A little about the advantages and disadvantages

All classes of underfloor heating have both advantages and disadvantages. The first include:

- there is no need to carry out large-scale repair work;

- you can create an effective heating system in a wooden house or a structure with ceilings on beams;

- there are no strict requirements for the existing base - a water-heated floor without a screed or an electrical system can be arranged on almost any surface;

- you can carry out any thorough work on floor insulation;

- much higher system maintainability. To access the pipes or the heating element, it is enough to disassemble or remove part of the finish floor covering;

- a number of ready-made options are offered, constructs that allow you to assemble a heating system in a matter of days.

Cost is one of the main characteristics that water underfloor heating without a screed or an electrical system have. At the same time, not only the cost of creating a structure is higher than the classic schemes, but also the monthly operating costs. This is due to some of the disadvantages of underfloor heating without a screed:

- not surrounded by a layer of concrete, pipes or electric heaters are protected from damage only by the floor covering. Therefore, it is recommended to use sufficiently rigid materials as a finishing layer;

- without a damper, a heat accumulator in the form of a concrete layer, water-heated floors without a screed become low-inertia. They lose heat quickly;

- there is a pronounced temperature difference in certain areas of the floor if the tubes are laid with a large pitch.

Infrared underfloor heating has similar problems. However, in the case of using electric heaters, the average user is immediately ready for both low inertia of the system and increased bills for paying for the energy carrier.

When pipes are laid with a small mesh pitch, the costs of basic construction materials immediately increase. In addition, underfloor heating without a screed will require a larger amount of heating medium to ensure sufficient energy efficiency. This immediately places increased demands on the heating boiler. But for all its shortcomings, heating systems without screed are quite popular, since they are easy to arrange and show reliable operation.

Advantages and disadvantages of electric heating

Electric heating of a privately owned house has a number of advantages:

- Simplicity and ease of installation... To carry out an independent installation of the system, you do not need an expensive tool and possession of special knowledge. All installed equipment can be easily transported and moved from one room to another. Also, a separate arrangement of the boiler room and chimney is not required.

- Safe operation... The electric heating system of a private house does not emit carbon monoxide, there are no combustion products. They are also missing in the event of a malfunction or disassembly of the equipment.

- Minimum preparation costs... There is no need for permits. Also, to draw up a project, you will not need to seek the services of specialists.

- Reliable and quiet operation... The electric space heating is maintenance-free. The equipment operates silently as no fan and pump are used to operate it.

- Simple operation... There are no elements in the system that fail quickly. There is no need for constant monitoring of sensors and fuel availability.

- High efficiency... Electric heaters allow private households to be heated very quickly, even on cold winter days. They are equipped with special devices that allow you to regulate the temperature regime separately in each room, so that during the heating season you can significantly save on costs.

Disadvantages of electric heating:

- High power consumption... This is the main disadvantage of using such heating systems. Due to the high prices for electricity for consumers, this heating method is not entirely profitable.

- Energy dependence... Heating the house is impossible without electricity.

- Unstable voltage in electric lines... This problem is especially common in rural areas. Installing your own generator will help to solve it, which will lead to an increase in financial costs.

If you plan to heat a residential building with electricity, first of all, you should take into account the state of the electrical wiring and the power consumed by the equipment. When the household is large, then a three-phase power grid may be required. You need to know how much power is needed for lighting the house and for heating.

How to make an electrical type system

Let us briefly dwell on the arrangement of infrared electric type warm floors. These are very popular systems not today, especially in old wooden houses. They perform well both in the role of additional and main heating.

The electrical system can easily be made by hand. Today, manufacturers of film heaters immediately plan to use their constructs to build large systems and provide connection diagrams in the documentation that allow regulating power consumption.

On the retail market, you can purchase:

- film heaters with a conductive structure sandwiched between layers of a very strong film;

- road-grade carbon film heaters, which are a development of the previous technology;

- continuous warm floor, which is a continuous area of the resistive element located between the layers of the protective film.

The most reliable today are conductive film heaters and carbon track heaters. The technology for making films allows you to put furniture on them, the system is protected from water, and has good fault tolerance.

Separately, it is worth noting: the conductor system is built on a parallel type of connection. Therefore, one large heating film never fails completely if the surface is damaged. It stops working only if the connection is broken in the system.

Compared to conductive heaters, carbon track heaters are 40-60% more economical. They do not show any other improved operating results, they have the same recommendations for connection. Carbon technology is more expensive, but it allows you to get more heat output at the same cost of paying your electricity bills.

A continuous warm floor is even more economical. Compared to film heaters of a conductive structure, electricity bills are reduced by 5 times. But the film has some limitations. Heavy furniture should not be placed on it because of the danger of the formation of local overheating zones, where the structure of the carbon resistive site is destroyed.

The general characteristics of film electric floors without a screed looks like this: they fit under any coating (linoleum, laminate, carpet), they are connected according to a simple scheme, no control equipment (floor sensors) is required, adjustment is made only by applying different voltages. The nominal electric heater temperature is 30-40 degrees, maximum - up to 80 degrees Celsius.

Water and cable electric floors without screed

The device of water and cable heating structures without a concrete layer is in many ways similar. The answer to the question of how to make a warm floor without a screed will contain a listing of the same requirements for the flooring surface, a description of similar laying structures, consumables, and control systems. Therefore, the general technology will be considered, without focusing on a specific type of heat source (water tube or electric cable).

To equip an underfloor heating system without a screed, you will need:

- strong and relatively flat base surface;

- insulation layer;

- supporting structure for accommodating a tube or cable;

- elements for better heat dissipation;

- finishing floor covering.

Depending on the characteristics of the house or apartment, namely the degree of their insulation, the laying step is chosen. Depending on the availability on sale in the region of the work, certain components are selected.

Wooden warm water floors

There are enough ways to make a water floor in a wooden house by the "dry" method, but when laying on a rough wooden floor or on logs, there are some requirements:

- Depending on the finish used, the logs should be located: after 30 cm, if you will be laying tiles;

- after 60 cm under other coverings.

Read more about the choice of materials for a warm floor here.

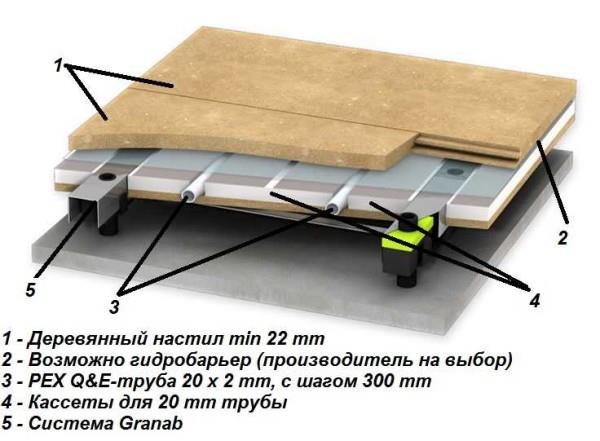

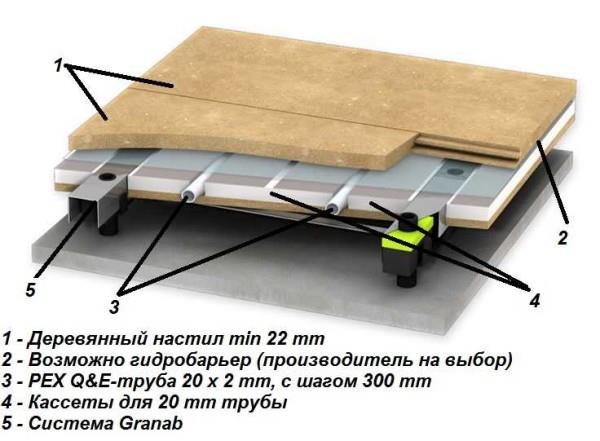

First option: "Floating" floor without rigid connection with the base. In this case, ready-made fiberboard modules with molded grooves are used. They are laid on the floor joists, between which a layer of insulation is laid. A metal strip is placed on the fiberboard for better heat transfer, and the pipes are fixed in it.

The pipe spacing can vary, as well as its diameter. It is selected depending on the required amount of heat to replenish the heat loss in the room. Depending on the topcoat that you are going to use, a hydro-barrier, a vapor barrier can be laid on top or not. If you plan to lay a soft topcoat (linoleum or carpet), you need to put a gypsum fiber sheet (gypsum fiber board is the best option), chipboard and OSB. Boards with an adhesive component must have an emission class E-1 or E-0, their thickness is at least 22 mm (for normal bearing capacity). These plates will serve as a rigid base and, at the same time, a heat distributor and accumulator.

The same modules for pipes (or others, with a different pitch, a different base thickness) can be laid on any flat base. They can be fixed, or floating incoherent warm floors can be made. Floating floors are the best option due to the different thermal expansion of different materials.

Second way: the wooden system of the water floor provides for the installation on the logs not of modules, but of tube boards. These are boards of different lengths, but of the same thickness and width, from which the previously developed pipe laying pattern is laid out.Boards can also be laid on any flat surface, but the degree of heat and hydro insulation is important. The figure shows the ideal variant in which the difference in temperature expansion will not be felt.

Third option: the GRANAB system, which allows you to lay the water floor "dry" on any, even curved and uneven base. The whole point is in special modules with adjustable legs. Having installed and aligned these modules, wooden (made of fiberboard) blocks for pipes are laid out on them, on top, as usual, metal plates, and in them - pipes. Further, hydro / steam protection, depending on the topcoat used, for soft coatings, either gypsum fiber board or chipboard will be required.

Thermal insulation

A layer of heat insulator, required for a dry, without screed arrangement of warm floors, is required. Moreover, he can perform several tasks at once:

- work only as a means of reducing parasitic heat losses through the ceiling;

- increase the strength of the floor as a whole;

- serve as a reliable base for laying the topcoat.

In the latter case, when arranging the heat insulator layer, a power frame is made. In old houses or structures with weak floors, this method is optimal. The resulting strength and rigidity of the floor increases, and the weight of the structure is rather low.

Base for laying pipes or cables

When arranging a dry floor without a screed, the following can be used as a basis for laying:

- special pads, where protruding elements for horizontal laying and turns are formed;

- special constructions made of chipboard, boards, plywood or OSB;

- processed board, strips 21 or 28 mm thick.

The technology for working with different substrates is not much different from each other. To lay the circulation network you will need:

- cover the surface with a substrate, while the finished constructs are connected by themselves with lock zones, a rack system is formed from a thin board to accommodate the heating circuit;

- carry out a rough installation, if necessary, moving individual zones of the substrate;

- check docking or electrical connections for compliance with the recommendations of the tube or cable manufacturer.

At this stage of work, it is not necessary to fix or in any other way fix the coolant circulation routes or cable. If everything went well and the installation is in accordance with the plan, you should fix the substrates on the base (mandatory for boards and structures made of wood-containing materials).

Ready-made panels for laying the underfloor heating tube without screed are strips located at a distance from each other, united by a single perimeter. In terms of functionality, they are no different from prepared boards, but more expensive. Ready-made constructs allow you to work faster, but they can impose certain restrictions on the laying of the heating route.

DIY underfloor heating installation

An integral companion in solving the issue of heating is thermal insulation and heat conservation. That is why these factors must be taken into account before installing underfloor heating.

First you need to exclude heat leakage, and the most frequent areas of heat leakage are windows and walls. First of all, it is necessary to install plastic windows, while it is important to pay attention to strict adherence to the installation technology, since its violation can lead to heat loss. No less important is the finishing of the slopes of the windows from the outside and inside, again to prevent blowouts. Also, if you insulate the walls, then the increase in heat saving will be quite high.

Now let's touch on the very procedure for installing the floor.

Laying underfloor heating

First of all, when installing underfloor heating, it is necessary to prepare the base.In accordance with the rules for laying underfloor heating - the base must be flat, without bumps and other irregularities. First you need to check the floor level, and if necessary, level it. When the floor is dropped, we proceed to laying the thermal insulation material, which is necessary so that the heat goes up and does not heat the floor slab. The next step will be the choice of the location of the thermostat and the supply of communications - with electric underfloor heating, or where pipes and taps will come from - with water heating. Further, the procedure for laying a heating system of these two types is different from each other, and we will consider each of them separately.

Installation of underfloor heating

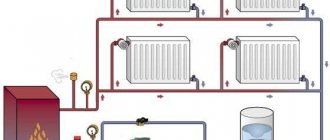

Let's first find out how best to mount underfloor water heating. The beginning of the installation of water heating is carried out with the organization of the place for supplying the coolant. To do this, it is necessary to make the appropriate holes in the wall for supplying pipes and installing taps on them. We recommend making a special cabinet-niche for this, which will close all these so-called coolant supply mechanisms.

Then, on the leveled floor, on which the heat insulator is laid, a special mesh is laid, which will be the basis for fastening the pipe. The pipe itself is folded in half and laid on the floor, fixing to the base with ties. It is important to note that the pipe must necessarily be folded in half and that is how it is laid, since it is necessary to ensure that the water coolant is removed from the system. The pipes are laid in the form of a spiral, while there should be no kinks, otherwise this will significantly reduce the permeability of the coolant.

Additional constructs

For better heat dissipation in warm floors without screed, special panels are used. It is an aluminum alloy profile element. It has a straight recess for the tube. These constructs are located in the straight zones of the contour and act as an effective reflector, distributing heat over a larger area.

The use of diffusing panels improves the operation of the underfloor heating without screed. This is especially noticeable if the surface is covered with a finishing layer with high thermal conductivity, for example, ceramic tiles. Diffusion panels should be handled carefully.

They perform well (do not shift, do not creak) on a solid base surface. When installing heating circuits without screed on ready-made structures made of wood-containing materials or a rack structure created from boards, the diffusion panels can be fixed with self-tapping screws.

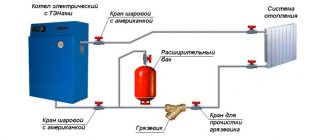

Underfloor heating system using water

The water is connected to the central unit, which is responsible for heating. However, when installing such a system, it is worth remembering that installation can be done only if the building is equipped with a separate riser. If it is not possible to install it, it is advised to install a boiler that will help create a durable and environmentally friendly system. Also, a floor of this type is characterized by high heat transfer, and its service life will become longer. The coolant comes from the boiler, it can be either gas or coal. The cost of this type of heating is lower than that of electric heating.

Underfloor heating with water heating

However, it is worth paying attention to the disadvantages of a water heating system. The price of the entire installation for underfloor heating with a water system is significantly higher than the cost of an electrical installation. For this reason, the amount of savings will be noticeable over time.

Such a floor heating installation is more designed for rooms with a large area.

It remains to polish

After installing the heating structure without screed, you do not need to do a lot of work. All that remains is to locate the control temperature sensors and lay the topcoat. Laminate does not require additional preparation. It is necessary to spread the substrate and assemble the flooring. For tiles, you will have to work with adhesive building mixtures.But even such work will not take much time.

In apartments on the 1st floor and in private houses, the floors are not very warm, which gives residents discomfort, and heat leakage through the floors reduces the weight of their wallets. How to quickly and inexpensively make the floor warmer?

Since there are many design options, there is no definite answer. Let's consider the basic principles of how to make floors warmer, as well as insulation technologies for floors that are often used.

Make your floor warmer quickly with cheap materials

Often no one wants to start long repairs. But at the same time there is a great need to make the floor warmer.

In order to quickly, slightly warm up the floor, you need to put a layer of heat insulator on top of the existing coating, but elastic, on which you can walk. We are talking only about felt up to 2 cm thick. On top of the felt, you can also put carpet up to 0.5 cm thick. Under the furniture legs, you will need to put planks, for example, from a laminate, so that it does not heavily load.

In total, you can quickly, in one fell swoop, make the floors a little warmer. But such warming will not fundamentally correct the situation with cold floors. Why?

A little theory about floor insulation

A significant part of the heat from the house (apartment on the 1st floor) leaves through the floors, if they are not insulated. This requires an increase in the heating power in order to keep the indoor temperature within the normal range. And the floors themselves become cold, forcing the tenants to keep their feet higher.

You can change the situation and make the floors warmer only with the help of insulation. Those. a barrier made of insulation is needed, which would significantly reduce the escape of heat through the floors.

The floors above cold undergrounds and basements must have a certain resistance to heat transfer, which is regulated by the standard. For the south-temperate climatic zone, this value is 3.7 m2C / W (while for the walls only 2.8 m2C / W). But when there is outside air below the floor - for overlappings over driveways, or when the house is on stilts…. - already 4.2 m2C / W is required.

The farther north, the greater the resistance to heat transfer should be at the floors - for the north-temperate zone - 5.5 and 6.2 (m2C / W), respectively.

At the core of the economic benefit

The requirements of the standards are “invented” based on economic feasibility. The state does not order to create less heat resistance, because it is not profitable in the first place.

Conventional floors have very low resistance to the movement of thermal energy - it is either just a concrete slab or a 40 mm board. Therefore, to achieve the required thermal resistance, a significant thickness of the insulation will be required.

To make the floor warmer in the south-middle regions, you need to apply 10 centimeters of Styrofoam or 13 cm of mineral wool. And for the northern ones - 15 and 20 cm, respectively.

Why do you need a warm floor

Indoor floor heating equipment can solve a huge number of problems.

Children catch colds less

In families with children, it is quite common for a child to play while sitting or lying on the floor. Parents do not always have time to control this moment, and in the future, the baby may develop dangerous diseases from being constantly on a concrete surface, even if covered with linoleum or carpet. If a warm floor is installed in the apartment, mom and dad will no longer have to worry about the health of their child and be afraid of colds, drafts and other unpleasant moments.

Compensation for insufficient heating

Unfortunately, today the central heating system does not always make users happy with quality work. Citizens are often faced with the fact that it is already colder outside, and the heating has not yet been turned on.Of course, it is possible to use a heat fan or an electric fireplace for such force majeure circumstances, however, these devices do not provide uniform heating of the room, burn useful oxygen, reduce the level of humidity in living rooms and consume just a gigantic amount of electricity. Floor-standing heating equipment is free from these disadvantages and is able to provide optimal heat without unnecessary energy consumption.

Getting rid of the problems of the "first floor"

The owners of apartments located on the ground floors in old buildings often suffer from the fact that under them there is an unheated basement or, worse, an empty, abandoned basement for years. Dampness from it inevitably penetrates into the apartment, leading to excessive moisture, expressed in darkening of the walls and fungi on the ceiling and corners. People who permanently live in such rooms develop pulmonary diseases and all kinds of allergic reactions over time. The underfloor heating system will forever relieve the tenants of the property from all basement-basement problems. Having installed heating equipment, residents will forever forget about mold, dampness and other unpleasant moments.

Heating of balconies and loggias

Almost all apartment buildings do not have central heating on balconies and loggias. As a result, these premises absorb excessive dampness from the street, thus worsening the microclimate in the inner living quarters. Only the warm floor system, fully functioning in winter and conveniently disconnected for the summer period, will help to neutralize this moment.

It's nice to walk barefoot

In rooms with tile flooring, the floor temperature is always much colder and walking barefoot is not a pleasure, especially in autumn and winter. Underfloor heating easily eliminates this drawback and brings the necessary comfort and coziness to the room.

Eliminates fungus and dampness

In rooms with a traditionally damp microclimate (bathrooms, toilets, kitchens, etc.), fungus and mold often appear on the walls and ceiling, spoiling the appearance and impairing the overall atmosphere. It is almost impossible to deal with these unpleasant manifestations, unless, of course, you install a heating floor system in the problem room.

Heating of country houses

Private country cottages and country houses of modern construction are rarely connected to the central heating system. For them, the only convenient and logical heating option is underfloor heating. They easily cope with the role of the main heat supply system and provide coziness and comfort for residents wherever there is an opportunity to connect to the power supply system.

Makes life easier for allergy sufferers

For people suffering from allergies, warm floors are a real boon. They allow you to minimize the amount of dust in the room, get rid of drafts and at the same time get a full and high-quality heating of the room.

Taking into account all the above factors, we can safely say that today the most comfortable, convenient and relevant heating system is a warm floor.

Types of floor insulation systems

Nowadays, there are several types of floor heating systems: water underfloor heating, electric, infrared. Their main advantage is the even distribution of heat over the entire surface of the floor and the room, the absence of external heating devices (batteries and radiators), as well as the ability to control the temperature in the room. Their main disadvantage is the high cost of installing the system itself, installation by qualified specialists and further maintenance by specialized workers.

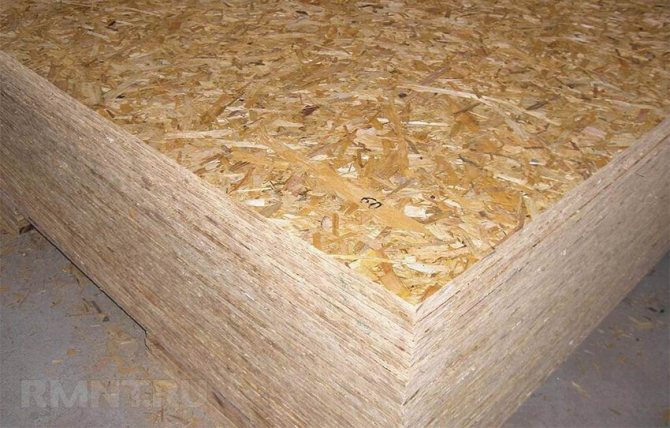

But you can insulate the floor without using these expensive and time-consuming structures, as well as without professional help.To do this, you will need extruded polypropylene boards and OSB wood boards, with standard batteries in the room, such a floor will be no less warm.

About underfloor heating

The picture of room heating is changing when using floor heating. Floor heating occurs evenly over the entire area of the room. Warm air rises evenly, creating an almost ideal temperature difference from floor to ceiling.

With the correct temperature of the floor heating system, a temperature of 24 ° C is created at the level of the feet, and 20 ° C at the level of the head. This is the most comfortable temperature climate in a room for a person.

How can floor heating be done?

Choice of tool and material

To insulate the floor, you will need the following tools:

- Perforator.

- Screwdriver.

- Drill.

- Mixer.

- Rule aluminum trapezoidal 2-2.5 m.

- Aluminum level 2-2.5 m.

- The jigsaw is electric.

- Sealant gun.

- Wood plane.

- Roulette.

- Knife.

- Plastic bucket with a volume of 20-25 liters.

- Pencil.

When choosing a material, the manufacturer is not so important as its quality and characteristics. You will need:

- Extruded polypropylene plates (at least 30 mm thick).

- OSB boards (at least 10 mm thick).

- Self-leveling starting and finishing floors.

- Deeply penetrating polymer waterproofing primer.

- Polyethylene (at least 100 microns).

- Driven dowel (not less than 8x80 mm).

- Liquid nails for styrofoam and wood floors.

- Plastic wedges up to 10 mm in size.

Floor preparation

Before laying the insulation system on the floor, it is necessary to prepare it. Floor differences should not exceed 3 mm per 1 meter.

Checking the quality of the subfloor

If there are old floors in the room (wood, laminate, linoleum), then they need to be dismantled. Weak and peeling areas must be removed. Then prime the entire floor with a deep-penetrating primer according to the manufacturer's instructions. Further, after the primer has dried, it is necessary to fill in a preparatory bulk cement mixture, which has a high leveling ability. If the differences in the floor exceed 5 mm, then it is necessary to fill in with a starting self-leveling leveling mixture, with differences of less than 5 mm, finish self-leveling self-leveling floors are poured. Such a surface is environmentally friendly, and in the future will have high wear and water resistance.

Pouring the self-leveling floor

To do this, you need to take a bucket with a volume of 20-25 liters, pour 10 liters of water into it. Gradually pour the dry mixture into the water, stirring with a mixer with a whisk until the mixture is homogeneous and without lumps, and the density has the consistency of liquid honey (the mixture should be poured out, but not spread like water). The finished mixture must be poured onto the prepared floor immediately after preparation, since it quickly settles in the bucket and you need to mix it again. After the solution is poured onto the floor, it is leveled over the floor surface by the rule, and then evenly rolled out with a spiked roller. Such a surface, as a rule, hardens after 6-10 hours, and after a day you can confidently walk on it. After 2 days, further work can be carried out.

General principle of underfloor heating

Any floor heating system is a heating element evenly spread around the perimeter of the room and neatly hidden under the floor finish. But it’s not that simple. The underfloor heating electric cable must be insulated from direct contact with the base of the floor and the walls of the room. This insulation should prevent heat loss from the heating element and direct all of its heat to the floor heating and not to the adjacent rooms. This insulation is called thermal insulation and is an integral part of the underfloor heating system.

To increase the heat transfer of the heating element of the floor heating system, it must be enclosed in a layer with good heat transfer (screed) or placed in a kind of "sandwich", where the lower layer is a heat sink, and the upper layer is a good heat conductor.

- The first floor heating system is called concrete.

- The second floor heating system is called floor heating.

Installation of extruded polypropylene plates

After the floor is leveled with a bulk mixture, you can proceed directly to the installation of the system itself. To do this, first you need to spread polyethylene on the floor, this is done for complete waterproofing. Polyethylene must be at least 100 microns thick.

When joining on the floor, polyethylene must be laid with an overlap of 10-12 cm and with a margin of 8-10 cm on each side of the wall. Further, extruded polypropylene plates are laid on the floor, the thickness of which in this case should not be less than 30 mm. Polypropylene boards are, first of all, a very good thermal insulation material with practically zero capillarity, very low water absorption and high compressive strength.

In addition to these characteristics, polypropylene is durable (does not rot) and is chemically resistant. Plates have standard dimensions 1250x600 mm and end locks for better joining.

When laying the slabs, each subsequent row must be shifted from the previous one by 30-40 cm, so that the end seams in the end result are in a zigzag position. When installing polypropylene, liquid nails for expanded polystyrene are applied to the sheet lock using a sealant gun, the amount and method of application of which is performed according to the instructions. Polypropylene is easy to cut with a knife, so if you need a smaller sheet, it can be cut without much difficulty.

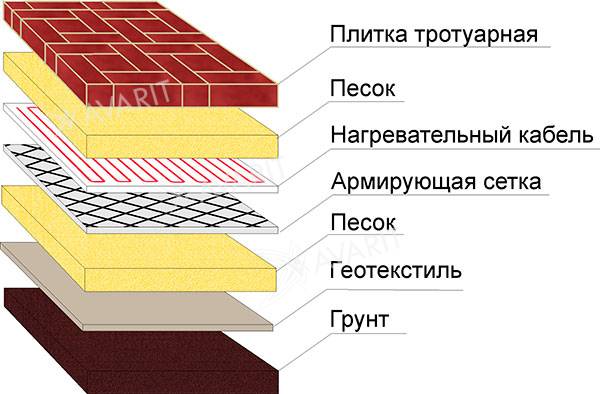

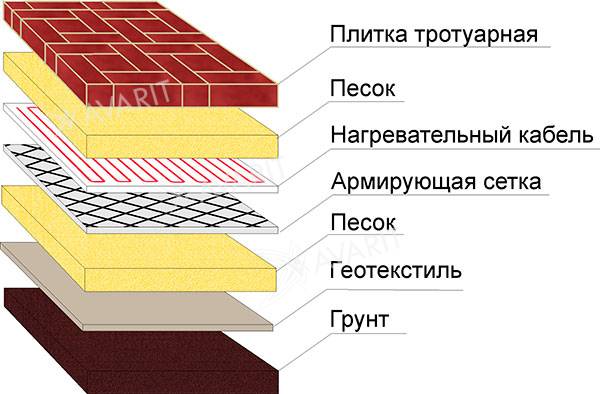

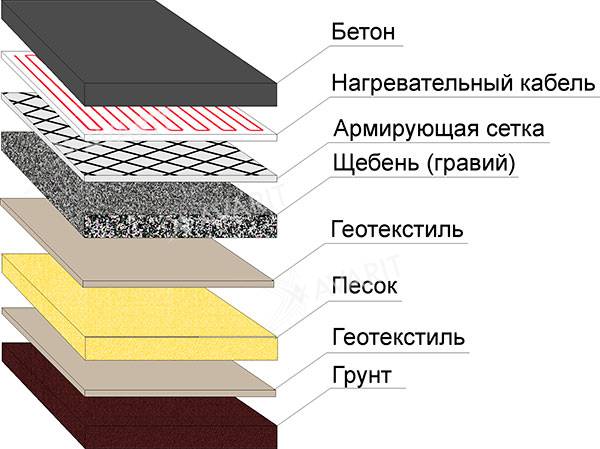

Paving slabs (fig. 2)

- Paving slabs, 6-8 cm

- Sand (3-5 cm)

- Heating cable

- Reinforcing mesh

- Sand (10-15 cm)

- Geotextile

- Priming

Fig. 2. Installation of a heating cable under the paving slabs

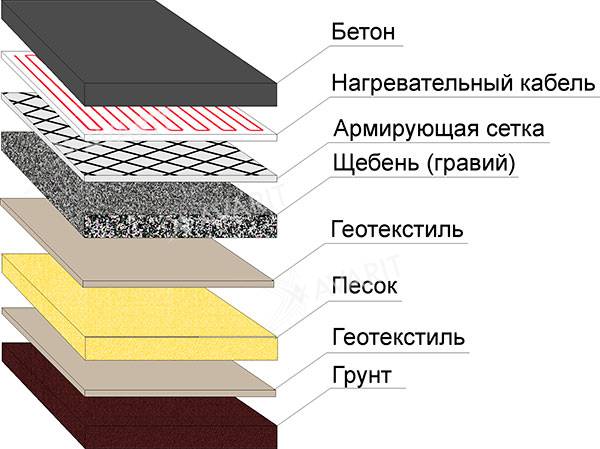

Concrete pavement (fig. 3)

- Concrete, (in the area of freight transport - 15 cm, in the area of cars - 10 cm, in the pedestrian area 5-7 cm)

- Heating cable

- Reinforcing mesh (with stands)

- Crushed stone-sand mixture 15-20 cm, or in two layers: large crushed stone (15 cm) and small crushed stone (10 cm)

- Geotextile

- Sand, 50 cm

- Geotextile

- Priming

Installation of OSB wood-based panels on the floor

After all the extruded polypropylene boards are laid, proceed with the installation of OSB wood boards, the thickness of which must be at least 10 mm. It should be noted that OSB boards are specially designed for the construction industry. With this in mind, they can be used as a finishing material on roofs, walls and floors.

OSB Wood Boards

OSB boards are chips that are oriented to each other glued to each other using special resins by pressing. Thanks to the three-layer perpendicular placement of the chips and the homogeneous composition, the boards have high strength. When laying the slabs on the floor, the gap between them and the wall should be at least 5 mm, therefore, in this case, it is better to insert wedges from the wall, with the help of which the distance will be observed. After installing all the slabs, the wedges must be taken out. OSB boards are stacked close to each other and should be perpendicular to the rows of extruded polypropylene.

Stacking OSB sheets

OSB sheets, as a rule, are cut with a jigsaw, it is better to direct the cut seam to the wall, since the factory ends will still be smoother than the ones cut by themselves.

Cutting OSB sheets with a jigsaw

After all the slabs are laid, they proceed to fasten them to the floor. To do this, using a drill and a wood drill with a diameter of 12 mm, holes 3-4 mm deep are drilled on the sheet, at a distance of 25-30 cm from each other in 4 rows along the length of the sheet.Next, a perforator and a drill with a diameter of 8 mm to a depth of 10 cm make holes for a driven dowel 8x80 or 8x100 mm. The dowels are driven in with a hammer and then tightened with a screwdriver.

Fastening OSB with dowels

So that when drilling with a perforator the sheets do not walk and there is no further displacement, 2-3 holes are drilled at different ends of the sheet and dowels are immediately hammered into them, only after that the remaining holes are drilled. Before you start sealing all the ends of the dowels with a sealant, you must carefully walk over the OSB boards with a plane on a tree, since they may have small differences in their joints, which must also be removed with a plane.

Now you need to thoroughly vacuum the floor and only after that all the ends of the dowels and gaps are sealed with liquid nails for wooden floors, using a sealant gun and a metal spatula. The floor is insulated, in a day you can lay linoleum or laminate on it.

Heating a house with a heat pump "turnkey"

Heat pumps (HP) are usually divided according to the type of media with which heat exchange takes place: a) “air-to-air” - a household air conditioner (split-system) can serve as a good example; b) "air-water" - the application of these heat pumps is presented in further estimates and calculations; c) "water-water" - geothermal.

The main criterion for evaluating the efficiency of work, which unites all types, is the coefficient of heat transfer (COP). Its value should be regarded as the ratio of the consumed electrical energy to the amount of radiated heat. Marketing activities from different manufacturers represent a given value with a value of 3.6 or more. In fact, this coefficient depends on the temperature difference between the medium from which heat is taken and the medium to which it is transferred, including the design features of the heat pump itself. The smaller the difference between the media, the larger the COP.

Air-to-air heating refers to air systems. Practical applications are found on a daily basis: in shopping centers, production halls, etc. The principle of operation is based on the transfer of heat from the outside air to the air supplied to the room. A big advantage is the fact that these systems can work for both heating and cooling, without connecting additional equipment (in most cases). In practice, the engineering group ThermoPier is systematically faced with the solution of this kind of technological problems. Engaging our company as a contractor for the design and installation of an air heating system (CO) for your home, using an air-to-air heat pump, will allow you to be sure that this heating system will be correctly designed, installed and will serve you for many years. with minimal costs for its creation.

Ground source heat pumps take heat from the groundwater (heat source) and transfer it to the system. The use of this technology is associated with a constant temperature of the heat source, which, with proper design and installation, is from 0 to 3 ° C. Thus, a constant and high COP is achieved during the entire heating period. Geothermal HPs are rarely practiced due to the high costs of creating this system, the payback period of which exceeds ten years. The basis for effective work is correct design, which is necessarily accompanied by geological surveys to assess the groundwater delta.

Further, attention will be focused on heat pumps operating on the air-to-water principle. Key Features: