How to bend a pipe at a right angle

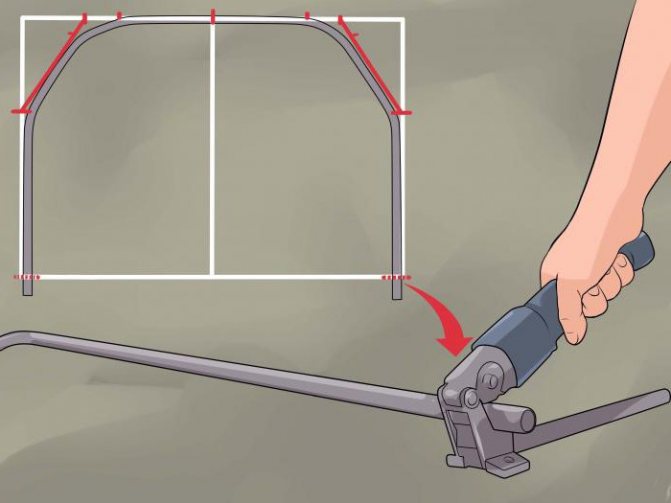

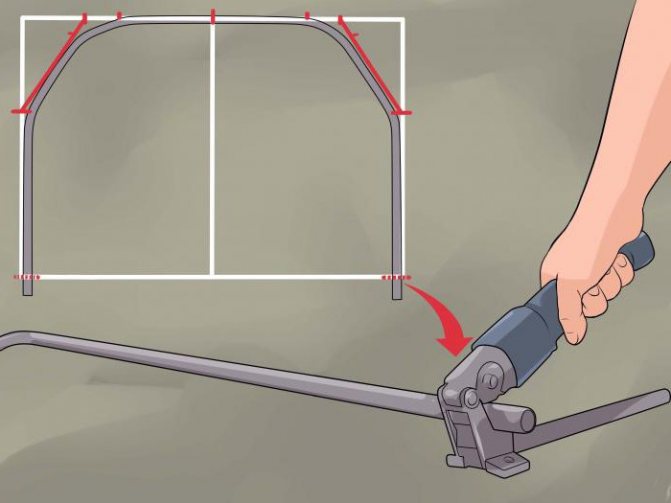

Metal acts as a fairly strong material, but with special exposure it can be bent. To date, there are several ways to address this issue. The first technology is the use of pegs. But you must remember that this method can damage the pipe or even break it. This can be avoided by filling the inner cavity with dry sand. Plugs should be installed at both ends.

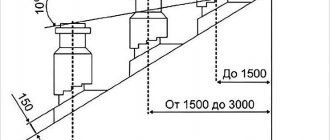

The next step is to start flexing. For this, pegs are dug into the ground. You will use them as leverage. If you are not confident in your abilities, then first you should practice on unnecessary pipe sections. If you are faced with the question of how to bend a pipe without a pipe bender, then using this technology you can change the shape of a product, the diameter of which varies from 16 to 20 mm. For pipes of a more impressive diameter, this technique is not suitable, since the process will be rather complicated. It is also important to consider the underlying material. For example, other methods are recommended for galvanizing.

Wall thickness according to GOST: weight, dimensions

This indicator depends on the method of production of the hollow thing. If a thick wall is needed, then the product is made in a hot way. Such samples are irreplaceable when extreme strength is important in hazardous conditions of chemical plants, nuclear reactors, chimneys of enterprises, high-pressure gas lines. A stainless steel pipe is a fairly strong material.

Thin-walled seamless pipes of the product come out more durable, but electric-welded pipes are cheaper. In addition, in production for solving special problems, hollow objects with the thinnest walls (0.12-1 millimeter) are occasionally used. They are either cold worked or hot worked.

According to GOST, the smallest diameter of welded stainless steel pipes is allowed - 8 millimeters, the largest - 102 millimeters. The same applies to the wall thickness, respectively - from 0.8 to 4 mm.

Hot rolled are made in the range from 57 to 325 millimeters in diameter and wall thickness from 3.5 to 32 mm. The section of cold rolled products is in the range from 5 to 273 millimeters, the wall thickness is from 0.2 to 22 mm.

Using heating technology

Before bending a pipe without a pipe bender, you should think about which technology is best for this. Heating may be a great solution. This method is commonly used for steel and aluminum piping. For the procedure, the product is fixed in a vice, but first it should be filled and heated with a gas burner to the place that you plan to bend. The temperature is determined quite simply: when a piece of paper approaches the pipe, it should start to smoke. When a steel billet is used, it should turn red when heated. For safety, the technician should wear gloves.

Plane-parallel plate

If you are faced with the task of how to bend a pipe without a pipe bender, you can use a plane-parallel plate. This technique involves fixing the product in a clamp. After that, you can bend, and this must be done along the plate. This technique is considered not only economical but also simple. In order to achieve a positive result, several plates should be used, each of which has a different curvature.The main condition is the use of a steel pipe. The length of the product should be quite impressive.

Using a metal spring

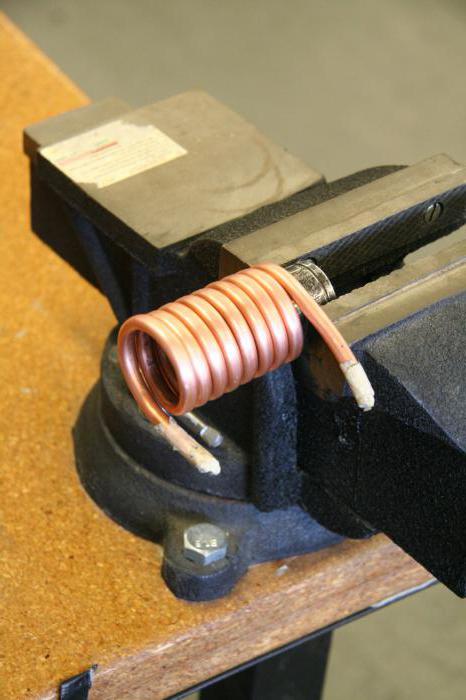

Quite often, home craftsmen think about the question of how to bend a pipe without a pipe bender at home. A metal spring can be used for this. This technique is excellent for non-ferrous pipes, which have good ductility.

A spring is used to prevent deformation. To obtain a good result, the size of the spring must be taken into account, which must correspond to the inner diameter of the metal structure. This requirement is due to the fact that the pipe is to be inserted into the cavity. Bending can then be done by tying the spring with a wire to make it easier to pull it out later.

How to make emery with your own hands

Each owner, one way or another, is faced with a situation where she needs to sharpen knives, scissors and other sharp objects that become dull over time. You can contact the master every time and pay a lot of money for his services or buy ready-made emery, or you can be smart and please your wallet by making emery with your own hands.

Basic materials and tools

The principle of operation of a homemade device

In order to design a homemade emery, you need an electric motor left over from the operation of old household appliances.

It is the electric motor that starts the product into operation, as a result of which the nozzles pre-sharpened on turning equipment installed on the engine shaft sufficiently clamp the emery wheel.

How to choose an electric motor

Most often, craftsmen choose an electric appliance as an engine, left over from an old washing machine, for example, Volga, Siberia or Vyatka. As you know, the equipment made during the Soviet era was of high quality, so the engines were also powerful enough, with high reverse rates. A switch with a manual starter mechanism will also come in handy from such a washing machine.

The main challenge to be faced is the exact placement of the sharpening stone directly on the engine shaft. There is not always a thread on the shaft, the size of the hole in the stone may also not correspond to the size of the shaft. A specially turned part will help to cope with this task, which will smooth out the dimensional discrepancy.

The maximum speed limit used in emery is 3000 rpm. This nuance must be taken into account, because a high rotational frequency can cause the grinding stone to rupture. It is preferable to use a product at home with an engine from 1000 to 1500 revolutions.

However, if you wish, you can make a more durable emery with your own hands, for this it is enough to fix a high-quality flange. A powerful device may be needed rather not for sharpening, but for polishing different surfaces.

So, the power of a wear-resistant machine should be 400 W, at home a device with a power of 100-200 W is enough.

Manufacturing process

Flange recess

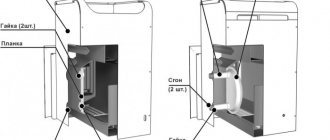

As you know, the flange connects the engine and the stone. If you do not have experience working on a lathe, contact a specialist for help, providing a detailed drawing of the future device, with measurements of the diameter of the stone on the inner surface and the size of the shaft.

The made flange must be correctly mounted on the shaft, the result must be fixed with fasteners, for example, a bolt and a nut, preferably using an additional threaded washer located on the left side.

Depending on the vector of rotation of the shaft, a thread is formed on the fasteners.Clockwise rotation requires left-hand threading, counterclockwise right-hand threading. This is the principle of tightening the nut, if you neglect it, the part will unwind, and the stone will most likely fly off the established place, which is traumatic for a person who works with emery.

However, not everyone has the opportunity to make emery with their own hands with point bushings of a certain size, as required by the technology. Pieces of pipes will help to cope with this situation at home, gaps and voids formed between the bushings and the shaft can be hidden by winding up with textile tape. Another option is to sequentially place a smaller sleeve in a larger one.

When wrapping tape, follow uniformity. The sleeve is made from a pipe with a diameter of 32 mm, which coincides with the inner diameter of the emery circle. After that, the circle must be placed over the sleeve.

Profile pipe and its modification

This type of metal structure is quite popular when building greenhouses and gazebos on a personal plot. The main feature of the building material is that it can be damaged when bent. A way out of this situation can be filling the inner cavity with fine sand or water. These actions eliminate the possibility of damage to the pipe and achieve an excellent result. This technique is suitable for brass and duralumin piping.

If you are thinking about the question of how to bend a pipe without a pipe bender for a canopy, then you can use a rubber mallet for this. It is used for square shaped products. The pipeline is installed on reliable supports, and then a mallet is used. Actions must be accurate and smooth to eliminate the possibility of damage. If it is necessary to achieve a large angle, then to facilitate the process, it is necessary to heat the pipe in the place where it should be bent.

Methods of bending metal-plastic

Quite often, owners of suburban real estate are wondering how to bend a pipe themselves without a pipe bender. When there is metal-plastic available, you can use your own strength without using the tools at hand. The product is clamped and bent smoothly. In this case, it is important to exclude the likelihood of an inflection. It is important to be guided by the rules, which state that for every 2 cm of the workpiece, the bending angle can be 15 °.

If you are faced with the question of how to bend a pipe without a pipe bender for a greenhouse, then you can use pieces of wire that fill the inner cavity. This allows you to achieve an even and smooth bend in the shortest possible time. Dry fine sand can be used as a filler. It is poured inside, and the edges are closed with plugs. Then one end of the product must be fixed, ensuring the reliability and strength of the fastening. Use a gas torch or blowtorch to heat the fold. The material is checked for readiness with a piece of paper.

What products can be made from a bent profile pipe

Quite often, for the construction of numerous structures, it is necessary to use bent shaped pipes as a decoration or to create a certain shape of the building.

Before starting any work, you need to calculate the material and sketch the future structure schematically.

Any outdoor structures and some elements of the interior of the room can be made from shaped pipes.

What can be created using a bent professional pipe:

- Greenhouses - arched, gable structures for growing vegetables and seedlings;

- Stepladders;

- Entrance gate;

- Gazebos;

- Benches;

- Forged fences;

- Decorative arches.

Quite often, a bent profile pipe is used to create a canopy over the entrance to a house or a railing for steps to the second floor.Making furniture from a professional pipe will take more time and effort, but as a result, you can get an exclusive and beautiful decor.

Polypropylene pipe bending methods

If it is necessary to change the direction of bending of a polypropylene pipe, one of two possible methods can be used. The first involves heating the fold. For this, a construction hairdryer is usually used. The optimum heating temperature is 150 ° C. Hands should be protected with gloves that are resistant to high temperatures.

At the final stage, the product is bent to the required shape. The thickened wall should be located on the outside of the bend. Once the material has cooled, it will need to be checked for cracks and dents. Another way to bend such a pipe is cold. However, the bending radius should not be more than 8 diameters, otherwise the product may break.

How to bend a plastic pipe

In order to bend a PVC pipe, you need to buy fiberboard. From them, you can build a frame, which is needed to give the structure a certain shape. As soon as you give the plate the desired shape, it should be sanded, it is better to use fine sandpaper for this.

The next step is to form a silicone shell for the plastic blank. It will act as a fastener for the PVC structure in the frame. In addition, it will play a protective role against chips, mechanical damage and scratches. The object is placed in a prepared protective shell, and then the place of bending is heated. The plastic softens and sits on the frame. Doing so will produce the desired shape of the plastic blank. The product is left until it cools down. This will take 15 minutes. After that, the PVC pipe can be removed from the frame, leaving it to cool completely.

Expert advice

The service life and quality of the installed water supply system depends on many things, so you need to carefully select the appropriate products.

What to consider:

- inspect the purchased product: it should not have cracks, kinks or other visual damage;

- the product should bend easily, while maintaining its strength - this allows installation in cramped conditions;

- it is not worth saving and buying cheap products - it is better to choose a reputable manufacturer, a high-quality stainless pipe can have a price of 1 to 3 thousand rubles, which depends on the type of product and the type of steel;

- during installation, follow the instructions;

- having installed the system, be sure to check its integrity, for which you will need to set the maximum level of allowable pressure;

- make sure fittings are complete;

- if you need to combine corrugated stainless steel with a pipe made of another material, use fittings made of brass;

- if you want the systems to last longer, do not install cheap, poor quality fittings;

- tightening the plastic elements do not need to overdo it, otherwise they will simply burst;

- Prepare the necessary tools in advance: open-end wrenches, metal scissors, fittings.

Corrugated pipes are durable and reliable products, the demand for which is gradually growing. They are popular in the fields of construction and repair: they are used to assemble gas and water pipelines, heating systems and even chimney structures are laid. In addition, they are mounted quite simply. The only condition for a long service life of the assembled system is that the materials must be of high quality, so make your purchase wisely.

Specialist recommendations

If you are faced with the question of how to bend an aluminum pipe without a pipe bender, then you can use a grinder to carry out the work, with which several thin cuts must be made at the place of the intended bend. The product is preliminarily clamped in a vice.As soon as the cuts are made, they should be cleaned of chips, only after that you can begin to bend the pipe.

Sometimes the product needs to be bent in a circle. As soon as the ring closes, the holes are welded, and some craftsmen even use a soldering iron for this. In order to make the place of the fold neat, it is additionally sanded and covered with a protective agent. This eliminates corrosion and premature failure of the joint.

How to bend a sheet of metal evenly

If the workpiece is relatively small, then you can use a vice, in which, with the help of two wrapping bars, you can firmly fix a sheet of metal, and only then bend it with a hammer. If necessary, the bend can be heated with a gas burner, but this method is not applicable to galvanized products!

Bending a sheet of metal

When it comes to a thin sheet of metal, the folding procedure can be greatly simplified.

To do this, in the place of the bend, the metal is "scratched" (we use a rule or a metal ruler, as a cutter - a sharpened piece of a hacksaw blade for metal). The metal cut to half the thickness is subsequently easily bent along the outlined line. We can say that we almost figured out how to bend a sheet of metal.

We bend galvanized

How to bend galvanized steel?

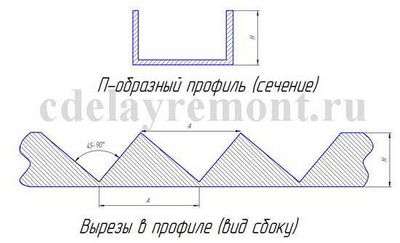

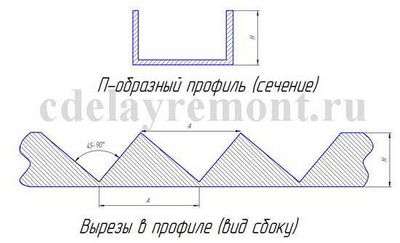

It can be either a galvanized metal sheet or a finished product, for example, a profile. The sheet is bent in the same way as when bending any other metal sheet. How to bend a profile? You will have to tinker with him. To obtain a large radius of curvature of a square or rectangular profile, you can use the following method: fill the profile tightly with fine sand, plug both holes with wooden stakes, and only then gently knock with a mallet.

To bend a U-shaped profile (this, in principle, also applies to obtaining sheets of a curved shape), it is necessary to additionally use an object-shape, the curvature of which corresponds to the finishing part. To facilitate the bending process, triangular elements can be cut into the profile.

Then the bendable product is "wrapped" around the item by uniform tapping with a hammer.

Important! To make the fold as even and correct as possible, the hammer blows should be light and fall as close to each other as possible. How is it easier to bend galvanized steel? Using a grinder, we make one or two cuts in the bend area (thereby the structure is temporarily weakened), bend the product, and then weld the bend

This approach is relevant to use when bending profiled pipes and products of complex metal shapes. Remember that you cannot heat galvanized steel to simplify curvature!

Perhaps one of the most difficult tasks facing people who are thinking about how to bend a corner. To get a whole product, you will have to sweat, evenly and slowly tapping the surface of the corner, gradually bending it.

It is recommended to use a gas burner, which can heat up the bend. You can do it easier - use a grinder as in the above case with a galvanized product. It is even easier to buy an already curved product, then the question “how to bend the corner” will disappear by itself.

How to bend the reinforcement

At home, it is quite possible to bend the reinforcement, however, a lot depends on your physical data and the diameter of the metal rod.

How to bend the reinforcement? To do this, we need two pieces of steel pipes, the diameter of which is greater than the diameter of the bent rod. The longer the length of such pipes, the easier it will be to bend the reinforcement (gain in strength due to the lever). All that needs to be done in order to bend the reinforcement is to insert it into two pipes and, fixing one of the pipes (pressing it with your foot or resting it between the pillars), wielding the other as a lever to give the reinforcement the desired curvature.

That's all!