Technical requirements

The chimney arrangement in the bath is planned before the start of construction. In the diagram, the stove in the steam room is positioned so that the pipe leading to the roof is placed as close as possible to the ridge or to the outer wall. Channels with horizontal sections of more than 1 m do not provide good traction. Light furnaces are equipped with packed pipes, and large ones with free-standing massive root pipes.

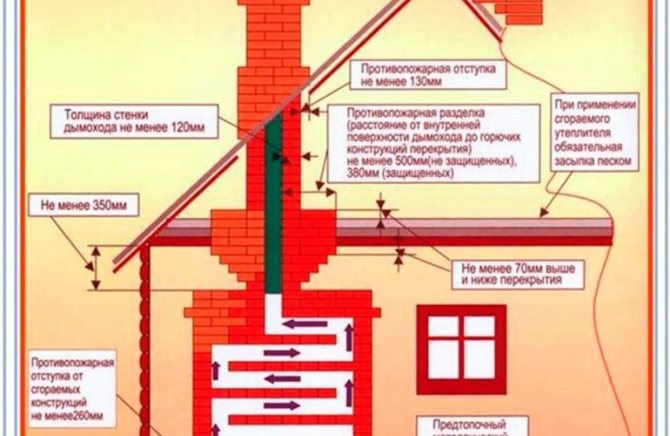

The basic requirements for the size of the chimney are as follows:

- Channel diameter. They are chosen depending on the heat output of the furnace. The minimum size is 150 mm, and if the oven is brick, the flow section of the pipe must be at least the area of 1 brick (25x12 cm). The cross-sectional area of the channel for electric furnaces is from 8 cm² per 1 kW. If the duct is too large, the rising smoke will quickly cool down and cause condensation to form, and the narrow duct will not be able to generate the required draft.

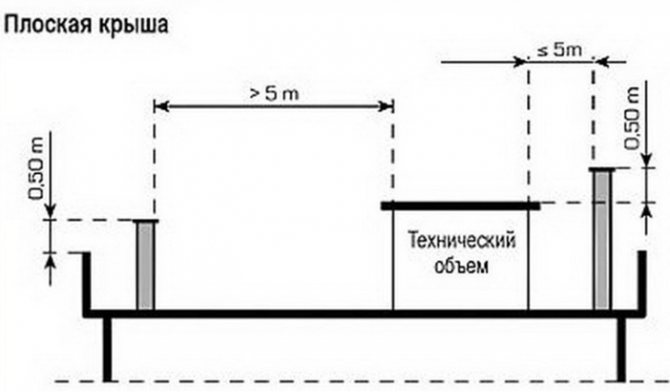

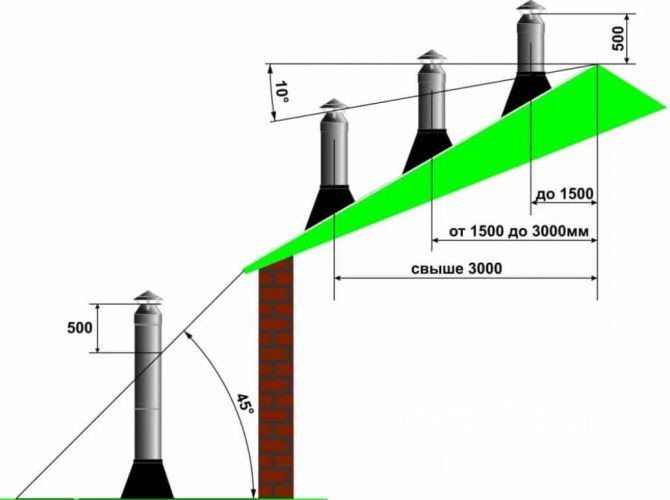

- The height of the internal chimney for good draft should be at least 5 m (from the hearth of the stove to the upper edge) and should be located on the roof closer to the ridge. If this distance is less than 1.5 m, the pipe should be 50 cm higher than the ridge. For flat roofs, the optimal pipe height is 1.2 m. The structure above 1.5 m must be additionally secured with braces.

- Thickness. The walls must allow the chimney to cool slowly. For an internal structure, their thickness should be at least 12 cm, and for an external one - 38-40 cm.

Channels made of ceramic or brick keep warm for a long time. Less than others, a sandwich is covered with drizzle, which is a structure of two pipes nested one into the other with thermal insulation between them. For a bath, its layer of expanded clay or basalt wool should be at least 50 mm.

It is important that the inner surface of the canal is smooth, not porous. This provides traction and prevents large amounts of soot from accumulating on the walls. Irregularities hinder the movement of smoke, so it is better if the inner part has a circular cross-section.

Features of the

The unique chimney device consists of three parts:

- inner pipe made of stainless steel of excellent strength and heat resistance;

- heat-insulating material in the form of basalt or ceramic wool, polyurethane foam, vermiculite.

- protective outer tube made of galvanized / stainless steel.

To improve aerodynamics, the designers have provided a cylinder shape. All three layers of stainless steel sandwich pipes are glued together, and some parts of the chimney are mounted, as in drainage pipes, with sockets.

Double-walled sandwiches solve the problem of condensation formation on the walls of the chimney in cold weather due to the insulation included in the structure. This insulation prevents soot from forming on the inner surface and prolongs the service life.

To facilitate the assembly of the prefabricated structure, fittings are available for connection, channel rotation and other functions.

- The main length of the chimney is carried out in segments of 1 and 0.5 m in length.

- Horizontal sections (loungers) are connected using revision tees to eliminate pipe clogging.

- A tee for collecting condensate and cleaning the internal cavity is installed at the beginning of the vertical section of the channel. This often happens immediately after the chimney exits to the outside of the building. One of the outlets of the tee is threaded to remove condensation moisture.

- The corners for the device for turning the chimney by 90º are made of pipe materials and insulated with an insulator layer.

- Compensator for smooth changes in the linear dimensions of the sandwich when changing temperatures.In high-rise buildings, it is installed on each floor, and in one-story buildings above the floor.

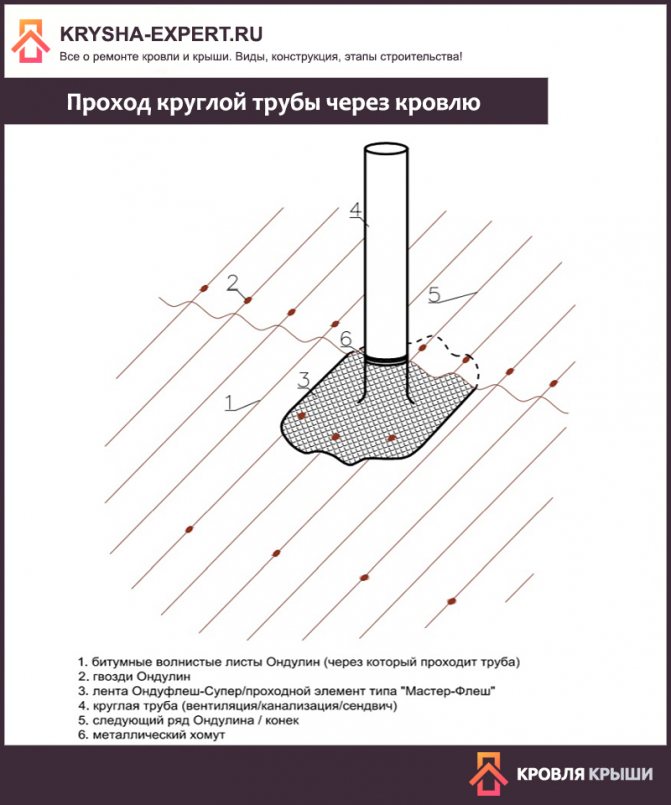

- The roof abutment structure is designed as a single unit and serves to form the exit of the chimney channel to the roof.

- Node for eliminating leakage in the roof outlet. Installation is carried out around the chimney.

- A tip to keep debris, snow and dust out of the duct openings.

Material

Stove pipes for a bath are made of the following materials:

- fired brick (silicate is not suitable) - has good heat exchange with the environment, is fireproof, a solid support is required for such a chimney;

- ceramics - resistant to high temperatures, physical and chemical influences, ceramic blocks are made specifically for chimneys.

- ferrous metal - to protect it from corrosion, it is covered with enamel, it can withstand temperatures up to 500 ° C, but is not suitable for intensively working baths;

- stainless steel - it is durable and lightweight, a pipe from it can be installed on a furnace with a wall thickness of half a brick, the best brand is AISI 321 (with an admixture of molybdenum), the material must be bought from a trusted manufacturer.

Asbestos cement is too porous material, easily absorbs condensate, which, when combined with soot, destroys the pipe, it can burst. To avoid this, it must be insulated and overlaid with brickwork. Chimneys with a galvanized outer casing are not used in the steam room. this material emits harmful substances when heated.

Wooden parts of the roof and roofs made of combustible materials have a high fire hazard. The pipe is placed from them at a distance of 15 and 30 cm, respectively, and these structural elements are insulated with roofing steel, flexible sheet asbestos.

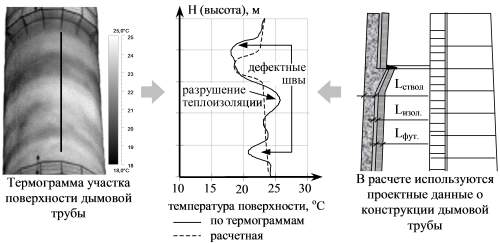

The main types of calculations for industrial chimneys

Designing industrial chimneys requires complex, multi-step calculations

Calculation of tube aerodynamics

Note!

This part of the design is needed to determine the minimum throughput of the structure.

It must be sufficient to ensure the trouble-free passage and further removal of fuel combustion products into the atmosphere, when operating the boiler room at maximum load.

It should be noted that the incorrectly calculated pipe throughput can cause the accumulation of gases in the duct or boiler.

A competent aerodynamic calculation makes it possible to objectively assess the performance of the blast and traction systems, as well as the pressure drop in the air and gas paths of the boiler room.

The result of aerodynamic calculations is the recommendations of specialists on the height and diameter of the chimney and optimization of sections and elements of the gas-air path.

Determination of the height of the structure

The next point of the project is the environmental substantiation of the pipe size, based on calculations of the dispersion of harmful products of fuel combustion in the atmosphere.

The chimney height is calculated based on the dispersion conditions for the emission of harmful substances.

In this case, all sanitary standards for commercial and industrial enterprises must be observed, as well as the background concentration of these substances must be taken into account.

The last characteristic is dependent on:

- the meteorological regime of the atmosphere in a given area;

- air mass flow rate;

- terrain;

- the temperature of the discharged gases and other factors.

During this design stage, it is determined:

- optimal pipe height;

- the maximum permitted volume of emission of harmful substances into the atmosphere.

Durability and stability of the pipe

Calculations are also needed to determine the structure of the pipe.

Further, the method for calculating the chimney provides for a set of calculations that determine the optimal stability and strength of the structure.

These calculations are performed to determine the ability of the selected structure to withstand the effects of external factors:

- seismic activity;

- soil behavior;

- wind and snow loads.

Operational factors are also taken into account:

- pipe weight;

- dynamic vibrations of equipment;

- thermal expansion.

Strength calculations make it possible to choose not only the structure and shape of the structure's trunk. They allow, and calculate the foundation for the chimney: determine its structure, depth, foot area, etc.

Thermal calculation

Heat engineering calculation is required:

- to find the thermal expansion of the material of the industrial chimney;

- determining the temperature of its outer casing;

- selection of the type and thickness of insulation for pipes.

Installing a pipe in a bath

The chimney can be installed like this:

- inside the bath with access through the roof;

- brought out through the wall to the outside of the building.

With an internal design, the pipe additionally heats the room. But its installation is considered difficult due to the need to eliminate gaps in the roof so that there are no leaks and to protect the roof from fire.

It is easier to make a chimney in a bath through the wall with your own hands. To do this, it is necessary to place the furnace near the outer wall and exclude contact of the gas or electric mains with sections of the structure.

Installation of the sauna chimney starts from the bottom - each section is inserted inside the previous one. All joints are clamped with clamps and treated with a sealant. The vertical part is installed assembled. Depending on the design and pipe outlet, the channel can have 1-2, maximum 3 turns. Installation recommendations are as follows:

- Part of the chimney is connected to the furnace branch pipe using an adapter. Then a piece of pipe with a gate valve (gate) is put on and sealed.

- The horizontal section is drawn through a hole in the wall with a diameter of at least 450 mm, a tee with fasteners for the vertical part is installed at its end.

- At the exit of the pipe, brickwork is made on cement mortar or a fire-resistant box is made of sheet metal or asbestos cement. A non-combustible thermal insulation material is placed between the walls of the box and the pipe.

- The vertical part of the chimney is attached to the wall with special brackets at a distance of 1 m.

- The lower outlet is blocked by a plug, which is removed when cleaning from soot.

- Inside the room, the channel laying area is sheathed with metal sheets, which will protect the wall surfaces from overheating and fire.

Sandwich pipe installation: highlights

All work on installing a sandwich chimney begins with marking and cutting out all the necessary technological holes. This refers to the ceiling or wall, as well as the roof itself. It should be borne in mind that the distance from the pipe to unprotected wooden structures should not be less than 40-45 cm. For fire safety purposes, let it be more than less. Otherwise, the use of protective screens is imperative!

Options for sandwich pipes for a bath

Installation of the "designer-chimney" is started from the bottom up. First of all, a single-circuit pipe is installed on the furnace. Due to the lack of insulation, heat transfer is significantly increased. For example, a single-circuit sandwich pipe for a bath can be completed with a hinged one. It is possible to use a cylindrical metal mesh for stones, which greatly increases the efficiency of the stove. The use of special economizers-convectors on the first chimney segment also increases the heat transfer coefficient.

The so-called starter adapter is mounted on the installed "single-circuit sleeve". It is needed in order to reliably and beautifully connect a single-wall pipe with a sandwich. Then a gate is mounted to adjust the draft level or a double-circuit chimney is immediately put on.

The following nuance should be clarified: sandwich pipes can be assembled in two ways ("by smoke" and "by condensate"). "On smoke" is when the upper pipe is pushed onto the lower one.At the same time, the smoke does not meet any obstacle. “By condensation” - the opposite is true: the upper segment is inserted into the lower one. For an optimal result, we put on the inner pipe sleeves “for smoke”, and the outer ones “for condensate”. For a better sealing effect, it is advisable to use a special heat-resistant sealant and crimping clamps.

Calculate the height of the chimney to the ceiling in such a way as to exclude the junction of the segments in the area of overlap. This will increase the degree. And now the most important point. Many people consider sandwich chimneys to be the absolute standard of safety and do not install a passage box in the ceiling passage, relying only on the thermal insulation of the pipes themselves.

The result is often very disastrous. It is compulsory to use the pass-through ceiling box. It will protect wooden structures from heat and fire. It can be covered with expanded clay, but not with sand. It is possible to use the same mineral wool as a heat insulator.

When passing the chimney through the roof, it is reasonable to use an element such as a flash master

... This is a special sealant for roofing passages, which in the common people is called a "flash drive". The element is necessary and practical, you cannot do without it. Here, a metal element of the roof cut is also used, which ensures a reliable and stable position of the chimney.

Chimney support bracket

Portable enamel sandwich

Ceiling cut

Depending on the design of the chimney, a "revision" is sometimes installed in the lower part. This sandwich pipe element is usually installed on a side chimney, which has a horizontal section. There is a small door for. A very convenient and necessary moment.

On the upper part of the chimney, spark arresters, umbrella-deflectors are installed. Purpose: to extinguish sparks and protect the pipe from atmospheric precipitation and debris.

When installing sandwich pipes for a chimney, you should exclude their touching various communications (electrical wiring, gas pipelines, water and sewer pipes, ventilation ducts). Following the manufacturer's instructions for assembling such a "constructor", you can easily do the installation of a chimney from a sandwich pipe with your own hands. It will not be difficult, although you still have to “move your brains” and work with your hands.

Quote of wisdom: He who does not need someone else's, but lives independently, is richer than everyone.

Between the two pipes of the chimney structure (external and internal) there is a material for thermal insulation. Basically, it is mineral wool (basalt or ceramic).

We offer you to familiarize yourself with Ventilation from sewer pipes - myth or reality?

Sometimes the natural material vermiculite acts as a heater. To use it for its intended purpose, it is preliminarily crushed to a granular state, and then fired in a special furnace.

Such procedures are necessary to obtain the highest quality characteristics:

- resistance to high temperatures and their drops;

- low weight;

- strength, etc.

Vermiculite is much more expensive than mineral wool, but it is distinguished by the ability to maintain its quality characteristics at an operating temperature of the chimney of 1150̊ С.

But ceramic wool is more heat-resistant and can withstand an operating temperature of 1260̊C, i.e. more than twice that of the previous material. Accordingly, the price of sandwiches with such a filler will be higher than pipes with basalt wool or vermiculite.

It is important to remember that the dimensions of the chimney sandwich pipe depend on the diameter of the boiler outlet. During installation, the product is mounted on it; therefore, the cross-section of the sandwich pipe must necessarily exceed the outlet pipe.

Today, chimney sandwiches with a cross-sectional area of 0.5 and 1 m are more in demand, but there are also diameters in the range of 110-300 mm. In the line of standard sizes of pipes for a chimney structure, there are other options, but much less often.

Pipe connecting elements have corners:

- 90̊ С - for corners and tees;

- 135 ° C - only for tees.

The thickness of the inner wall is 0.5-1 mm, and the outer wall is 0.7 mm. The indicator of the thickness of the layer of internal thermal insulation ranges from 2.5-6 cm, and the outer diameter of the sandwich structure is 200-430 mm.

How to calculate the diameter of the chimney

When designing a chimney, you must choose the material to use. And the material largely depends on what kind of fuel will be used for heating. After all, the chimney is designed to remove the combustion residues of one fuel, and will not work with another. For example, a brick chimney works great with wood, but is not suitable for gas-fired heaters.

In addition, a correct calculation of the diameter of the chimney is required. If the flue gas vent is used for a single heater, the problem can be solved by reviewing the technical documents provided by the manufacturer of the appliance. And if several different systems are connected to one pipe, then to calculate the chimney, you need knowledge of the laws of thermodynamics, professional calculation, especially the diameter of the pipe. It is wrong to assume that a larger diameter is needed.

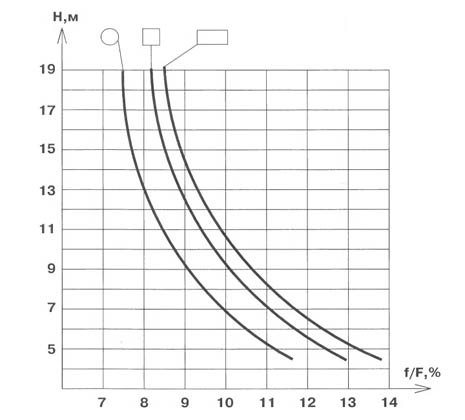

Swedish method

Among the different methods for calculating the diameter, an optimally suitable scheme is important, especially if the devices are low-temperature and long-burning.

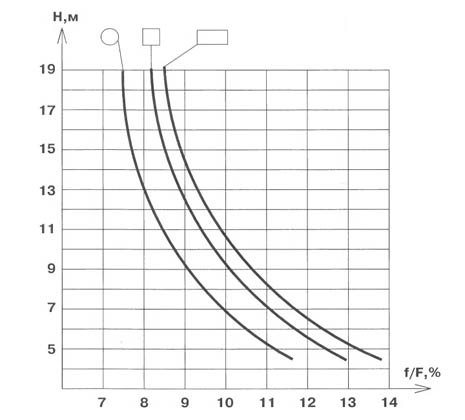

To determine the height, the ratio of the cross-sectional area of the chimney to the internal combustion chamber is taken into account. The height of the pipe is determined according to the schedule:

Where f is the area of the chimney cut, and F is the area of the furnace.

Suppose, for example, the cross-sectional area of the furnace F is 70 * 45 = 3150 sq. cm, and the cross-section of the chimney f is 26 * 15 = 390. The ratio between the above parameters is (390/3150) * 100% = 12.3%. Having compared the obtained result with the graph, we see that the height of the chimney is approximately 5 m.

Important! This method of calculation is more suitable for fireplaces, because it does not take into account the volume of air inside the firebox.

Important! In the case of installing a chimney for complex heating systems, it is important to calculate the parameters of the chimney.

Exact calculation

To calculate the required section of the chimney, be sure to take into account all its characteristics. For example, you can perform a standard calculation of the dimensions of a chimney connected to a wood-burning stove. They take the following data for calculations:

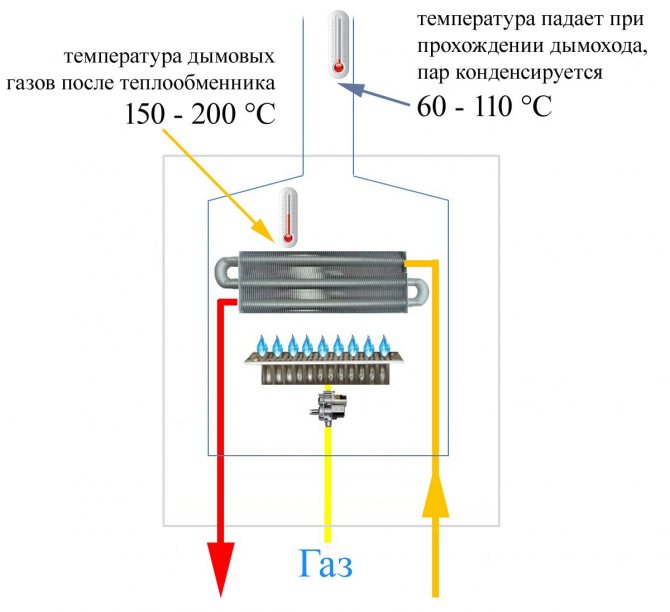

- the temperature of the combustion waste in the pipe is equal to t = 150 ° С;

- the speed of passage through the waste pipeline is 2 m / s;

- the burning rate of wood B is 10 kg / h.

If you follow these indicators, you can do the calculations. For this purpose, the amount of outgoing combustion products is calculated by the formula:

Here V is equal to the amount of air required for fuel combustion at a rate of v = 10 kg / h. It is equal to 10 m³ / kg.

Then the required diameter is calculated:

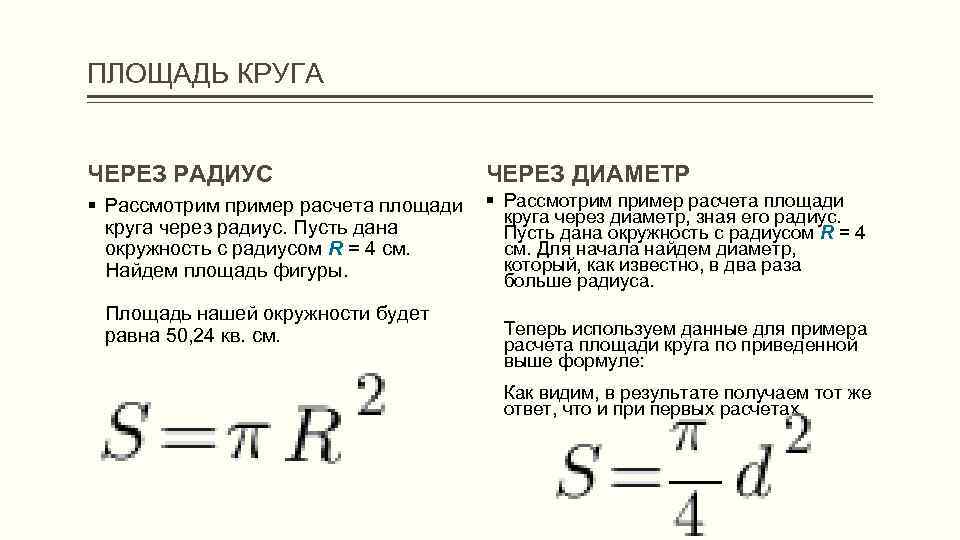

How to calculate the chimney cross-sectional area?

There are several methods for calculating the optimal section. For example, from the size of the hearth combustion chamber or from the area of the furnace blowing window. But in this publication, attention will be focused on the methodology, which is based on the assessment of the volume of flue gases formed during combustion.

The combustion of wood and other solid fuels is always accompanied by a very significant smoke generation. And the chimney must be able to divert these volumes to the outside in a timely manner.

On the basis of calculations and experiments, specialists have long compiled tables from which it is possible to obtain information on the specific smoke production for different types of solid fuels. That is, what volume of combustion products is formed when burning, say, one kilogram of firewood, coal, peat, etc.

We will also present such a table (in an abbreviated version). In addition to specific smoke generation, it shows the calorific value of the fuel (the amount of heat released during the combustion of one kilogram) and the approximate temperature of the combustion products at the exit from the chimney. The first of these characteristics is not of particular interest to us at a given moment - it just gives a general idea of the fuel efficiency. But the temperature, yes, is needed for calculations.

| Fuel type | Specific calorific value of fuel, kcal / kg, averaged | Specific volume of emitted combustion products from combustion 1 kg, m³ | Recommended temperature at the exit from the chimney, ° С |

| Firewood with an average humidity level - 25% | 3300 | 10 | 150 |

| Peat lumpy (in bulk), air drying, with an average moisture level not exceeding 30% | 3000 | 10 | 130 |

| Peat - briquettes | 4000 | 11 | 130 |

| Brown coal | 4700 | 12 | 120 |

| Hard coal | 5200 | 17 | 110 |

| Anthracite | 7000 | 17 | 110 |

| Pellets or wood fuel briquettes | 4800 | 9 | 150 |

As you can see, the volumes are impressive. Even the types of fuel that give the minimum smokiness are already about 10 cubic meters for each kilogram burned. This means that simply for reasons of physics and geometry, the cross section of the chimney should be able to constantly divert these considerable volumes out.

From this and "dance" when calculating.

chimney

The volume of combustion products released during the combustion of solid fuel within an hour can be determined by the following formula (taking into account the thermal expansion of gases).

Vgh = Vsp × Mth × (1 Td / 273))

Vgч is the volume of combustion products generated within an hour.

Vsp is the specific volume of the generated combustion products for the selected type of fuel, m³ / kg (from the table).

Mtch is the mass of the fuel load burned during one hour. It is usually found as the ratio of the total fuel load to the time of its complete burnout. For example, 12 kg of firewood is loaded into the oven at once, and they burn out in 3 hours. This means that Mtch = 12/3 = 4 kg / hour.

Тд - gas temperature (℃) at the outlet of the chimney (from the table).

273 is a constant to bring the temperature parameters to the Kelvin scale used in thermodynamic calculations.

We suggest that you familiarize yourself with the Wood-burning water heater with your own hands

Vgс = Vgч / 3600

To find out the cross-sectional area of the channel, which is guaranteed to pass this volume through itself at a certain speed of gas movement, it is necessary to find their ratio

Sc = Vgc / Fd

Sc - cross-sectional area of the chimney channel, m2.

Fd - gas flow rate in the chimney, m / s

A few words about this speed. For heating devices and structures of a household class, they usually tend to stop in the range from 1.5 to 2.5 m / s. With this, on the one hand, low speed, there is no significant resistance to the flow, there are no strong eddies that slow down the movement of gases.

If a cross-section is found (and this is its minimum value), then according to the known geometric formulas, one can find either the diameter for a pipe of circular cross-section, or the length of the side - with a square cross-section, or choose the lengths of the sides with a rectangular one.

Below is a calculator that will simplify these calculations to the limit. It is necessary to indicate the type of fuel, the approximate consumption of its consumption (more precisely, the mass and burnout time of the full load) and the expected flow rate of gases in the chimney. The program will do the rest by itself.

- the minimum diameter for a circular section;

- the minimum side length for a square section;

- cross-sectional area, according to which, for example, you can choose the dimensions of the sides for a rectangular section

Go to calculations

Chimney diameter table

Nowadays, the tables of diameters compiled for various chimneys are relevant, since many prefer to install ready-made pipe elements from various materials.In order to easily understand these various materials and learn how to choose the correct parameters, documents with regulatory data entered into special tables have been developed. The relevant parameters are listed here. To calculate the required dimensions, you can use these tables.

Attention! It should be remembered that the cross-section of the flue pipe must be greater than or equal to the cross-section of the internal channel of the heater.

The exact tables of the calculated diameters of the flue pipe for its correct operation are calculated in accordance with the technical parameters of all elements, in accordance with the recommendations of specialists, the materials of the flue duct, or using the diameter - power tables.

Chimney diameter.

Installing the chimney, it is very important to calculate the correct chimney diameter, this issue needs to be given special attention when designing an autonomous heating system. Often the chimney is selected based on approximate parameters. Many ordinary people believe that it would be better to make the diameter of the chimney section larger, but this is not at all the case. In order for the heating system to function optimally, an accurate calculation of the chimney diameter is required.

What should be the height of the chimney pipe for the stove?

The calculation of this parameter allows you to avoid the occurrence of reverse thrust and other possible troubles. This issue is regulated by the rules of SNiP and other documents.

Why is this parameter needed?

In order to understand the importance of this factor, we will analyze in more detail several physical laws and the consequences of improperly made chimneys. When heated gases pass, the temperature drops, but warm air or gases always rise up.

Initial parameters calculation of the chimney.

To calculate the chimney, you can use the chimney calculator.

The characteristics of the future chimney are directly influenced by certain parameters, of which the most important are:

1. Type of heater. The organization of the gas discharge system in most cases is necessary for solid fuel boilers and furnaces. The calculation takes into account the volume of the combustion chamber, as well as the area of the opening of the chamber for the intake of air into the furnace - the ash pan. Often, the calculation is made for home-made boilers that run on diesel fuel or gas.

2. The total length of the chimney and its configuration. The most optimal design is considered to be 5 meters long and with a straight line. Additional vortex zones that adversely affect thrust are created by each pivot angle.

3. The geometry of the chimney section. The ideal option is the cylindrical design of the chimney. But this shape is very difficult to achieve for brickwork. Less effective is a rectangular (square) section of the chimney, but it will also require less labor.

Types of connecting elements

The heating device, in addition to sandwich pipes, includes other fittings, for example:

- chimney-convector, used for the exit of combustion products outside the building;

- knee, consisting of several parts, which are joined together at an appropriate angle. With the help of the knee, you can change the direction of the output of combustion products;

- a tee that performs the function of removing condensate and smoke is used very often;

- an adapter for connecting some pipes, the most common element;

- revision - to clean the structure from soot;

- kagla regulating traction;

- rosette - for decorating the chimney;

- weather vane and cone that protect the heating system from natural precipitation;

- a fungus made of galvanized steel sheet, which protects the chimney structure from snow and rain. Installed at the very edge of the outlet pipe.

All these connecting elements can have diameters: 120, 150,200 mm and are used depending on the design features of the chimney device and other factors. The diameter of the inner pipe always corresponds to the size of the chimney sandwich and its accessories.

Approximate and accurate calculation of the chimney diameter.

Accurate calculations are based on a complex mathematical platform. To calculate the diameter of the chimney, you need to know its main characteristics, as well as the characteristics of the fuel and the heating device. For example, you can take the calculation of a standard pipe with a circular cross-section without rotary nodes, connected to a stove and running on wood. The following input parameters of the calculation are taken:

- temperature of gases at the entrance to the pipe t– 150 ° С;

- the average speed of passage of gases along the entire length - 2 m / s;

- firewood (fuel) burning rate with one tab B = 10 kg / h.

Following this data, you can go directly to the calculations. First, you need to find out what volume of exhaust gases is, it is determined by the formula:

Where V is the volume of air required to maintain the combustion process at a rate of 10 kg / h. It equals - 10 m³ / kg.

Substituting this value, we get the result:

Then we substitute this value into the formula by which the diameter of the chimney is calculated:

To make such a calculation, you need to know exactly all the parameters in the future gas removal system. This scheme is very rarely used in practice, especially in the case of organizing a household autonomous heating system. Determine the diameter of the chimney it is possible in other ways.

For example, based on the dimensions of the combustion chamber. Since the amount of fuel burned depends on its size, then the volume of incoming gases also depends on it. If an open firebox and a chimney with a circular cross-section, then the ratio is taken 1:10. That is, when the size of the combustion chamber is 50 * 40 cm, then the optimal chimney diameter will be 18 cm.

When erecting a brick structure of a chimney, the ratio is 1: 1.5. Chimney diameter in this case, it must be larger than the size of the blower. The square section will be at least 140 * 140 mm (this is due to the vortices created in the brick pipe).

Choosing the right chimney

The dimensions of the chimney used simultaneously for several heating devices is a separate topic for conversation.

If it is necessary to remove smoke from a number of heating devices, then the chimney is calculated taking into account all heating devices used in the system, their type, power, fuel consumed.

- For example, in a house with a single chimney, several heating devices, a boiler for a common heating system and a fireplace are installed.

- It immediately becomes clear that we have completely different systems. The chimney diameter of the fireplace does not correspond at all to the diameter of the boiler chimney.

- As a rule, fireplaces run on wood fuel, and boilers for the heating system at home run on natural gas.

Is it possible to combine these 2 completely different systems? Can. Moreover, with the correct placement of heating devices, they not only will not create problems, but will also complement each other.

How does this happen?

- One chimney includes a boiler and a fireplace. During operation, the boiler periodically turns off and goes into standby mode. At this time, we have a fireplace. Therefore, a normal temperature is maintained in the chimney, the gases do not cool down.

- Hence the absence of condensation and good draft during the next boiler start-up.

- But the size of the chimney for the fireplace should be much larger than for the boiler. And if we use only the boiler without starting the fireplace, we may have problems with excessive draft, leading to improper operation of the boiler.

- As we know, the chimney diameter for a fireplace is calculated at a ratio of 1:10 to its firebox. It becomes clear that such a chimney diameter is very large for a boiler.People rarely use the fireplace, and the heating boiler works constantly in the winter.

- So, you need to make a chimney with a smaller diameter, suitable for the boiler? No, that would be a big mistake. When the boiler works on its own, everything will be fine. When the fireplace starts up, increased aerodynamic resistance will be created in the chimney.

Two-way chimney. Fig. one

As a result:

- improper operation of heating devices;

- ingress of carbon monoxide gases into the room.

This is already life-threatening. Carbon monoxide poisoning is often fatal.

How can this issue be resolved?

Our advice is to use a two-way chimney.

Two-way chimney. Fig. 2

- the possibility of using various heating devices simultaneously and separately in one chimney;

- stable operation of each device;

- savings in construction and installation;

- saving space.

When installing such a chimney, it is necessary to comply with all conditions for the correct operation of each device. If the fireplace can function perfectly with a brick chimney, then a sleeve must be made for the boiler. This will protect the brick from the alkaline effects of condensation.

The "Fireplaces and Stoves" store offers a wide range of stove pipes and chimneys from reliable manufacturers. In our catalog you will find single-walled chimney systems for liner and protection against aggressive condensation of brick ducts. We also have double-walled models with a heat-insulating layer, with the help of which chimneys are equipped outside the room. Sandwich pipes do not allow flue gases to cool down quickly, preventing a decrease in draft in the cold season.

When choosing a chimney for a bathhouse, a cottage or a small country house, it is important to purchase truly high-quality products. This is the only way to ensure the correct operation of modern heating equipment. Our task is to help you make the right decision!

In this case, some factors are important:

- The high-quality functioning of the entire sandwich structure is in direct proportion to the strength of the material used in its manufacture.

- Sandwich pipe dimensions.

- The density of the insulation layer.

- Type of pipe seam (rolled, laser).

Swedish method for calculating the diameter of the chimney.

In the above examples, the height of the flue system is not taken into account. For it, the ratio of the area of the combustion chamber to the cross-section of the pipe is used, taking into account its height. The pipe value is determined according to the graph:

Where f is the area of the chimney, and F is the area of the furnace.

However, this method is more applicable to fireplace systems, since the volume of air for the firebox is not taken into account.

You can choose from different methods for calculating the diameter of the chimney, but when installing complex heating systems, an optimally accurate scheme is important, especially for low-temperature long-burning heaters.

Effect of diameter on pipe height

As is clear from the above, the work of any heating equipment consists in the fact that for the formation of good draft, warm air must cool down gradually, that is, the closer to the end of the chimney, the colder the air. If the diameter of the pipe is too large for the chimney, then the cross-sections inside it too, then the cooling of warm air occurs several times faster. As a result, moisture is formed, which is called condensate. It is he who negatively affects the quality of traction. The “dew point” is the optimum temperature at which moisture from the air turns into water.

In such a situation, it can help if the height is made higher by reducing the sections. Then a sufficiently strong thrust can form, leading to a decrease in the efficiency of the heating device. But it must be taken into account that the air flow increases sharply and the device heats up badly. As a result, more fuel and more time will be spent on heating the premises.

Let's look at another option that is often used and is erroneous. Many non-professional builders believe that if the chimney is made high and the size of the sections inside it is reduced, then the draft will improve. This is not true! The opposite is happening here. It is even possible that smoke from the chimney will start to enter the living space of the house. As a result, the premises will be filled with carbon monoxide, which will lead to disastrous consequences.

According to the recommendations of experts, it will be ideal if the cross-section of the pipe is the same as the size of the blower hole.

Do-it-yourself chimney in the bath

Photo from the site Tuning-house.ru

A private bath is a sign of success and an indispensable attribute of every wealthy owner of a private house. If you plan to build such a structure on your own, you will need to carefully approach the calculations. In order to correctly install the chimney, you need to research what the options are and how to install them correctly. A correctly selected smoke outlet will not only allow your steam room to function evenly, but also to remain a safe place.

Today in the article we will tell you how to correctly make, install and bring the chimney in the bath through the wall with your own hands, as well as which of the options is best for your structure.

How to install a pipe in a bath: what devices are there

The installation of a chimney in a steam room can be done in several ways, depending on the place of the stove. The types of smoke removal are distributed according to the following indicators:

- Used raw materials. There are two options here - a metal chimney or a structure made of fire-resistant bricks. The second way is classic. It has long been used by most builders. However, in recent years, many people have preferred metal structures when building a chimney. The main reason for this is that such pipes are easy to install by yourself and it will take much less time.

- Installation method. There are two methods - internal and external chimney. A logical question arises: how to get the pipe out of the bath through the wall? For this, a special hole is drilled and the whole system goes outside. This type is also called North American. This method of constructing smoke ventilation does not have the main drawback of the generally accepted installation method - installing a pipe through the ceiling. This means that you do not have to perform complex manipulations to withdraw the bend. It is enough to drill a hole in the wall and lay the pipe outside. The installation of a chimney in a bath through the ceiling is more costly to install, so we recommend using a proven method.

If you are in doubt and do not know which type of chimney to choose, keep in mind that the metal version is much cheaper and easier to install. Next, we will consider the advantages and disadvantages of each type of pipe.

How to put a pipe in a bath correctly: the advantages of brick devices

In comparison with the metal counterpart, this method has been used for much longer. Previously, there were no metals in the production that could withstand extremely high temperatures. Making a brick chimney is a very painstaking task and requires professional training, experience and perfectly verified calculations. We highly do not recommend building such a device yourself, unless you are a pro. Unlike metal pipes, the brick masonry method has the following advantages:

- Thermal and thermal insulation. The old and proven method will allow you to keep warm inside the bath for a long time. Vapor circulation is also improved.

- Durability. The bend, made of refractory bricks, lasts much longer than its iron counterpart. The construction, built according to the correct drawings and made of high-quality material, will delight the owner for many years, and the system will not have to be replaced.

- High fire resistance.The bathhouse is a place with an increased risk of fires, therefore safety and fire resistance become one of the main indicators when choosing materials. The brick structure will prevent the flames from spreading, thereby protecting both the property and the owner himself.

An important feature of the maintenance of a brick chimney is the need for periodic cleaning. The surface of the material tends to collect dust, ash and other elements on itself, thereby impairing the throughput and traction of the pipe. The cleaning process is not complicated and will help keep your sauna clean and safe.

Brick pipe for a chimney in a bath: how and how to clean a chimney

To perform this procedure, it is not necessary to call a specialist, the cleaning technology is simple and within the power of every person. To do this, you will need brushes and chemicals to remove dirt.

The easiest method is to work with a nylon brush. Treat it in the solution and start cleaning.

Varieties of chimney

Currently, the most popular are pipes for removing smoke from the following materials:

- Brick.

- Steel.

- Steel plus sandwich panels.

- Corrugated steel.

- Ceramics.

- Asbestos with cement.

- Polymeric material.

Brick chimneys

Chimneys made of this material have been very popular until recently. Brick has been used in their construction for a long time. A prerequisite for the construction of a chimney from this material is that the brick must be solid, and the channels must be located in the brickwork itself.

Positive properties include:

- Mechanical strength;

- Brick gives off heat for a long time.

- Subject to the necessary fire safety requirements, a chimney made of this material can be classified as safe.

Brick pipe

Experts refer to negative qualities:

- Since the brick is rectangular, smoke can linger in the corners of the pipe.

- The rough outer surface also affects the rate at which smoke is removed from the heater.

- Clay, which is used to make bricks, has a porous structure. As a result, they are susceptible to internal destruction, since condensate settles on the walls of the chimney over time.

- Brickwork is a very massive structure that requires additional laying of the foundation.

- It takes a lot of time and effort to build a brick chimney.

- Difficult to maintain and repair.

- Additional lighting devices are used to check the chimney channel.

Steel

Steel is used in the manufacture of the following types of pipes: modular, steel single-circuit chimneys. These are constructions that are assembled from separate parts, like a constructor. The best material for the manufacture of such a chimney is recognized as steel with increased heat resistance, acid resistance, as well as "stainless steel". The thickness of the steel sheet varies from 0.6 to 1 millimeter. But, unfortunately, these chimneys quickly fail.

Advantages of a modular steel single-circuit chimney.

- It has a round cross-section.

- The inside is smooth.

- It is not expensive.

- Very easy to assemble.

- Easy to make repairs.

- Excellent corrosion resistance.

The main disadvantages include:

- In such structures, there is no heat-insulating material, therefore, the gases in such a chimney quickly cool down.

- Not long service life on average about 12 years.

Steel corrugated chimneys

The corrugated steel chimney is so called because it is a very flexible pipe made from the thinnest strip of steel. It is used for waterproofing in chimneys of their ceramic bricks, that is, the pipes are finished with this material inside. Their cost is quite high.

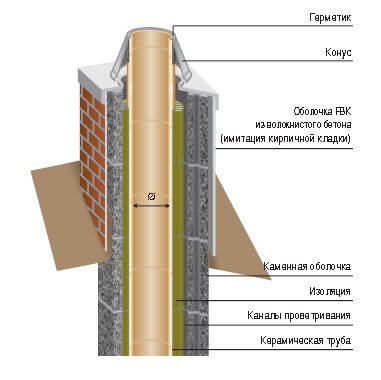

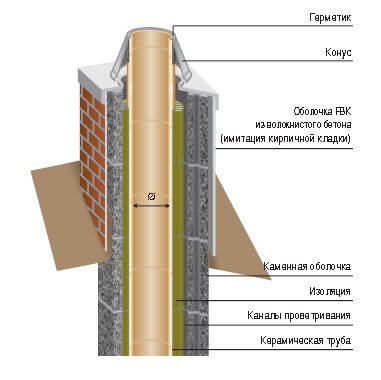

Chimneys made of ceramics

This is a relatively new material, but it has already won its market share and has received recognition from builders.Such a chimney usually includes three main parts:

- Chimney made of refractory ceramics.

- Thermal insulation (non-combustible insulation).

- External box for protection. Consists of cellular concrete blocks.

There are more positive characteristics in use and operation:

- The cross section is only round.

- Smooth surface inside.

- Refractory material.

- Excellent thermal insulation and tightness.

- Simple installation.

- Reliable and durable.

As for the minus. He is the only one - it is very expensive.

Chimneys made of asbestos and cement

It is used only for those heating devices, the heating of which does not exceed 300 degrees Celsius. This limitation is directly related to the fact that the material from which such pipes are made has a low fire resistance.

There are only four main advantages:

- It weighs a little.

- It has round sections.

- Easy to build.

- It is inexpensive.

The disadvantages include:

- Low heat resistance.

- Quite fragile material.

- No insulation.

- When performing turns in the structure, it is very difficult to mount.

- The material has a porous structure.

- Requires constant cleaning.

Chimneys made of polymer materials

It is mainly used to repair and create additional waterproofing of old chimneys. Heat resistance is not high. So the application is limited, only to those heating equipment that has a low temperature.

The positive properties include:

- Elasticity.

- It weighs a little.

- Easy to build and install.

- By service life - wear-resistant material.

- It is inexpensive.

Negative characteristics include:

- Low heat resistance.

- Low resistance to mechanical damage.

Chimney operation recommendations

When operating chimneys, you should avoid:

- Dry any items.

- Clean soot by burning.

- Violate the operating rules stipulated in the equipment documentation. Each heating unit has instructions for further operation of the chimney.

- It is strictly forbidden to use chlorine-containing substances.

- It is also worth avoiding close storage from heating equipment and its components, substances that are flammable.

- Use household chemicals, litter in the form of building materials as fuel.

- For better functioning, smoke generators are installed in the chimney.

Fire safety

In case of fire, it is best to wrap the chimney pipe. It is quite simple to do at the present time, since the range of such materials is large.

Advantages of a metal chimney

If you plan to install a pipe in a bath with your own hands, the most convenient solution is a chimney from an iron pipe. In any building supermarket or market, you will find many ready-made units. The advantages of such systems include:

- Affordable prices. The cost of such a solution is several times lower than that of brick chimneys.

- Simple installation. The entire installation process can be performed independently and without resorting to expensive wizard services.

- Ease of use. Unlike brick, the surface of the metal is smooth, which means that soot and other dirt will not accumulate on the walls. Thus, you will save your own efforts and time, since there is no need to clean the chimney.

Metal structures also have their drawbacks. The most important of these is poor thermal insulation. In winter, the element brought out to the outside will accumulate condensation on itself. To solve this problem, sandwich pipes have been created. They consist of two layers of metal with thermal insulation material between them.

Next, we will tell you how to properly install the pipe in the bath.

Do-it-yourself chimney installation in a bath: a step-by-step guide

First of all, to start the installation, you should draw up the correct diagram for your chimney. We advise you to contact a specialist.He will arrange a detailed plan for how to make the chimney in the bath and install the outlet through the ceiling and roof. The choice should first of all be based on the oven installed in the bath. Each unit has its own requirements and the pipe should be chosen based on these indicators.

Then you need to select the material of the bend. If you plan to carry out the installation yourself, we advise you to take a closer look at the metal options.

Now let's take a look at the step-by-step instructions for installing and passing the pipe into the bath through the ceiling.

- Step 1. Insulate the passage in the ceiling for the chimney in the bath. It is important to leave a gap of ten centimeters between the bend and the surface. We recommend using glass wool for fencing.

- Step 2. Install the unloading assembly. It is this part of the chimney that takes over all the loads and dampens lateral vibrations.

- Step 3. Assemble the starter sandwich. An important point - this part must fit snugly to the main pipe, otherwise you can allow the room to smoke.

- Step 4. Place clamps or fasteners on all pipe connections. This will maintain the tightness inside the system.

- Step 5. Close the chimney passage through the ceiling in the bath. To prevent warm air from escaping, use mineral wool to block the hole.

- Step 6. Passage of the ceiling and roof for the pipe in the bath. After insulating the hole in the ceiling, drill a hole in the roof. The chimney outlet must be half a meter above the roof level.

- Step 7. How to fix the chimney pipe on the roof? Install the accessory and fix it tightly. This will be enough for the element to hold firmly.

Chimney for a bath: installation diagram

Today we looked at how to put and mount a pipe in a rooftop bath, talked about the types of chimneys and gave useful tips. If you follow the suggested rules, installing the chimney will be an easy task for you.

Article rating:

How to calculate the diameter of the chimney for a bathLink to the main publication

Similar publications

- Soft roof ventilation roof aerator

Technological regulations and rules for installing a chimney

All standards for the competent determination of the height of the gas duct in relation to the ridge are established by SNiP 2-04-05 / 91.

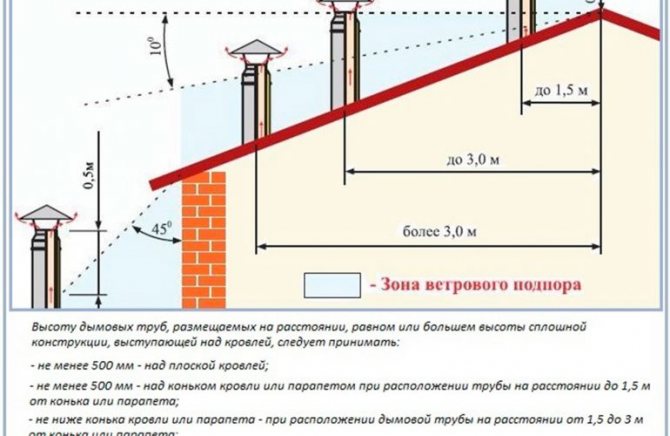

According to the requirements of the standard:

- The total length of the chimney must be more than 5.0 m.In buildings where there is no attic, the height of the chimney is taken to be less than 5.0 m.

- In this case, the condition for creating a working draft will be fulfilled.

- The height of the part of the channel, which protrudes beyond the border of the roof, must be more than 500 mm.

- Above the ridge, it should protrude 500 mm or more, in cases where the gap between it and the ridge does not exceed 1500 mm.

- The length of the pipe is taken to be equal to the height of the ridge or slightly more if part of the horizontal surface from it to the ridge contour is set in the range from 1500 to 3000 mm.

- The maximum level of the pipe must be above the line drawn from the ridge to the eaves at an inclination of 10 degrees.

- If the distance of the chimney from the ridge is 1500 mm, then the height is set taking into account the configuration of the structure.

Chimney installation

Before you establish how high the chimney should be, perform the calculation:

- On the diagram, a parallel line is drawn in relation to the soil level. From this line, at the point where the roof intersects with the smoke channel, a section of 500 mm is marked on the top on a similar scale.

- At the newly formed point, a new line is drawn - this will be the smallest height at which the mouth of the pipe will be located.

- According to this method, the maximum size of the pipe height is set if the distance between the ridge and the pipe is more than 1500 mm, but less than 3000 mm. A horizontal line is laid from the top on the roof structure, indicating a lower level of the pipe section.

- It must be remembered that it is prohibited to increase the height of the pipe above the roof in violation of the standards. A large wind pressure can easily bring down such a chimney.