Home / Gas boilers

Back to

Published: 03/16/2020

Reading time: 6 minutes

0

355

The Italian brand Baxi is very popular in the Russian HVAC market. Gas boilers of this brand are available in several installation options: wall-mounted and floor-standing, as well as single-circuit for heating and additionally double-circuit for hot water supply.

The manufacturer's specialists made sure that the installation and operation processes were as simple and accessible to any user as possible. Therefore, to connect the Baxi boiler to work, the owner does not need to make significant efforts.

- 1 Advantages of Baxi boilers and equipment

- 2 Schemes of piping of heating systems Baxi 2.1 Two-pipe scheme

- 2.2 One-pipe scheme

- 2.3 Combined diagram of the Baksi gas heating system

- 5.1 System clogging and cleaning

Periodicity of coolant replacement

Closed heating system with water connection

During the heating season, even an initially high-quality coolant gradually loses its properties. This is due to a periodic change in its temperature, resulting in precipitation (for water) or a change in the viscosity of the substance (synthetic heat transfer fluids). If you do not fill the heating system with coolant in time, the following negative moments may occur:

- Decrease in efficiency in heating operation. This is a consequence of a decrease in the efficiency of heat transfer due to the presence of third-party elements in the liquid - lime scale and rust.

- The likelihood of failure of the heating boiler, radiators and valves. Only by filling the heating with a coolant can such problems be avoided. This is due to the gradual saturation of water with oxygen, as a result of which foam formation increases and corrosion processes on the inner surface of the steel elements of the system are significantly accelerated.

Timely filling with water of a closed heating system can be different in time. It all depends on the composition of the coolant and the temperature regime of the boiler. For distilled water, the optimum replacement interval is 1 year, i.e. before each heating season. In the case of using heat transfer fluids based on ethylene glycol, propylene glycol or glycerin, the service life is 3 to 7 years. It depends on the concentration of chemical components - the more there are in the total volume, the longer the liquid will serve.

However, before filling a closed heating system with water, you need to decide on the type of coolant - it will be ordinary H2O or improved fluids.

In order to fill or add antifreeze to the heating system of a double-circuit boiler, you need to find out if this can be done. Boiler manufacturers indicate solutions that can be used to fill the heating system.

Solutions for intravenous drip administration. Ringer's solution (pharmaceutical company YURIYA-PHARM)

- Balanced electrolyte solution;

- Restores water-salt and acid-base balance;

- Increases the alkaline reserve of blood.

Structure :

- Sodium chloride - 8.6 g

- Calcium chloride - 0.48 g

- Potassium chloride - 0.3 g

- Water for injection up to 1 liter.

Ionic composition, mmol / l:

Na + - 157.0; K + - 2.7; Ca ++ - 1.8; CN - 159.1; HCO3 ++ - 2.4.

The theoretical osmolarity is 323 mosm / l. It is produced in glass bottles of 200 or 400 ml for blood, transfusion and infusion preparations, hermetically sealed with rubber stoppers and crimped with aluminum caps. Pharmacological group: plasma substitutes, saline solutions. Pharmacological properties: Ringer's solution contains a balanced mixture of basic cations and is more physiological compared to 0.9% isotonic sodium chloride solution.

Ringer's solution restores the water-salt and acid-base balance and replenishes the fluid deficit in the human body that occurs during its dehydration or in connection with the accumulation of extracellular fluid in the foci of extensive burns and injuries, during cavity operations, peritonitis. The drug increases the alkaline reserve of the blood. Along with this, Ringer's solution improves the rheological properties of blood and tissue perfusion, increasing the effectiveness of blood transfusion measures in case of massive blood loss and severe forms of shock.

The drug also has a detoxifying effect as a result of a decrease in the concentration of toxic products in the blood and activation of diuresis.

Indications for use

Iso- and hypotonic dehydration and metabolic acidosis as a result of prolonged diarrhea and indomitable vomiting, with acute massive blood loss, shock, extensive burns, with severe postoperative period, toxic poisoning of various etiologies. Ringer's solution is also used externally for various diseases of the eyes, nose, mucous membranes, for washing wounds.

Contraindications

Ringer's solution is not used for alkalosis, as well as in cases where fluid infusion is contraindicated (cerebral hemorrhage, thromboembolism, severe cardiovascular decompensation, hypertension, grade III).

Side effect . With a significant overdose of the drug, there may be phenomena of chloride acidosis, overhydration. Features of the application. In order to increase the effectiveness of detoxification and anti-dehydration therapy, Ringer's solution can be prescribed simultaneously with blood transfusions, plasma transfusions and plasma substitutes. With prolonged use, especially in large volumes, control the composition of electrolytes in plasma and urine, diuresis.

Conditions and shelf life. Store in a dark place at room temperature.

Water or heat carrier: choosing the optimal filling of the system

Antifreeze for the heating system

The optimal composition of the liquid should be determined by the parameters of the heating system. The heating system is often filled with water, as it has a number of significant advantages. The determining factor is the affordable cost - they often take simple tap water. However, this is fundamentally wrong. A large number of metal and alkali elements will contribute to the formation of build-up on the inner walls of pipes and radiators. This leads to a decrease in the bore diameter, an increase in hydraulic losses in certain sections of the pipeline.

But how to properly fill a closed heating system with water to avoid such troubles? Experts recommend using distilled water. It is maximally cleaned of impurities, which has a positive effect on its physical and operational properties.

- Energy intensity. Water accumulates heat well in order to subsequently transfer it to the room;

- The minimum viscosity index. This is important for closed heating systems with forced circulation and affects the power of the centrifugal pump;

- As the pressure in the pipes rises, the boiling point shifts upward. Those. in fact, the process of transition from a liquid to a gaseous state occurs at a temperature of 110 ° C. This makes it possible to use high-temperature heating modes.

But if there is a possibility of exposure to negative temperatures, then water, as a liquid for filling heating systems, is unacceptable. In this case, antifreeze agents should be used whose crystallization threshold is significantly lower than 0 ° C. The best option is propylene glycol or glycerin solutions with special additives. They belong to the class of harmless substances and are used in the food industry.The best technical properties are possessed by solutions based on ethylene glycol. Until recently, they were used to fill closed heating systems. However, they are extremely harmful to humans. Therefore, despite all their positive qualities, it is not recommended to use ethylene glycol-based antifreezes.

But what can you fill the heating system with - water or antifreeze? If there is no chance of exposure to cold temperatures, water is the best choice. Otherwise, it is recommended to use solutions of a special heat carrier.

Car antifreeze must not be added to the heating system. This will not only lead to a breakdown of the boiler and failure of the radiators, but it will also be hazardous to health.

Water drain technology, cleaning heating pipes

Drain valve in the heating system

Before filling the heating system of a double-circuit boiler, it is necessary to drain the old coolant. This procedure is mandatory and, despite its apparent simplicity, must be performed according to a certain technological scheme. First you need to turn off the heating and wait until the water temperature drops to room temperature. Only then can the closed heating system be properly filled with distilled water.

The drain valve is then opened, located at the lowest point in the system. After waiting for the water to drain, you need to open the Mayevsky tap, which is located at the top point of the circuit. This is necessary to stabilize the pressure in the pipes. After completing these works, you need to flush the system. This is done before the heating system in a private house is filled. This requires the use of special tools and equipment. A pump is connected to the heating circuit, which pumps flushing liquid into the heating system. It also has a destructive effect on deposits in pipes. After several cycles of passage, contaminants are removed along with the liquid.

The used liquid must not be discharged into the sewer system. It must be collected in sealed containers, which are then disposed of by special companies.

Filling methods - built-in mechanism and pumps

Heating filling pump

How to fill the heating system in a private house - using a built-in water connection with a pump? It directly depends on the composition of the coolant - water or antifreeze. For the first option, it is enough to pre-flush the pipes. The instruction for filling the heating system consists of the following points:

- It is necessary to make sure that all shut-off valves are in the correct position - the drain valve is closed as well as the safety valves;

- The Mayevsky valve at the top of the system must be open. This is necessary to remove air;

- Water is filled until the moment when water flows from the Mayevsky tap, opened earlier. After that it overlaps;

- Then it is necessary to remove excess air from all heating devices. They must be fitted with an air valve. To do this, leave the system filling valve open, make sure that air comes out of a particular device. As soon as water flows from the valve, it must be shut off. This procedure must be done for all heating devices.

After filling the water in a closed heating system, you need to check the pressure parameters. It should be 1.5 bar. In the future, pressing is performed to prevent leaks. It will be discussed separately.

Filling the heating with antifreeze

Before proceeding with the procedure for adding antifreeze to the system, you need to prepare it. Usually 35% or 40% solutions are used, but to save money it is recommended to purchase a concentrate. It should be diluted strictly according to the instructions, and only using distilled water.In addition, a hand pump must be prepared to fill the heating system. It is connected to the lowest point of the system and the coolant is pumped into the pipes using a hand piston. During this, you need to monitor the following parameters.

- Air outlet from the system (Mayevsky valve);

- Pipe pressure. It must not exceed 2 bar.

All further procedure is completely similar to the one described above. However, one should take into account the peculiarities of the operation of antifreeze - its density is much higher than that of water. Therefore, special attention should be paid to the calculation of the pump power. Some glycerin-based formulations can increase the viscosity index with increasing temperature.

Before pouring antifreeze, it is necessary to replace the rubber seals at the joints with paronite ones. This will greatly reduce the likelihood of leaks.

Automatic filling system

For double-circuit boilers, it is recommended to use an automatic filling device for the heating system. It is an electronic control unit for adding water to pipes. It is installed on the inlet pipe and works in fully automatic mode.

The main advantage of this device is the automatic maintenance of pressure by the timely addition of water to the system. The principle of operation of the device is as follows: a pressure gauge connected to the control unit gives a signal about a critical drop in pressure. The automatic water supply valve opens and remains in this state until the pressure stabilizes. However, almost all devices for automatic filling with water in a heating system are expensive.

The budget option is to install a check valve. Its functions are completely similar to the automatic filling device of the heating system. It is also installed on the inlet pipe. However, the principle of its operation is to stabilize the pressure in pipes with a water make-up system. If the pressure in the line drops, the pressure of the tap water will act on the valve. Due to the difference, it will automatically open until the pressure stabilizes.

In this way, it is possible not only to feed the heating, but also to fully fill the system. Despite the apparent reliability, it is recommended to visually monitor the coolant supply. When filling the heating with water, the valves on the devices must be opened to release excess air.

Intravenous drip infusion. Technique: intravenous drip infusion

Indication: Doctor's prescription

Equipment:

- sealed medicine bottle

- rubber venous tourniquet

- oilcloth pillow

- diaper

- alcohol 70

- containers with disinfectant. solutions

- adhesive plaster

- drip stand

- pharmacy gum

- scissors (in 1% chlorhexidine solution)

Sterile:

- system for IV cap. infusion

- cotton balls

- gloves

- kidney-shaped tray with small oilcloth

Areas for the introduction of medicinal substances: veins of the elbow region, in some cases - smaller veins of the forearm, hand.

Intravenous drip infusion.

| Get to know the patient (if you are not familiar) | Establishing contact with the patient |

| Explain to the patient the course and meaning of the upcoming manipulation, obtain the patient's consent to carry it out | Patient motivation to cooperate. Ensuring the patient's right to information. |

| FILLING THE DROP SYSTEM (m / s in the mask) | |

| Read the name of the solution, expiration date, concentration, volume on the bottle label | Elimination of erroneous drug administration |

| Treat the metal cork of the bottle with a cotton ball moistened with 70 ⁰ alcohol | Reducing microbial contamination of the plug |

| Open the central part of the metal plug with scissors in 1% chlorhexidine solution | Providing access to the rubber stopper. Avoiding needle damage |

| Treat the rubber stopper of the bottle with a cotton ball moistened with 70 ⁰ alcohol (leave the cotton ball on the rubber stopper) | Reducing microbial contamination of the plug |

| Take a bag with a system for intravenous drip infusion, check the expiration date of the system, the tightness of the bag | Elimination of the wrong choice of the system. |

| Spread the edge of the bag with a cotton ball soaked in 70 ⁰ alcohol | Reducing microbial contamination of the package |

| Open the package with scissors, remove the system from the package | |

| Remove the cap from the airway needle and insert the needle into the vial until it stops. | |

| Close the adjusting screw | |

| Turn the bottle over and fix it on a tripod | |

| Remove the needle from the cannula | |

| Open the adjusting screw | |

| Fill the lake and then the entire system until the air is completely displaced. The duct opening must be open | Prevention of complications |

| Close the adjusting screw | |

| Attach the needle by removing the cap, check its patency, put the cap on the needle. | |

| PERFORMING THE INJECTION | |

| Wash and rub hands, wear gloves | Universal Precautions, Safety |

| Examine the elbow bend areas. Choose an injection site. Ask the patient (if necessary help) to take a comfortable position, put his hand on the table. | Facilitation of manipulation. Choosing an injection site |

| Apply a venous tourniquet on the middle 1/3 of the shoulder, on the diaper. The free ends of the bundle should be directed upwards, and the loop down | Providing blood supply to the veins |

| Ask the patient to clench and unclench his fist several times, then leave the fist clenched | Condition for Improving Vein Filling |

| Treat the injection site with 3 cotton balls moistened with alcohol: 1st large area (drop into the tray), 2nd smaller (drop into the tray), 3rd directly the injection site (hold it with the little finger of your left hand) | Processing the skin allows you to disinfect it as much as possible Prevention of the danger of nosocomial infections and infection with parenteral hepatitis and HIV infection |

| Fix the vein with your left hand (with your thumb slightly pulling the skin along the vein) | Facilitating entry into the vein |

| With a needle, cut upwards, pierce the skin and puncture the vein until it feels like it is "into the void" (the angle depends on the location of the veins and subcutaneous adipose tissue) | Needle position control |

| Make sure the needle is in the vein by pressing the rubber band | The appearance of blood in the system indicates that the needle is in the vein |

| Untie the tourniquet with your left hand by pulling on one of its free edges. Ask the patient to unclench their fist | A prerequisite for the introduction of a medicinal substance into a vein |

| Re-verify that the needle is in the vein by pressing the elastic band | The appearance of blood in the system indicates that the needle is in the vein |

| Fix the gum of the drip system with a plaster | Preventing the exit of the needle from the vein. Prevention of complications |

| Cover the needle with a sterile gauze cloth and fix it with a plaster. |

Heating system pressing

Heating system pressing

Before filling the heating system with coolant, it is necessary to check the tightness of all joints and connections. For this, pressing is performed - creating excess pressure in the pipes, i.e. a situation of destabilization of the system is artificially created.

This can be done in two ways - by pumping air or a coolant. This must be done even before the heating system of the double-circuit boiler is filled. This procedure can be carried out using a mechanical (electrical) pump or by connecting the water supply. The latter option is not recommended, as it will be very difficult to control the process. The order of execution is as follows:

- Preliminary visual inspection of joints and joints;

- Connecting the mechanism to the inlet pipe of the system;

- Creation of excess pressure, the value of which should exceed the norm by 1.5 times.

The condition of the heating elements must be checked. In the event of a leak, the process stops immediately and can only start when the defect has been eliminated.

Manipulation

The patient for the intravenous drip procedure must lie comfortably: he will have to lie with a motionless hand for a certain period of time. To install a drip, you need to puncture a vein. It is preferable to puncture the veins on the "non-working" arm. It is better to choose dark venous vessels to make it easier to control the process.

It is better to put the dropper in the median vein of the elbow or the medial saphenous vein. They are also easier to insert catheters into. Less commonly, the veins on the back of the hand are used for drip injection of solutions. In order for the medical staff to have the opportunity to puncture the vein a second time (if the first time was unsuccessful), it is better to make the puncture closer to the hand. The second time, it is impossible to prick into the previous puncture site: it is dangerous by rupture of the venous wall.

After choosing a vein for venipuncture and before puncturing the venous wall above the injection site, a tourniquet is applied to the arm. It is necessary to tighten the tourniquet so that the pulsation of the veins in the arm below it stops. After the tourniquet is applied, a pad is placed under the patient's elbow to achieve maximum joint extension. The patient has to "work with a fist" to create an artificial venous stasis.

Before venipuncture, the medical staff should put on sterile gloves and treat the skin around the puncture site three times: the first sterile ball is a large field of skin around, the second is a small field, and the third is the venipuncture site itself. This triple treatment of the skin ensures sufficient decontamination of the skin at the place where the dropper is placed.

After disinfecting the skin, the cap is removed from the free needle of the infusion tube, the needle is turned upward, the vein is fixed with the thumb of the left hand to immobilize it as much as possible. A puncture of the skin and venous wall is made at an angle of 30-45 °. Blood should appear from the cannula of the needle when properly manipulated.

A sterile ball is placed under the cannula of the needle, the tourniquet is removed, the clamp on the infusion tube of the system is opened, a few drops of the solution are poured, the system is connected to the cannula of the needle. The ball with blood drops is removed. To fix the needle in the vein, it is attached to the skin with adhesive tape.

The solution bottle and drip chamber should be higher than the lower cannula of the system. Violation of this rule can lead to the ingress of air into the bloodstream. The required drug delivery rate is adjusted using a clamp on the infusion tube of the dropper. The drug delivery rate is determined by the hour with a second hand. As the drug solution is dripped, the patient's well-being and the place where the dropper is installed must be constantly monitored.

If during the procedure, the patient needs to inject any more medication intravenously, this is done by puncturing the infusion tube, having previously treated it with a disinfectant solution.

Quality control of heating filling

Before filling a closed heating system with water, make sure that all protective elements are present. These include Mayevsky taps, bypasses, and control devices - thermometers and manometers. They are necessary not only to control the pressure in the pipes during the supply of the coolant, but are also the main safety measures during the operation of the heating. This is how you can properly fill the heating radiator with water.

During the correct filling of a closed system with water, the following parameters must be monitored:

- Pressure. Manometers must be installed in key places of the system - extreme radiators of heating, and the highest point.After the final air outlet, the pressure on all pressure gauges should be the same;

- No leaks.

Only in this way can a stable pressure be achieved. However, the main check process takes place when the boiler is turned on. The thermal expansion of water at maximum operation should not affect the integrity of the piping of the heating elements.

Preparing for the procedure

In order for the manipulation to be safe, the personnel performing it must strictly observe the algorithm of actions when setting the droppers.

Preparation for the procedure is performed in the manipulation room, observing the rules of asepsis and infectious safety:

- Check the tightness of the packaging of the dropper set, its expiration date, and the presence of caps on the needles. If the package is leaking or its expiration date has expired, this kit cannot be used, since its sterility is violated.

- Before unpacking the dropper kit, personnel should thoroughly wash their hands with warm soap and water, dry them, and wear sterile gloves. Spread out a sterile diaper on the surface of the injection preparation table. Treat the bag with the dropper set with a sterile ball moistened with medical alcohol, then open it, and put the contents of the package on a sterile diaper.

- The medicine bottle should be examined carefully. It must have a label with the name of the drug inside and the expiration date. The bottle must be shaken to make sure that the appearance of the solution has not changed. If it is necessary to inject additional medications into the vial with the solution, you need to inspect the ampoules or vials with these medications, make sure that their names correspond to the prescription sheet. They must be usable. The absence of names and / or expiration dates of drugs on ampoules is the basis for refusal to use them.

- Remove the aluminum cap from the bottle. To do this, it must be treated with a cotton ball dipped in, and then remove the lid with sterile tweezers or scissors. Treat the rubber stopper on the bottle with a ball moistened with alcohol.

- The cap is removed from the needle of the airway and the needle is inserted into the cork of the bottle until it stops. There is no need to process the needle additionally: if the conditions for opening the bag with the dropper set are met, the needle is sterile. Do the same with the infusion tube needle. Check that the clamp (wheel) on the infusion tube is closed. The bottle is inverted and placed on a tripod.

- Press the drip chamber twice to fill it halfway with the solution from the vial. To expel air from the infusion tube, open the clamp, remove the cap from the second tube needle, and slowly fill the entire system with solution from the vial. After complete displacement of air, the clamp on the tube is closed, and a cap is put on the needle. The drip system is considered ready to use.

The drip procedure cannot be carried out without the knowledge of the patient himself or his relatives. Therefore, immediately before carrying out it, they need to take consent to manipulation.

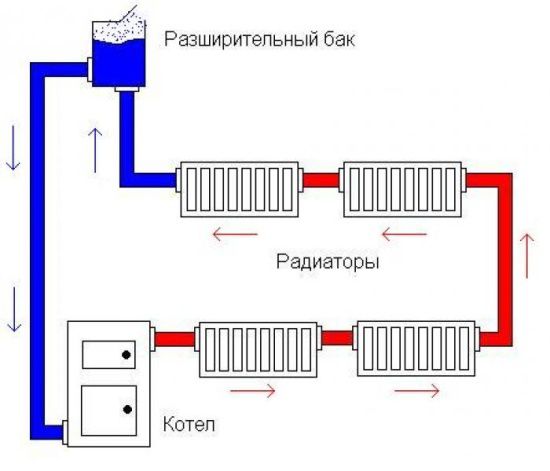

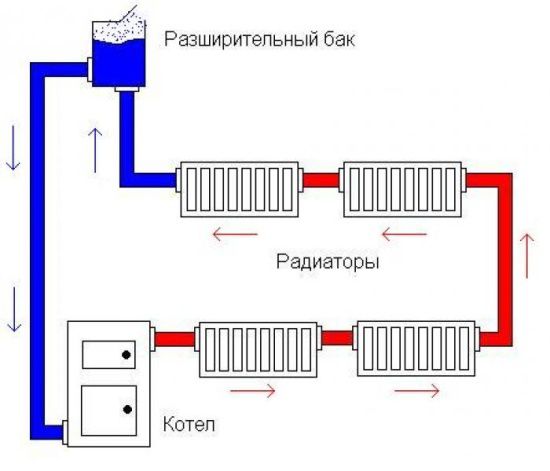

Open heating system

Open heating system

If the filling of an open-type heating system in a private house is performed, then the procedure for performing the work is somewhat different. The peculiarity is that the pressure in the pipes is equal to atmospheric. Therefore, the main control element is the expansion tank, which is installed above the other heating devices.

In this case, the order of filling the heating system is as follows:

- The old coolant is drained and the pipes are cleaned.

- Mayevsky's tap opens on all heating devices.

- The flow of liquid for filling the heating system can be carried out through a return pipe.

- As soon as all the air has left the system, the water level in the expansion tank is checked. It should be 2/3 full.

It is noteworthy that with the help of a hand pump used to fill the heating system, you can also add coolant.

No overpressure is allowed for an open heating system. Otherwise, it can lead to incorrect operating temperature.

How to top up the coolant

In addition to instructions for filling the heating system, it is necessary to know the correctness of the procedure for adding a coolant. This situation can occur 2 or 3 times during the heating season. It is important to determine in time that the volume of water has fallen below the critical value. Depending on the type of heating, there are different procedures for filling the heating system.

Closed heating system

The main indicator is a decrease in the pressure level in the pipes. For timely monitoring, several pressure gauges are installed in the system. One of them is necessarily located immediately after the exit of the hot coolant from the boiler. Also install a pressure gauge on the upper air valve. The drop in pressure in the system is the result of 2 factors - the occurrence of an emergency (leakage) or natural evaporation of the liquid. If this process occurs very quickly, it is most likely that the pipe has burst. A gradual decrease in pressure indicates a second factor.

The method of adding liquid completely repeats the procedure for filling with water any closed heating system. To do this, you can use hand pumps to fill the heating system (antifreeze), or use the central water connection.

Open heating system

It is recommended to fill an open heating system with water through an expansion tank. This can be done even with a relatively high temperature of the water in the pipes. This method has several advantages - controlling the level of the coolant in the system during filling and improving circulation due to the difference in water density.

There is a risk of failure of the boiler or heating radiators if additional filling of the open heating system with coolant occurs while the boiler is running. Therefore, this procedure is recommended to be performed when the water in the pipes reaches room temperature.

To choose antifreeze, we recommend that you familiarize yourself with the video material.