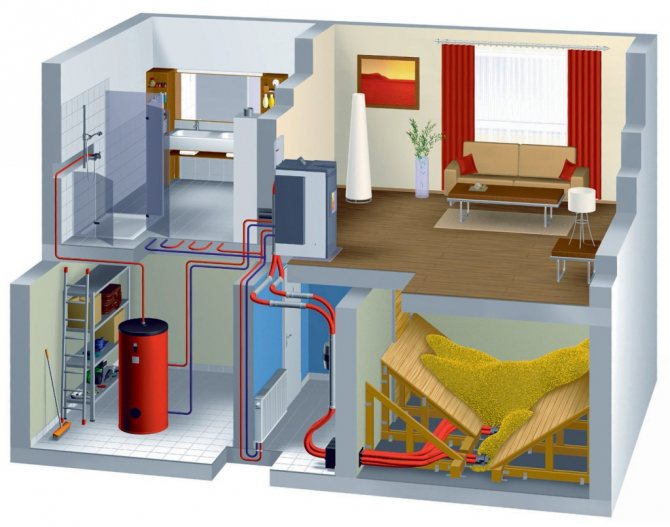

In the system of individual heating of a private house, a coolant is constantly circulating - a liquid that transfers thermal energy from a generator to remote rooms. Antifreeze or filtered water acts as a coolant.

Antifreeze does not freeze at air temperatures below zero, due to the inclusion of propylene glycol or ethylene glycol.

Heating system

The coolant circulates in a loop, which is a closed pipeline. The circuit includes: a heating element, pumps, taps and other elements. Depending on the scheme, the coolant moves in two directions:

- Direct movement - circulation of liquid from the boiler to the batteries or radiators.

- Reverse current - the liquid that has given off heat to the hot water heating device moves towards the heating element.

Water heating devices (radiators, batteries, underfloor heating) are equipment that transfers heat to the atmosphere of the room.

Leningradka scheme

The circulation of the coolant is carried out through pipes of different material and diameter, depending on the wiring diagram:

- Metal piping is rarely installed due to gradual rusting, short service life. It is mounted only on threaded connections.

- Copper pipes. They are distinguished by their durability and reliability. Withstand temperature drops, high pressure. Soldering is required for the connection - a method of high-temperature solder with silver inclusions. After installation, the pipes can be hidden in the wall. Copper is expensive.

- Polymer pipes (polypropylene and polyethylene). The main advantage is ease of installation. Polypropylene pipes are a cheap material, but they do not rust. If flushed regularly, they work effectively for several years.

- Reinforced-plastic products are composed of plastic and aluminum. They are mounted by means of a thread, sometimes using press connections. The disadvantages include a high coefficient of expansion under the influence of heat. If the temperature of the coolant changes sharply, the pipes will crack.

What are water heating systems made of

The main element of the water heating system is the boiler. It can work with any type of fuel, be it wood or coal, electricity, water or gas. The most common devices among consumers are solid fuel and gas boilers.

By the way, a water heating system can be installed on several boilers at once. But at the same time, it is important to have certain equipment that allows you to switch between units.

The water heating system includes a heating boiler, piping and, of course, batteries. It is through these elements that a liquid or antifreeze moves.

Pipes used for the heating system:

- Steel - can be stainless and galvanized, which makes them immune to corrosion;

- Copper - perfectly withstand high pressure and temperature, are distinguished by their reliability;

- Reinforced plastic - not subject to corrosion, easy to install, but poorly tolerate temperature changes, which can cause leakage Everything you need for water heating can be purchased in a specialized store

Among other things, the heating system includes expansion tanks and elements that regulate the heating process itself. As a rule, these are various thermostats, safety valves, a circulation pump, a pressure gauge, shut-off and automatic drain valves.