The operation of water heating systems can be accompanied by the ingress of air into the inner cavity of pipes, radiators and a heat source. The appearance of an air lock leads to a change in the parameters of the coolant in individual sections or in the entire heating main. Airing the boiler can lead to overheating of the heat exchanger and failure of the heating equipment. Each user of an autonomous heating system should be able to independently get rid of congestions that arise inside the water system.

How to bleed air from the boiler

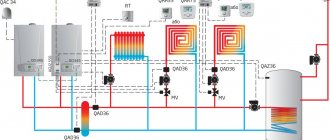

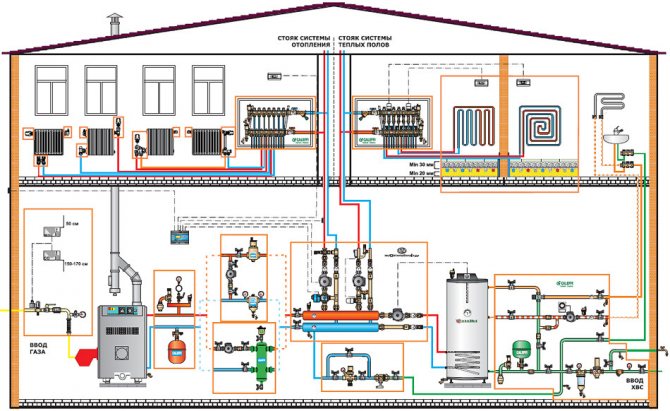

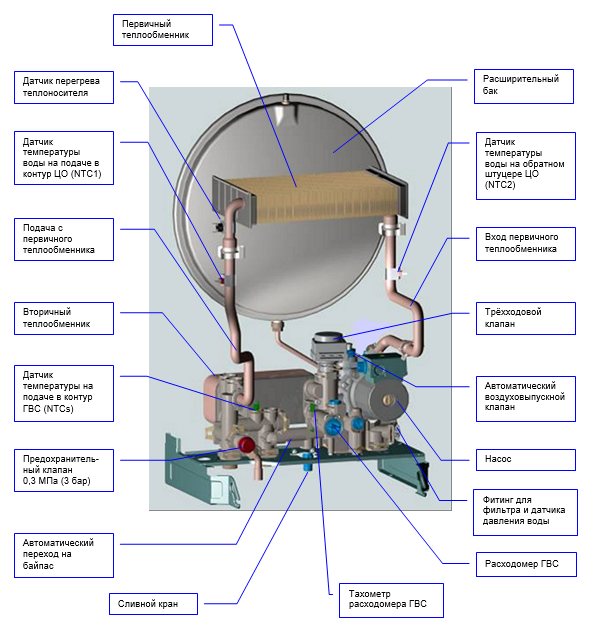

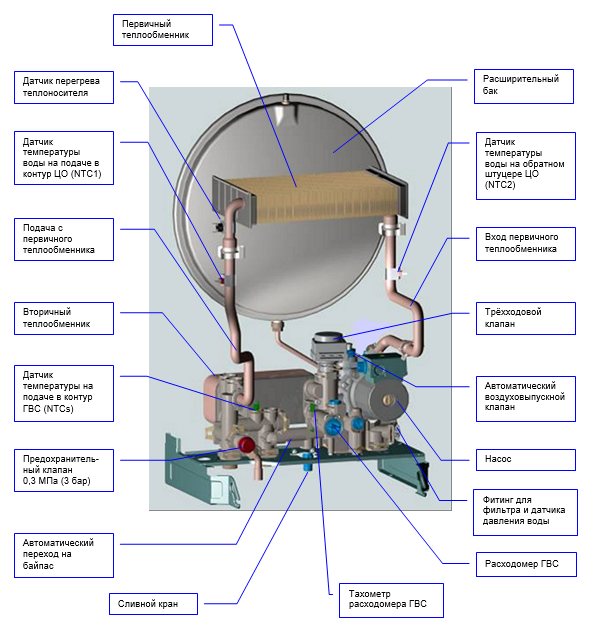

Modern heat sources are equipped with automatic air vents or Mayevsky taps located in the upper part of the unit. Such a constructive solution allows air to be vented during operating mode without stopping the heating process of the room, just like from any radiator on which a similar valve is installed.

To do this, periodically open and close Mayevsky's tap, at intervals of several minutes. The procedure is repeated until a hiss or whistle appears, indicating the release of an airlock. The appearance of sound requires holding the bleed device in the open position until the coolant appears.

ATTENTION! The automatic air vent must remove plugs from the boiler itself when the unit is in operation. But if it is possible to bleed air from the heat exchanger after pressing the spool located under the cap of this device, then this indicates a malfunction of the air vent!

The lack of special devices for eliminating plugs on the boiler requires resorting to the help of the same devices on pipelines located above the heat source.

REFERENCE! Correctly mounted autonomous and stationary heating systems are equipped with bleed elements at the top points of the mains and next to all devices that produce or give off heat!

The ideal conditions for clearing the air lock in the boiler is the possibility of a separate shut-off of the heat source circuit with a return pipe and a circulation pump. When turned on, the pumping of the coolant is ensured, and periodic opening of the Mayevsky valve or control over the operation of the automatic air vent, by pressing the spool, allows the closed circuit to be released from the plug.

If there is no circulation pump in the closed circuit, which cuts off the boiler with a return pipeline, then the energy source is turned on: gas, electricity, and in the solid fuel, the furnace is ignited. After heating the "supply" pipeline, the air release device is periodically opened. The heating medium, when heated, will rise from the boiler along the main line due to heating and return through the connecting pipeline - back to the heat exchanger. This technique requires careful temperature monitoring, especially when servicing a non-solid fuel heat source. The movement of the coolant along such a circuit will be very slow and this is taken into account when performing work.

If there is no possibility of shutting off the boiler water circuit and there are devices for venting air only in the upper part of the line, it is necessary to drain the coolant, and then fill in the entire required volume of water. Before embarking on such global events, it is recommended to cut off all devices (except for the boiler) and, by turning on the pump, release the pressure through the nearest air vent on the line until sound or bubbles appear. The lack of a result indicates the need for complete drainage of the coolant.

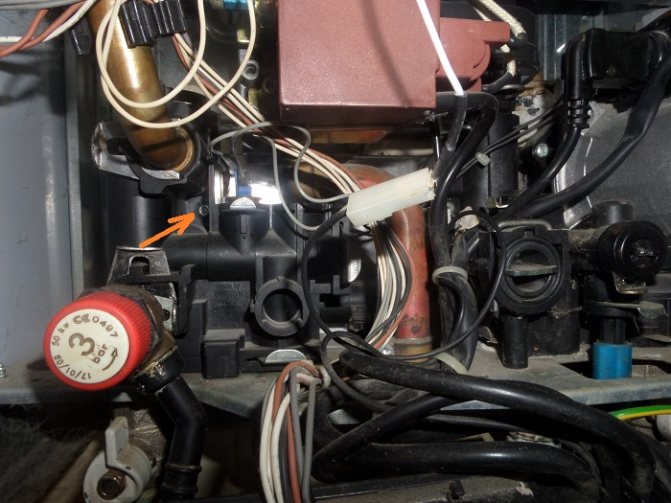

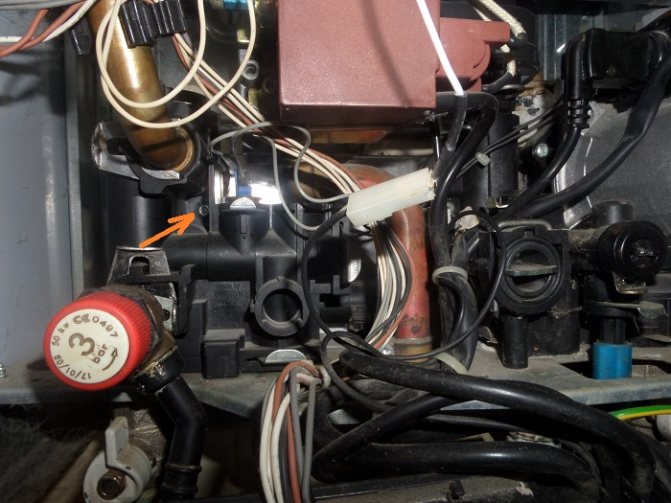

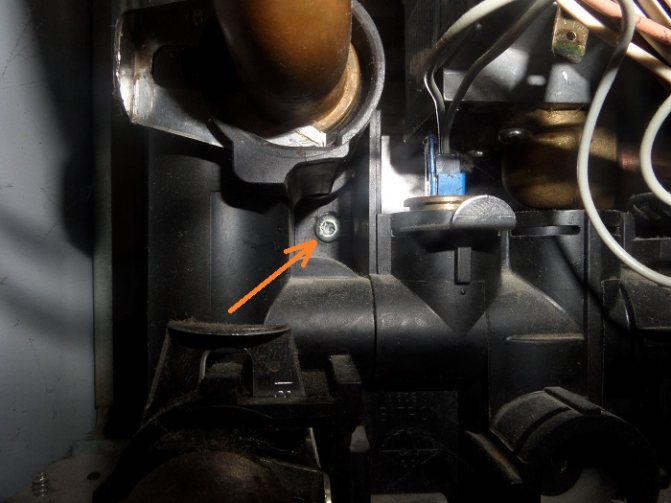

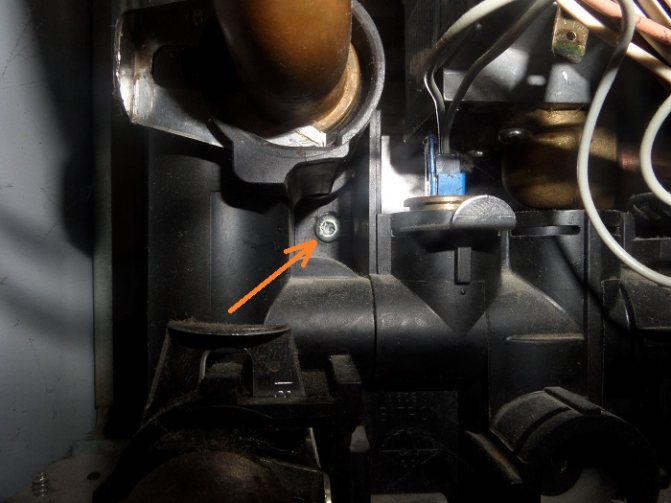

IMPORTANT! The blockage may not form in the boiler itself, but inside the pump, which is built into the body of the unit! To get rid of the air that has formed in the impeller cavity, unscrew the central pump screw by 1-1.5 turns and back, until bubbles appear!

How to remove air from the heating system

First you need to determine where the airlock is. This can be done as follows: lowering the temperature in devices, tapping system elements or by the characteristic sound in pipes.

After determining the location of the formation of an air lock, it is necessary to find the air vent, which is closest to the highest point in the direction of movement of the heat carrier. In order to get rid of the air, it is necessary to turn on the make-up of the system.

But there are times when it is impossible to determine the location of the airlock formation. In this case, you need to seek help from the methods of specialists:

- As the pressure in the system rises and the temperature rises, the plug will either be removed by automatic devices or moved to a place where it can be found.

- If you hit the pipes hard, the possibly generated air will move. But this method does not always work.

If during the period of use of the heating system, its airing often occurs, then it is necessary to find and eliminate the cause of its appearance.

Reasons for air entering the heating system

The formation of traffic jams can be caused by various reasons, we will consider them in more detail.

- Lack of tightness of assembly joints. Especially often this reason is the initial one when operating systems without pressure. Small water leakage is not visible and borders on possible evaporation. In the place of a loose connection, air is sucked in and accumulates in the free cavity of the line, forming a plug.

- Inaccuracy in the design or installation of highways, which entails the creation of unwanted "loops" that inhibit the movement of the coolant, entails the accumulation of air in such circuits.

- A low-tech method of filling the system with a coolant is also the reason for the appearance of blockages. Very fast or top-down directional filling of the lines promotes the formation of air gaps that impede normal operation.

- Malfunctioning of the automatic air vents located on the upper pipelines provokes the creation of traffic jams.

- Poor pipe installation with the formation of wavy lines (relative to the horizon) is a frequent and difficult to determine cause of the appearance of air. Elimination of this cause requires periodic removal of traffic jams, and complete elimination requires the repair of a separate section, with the possible installation of additional devices for air exhaust.

- Overheating - this reason is typical for solid fuel units. When water boils, air bubbles form in the inner cavity and accumulate in the boiler heat exchanger.

ATTENTION! It is dangerous to vent air while the boiler is boiling! There is a high risk of scalding and burns!

How air enters the circuit

There are two types of contours:

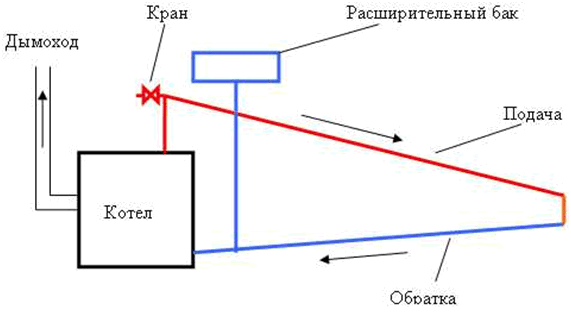

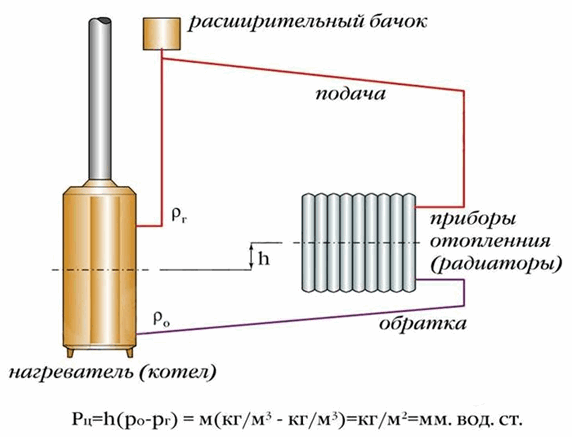

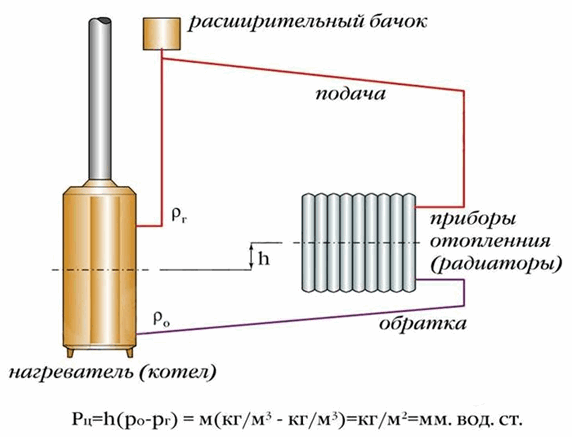

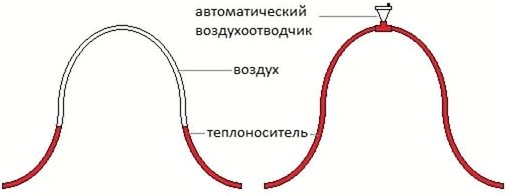

A kind of automatic air vents in an open-type heating system pass a coolant through itself, which circulates by gravity. The direction of circulation is determined by the design of the circuit. It always maintains a slope from the highest point, at the flow, to the lowest, at the return. In this case, there should be no air pockets. Air enters the heating system together with the coolant, which comes into contact with it in the expansion tank. Then it is drawn into the flow in the form of small particles, since it is impossible to bleed air from the heating system with a coolant with a temperature of 20 degrees. The hotter the water, the more intense the process of separating bubbles from the coolant. The liquid forces the bubbles upward.Accordingly, they reach a peak where they find a way out.

Since removing air from the heating is one of the key tasks for safe and efficient heating of premises, specially designed equipment is installed in the circuit.

Closed systems are hermetically sealed and circulate in them thanks to the pump. In such circuits, the flow rate is higher. They are designed in such a way that air pockets are formed in them. In this case, the installation of special equipment is required, since it is necessary to bleed air from the heating system, while maintaining its tightness. It is called an automatic air vent for the heating system. Since the system is not in contact with the environment and is sealed, oxygen can only get into it with the coolant.

In addition to the transit of oxygen by the coolant into the circuit, airing can occur:

- due to mechanical damage;

- due to repair work;

- in the event of a leak;

- after verification work.

Since it is not possible to exclude the ingress of oxygen into the system, it is necessary to make sure that it finds a way out. For this, several types of equipment are used that perform the assigned task. They can work autonomously or in manual mode.

Types of equipment and how it works

- open-type expansion tank.

How to remove air from a closed-type heating system with a simple tank? It can perform the function of an air vent only in open circuits. Since it is not possible to air the closed circuit heating system using a tank. Only sealed tanks are installed in them. An open reservoir is at the peak of the circuit, where oxygen bubbles tend to. The problem is that the water is enriched with it in the same tank, so the coolant has a high level of air, which is there until the liquid is heated;

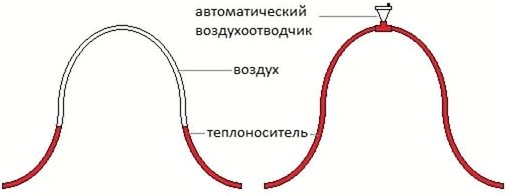

Installed at the highest point or where oxygen accumulates. The threaded portion of the heating air vent is available in two diameters: ½ ”or ¾”. In shape, they can be straight or bent at a right angle, the letter "g". The air outlet is located either at the end or on the side of the body. Works offline. Air discharge from the heating system occurs when the pressure in the system rises to a critical level. Consists of a valve and a float. The principle of operation is that when oxygen rises up, the float drops and opens the valve. As soon as the ejection has occurred, the float rises, returned to its initial position, and closes the valve;

- air separator for heating.

Placed on the serve. Unlike an automatic air vent, it does not remove the oxygen that itself separated from the coolant and rose up. The air separator in heating independently separates oxygen particles and gets rid of them. It is designed in such a way that the flow mixes, bumping into obstructions. The obstacles can be:

Air separator for heating

Methods for removing air from the pipeline

In modern heating systems, even at the design stage, there are standard means for bleeding air - air vents, automatic or manual, therefore, with proper installation and staffing of heating equipment, it is not difficult to blow through the airlock.

If the heating is mounted in an open circuit, then the air can be released from it through the expansion tank, which is the highest point of the system - the supply valve opens, and the gases from the pipeline will be displaced by the coolant into the tank, which will be manifested by the release of air bubbles there. After that, the water level in the tank is brought to normal.

Important! The water supply pipe is mounted towards the riser of the expansion tank with an upward slope.

In closed circuits with forced circulation, the possibility of air discharge is ensured as follows:

- pipes for supplying a hot coolant are mounted from the main riser to the remote ones with an upward slope, providing associated water movement to the air released from the water;

- an air vent is installed at the highest point of the supply pipe.

In a pipeline of this design, the ability to blow through the plug with a coolant is also provided by other air vents installed at the top points of other sections of the network.

If repairs are required, the system is drained through a return pipeline arranged with a slope, the size of which ensures complete drainage of the water.

Air vent device

They are installed at critical points - as a rule, the highest points of the pipeline spans and at the top of the radiators.

According to the method of operation, air vents are produced in two types:

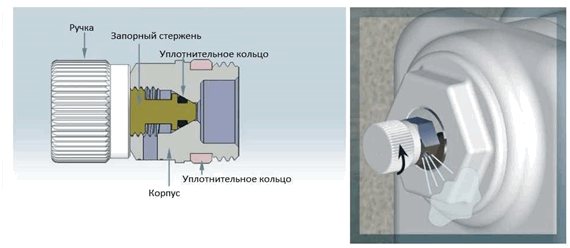

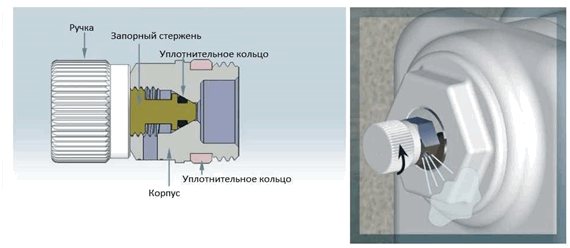

- manual control - a needle-shaped shut-off valve (in common use - "Mayevsky's tap");

- automatic.

Valves for venting air from the heating system are also different in size, design and materials of execution, but their general purpose is to remove gases.

Important! Air vents are installed on aluminum radiators without fail, since water in contact with this metal decomposes into components, one of which is hydrogen, which is explosive when mixed with oxygen or air in certain proportions. If at the same time the heating is gas, then the situation is aggravated.

Automatic air relief valves are manufactured for installation on pipelines and radiators, they are simple in design and convenient in operation, they can be straight or angled, while they do not significantly exceed the price of manual action devices. The price range for products of such well-known manufacturers as Danfoss, Wind or Valtec is $ 5-15.

Important! The automatic relief valve, regardless of design, is always installed with its cap (outlet) pointing upwards.

Manual air vents are a primitive in design, but reliable device for venting air from the system, installed mainly on heating radiators in their upper part. Models may differ in mounting thread size and design.

The device is characterized by simplicity of operation - it is opened with a regular screwdriver, and its drain hole can be directed in the direction convenient for receiving water at the end of the operation with the help of an adjusting thumb.

Bleeding of air is carried out when the heating is on, when the pressure in the system has reached the operating value. After smoothly opening the Mayevsky tap, air will first go out of the drain hole, then cold water, and so on alternately. The descent is stopped when a hot coolant of constant temperature without air comes out of the hole, and the valve is closed.

Abnormal ways to remove the airlock

There are situations when the step of the pipeline supports is significant, and the pipe sagged on the spans, forming a wavy contour with domes-sinuses without air vents. The air in such heating pipes accumulates in the sinuses, what should I do?

If the pipeline is of small diameter, then additional supports are installed under it in order to align the profile. After that, the gas from the sinuses will be displaced by water, and it is removed through the expansion tank or air vents.

If the pipeline is of significant diameter (50 - 100 mm), and even steel, then leveling its profile is a very time-consuming process. In such cases, a self-drilling screw with a sealing gasket is screwed into the upper part of the "dome" of the pipe until it stops, after which it is slightly unscrewed to bleed air and again tightened to the stop.

How to manually bleed air from the system if the coolant pressure is high

In this situation, it is necessary to first close the water supply valve to the system and release the plug in the standard way, but opening the Mayevsky valve slowly, avoiding a sharp release of gas or water.

What to do if the manual air vent does not turn away

If the threaded connection of the drain screw is stuck, and it does not turn away, you need to drip kerosene, brake fluid on it or sprinkle it with a special WD-40 agent. After waiting the required time, the screw is carefully tapped with a hammer and turned with a wrench.

What can jams in the circuit lead to?

The importance of air ducts cannot be overstated. Traffic jams in the circuit can lead to different processes:

- violation of circulation;

- pressure surges;

- decrease in the efficiency of heating equipment;

- corrosion of metal.

Stand-alone air vent

Installing an air vent in the heating system prevents the formation of plugs and pockets. Bumping into them, the coolant stops. Sometimes plugs cut off whole sections with radiators from the circuit. At the same time, the pressure in the system increases. When it reaches a critical level, an emergency release of the coolant occurs. This, in turn, leads to a drop in pressure. At the same time, there are many cases when air was collected in the batteries, the circuit continued to work, only half of the radiator becomes cold. This significantly reduces the efficiency of heating and slightly increases the cost of its operation.

One of the greatest threats to open systems is rust. At the same time, the question of how to remove air from the heating system arises only at the design stage. Such circuits are assembled at an angle from pipes with a large diameter, respectively, there is a lot of water in the system. Considering the fact that the coolant is in contact with air and draws it into circulation, the oxygen level in the pipes is more than sufficient. Since it takes a long time to discharge air from the heating system, oxygen intensively reacts with the metal. The result of the interaction is the formation of corrosion on the inner walls of the pipes. Rust sometimes eats up the tank so much that you have to change it.

Direct consequences of traffic jams in the circuit entail indirect ones, which are no less dangerous:

Occurs when the valve for bleeding air from the heating system and all sensors are in good order and work correctly. Due to an increase in pressure, an emergency release of the coolant occurs, which leads to a decrease in its amount in the circuit. After cooling down, there will be not enough fluid in the system, the pressure will drop sharply. If it does not correspond to the minimum required to turn on the boiler, the heater will not turn on accordingly. And from this moment in winter, the countdown begins when the pipes will defrost. Depends on how insulated the house is. It happens that this happens in just three hours. In this case, unpleasant news awaits at home from work;

This happens if a malfunction occurs in the valve for bleeding air from the heating system, or temperature control equipment. Unlikely situation, although possible. The results are very disastrous. At best, boiler repair or replacement, at worst - injury;

- rupture of the circuit and release of a hot water fountain.

A very likely situation, the joints may not be tight enough. With increasing pressure, they do not withstand and crack. At the same time, a hot coolant flows from the pipe, like a fountain. Not only does the circuit need to be repaired, so also the neighbors do the ceiling, since you filled it in order. This is the chain that simple airing of the system can cause.

A blockage in the circuit can lead to serious consequences such as defrosting of the system or an accident.

How to clean the heating system

At the heart of any water heating system are pipes and water.And over time, the pipes rust, the rust scales fall off, and the pressure of the water carries them through the system until they are delayed by some pipe bend or joint. And even if the pipes are plastic and not subject to corrosion, then the water itself, when heated, forms limescale on the surface of the pipes and sediment. And if the heating often boils and you have to constantly add water, then this further accelerates the process of sludge formation. Another source of pipe clogging is microorganisms and their waste products, which can develop in the heating system during the inter-heating period. As a result of their vital activity, black sediment may appear at the bottom of the system, which is also a source of blockage.

But whatever the source of blockage in the heating system, the result is always the same -

after a while the pipes are clogged,

their throughput decreases and then even a water pump is not able to pump water through the heating system. Not to mention the thermosyphon system, operated without a water pump. And then not only do the batteries remain cold or almost cold, but also the boiler begins to overheat, which can disable it.

Some owners practice annual prevention of blockages in the heating system by replacing the water. Those. drain the old, dirty, rusty water and pour fresh instead of it. There is logic in this - with old water, some of the scale and rust leaves the heating system. However, there is a downside to the coin. The fact is that iron and oxygen are necessary for the formation of rust. When these two components interact, rust is formed. And if there is always iron in the pipes - these are the pipes themselves, then oxygen is supplied along with water. In the water that has been poured into the heating system for a long time, very little oxygen remains and the process of rust formation is greatly slowed down. But if the old water is drained from the system and fresh water is poured, then the system will receive an additional flow of oxygen and the process of rust formation will begin with full force. So it turns out that by replacing the water, we will remove a little old rust from the system, but we will speed up the process of new rust formation.

So how do you deal with a blockage in your heating system? If desired, you can a priori get rid of blockages. To do this, it is necessary to fill in the heating system not with tap water, but with a special antifreeze for heating systems. It works just like a car - it provides good thermal conductivity, protects metal parts from oxidation and rust, and prevents the formation of limescale and other types of sludge. This option is the most expensive, but it allows you to forget about maintenance and cleaning of the heating system.

Cleaning

The easiest way to clean the heating system is chemical cleaning (chemical flushing). To do this, you need to purchase a product that can dissolve rust and limescale. As such, you can use regular citric acid from the grocery store. Several glasses of citric acid (the more, the better) dissolves in water and is poured into the heating system. After that, the boiler turns on, we set the temperature higher and leave it for a day. Then we drain the water with the sediments dissolved in it. We pour clean water into the system and drain it again in order to get rid of the remnants of chemistry and precipitation.

You can also use food vinegar for this purpose. But to get at least some effect, you need a lot of vinegar. A more reliable result is obtained when using hydrochloric acid (10 or 20 percent). It cleans the system well, but you should be careful with it so that the strong concentration of acid does not damage the pipes. Well, it is most correct to use for this purpose special flushing agents designed for flushing heating systems, such as inhibited hydrochloric acid.They are based on all the same acids and additional additives that enhance the flushing properties and, moreover, protect the pipes.

But such chemical cleaning only helps with mild blockages. If the heating system is more severely clogged, then chemical pressure flushing will help. For this, a water pump is used, which is connected to the heating system and provides increased circulation of water with chemical reagents. But an ordinary pump will not work for this purpose, because the aggressive chemicals that he will have to pump will render him unusable. You can also resort to hydropneumatic cleaning. For this, a compressor is used, which is connected to the heating system, and flushing with water is combined with pneumatic shocks, which allow even better getting rid of all deposits and sediments. To drain precipitation, disconnect the "return", i.e. a pipe that enters the boiler from below, and through it dirty water is removed. At the same time, fresh water is constantly supplied to the riser. If such equipment could not be found, or if its use did not help in solving the problem, then dismantling each radiator and flushing each of them under high water pressure will help. We connect a hose to the pipes at the radiator attachment points and also rinse with water under pressure. This method usually helps even with severe blockages.

Boiler cleaning

After cleaning the heating system, it is advisable to clean the boiler as well. Because it also accumulates plaque and deposits. Moreover, even in even greater quantities than in other pipes, because it heats up to higher temperatures. To clean the boiler, it is disconnected from the heating pipes. Further cleaning is carried out by the method of chemical washing. Those. the boiler is connected to a pump and water is passed through it, with the corresponding chemistry dissolved in it (inhibited hydrochloric acid, etc.). After that, the boiler is rinsed with clean water and connected back to the heating system.

How to remove a plug from a circuit

Before removing air from the system, it must be detected. Action options:

- before letting the air out of the heating system on your own, can it be better to call the master and end it?;

- try to find it yourself by knocking on the pipes. The sound in the area where the traffic jam is located will be different;

- check the uniformity of heating of the radiators. The top should be warm, there may be a slight difference with the bottom. The main thing is that the temperature at the top is higher. If this is not the case, then there is a plug in the battery.

To remove air in the private heating system from the batteries, it is enough to use the Mayevsky crane. In other cases, you must first check the condition of the equipment responsible for this process. If it is in working order, you can increase the pressure so that the plug comes out by itself, or feed the system. If the circuit is filled from scratch, then it is necessary to fill in water in several stages, without rushing. In this case, all taps, except for the drain one, must be open. We need to provide oxygen with more options for getting out. Some craftsmen kick out the cork by tapping on the contour. The method is working, but this does not mean that you need to take a hammer and charge harder through the pipe. No, you need to know how and where to hit, otherwise there will be no sense, only harm.

The reasons for the increase in pressure. Ways to solve the problem

To understand that there is too much pressure in the system, you can use the pressure gauges. Normally, the readings are 1-2.5 bar. If the pressure gauge needle reaches 3 Bars, sound the alarm. If the increase is constant, it is urgent to find the cause and reduce the pressure.

Also pay attention to the safety valve: it will constantly exude water to relieve pressure.

The case in the expansion tank

This tank can be located separately from the boiler or be part of the structure. Its function is to draw in excess water when heated. The hot liquid expands, it becomes 4% more.This surplus is sent to the expansion tank.

If the volume of the product is too small, then it will be completely filled with water. With a subsequent increase in temperature to 85-90 degrees, the tank will no longer be able to compensate for these 4%. Therefore, the pressure will rise.

The size of the tank is influenced by the power of the boiler. For gas equipment, its volume is 10% of the total amount of the coolant. For solid fuel - 20%.

Diaphragm rupture. If the part is damaged, the coolant is not restrained by anything, therefore, it completely fills the expansion tank. Then the pressure starts to fall. If you decide to turn on the tap to add water to the system, the head will rise above normal. Leaks will appear in the connections.

Replacement of tank or diaphragm is required to relieve pressure.

Head below or above normal... A machine pump will help to achieve normal values (nominal) in a gas boiler.

- Drain all water from the system.

- Close the valves.

- Pump the circuit until you are sure there is no water.

- How to release the air? Through the nipple on the other side of the inlet.

- Download again until the indicators reach the norm specified in the instructions for "Ariston", "Beretta", "Navien" and other brands.

The location of the tank after the pump provokes hydraulic shocks... It's about how the pump works. When it starts, the head rises sharply, and then also drops. To avoid such problems, in a closed heating system, install the tank on the return pipe. The next pump cuts in front of the boiler.

Why the pressure rises in closed systems

Air accumulates in a double-circuit boiler. Why does this happen:

- Incorrect filling with water. The fence is drawn from above, too fast.

- After the repair work, the excess air was not deflated.

- Mayevsky's air release taps are broken.

- The pump impeller is worn out. Adjust or replace part.

Fill fluid correctly to relieve or reduce pressure. The intake is carried out from below, slowly, while Mayevsky's taps are open to bleed off excess air.

Open system problems

The problems are the same as described above. It is important to properly fill in water and bleed air. If after this the pressure has not returned to normal, it is necessary to drain the system.

Secondary heat exchanger

The unit is used to heat hot water. Its design consists of two insulated tubes. Cold water flows through one, hot water through the other. In case of damage to the walls, the appearance of a fistula, the liquids mix and enter the heating part. Then there is an increase in pressure.

If you do not want to repair and solder the heat exchanger, you can replace it. To do this, buy a repair kit and get to work:

- Close the supply valves.

- Drain the water.

- Open the case, find the radiator.

- The assembly is secured with two bolts. Unscrew them.

- Dismantle the defective part.

- Install new gaskets in the mountings and connect the heat exchanger.

Other reasons

There are other reasons for these problems:

- Overlapped fittings. During the intake, the pressure rises, the safety sensors block the equipment. Inspect the taps and valves, unscrew them all the way. Make sure the valves are working.

- Clogged mesh filter. It gets clogged with debris, rust, dirt. Remove and clean the part. If you don't feel like cleaning regularly, install a magnetic filter or a flush filter.

- The make-up valve is out of order. Perhaps its gaskets have worn out, then you can get by with a replacement. Otherwise, you will have to change the tap.

- Problems with automation. Faulty thermostat or controller. The reason is wear, factory defect, incorrect connection. Diagnostics and repairs are carried out.

Check whether the boiler protection parts are in good working order: pressure gauge, valve, air vent. Clean radiators and other components from dust, soot, scale.Prevention helps prevent serious damage to gas equipment.

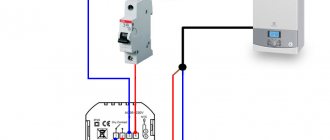

Filling the heating system with water

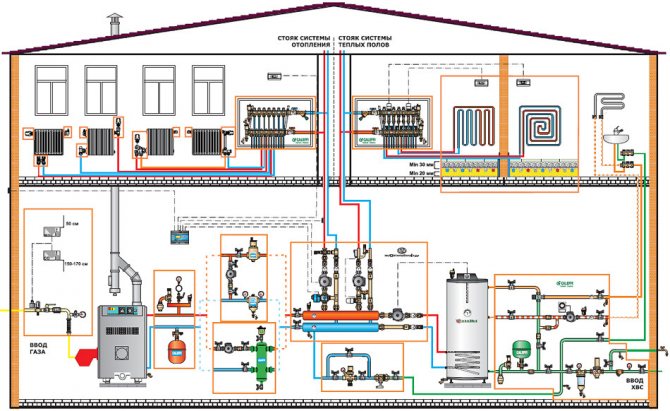

Starting a gas boiler begins with filling the heating system with water. Everything is simple here - modern double-circuit boilers do not require a special make-up unit for the system. It is already built into the boiler and equipped with a special tap, which, as a rule, is located at the bottom of the boiler in the immediate vicinity of the cold water connection. We open the make-up tap and slowly fill the system with water.

Starting the boiler - how to fill the system with water

A very important point in the operation of any boiler equipment is the fluid pressure. To control this parameter of the heating system, almost all boilers are equipped with a pressure gauge. In the process of filling the systems with water, it is necessary to monitor the pressure and after it reaches the level of 1.5-2 atm, the filling of the system will need to be stopped. In principle, the indicator of the working pressure of the boiler may vary depending on the manufacturer and model - therefore, see the instructions for the boiler for the exact figure of the working pressure.

Do-it-yourself first start of a gas boiler