Profiled timber attracts many Russians with its availability and excellent thermal characteristics. However, most of them mistakenly believe that such a house will not have to be insulated. Of course, I would like to preserve the unique wooden color of the interior and exterior of the building, but comfortable living is more important. In matters of warming a house from a profiled bar, there are some nuances. We will tell you about them today.

When is it possible not to insulate?

In fact, profiled timber does not always need to be insulated. If the house is being built in a region with a warm climate or for temporary (seasonal) residence, then it does not need insulation. The boards fit tightly enough to each other and are able to maintain a comfortable microclimate in the absence of too low temperatures.

This dacha is ideal for fans of eco-friendly wooden houses. The owners will be able to admire the beauty of the log house both inside and outside in summer. They will also enjoy pleasant coolness in hot weather and warmth in the event of an unexpected cold snap.

If the house is being built for permanent residence, then you need to insulate it. It is also definitely recommended to do insulation in the baths. How to do this depends on the thickness and type of the profiled bar.

What is a profiled beam?

This material can be very different in cross section. Thanks to this, it is easy for the master to select the boards for the desired building.

- The thinnest profiled bar reaches 95 millimeters in width and 145 millimeters in height.

- Next comes the size 145x145 - square.

- The rest are significantly larger than 195x145.

- 230x145.

- 250x145

- 195x195.

- 230x195.

- 250x195.

You must understand that even the thickest profiled timber is not able to fully protect from the cold in winter. Especially in the far north. The house needs additional insulation.

In any case, you must carefully select the material. High-quality profiled timber has a high degree of drying (humidity up to 20%). Compliance with the technology in the manufacture of the material prevents shrinkage and deformation of the walls later. For this reason, even when working with the best specialists, they need to be monitored when purchasing a bar. You will live in the house, and every mistake then repeatedly backfires with problems.

The level of thermal insulation to some extent depends on the selected profile. It can be different too:

- with one thorn;

- with two thorns;

- with beveled chamfers;

- "comb";

- Finnish profile.

Of course, the easiest way is to lay the last option, but the “comb” wins in terms of thermal insulation characteristics. If you need to build a house in a region with a harsh climate, they choose it.

Stages of home insulation

If you want to minimize heat loss, then you need to thoroughly approach insulation. The foundation, floor, walls, roof need it. In each case, you need to take into account the features of the designated elements of the house. Only then will it be possible to make housing truly comfortable.

Foundation

The base of the house is best insulated from the outside. So you will save money, protect the foundation from freezing and destruction during sudden temperature changes. In addition, in this case, the basement area will be preserved, which is also important.

Internal insulation is permissible only when external insulation is impossible. The house was originally erected without external insulation of the foundation, and this omission must be eliminated.

Basic materials for outdoor insulation:

- polyurethane foam;

- extruded polystyrene foam.

It is recommended not to use ordinary foam plastic, since it absorbs moisture well and is destroyed by temperature extremes.

Polyurethane foam has excellent hydro, heat and sound insulation characteristics. It is applied using special equipment. The layer of material must be at least 50 millimeters.

The advantages of polyurethane foam:

- the work does not take much time;

- lack of cold bridges in the foundation;

- lack of gaps and seams.

It takes longer to install the extruded polystyrene foam. However, it costs much less and practically does not absorb moisture, which ensures the maximum level of waterproofing.

The insulation must be installed at the depth of freezing. This is the most rational use of material, money and time.

Installation should be carried out along the walls of the building. This will reduce the depth and degree of freezing.

Floors

Even if the floorboards fit snugly against each other, over time they dry out and gaps form. To avoid removing the coating and carrying out insulation work in the future, it is better to do everything correctly at the initial stage.

Floor insulation involves the use of not only insulation, but also steam and waterproofing. The choice of materials depends on the type of floor, so it is better to consult a specialist before starting work.

The most common way to insulate the floor is by lags. To do this, logs are installed in the foundation or frame in a T-shape. From below, shields are nailed to them, on which the necessary materials are installed. First, hydro and vapor barrier, then insulation, and the third layer is again hydro and vapor barrier.

The finishing floor is laid after these works.

Walls

Can be insulated both outside and inside. There is another option for those who do not want to give up the wooden aesthetics of the timber - inter-crown insulation.

The choice already depends on your preferences. Do you want to admire solid wood both in the interior and exterior? Choose inter-crown insulation. If only the appearance of the house is important for you and you are not afraid of the decrease in the area of the rooms, insulate it inside. When only the interior matters, and siding or facing bricks seem attractive, then external insulation is best.

Matrials:

- for mezhventsovy warming, sheep wool, flax, flax or jute are used, the last option is a novelty in the construction market, which has excellent performance characteristics;

- for external insulation, you can take foam or cotton material;

- for the interior - only wadded insulation.

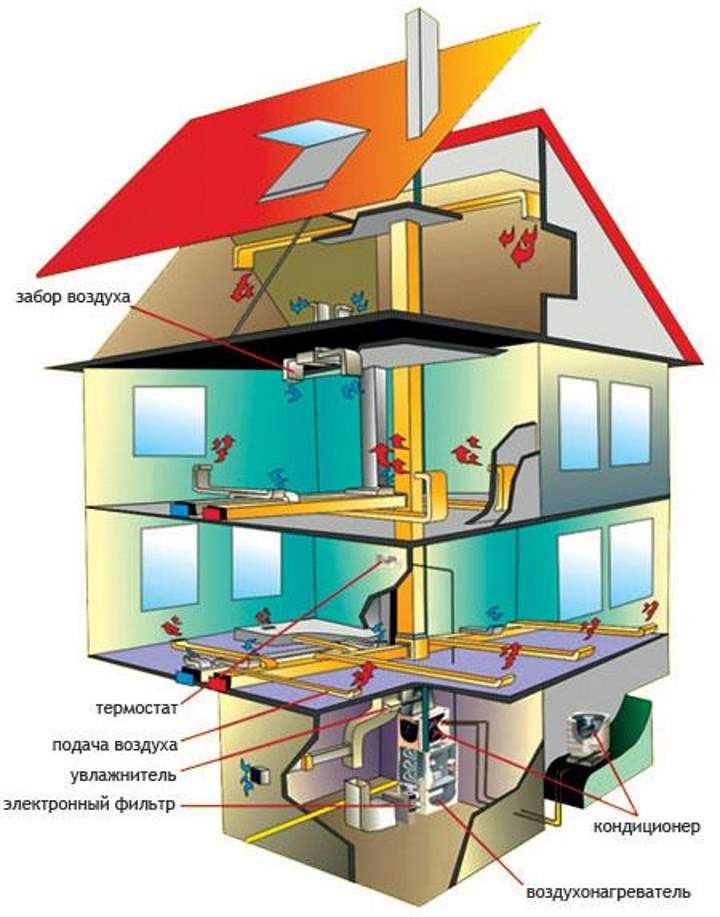

It is imperative to install vapor barrier materials to prevent the insulation from absorbing moisture. Also, take care of ventilation in the house to ensure a comfortable indoor climate.

The ceiling is insulated in the same way as the floor, and the roof insulation technology is similar to wall insulation. We will not dwell on these points.

It is better to consult a specialist about the details when carrying out insulation work. He will be able to give the best advice in your particular case.

In housing construction, more and more often, wooden beams are used as a consumable material. This is due to the fact that this building material has excellent qualities. In particular, they note the environmental friendliness of a wooden building, its high wear resistance, as well as the low cost of a wooden bar. Perhaps the only drawback is the poor thermal insulation of the building, which is explained by the natural characteristics of the tree. Sooner or later, gaps and gaps appear between the stacked logs. So that this problem does not catch the owners by surprise, the dwelling should be insulated in a timely manner.

House from a bar without insulation

Important! After completing the construction of a wooden house, you should wait at least one and a half years for the building to settle down.After that, you can freely proceed to the insulation of the outer walls, which can be combined with a major overhaul..

The size and thickness of the timber

The lumber is manufactured in a factory environment. The dimensions of the manufactured wooden beam meet a certain standard. The main indicator in this case is the thickness of the workpiece. The most common sizes are:

- 100x100 mm;

- 150x150 mm;

- 200x200 mm.

Lumber with a section of 100x100 mm is designed for the construction of lightweight structures... These buildings have a utilitarian purpose. We are talking about a bathhouse, a gazebo or a summer veranda. These structures are strong enough to withstand summer operation. For the construction of a country house, a beam with such a section is not suitable. In this case, you need to choose thicker lumber.

Wooden beams with a section of 150x150 mm are chosen for the construction of residential buildings in cases where savings are expedient... Such houses have an average heat loss coefficient, so they are designed for use in countries with a mild climate. For the construction of cottages, a bar with a section of 150x150 is not suitable. For a capital building, you need a material that can withstand high loads, for example, a bar of 200x200 mm... A multi-layer construction made of such material has a sufficient margin of safety.

What is the best way to insulate the house: from the outside or from the inside?

Thermal insulation inside the premises allows you to timely eliminate the shortcomings of wooden walls associated with rotting and destruction of wood.

Insulation of walls only from the inside is not recommended by builders, since in this case, the outside of the tree remains unprotected... Wooden walls suffer from direct contact with cold, that is, the load on them increases. Indoor ventilation is disturbed, excessive humidity appears. In addition, it should be borne in mind that with internal thermal insulation, the area of the rooms is reduced in proportion to the width of the insulation structure.

Internal insulation of a house from a bar

Nevertheless, the internal insulation of the home is not losing its popularity due to its relatively low cost. In addition, indoor thermal insulation work can be carried out at any time of the year. It is advisable to carry out internal insulation of a house in autumn or winter, when it is not possible to carry out insulation work outside.

When installed correctly, thermal insulation from the outside allows a solid effect to be achieved. The building structure becomes more solid. The walls of the insulated house do not allow the cold and cold wind to pass through. The following advantages of external wall insulation are noted:

- significant reduction in heat loss;

- protection of walls from the adverse effects of precipitation;

- individual design of the facade of the house.

Thermal insulation of a house from a bar outside

Thermal insulation of a house increases the level of indoor comfort, so it is at least unreasonable to save on thermal insulation. When choosing a heat-insulating material, special attention should be paid to quality. The reliability of thermal insulation depends on this.

Important! External wall insulation is necessary for a building built of ordinary planed timber, one of the main disadvantages of which is its susceptibility to deformation under the influence of unfavorable atmospheric conditions.

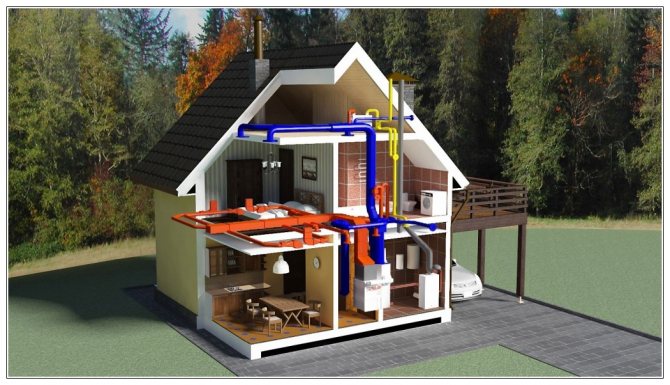

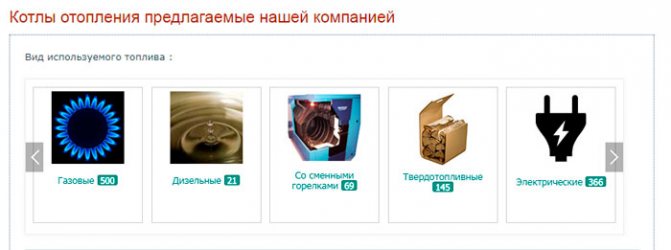

What to consider when choosing heating in a wooden house

When choosing heating, like other communications in a wooden house, it is necessary to focus on the availability of energy resources. If a gas main runs near the house, then it is advisable to install a gas boiler and water heating in the house. If there is no gas main, you will have to choose between electric, liquid fuel and solid fuel heating. Each of the heating systems has its own pros and cons.

- Electric boilers, infrared and convection systems are 5-10 times cheaper than any other type of heating, but depend on the stability of the electricity supply and energy costs are noticeably higher than for firewood, coal, peat, pellets or main gas.

- Liquid fuel heating systems operate not only on diesel fuel or fuel oil, but also on waste oil. Therefore, the owners of large car services often install this type of heating, despite the high cost of the equipment. Because during the year, tens of tons of used oil accumulate at the service. If the house is heated with fuel oil or diesel fuel, then energy costs will be 3-7 times higher than when heating with electricity.

- Heating and heating-cooking stoves heat the house for 10-14 hours from one firebox. Their main advantage is thermal radiation, which has a beneficial effect on the body. The disadvantages of such heating are the need to heat the stove 1-2 times a day and the inability to heat remote rooms.

- Solid fuel boilers with a heat accumulator heat the house for 30-60 hours from one load of firewood or coal. Boilers with automatic fuel supply will cost 5-10 times more. In this case, the cost of heating installation is comparable to the construction of a high-quality stove or installation of a liquid fuel system.

- Fireplaces are more suitable for the role of additional heating and decoration element. The exception is fireplaces with a built-in hot water heating register and a heat accumulator. In this case, they successfully heat the house and create a place of comfort and coziness, where it is so pleasant to sit on a cold winter evening. But even in this version, the fireplace is the most ineffective way to heat the house.

- Combined heating combines the best features of all the systems listed above. For example, a water heating register is inserted into a heating or heating-cooking stove, due to which remote rooms and a bathroom are heated. Or, in parallel with a gas / solid fuel / liquid fuel boiler, an electric convection or infrared heater is installed.

In addition, other factors must be taken into account when choosing a heating system:

- house area;

- house layout;

- the height of the house;

- heat loss of walls, windows, doors, roof and floor;

- average and minimum winter temperatures;

- wind speed and humidity in winter.

Therefore, only a qualified master with extensive experience can choose the right heating system for a house from a bar. Otherwise, it is likely that some rooms will be hot and others cold. If this happens, the walls of cold rooms will begin to damp. After all, warm air, in contact with a cold surface, leaves water condensation on it. As a result, a house made of timber will not only lose coziness and comfort, but also lose its reliability. After all, dampness in the room for 10-15 years will lead to the appearance of mold and rot even on the walls treated with the best impregnations.

Is it worth insulating a house from a bar with a section of 150x150 mm?

The popularity of lumber with a section of 150x150 is due to its low cost. A wooden building made of such a bar looks impressive. And, nevertheless, with the onset of cold weather, the owners ask themselves whether it is necessary to insulate the house from a 150x150 bar? Despite the fact that wood is a unique building material with a low coefficient of thermal conductivity, it is imperative to insulate a wooden house... This is due not only to the rise in energy prices. Over time, any, even the highest quality wood begins to dry out, cracks and gaps appear in the walls. Because of this, a residential building needs high-quality thermal insulation both outside and inside the building.

Over time, cracks and gaps form in the timber itself and between the logs.

In addition, it must be borne in mind that the walls of a residential building, made of 150x150 mm timber, are not thick enough, hence the high rate of heat loss. This leads to increased consumption of gas and electricity. This disadvantage is easily eliminated by high-quality thermal insulation.

Features of heating a house made of laminated veneer lumber

When choosing a heating system, it should be borne in mind that wooden buildings can be of several types:

- seasonal;

- permanent.

Thus, if the house is planned to be used only in the summer, then heating is not required. Electric fireplaces and heat guns are perfect as additional heating.

If the house will be used throughout the year, the heating must be installed in such a way that it maintains the required temperature inside the room in any frost.

The choice of insulation

One of the most crucial stages in the thermal insulation of a wooden house is the choice of insulation. There is a large assortment of heat-insulating materials on the construction market. The most common ones are:

- expanded polystyrene;

- mineral wool;

- Styrofoam.

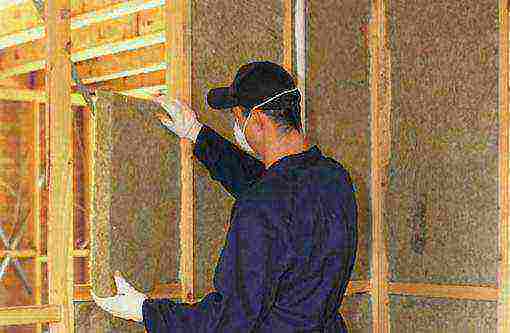

The most accessible and environmentally friendly foam and mineral wool. Due to its technical characteristics, polystyrene is more suitable for insulating buildings constructed from inorganic material. We are talking about brick, concrete, stone. Residential buildings made of organic material, including wood, should be insulated with mineral wool. This is due to its ability to allow air to pass through freely, which allows the wooden walls of the building to breathe unhindered.

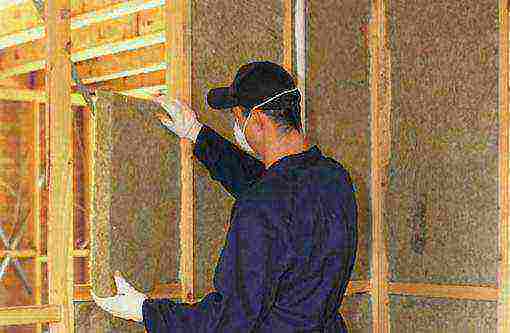

Warming a house from a bar

Popular option in Russia

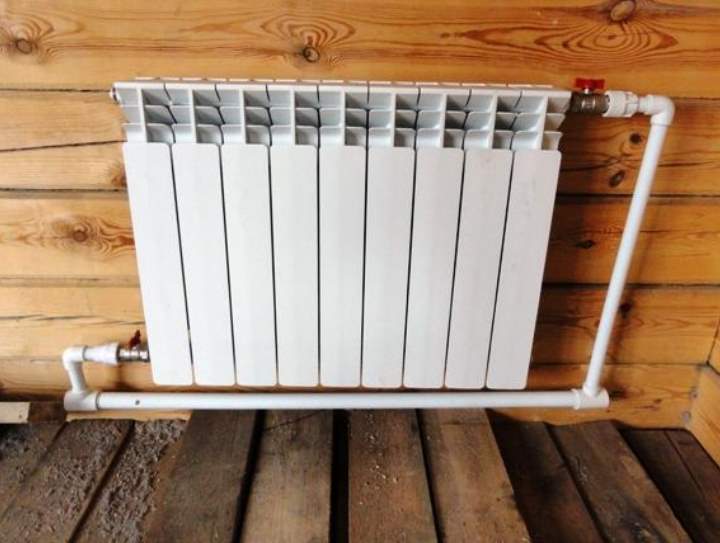

The equipment is cheap and for the correct installation of the system, it is only necessary to correctly calculate the location of the radiators.

Heating types

Gas boilers most common in those territories of Russia where there are no problems with gas. But, compliance with the measures of safe handling of gas should firmly enter your life.

Solid fuel boilers work mainly on wood and coal. Nowadays, they are used less often, but they are not without their advantages.

Heating radiators in a wooden house made of aluminum light in weight, but less durable, do not tolerate pressure drops. Biometal radiators combine the advantages of aluminum and steel. Lightweight aluminum body and heat transfer medium made of steel pipes, which do not corrode and thus have a long service life.

Local heating houses from a bar are made using heat guns, convectors, fireplaces, air heaters, stoves, stoves. The disadvantage of this type of heating is that these devices can only heat a small room.

To organize an autonomous system heating a house from a bar requires a centralized boiler and pipes. This installation must be stationary and warm up the room completely. Today it is the most popular type of heating for low-rise buildings. The effectiveness of this type of heating is achieved with the help of an individual approach to the creation of heating systems projects for each individual home.

Gas heaters not very often used on local systems. These designs provide for the presence of an open hearth. In addition, gas burners absorb large quantities of oxygen.

How to insulate a house from a bar with a section of 150x150 mm

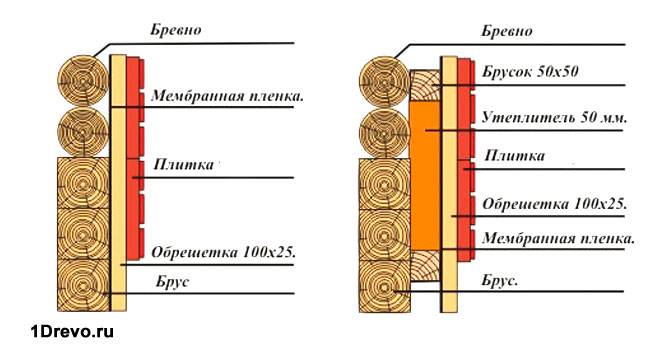

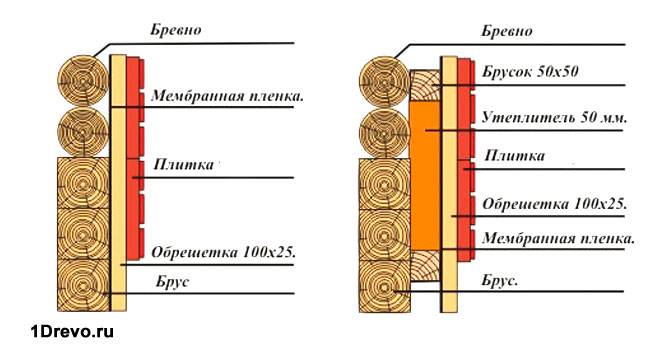

Builders recommend insulating a house from a bar 150x150 exclusively from the outside... This is due to the insufficient thickness of the walls of the building, which needs additional external protection against the adverse effects of atmospheric precipitation. Mineral wool, which is produced in rolls and slabs, is used as a heater.For timber walls, it is more convenient to use slabs with a standard thickness of 50 mm. Insulation of this configuration is easier to lay in the cells of the frame. The work consists of the following stages:

- pretreatment of walls with an antiseptic;

- elimination of visible cracks with a sealant (tow, fiber);

- installation of a rack frame 50-100 mm thick on the outside of the house;

- laying insulation plates in the cells of the frame;

- stretching and fixing the insulating film with beams with a section of 25x50mm;

- finishing fastening of the cladding.

Scheme of work on house insulation

Any decorative material can be used for cladding. Siding is considered the most reliable and affordable.... In addition to siding, clapboard, plank or any other decorative material are used. Recently, wood panels have been popular with consumers, in shape and appearance, plausibly imitating a wooden bar. The installation of the cladding can be started both from the bottom and from the top.

Decorating the house with clapboard after insulation

Heating price for wooden houses

Heating costs can be divided into several parts:

- costs associated with connection, purchase of equipment and installation work;

- monthly fee.

As a rule, the higher the one-time costs for the arrangement of heating, the lower the monthly payments will be in the future. Thus, the cost of the duty, connection to the mains and installation of the boiler will be much more expensive than purchasing an electric heater, but the payment for heating is several times less.

In addition, the final cost is influenced by the correctness of the calculations, during which the owners of residential premises do not take into account many of the nuances. That is why it is most optimal to seek help from qualified specialists who will make all the necessary calculations, orientate the cost, carry out turnkey installation work.

Advice! It is recommended to make an estimate of costs before the start of installation and construction work.

House insulation from a bar with a section of 200x200 mm

Despite the fact that the reliability and quality factor of a building from a bar with a section of 200x200 mm is an order of magnitude higher, such a building also needs additional thermal insulation... The process of warming is carried out in the same manner as when insulating buildings from a bar with a smaller section. Only one rule should be observed: walls are insulated not in one, but in two layers.... This means that two layers of mineral wool are placed in the frame cell instead of one. This technology is relevant for regions where the air temperature in winter drops below 20 degrees.

Laying mineral wool slabs in two layers

Features of the insulation of a log house

If the thickness of the wall of the house is less than 25 cm, in the middle lane it definitely needs insulation. For a bar with a section of 200x200 mm, a 5-cm layer of insulation is required, usually the insulation material is closed using a ventilated facade system.

How to insulate a house from a bar 200x200? Experts recommend choosing only external insulation: this applies to any wooden house for several reasons:

- When wooden walls freeze, condensation will accumulate between them and the layer of internal insulation. This will not only lead to a decrease in the effectiveness of insulation, since it will quickly begin to get wet, but can also cause the walls to rot.

- Internal insulation takes up the useful area of the walls. In addition, it will cover the beauty of the tree, and this will not allow you to use one of the main advantages of a wooden house.

- A wooden house requires strict adherence to fire safety measures, and many insulation materials are prohibited from indoor use. For example, it is possible to insulate a house from a 200x200 bar with foam only from the outside, although this material is generally not recommended for a building made of wood due to its minimal vapor permeability.

What insulation to choose for a thick bar

It is possible to insulate a house from a bar 200x200 from the outside with various materials, since the choice in the construction market today has expanded significantly. The most common and convenient option is stone or basalt fiber: mineral wool is the best option due to its high vapor permeability. This material keeps heat well, in addition, it does not burn, which means it creates additional protection against fire.

Minvata has many advantages, including low cost, but it has a significant drawback: under the influence of moisture, it loses its heat-shielding properties due to its high hygroscopicity. Because of this, it is necessary to take care of the moisture-proof membrane.

Another popular option is polystyrene, which is now increasingly being replaced by extruded polystyrene foam plates. Materials of this group are very convenient to use: they can be cut quickly, there are no problems with mounting on the wall. Modern insulation can be used on any building, they retain their properties for a long time.

Summing up

One of the rules for building a house is its compliance with thermal engineering standards. Initially, sawn timber with a cross section of 150x150 and 200x200 mm is not considered by manufacturers as a basis that can keep heat in the house. Such residential buildings should be insulated without fail! In addition, it is known that even the thickest walls are not able to ensure the absence of heat loss in harsh climatic conditions. Therefore, during the construction of a building, additional costs for thermal insulation are inevitable.

Important! Heat losses are often associated with a violation of the roof insulation. Improper installation of windows and doors also leads to heat leaks. Therefore, work on house insulation should affect absolutely all elements of a residential building.

We built a house from a bar of 150x150 mm. Flax is placed between the beams. Larger cracks were sealed with tow (however, it is periodically pecked by birds). Friends advised me to additionally insulate the outside and revet it with bricks, but I'm sorry, but they say it will be cold and blow in the crack. What to do?

As far as I understand, you have just built the house, before it can be insulated, it must go through a shrinkage period of 1 to 2 years. If you do not want to spoil the beauty on the outside, then you can make insulation from the inside. Mineral wool can be used as an insulating material, the outer side of the insulation must be protected from being blown by the wind using a waterproofing material, and from the inside, the insulation is covered with a reinforced plastic wrap, then you sew everything up with plasterboard or clapboard, if you wish.

You can insulate the house from the outside as advised, or from the inside. We insulated with foam, then sheathed it with drywall and glued wallpaper on it. It turned out very cozy and beautiful. Polyfoam is very durable and does not emit any substances into the air, the only disadvantage of foam insulation is that you will lose a little in the volume of the usable area. It is very easy to attach the foam boards to the adhesive mixture.

A wooden house must absolutely not be insulated with foam. Polyfoam does not allow moisture to pass through, and without it, wood, constantly being in extreme conditions, ages 3-5 times faster! Such a coating is suitable only for stone buildings; for wooden buildings, ventilated types of cladding are used.

kitman12390 likes this.

I agree with Kotjara that it is not worth “spoiling” (insulating) wooden walls with polystyrene, and it is best for you to insulate Tatiana1 with dense mines of cotton wool from the outside and then, as you would like to brick the whole house with. In this case, it is necessary to make an air gap of 3-5 cm between the insulation (mineral wool). And when laying bricks in the upper and lower rows of brickwork, do not fill every fourth vertical seam with mortar. And in this way all the moisture will be weathered and the insulation will not lose its insulating properties.And also do not forget about a bunch of brickwork with wooden walls. And from the inside to insulate your house is blasphemy (IMHO).

Having built a house from "living" building material, environmentally friendly, and it is necessary to insulate it with the same "breathing" material, i.e. wooden clapboard either from the inside or outside, so that everything is in one key.

It is best to seal the cracks between the timber with polyurethane foam in order to simply forget about them forever. The house made of timber is not very attractive in appearance, and in your case with cracks, even more so. You will have to do external wall decoration in any case, including for insulation. The cross-section of the timber is made up to about 30 cm, and usually 15 X 15 cm. This is not enough to save heat. Insulation must be done from the outside of the walls. The most effective insulation is done with cellulose wool.

150x150 is not enough for a residential building. In any case, you will have to sheathe the outside or brick it. A house made of a bar has cracks, and with what do not plug them, it will blow. As for the foam, I doubt it has appeared on the market relatively recently, and it is not known how it will behave in a few years. In the sun, the foam generally turns into crumbs. And tow and mineral wool are excellent material, they do not lose their properties for several decades. If you stop on foam, it depends on the type of wood from which the bar is made. If these are soft rocks, then it is undesirable, and if larch, then moisture is not terrible for it.

Having built a house from "living" building material, environmentally friendly, and it is necessary to insulate it with the same "breathing" material, i.e. wooden clapboard either from the inside or outside, so that everything is in one key.

Smiled frankly! The heat from the lining will certainly be immeasurable.

Timber houses are insulated according to the classical scheme: from the inside - a vapor barrier, according to it - finishing. Outside - 50 millimeters of mineral wool slabs, then wind insulation, then a ventilation gap, and then - any façade, according to your taste. The question is: what is the point of building a house from a bar that is insufficient for your climatic conditions of the section? Isn't it easier in this case to just build a frame with a normal thickness of insulation - the costs, for sure, will be several times lower.

Smiled frankly! The heat from the lining will certainly be immeasurable. Timber houses are insulated according to the classical scheme: from the inside - a vapor barrier, according to it - finishing. Outside - 50 millimeters of mineral wool slabs, then wind insulation, then a ventilation gap, and then - any façade, according to your taste. The question is: what is the point of building a house from a bar that is insufficient for your climatic conditions of the section? Isn't it easier in this case just to build a frame with a normal thickness of insulation - the costs, for sure, will be several times less.

Insulation system - Yes. But with the costs - I do not agree. Any house from a bar must be sheathed with something. The difference in current in min slabs for money. But you can form normal warm quarters under the windows of mines with slabs.

Only outside, without fail - otherwise the house cannot be considered a home. I would do this: outside isover (mineral wool), foil film, and on top I would sheathe it with wood. Or siding.

Viktor_Ageev said:

↑

Only outside, without fail - otherwise the house cannot be considered a home. I would do this: outside isover (mineral wool), foil film, and on top I would sheathe it with wood. Or siding.

Well, yes ... And the house would have rotted for a long time ... Have seen enough "Schools of repair" I mean that there is always this film everywhere pop. A vapor barrier must be installed so that the house can breathe. And this film with a falg is poured into the screed under the warm floors, but not on the facades of wooden houses. Yes, and the isover - they say it rots .... Min plates are usually placed outside.

We are also going to build a small country house. The question of insulation also arose. Can't be insulated with glass wool?

You can make an insulated plaster facade. The house communicates with OSB plates, pasted over with insulation (mineral wool or expanded polystyrene), then reinforced with glass mesh, and plastered. You can also paint with self-cleaning paint. Thus, the facade is “breathable” and at the same time protected from external influences.

you can insulate anything! The main thing when using wood is to provide ventilation. For this, make holes at the bottom and top of the protective facade of the walls. If you insulate outside, then it becomes possible to "turn on" in the summer, and "turn off" ventilation in the winter.

We also have a house in a dacha made of timber, two years after its development, we covered it with bricks. Warm in winter and we live in it until deep winter.

- Myalik is an advanced forum user.

We are also going to build a small country house. The question of insulation also arose. Can't be insulated with glass wool?

Can. For example, decorate the house with plasterboard in the middle, and lay glass wool between the plasterboard and the wall. Better mineral wool.

I advise you to insulate the cracks with caulking or mezhventsovy insulation. They are laid very tightly, if everything is done correctly and it will be warm at home.

First of all, the roof of a house from a bar must be insulated. Moreover, I do not advise you to insulate with cotton wool, it is better to try the expanded polystyrene plates, and you can sheathe the bottom with plasterboard - it will be much warmer, it is checked. By the way, I recently consulted with some guys I knew - they work in Triodom Stroy, there is such a company. They also said that it is possible. Well, they are building according to their technologies, there is nothing to insulate there.

Do not use glass wool. Everything will itch. Better mineral wool, they correctly suggest.

Wooden houses have always been popular in Russia, and today wooden housing construction is experiencing a real boom. And this is not surprising. Natural wood, as a building material, has a lot of advantages: it retains heat well in winter and cool in summer, fills the house with a useful aroma. The wooden house has a healing microclimate and special flavor. The natural pattern of the wood itself is very beautiful, so the log frame looks great. However, despite all the advantages of wood, many people prefer to hide this beauty under the cladding made of finishing materials. There is a reason for this. Let's figure out whether it is necessary to sheathe the house from a bar, or it is better to keep the wooden frame in its natural form.

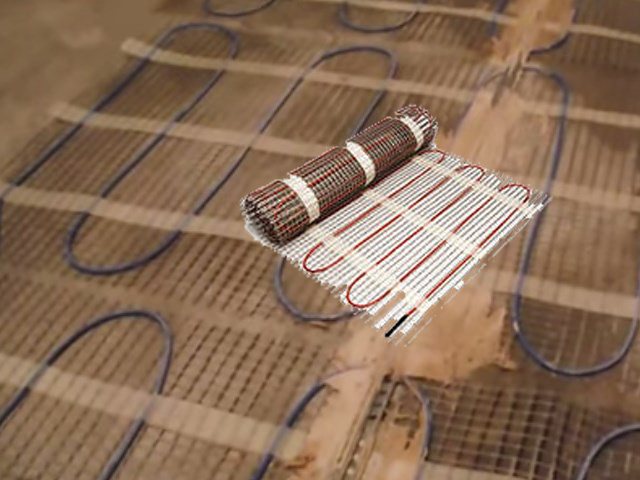

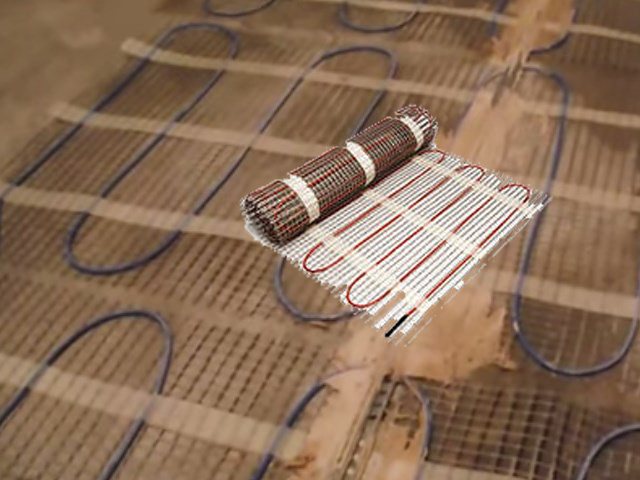

Warm floor

The underfloor heating system is based on the use of thermal energy obtained from:

- heat transfer fluids circulating through the lines located under the surface of the floor covering;

- heated electrical cable embedded in the floor.

Electric underfloor heating.

Applying electric heating in a wooden house for such a system, you will have to take care of creating a solid, strong and durable base for it. Floor boards can rot over time, even after impregnation with special antiseptics. Therefore, it is better to mount heating elements on concrete bases with the use of foil-coated heat-insulating coatings, which allow returning up to 30% of the heat directed down the floor.

The water system requires complex installation by trained specialists and the constant use of only high quality water. Scale and salt deposits inside the pipes are unacceptable: the resulting blockages will require expensive repairs, comparable in cost to the laying of new equipment.

The installation of an electric heating cable also requires strict implementation of technology and the use of accurate measurements, but they are not so difficult and can be performed by a home craftsman.

A warm electric floor can:

- serve as the main heating system for a wooden house;

- complement the existing one to ensure comfort.

In the first case, for each room, it will be necessary to use ≥70% of the total area in order to place heating elements with a consumption capacity of 0.13 ÷ 0.17 kW / m2.

Reducing the power to 0.11 ÷ 0.13 kW / m2 provides comfort and convenience, but does not completely solve the problem of heating in frosty weather.

Both schemes allow:

- adjust the temperature in the room manually or automatically;

- reduce the cost of using electricity by means of automation;

- to operate the system for more than 50 years without repairs.

Mandatory measures to protect a wooden house

No one disputes that wood has very high aesthetic characteristics and excellent appearance. But a tree is a living organism in which processes characteristic of all living things take place: it breathes, increases and decreases in size, gets sick and gets old. Therefore, wood is very vulnerable.

Any natural phenomena (rain, wind, snow, sun) and biological factors (microorganisms, mold, insects) can negatively affect the appearance of a wooden house. The tree darkens, cracks, foci of rot, mold may appear on it, which ultimately leads to the destruction of the wood.

To avoid such a development of events, it is necessary to take timely measures to protect the wooden walls of the house: grind, treat the wood with special protective equipment, paint or varnish. All these activities are carried out after the initial shrinkage of the log house, about a year after construction.

However, all paints and varnishes have their own service life, and sooner or later lose their protective properties. Therefore, those who think that one coating is enough for the entire life of a wooden house are greatly mistaken. One-off measures are clearly not enough.

So that the wooden structure does not collapse and retains its original appearance for a long time, it is necessary to periodically process the wood. At least once every three to five years, depending on the type of paint and varnish, the coating must be renewed.

Sheathing as an alternative way to decorate your home

For those who do not want to regularly carry out finishing work, there is another way of exterior decoration: sheathing the walls of a wooden house with siding, clapboard, imitation of a bar or other finishing materials. Having sheathed the house once, you can not return to repairs for many years.

However, do not forget that regardless of whether or not the house is sheathed, no one has canceled the mandatory measures for the protection of wood (grinding and treatment with antiseptics). It is also recommended to bore the house before facing. All these measures will provide the wood with a long service life, prevent the formation of rot and other unpleasant processes.

To the question: is it necessary to sheathe a house from a bar outside, you can give a positive answer for another reason. Sheathing serves not only as a beautiful finish and protection of a wooden building, but also solves another important task - house insulation.

Any finishing material is attached to a pre-assembled wooden or metal frame; a layer of vapor barrier, insulation and wind protection must be placed between the bars or profiles. This kind of layered cake provides condensate drainage from the house, as well as ventilation and thermal insulation of the walls. Definitely, a house sheathed with siding or clapboard will be much warmer than a building without sheathing.

For the owners of old log cabins, the question of why sheathe a log house is generally not worth it, since for old buildings, sheathing with finishing material is the best way to update the dilapidated walls of the house.

Facing with wooden clapboard, block house, imitation of a bar will turn even the most ordinary-looking building into a modern building, and at the same time preserve the indescribable flavor of a wooden house.

A house from a bar can be sheathed both outside and inside.Interior decoration, as a rule, is purely decorative, although it is far from uncommon when a heat-insulating layer is laid under the inner lining, due to which the house becomes even warmer.

How to create an insulation system

You can insulate a house from glued laminated timber 200x200 on your own, a one-story building can take several days. The ventilated facade system is a multilayer structure with cladding: the walls of a wooden house can be finished with imitation timber, clapboard, siding or other materials. The work is carried out in several steps:

- Lumber walls need preliminary preparation: it is necessary to treat them with antiseptics and fire retardants, since in the future they will be completely covered with insulation. If the house is built from ordinary non-profiled timber, additional caulking will be required to completely close the cracks.

- To fix the insulation on the walls, a vertical lathing made of a bar up to 5 cm thick is installed. The distance between the elements should be slightly less than the width of the insulation, this guarantees its snug fit and no cracks.

- Insulation plates are inserted into the frame, mineral wool should fit snugly to the timber. It is attached using special dowels with wide caps.

- Mineral wool is closed with a waterproofing membrane. This is a one-sided permeable film that will allow water vapor to escape outside, but will not allow moisture to enter the insulation. Such a film is attached with staples to the crate, it should be overlapped to prevent the formation of cracks.

- A transverse lathing is installed, which presses the insulation and creates a gap between it and the facing material. Ventilation will allow water vapor to be removed and ensure a long service life of the insulation.

After that, you can proceed to the installation of the cladding, and the house will take on a finished look. The cost of additional insulation quickly pays off, since in the future they will allow you to spend much less on heating, and the house will be reliably protected from the cold. From the street side, the insulation will be completely invisible, so the house will look beautiful and neat.

Sheathing of houses from different types of timber

This indicator also plays an important role in deciding whether or not to sheathe the walls in a log house with finishing material.

If we are talking about edged or planed beams, the type and quality of which is not always at a high level, then at the stage of finishing the box, the question of covering the house will certainly arise. Both the one and the other timber during assembly do not provide good heat-insulating properties, the joints between the bars will have to be caulked, which will not be reflected for the better in the appearance of the structure.

Sheathing with clapboard, block house or imitation timber is a great way to make a house from edged and planed timber warm, neat and attractive.

Another thing is a profiled beam, which has special fasteners that ensure a tight fit of the beams, due to which the house has good thermal insulation characteristics. Usually, a house made of profiled timber, if it is not supposed to live all year round, is not sheathed either inside or outside, finishing is limited to grinding and painting the wood.

The same can be said about laminated veneer lumber. This material has exceptional aesthetic and performance characteristics. Houses made of laminated veneer lumber themselves look great, have excellent thermal insulation properties and do not need any cladding.

Errors of self-execution of work

At first glance, it seems that the cladding of a log house is not particularly difficult. Therefore, many, without particularly delving into the process, undertake to decorate the house on their own, which is not the best reflected in the final result.Self-finishing leads to a bad appearance, poor-quality thermal insulation and in the most direct way affects the comfort of living in the house.

Among the typical mistakes that non-professional craftsmen often make, the following can be distinguished:

- Out of a desire to save on material, many home-grown builders increase the step between the beams when installing the battens. The recommended distance between the frame elements is 40-50 cm, the maximum step length is 60 cm. Even a slight increase in the distance will lead to sagging of the skin, which will reduce its service life.

- When installing a ventilated frame, it is imperative to install a counter grill, but not everyone does it. As a result, the slabs of mineral wool used as insulation are artificially pressed against by the waterproofing, which causes a quilt effect. This leads to irregularities and depressions during the installation of the skin, which will also bend, as in the first case.

- During the installation of siding or lining, not everyone uses a building level and a cord to properly install the planks. As a result, the cladding is uneven and looks skewed over the entire surface.

We have given only the most common mistakes made by home craftsmen that professionals have to correct. In fact, there are much more of them. We strongly recommend not to start decorating a house or a bath without experience and work skills. Specialists will make the cladding quickly and professionally, without making a single mistake.

Professional services

We employ specialists who have both experience and skills in working with any finishing materials. The cladding of wooden houses is one of the main specialties of our company.

Wood is the building material that we all know about, we have been working with wood for more than ten years, so we studied all the nuances of its behavior. We will carry out any kind of cladding with high quality, professionally and in compliance with the contractual deadlines.

To contact us, go to the "Contacts" section, where you can find all our coordinates.