Heating systems implemented in private housing construction are presented in several options.

Only knowing how best to make heating in a private house on your own and correctly, you can get a high-quality and durable system with a minimum investment of time and money.

Read on for more details.

Principle of operation

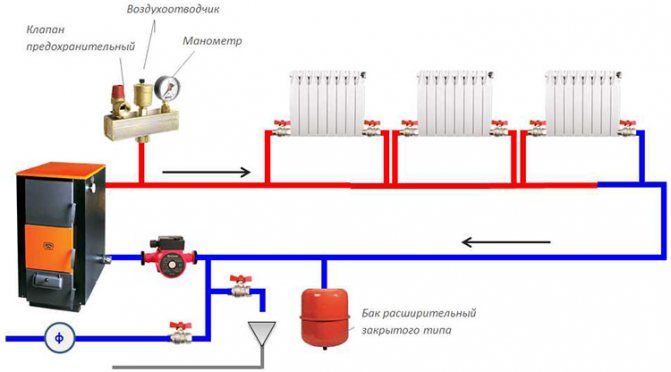

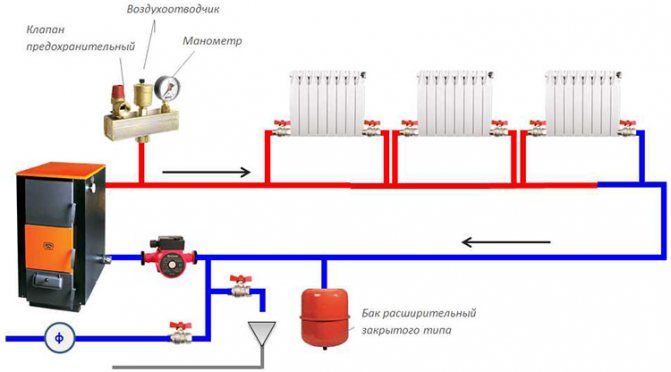

The heating system operates with the use of a heat carrier heated to certain temperature indicators. Heating is carried out inside the heat exchanger, after which, through the pipes, the coolant reaches the radiators, where it is cooled and, in compliance with the cyclic process, returns to the boiler again.

- In open systems the squeezing out of the heated coolant from the heating unit is carried out under the influence of cold water, therefore, gravity distribution through pipes and radiators is observed. Lightweight air from the system is forced into the expansion tank, which is able to maintain a stable pressure level in the heating system.

- Closed or forced systems differ in the circulation of the coolant using pumping equipment. A standard pump allows you to maintain a stable pressure in the range of one to three atmospheres.

Despite the fact that the forced operating principle is more promising and easy to maintain, today such heating circuits are used less often than the time-tested open systems.

Pipe routing: basic diagrams

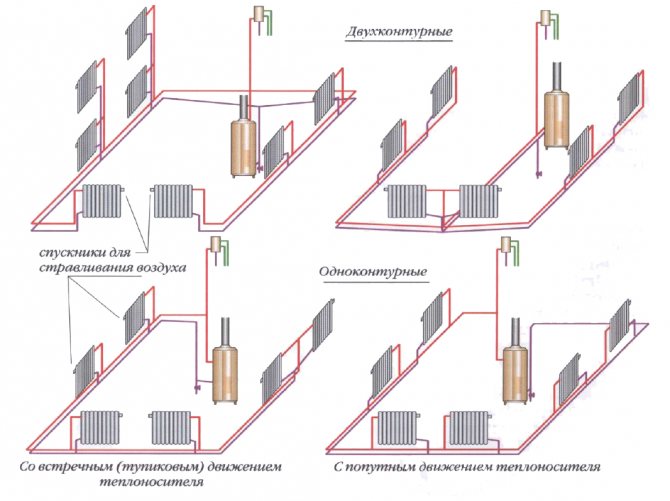

Installation of pipes is carried out according to one of two schemes.

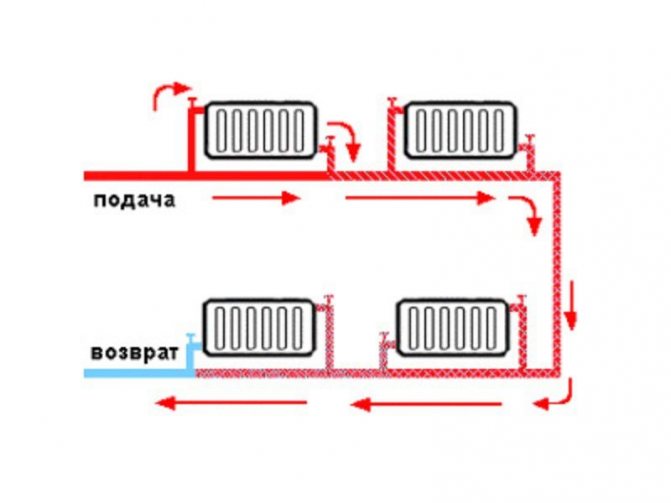

The first system provides for the passage of the coolant through the radiators in turn and return to the tank (boiler). This is a one-pipe system.

Extending radiators - a step-by-step description and tips on how to add a section quickly and easily (145 photos + video)

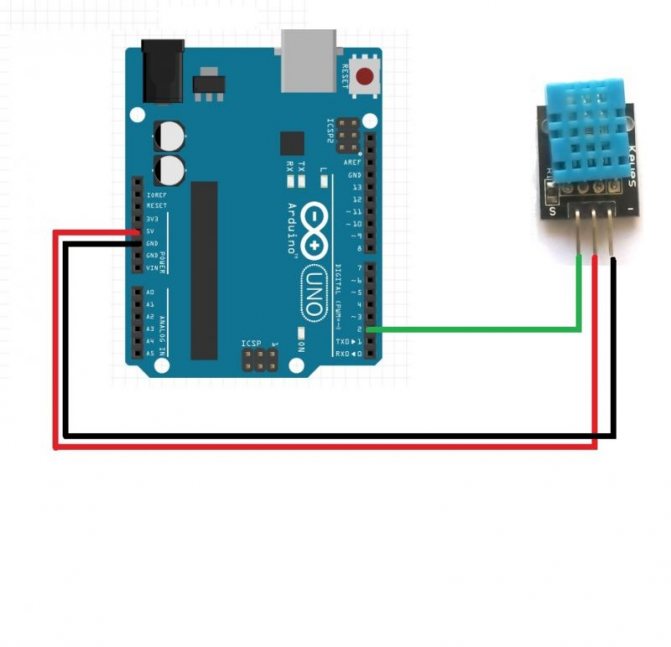

Connecting a temperature sensor - a diagram for connecting automation and the nuances of using it in a heating control system (130 photos, diagrams and video editing)

- Air solar collector - what it is and how to do it yourself. Step-by-step master class and tips for use in the heating system (110 photos and videos)

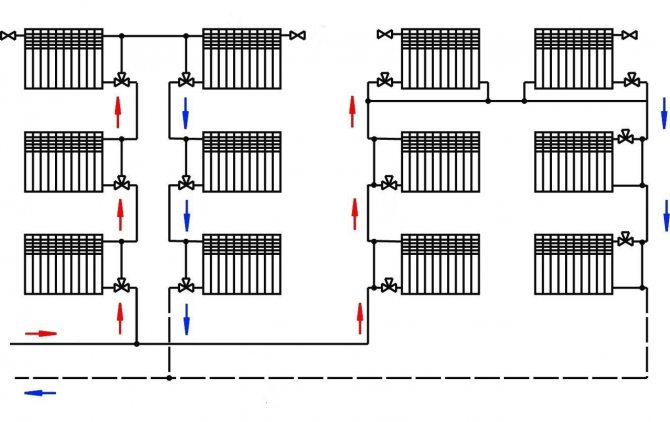

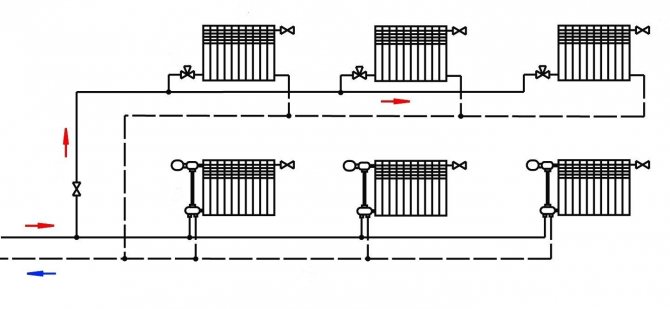

The second, two-pipe, assumes the flow of fluid into each individual radiator point, and then its return back to the main.

The easiest way is to make a choice after watching video materials on creating heating with your own hands or after studying the relevant literature.

Components

The main component of the heating system of a private house is a heating boiler:

- solid fuel models;

- gas models;

- electrical models;

- liquid fuel models.

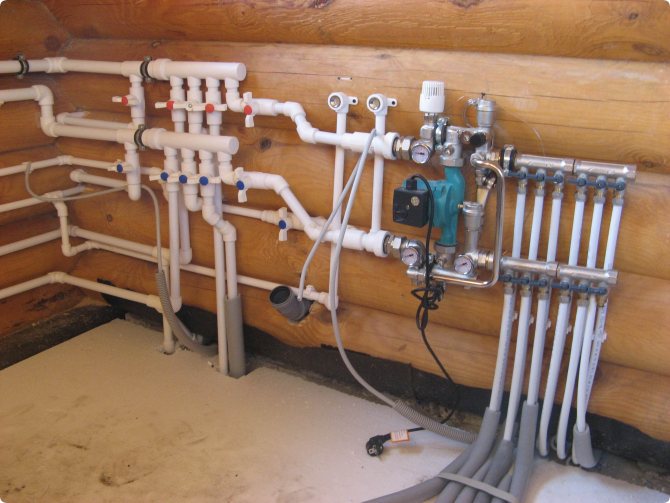

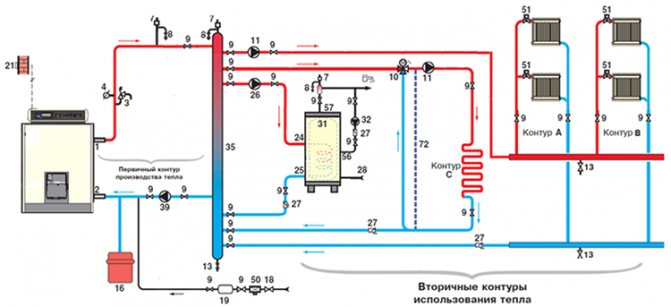

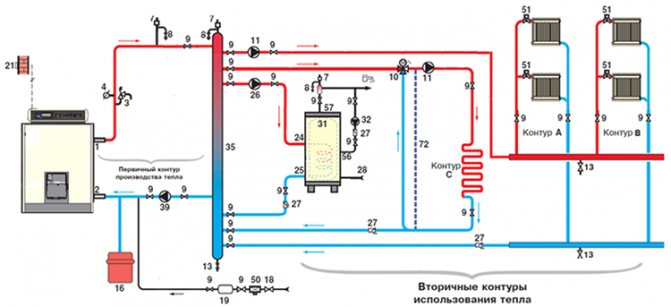

Heating system diagram

Also, for self-installation, it is necessary to purchase additional components, which can be represented by pipes and radiators, a circulation pump, an expansion tank and a coolant, an air valve and other devices.

Particular attention should be paid to the choice of a heating boiler, which may differ in the place of installation, the design of the chimney, the type of fuel used, the number of circuits, as well as the materials of the heat exchanger.

Purchase and installation of pipes

There is a large assortment of pipes for heating on the market. Each owner chooses the type of pipes he wants. In this case, it is necessary to take into account the characteristics of the material from which they are made.

Note!

Multi-level plasterboard ceiling with backlight: step-by-step instructions on how to do it yourself + 86 photos

Do-it-yourself home insulation: instructions for installing different types of heaters + 95 photos

- How to professionally carry out the installation of a built-in electrical panel? Useful tips from the pros and advice on choosing equipment

Liquid circulation options

Systems with a natural circulation option do not allow for fast and complete heating of large areas, which is due to the insufficient transfer rate of the heated coolant through the pipeline and radiators. The wrong location for mounting the expansion tank can cause the water to freeze, and moisture often causes corrosive changes to the metal components.

The forced circulation of the coolant allows you to equip the "warm floor" system, and is also widely used, if necessary, to install indirect heating equipment.

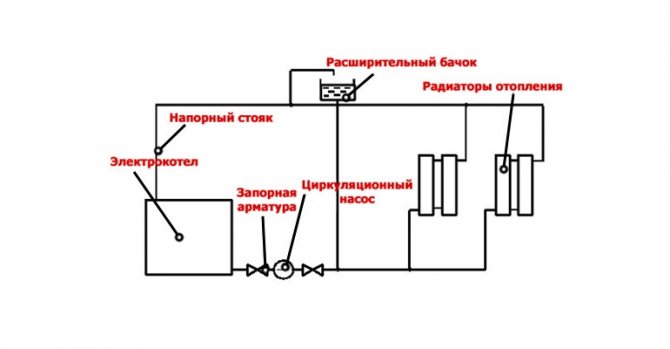

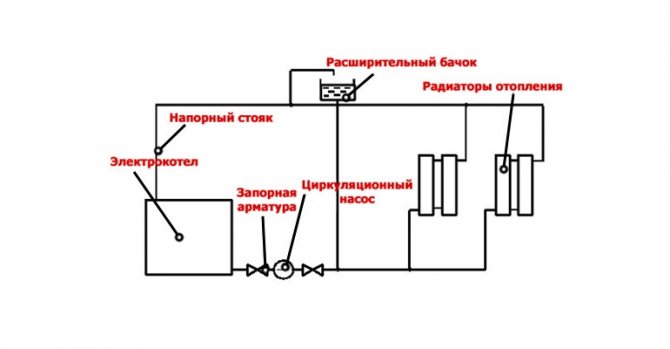

Scheme of a closed one-pipe heating system

Among other things, with a closed liquid circulation system, pumping equipment and an expansion tank can be compactly placed inside one room, which minimizes the risk of freezing of the coolant.

The forced circulation option is the most preferable, and allows not only to control the speed of fluid movement through the system, but also to regulate the heating temperature by means of thermostatic valves.

Choosing the right equipment

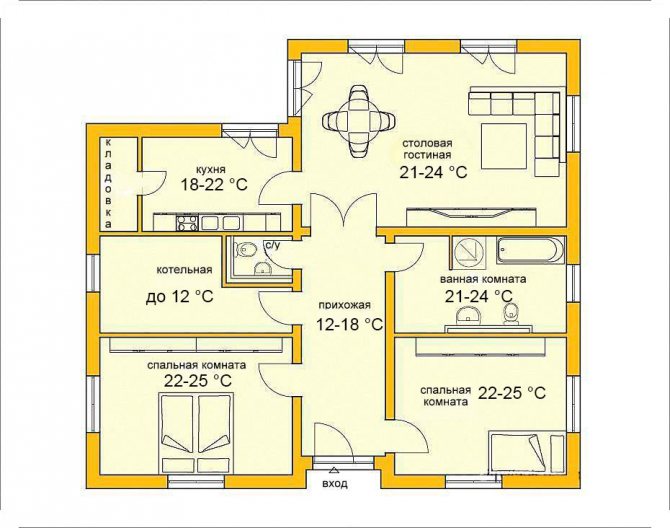

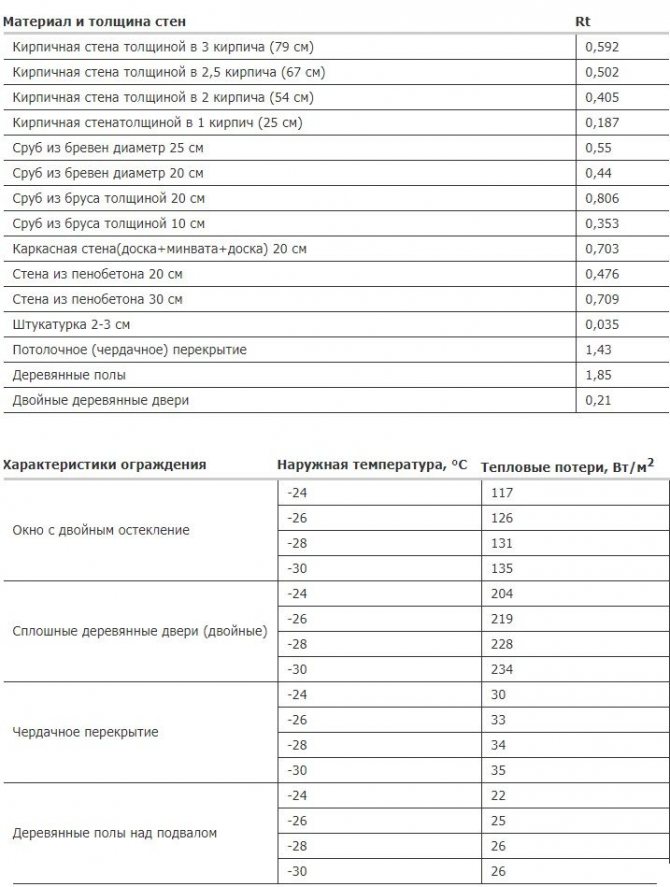

When choosing the equipment that will be used in the arrangement of the heating system, many factors must be taken into account, including the area of the room, the coefficient of thermal conductivity of the walls and the mode of operation.

Boilers

The main parameters of a heating boiler are represented by its power and the type of fuel used:

- For every 10 m2 of heated area in an insulated private house with a ceiling height of no more than three meters, 1 kW of boiler power will be required. If necessary, you can resort to the help of designers who perform the correct heat engineering calculations taking into account all environmental factors.

- Fuel can be liquid or diesel, as well as represented by electricity, mains or bottled gas. But the most widespread are solid fuel boilers operating on coke, pellets, wood or coal.

No less important selection criteria are the material of manufacture, as well as the method of installation. Modern and very easy-to-use boilers can be wall-mounted and floor-standing, single-circuit and double-circuit, non-volatile and volatile, with forced or natural draft.

Pipeline

The decisive importance in the integrity of the heating system is given to the pipeline, which ensures the movement of the coolant and its delivery to the radiators. The pipeline must be as strong and durable as possible, and also have maintainability.

Optimal thermal conditions are determined by the tightness and quality of the pipeline system, therefore, when choosing pipes, you need to pay attention to the following parameters:

- option of laying and arrangement of pipes;

- average temperature of the coolant;

- pressure indicators inside the pipeline system;

- heating system configuration.

Heating pipelines in a private house can be metal, plastic and metal-plastic. The first option is represented by copper and steel pipes, but it is best to use galvanized products, which are less susceptible to corrosive changes. Galvanizing can be diffusion or hot.

The organization of the natural circulation heating system is most often carried out with galvanized, stainless steel or steel pipes, observing the necessary slopes. The most modern, convenient in operation and maintenance option is the use of pipes based on reinforced polypropylene. Such pipelines can be not only external, but also internal, due to the high quality and durability of the material.

If in the house, in addition to the standard heating system, there is also a heat accumulator, heated floors and a pool, then you cannot do without a hydraulic arrow for heating. Read more about the functions of this system.

How to convert Gcal to kW and vice versa, read on. Formulas and examples.

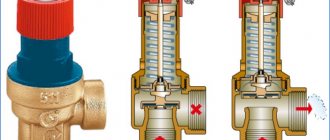

In the event of an emergency, the safety valve in the heating system relieves pressure to prevent a breakthrough. You will learn more about how such a valve works from this material.

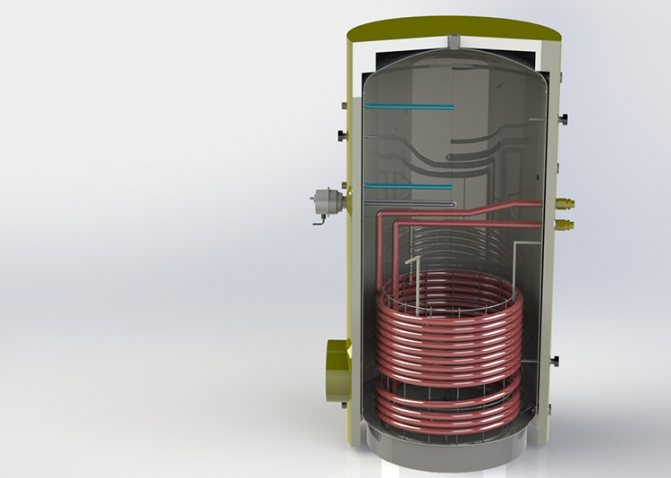

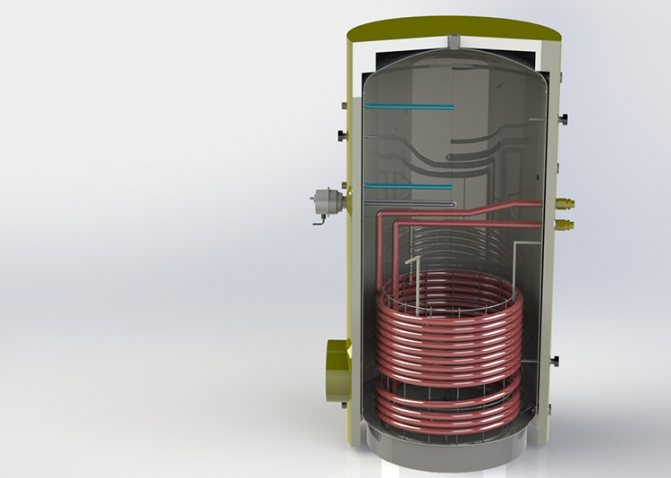

Heat storage devices

Heat accumulators provide the accumulation of thermal energy in the process of its excess generation by the source, as well as further use if necessary. It should be noted that devices for the accumulation of thermal energy are needed only for boilers that operate in a periodic mode..

These appliances include coal or wood-fired boilers. Uninterruptedly operating equipment, represented by gas or electric models, has continuous fuel supply systems, so they do not need heat accumulation.

Heat storage from the inside

The coolant can be represented not only by water, but also by antifreeze. To preserve heat, the capacity of the battery must be additionally insulated with layers of high-quality heat insulator and installed on a warm base. The sealed tank must have a pair of holes for piping connections.

The heat accumulator is connected to the heating system in parallel to the boiler with supply and return connections. A prerequisite for proper organization is the use of high-quality valves.

Electric heating

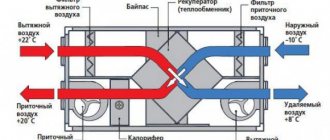

Electricity you can heat the house in different ways: using the piping system for distributing the coolant, and directly with heaters. Such a system of a private wooden house has many advantages before other ways:

- High efficiency and conversion of electricity into heat in a direct way.

- Rapid heating air.

- Convenient heat regulation to every room thanks to thermostats.

- Silent system operation, a high level of hygiene and environmental friendliness.

- Small size electric heaters - saving the usable area of the house.

- Aesthetic appearance heat sources.

- Easy installation of equipment, ease of use.

- The ability to quickly redevelop and easy change of system power.

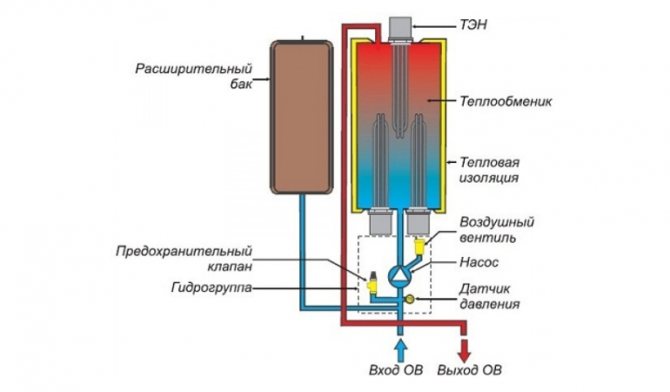

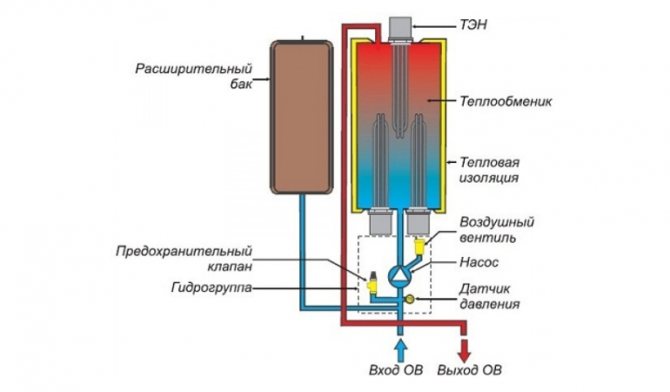

The principle of operation of the electrical system is shown on the diagram:

Electrical induction boilers can be installed as a backup option for heating a house when using gas heating. It is very convenient to have additional sources in case of gas pressure drops, emergency shutdowns, or insufficient boiler power in case of severe frosts.

By heat transfer method electric heaters are divided into:

- Convector type devices.

- Radiant heaters.

- Convective-radiation and combined.

- Electric heaters for indirect heating.

At the end of the material, we suggest looking video, in which experts give advice on choosing the optimal heating system:

Additional useful information is in our article - energy-saving heaters for home and summer cottages.

Execution of works

The level of complexity of self-installation of a heating system in a private house directly depends on many factors, including the type of pipeline and boiler installation, as well as the way of circulation of the coolant.

Boiler installation

First, the heating boiler is installed. For this purpose, a concrete or asbestos cement substrate must be installed. The easiest way to mount gas and electric hinged models. As a rule, such devices are equipped with special fasteners designed for the weight and dimensions of the installed heating equipment.

Oil-fired boiler in the heating system

It is somewhat more difficult to install a floor-standing solid fuel boiler yourself. The place reserved for the installation of such a heating boiler must be filled with a layer of standard concrete screed with a thickness of at least a centimeter.

The completed screed and the installed lower part of the boiler should be in contact as tightly as possible, and any gaps should be eliminated using a special heat-resistant sealant.

Installation of heating radiators

Before installation, you need to make sure that the purchased models comply with the requirements for the safe operation of devices:

- bimetallic radiators are designed for 35 atm .;

- steel radiators are designed for 6-9 atmospheres;

- cast iron radiators are designed for 10-15 atm .;

- aluminum radiators are designed for 16 atm.

It is necessary to start installing heating radiators by installing brackets, which are fixed with dowels to the wall. The best option for the location of the heater is installation in the window sill, taking into account the following basic requirements:

- the distance of the radiator battery from the vertical surface represented by the wall is 2 cm or slightly more;

- the distance from the window sill and the lower horizontal surface represented by the floor is within 10-20 cm.

The surface is pre-marked for fasteners in compliance with the level vertically and horizontally. Then, in accordance with the markings already made, radiators are installed, and the absence of any slopes that can impede the movement of the heat carrier is checked.

It is important to remember that for arranging a heating system in a private house, a pressure of two or three atmospheres is considered normal, so the mounted radiator should easily withstand such loads.

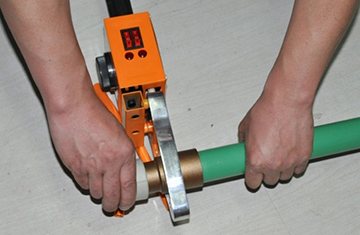

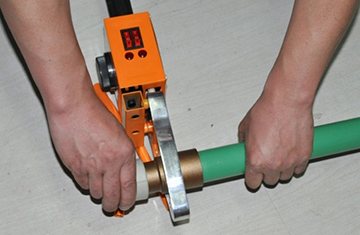

Welding of polypropylene pipes

Polypropylene pipelines are great for self-implementation of a heating system in a private house.

They are distinguished by a long service life, are not subject to the formation of rust and rot, are lightweight, and can also be installed by hand, without the involvement of specialists.

To create a heating system based on reinforced polypropylene, you will need to purchase fittings represented by corners, tees, bypasses, adapters and couplings.

It is necessary to weld polypropylene pipelines with a special device called a soldering iron or a welding machine. A pair of elements is heated by the tool to the melting temperature, after which it is combined in a hot state.

For high-quality heating of the inner part, a mandrel is used, and the outer surface is heated using a sleeve. If welding or brazing is done correctly, then the resulting joint is characterized by solidity and high reliability.

The heating temperature required for soldering is set on the regulator of the welding machine. Reinforced polypropylene pipes are welded at a temperature of 260 ° C.

Even if you want to entrust the installation of heating systems to a specialist, you need to know about some of the nuances of the heating system device.

You will find step-by-step instructions for making a thermostat for a heating system at the link.

Launch

At the first stage, it is imperative to carry out a visual inspection of the pipeline system and heating radiators, as well as to check the chimney. Then the system is filled with a coolant through a special sub-unit, which is located at the lowest point.

To remove air bubbles from the system, Mayevsky's taps are opened.

When filling the system with a coolant, pressure testing is carried out.

After the system is completely filled with coolant, a number of measures are performed:

- the valve at the bottom of the heating boiler opens;

- pressure values are checked, which should not exceed three atmospheres;

- after heating the coolant, the make-up valve opens and air locks are removed with the help of the Mayevsky valve.

Heating radiators are actually started twice: during the filling of the system with a heat carrier and when the heating boiler is turned on. It is necessary to control the operation of the heating system during operation by periodically checking the values on the dashboard or by visual inspection of all nodes.