Dear boiler owner "premium

Page 3

- Picture

- Text

Premium-M B. 1.03

3

Dear owner of the premium boiler!

we are grateful to you for choosing a brand product

lemax

.

you are now the proud owner of a highly efficient boiler, which

When properly installed, operated and maintained, it will reduce heating costs for your home and will serve you for years to come.

"Lemax"

- a trade organization of the federal level in the field of heating equipment

mining, provides consumers in russia and the CIS with steel, cast iron and wall-mounted boilers, gas water heaters and other related products.

"Lemax"

- the leader of the Russian market of household gas boilers (according to independent

my British expert agency BSRIA, Russian consulting agency Amiko). the company has been operating on the market for over 20 years.

"Lemax"

- has its own modern production base, having in

a modern

plant for the production of domestic heating gas

boilers

.

"Lemax"

- the only Russian manufacturer of heating equipment

the vania on which the robots work are high-tech Italian and German machine tools. we are waiting for your feedback and suggestions on the company's website

www.lemax-kotel.ru

.

Gas boilers Lemax Patriot

The Lemax plant, founded in 1992 in Taganrog, has firmly occupied its niche among the venerable manufacturers of gas heating equipment.

Its products are assembled on the basis of imported parts, combined with units of its own assembly.... The Patriot series are floor-standing gas boilers designed to heat the coolant in the heating circuit.

In addition to heating the coolant, Patriot boilers perform the functions of a convector, circulating air heated by its own heat inside the room. The main feature of the units is energy independence, which immediately cuts off all difficulties with connecting the power supply, fears of being left in the cold without heating, the need to pay bills, etc.

The lack of connection automatically excludes the presence of complex and unreliable electrical devices, electronic boards and other parts dependent on voltage quality.

This simplifies the design, removes expensive and fragile elements, making the boilers resistant to external factors..

Such features allowed the manufacturer to form an attractive pricing policy for consumers, which quickly brought Lemax products to the forefront in terms of popularity and popularity.

Attention, read, Stop

Page 4

- Picture

- Text

4

Premium-M B. 1.03

Content

1.

GENERAL INSTRUCTIONS ………………………………………………………………………………………… 5

2.

COMPLETE SET …………………………………………………………………………………………. five

3.

TECHNICAL SPECIFICATIONS ……………………………………………………………………… 5

4.

SAFETY REQUIREMENTS ……………………………………………………………………… .. 8

5.

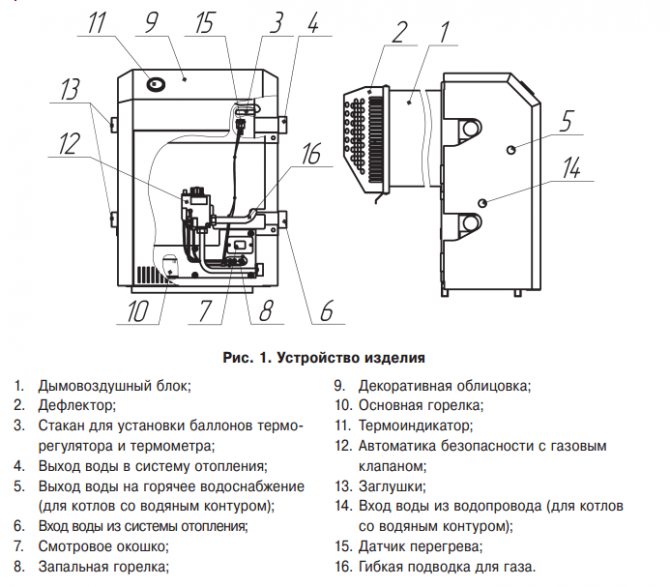

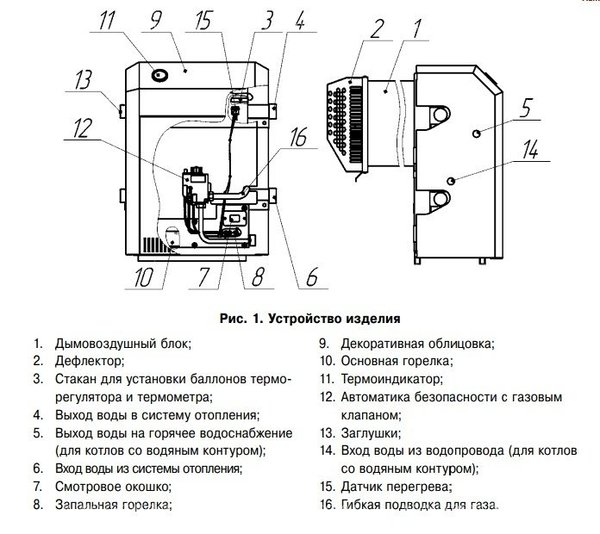

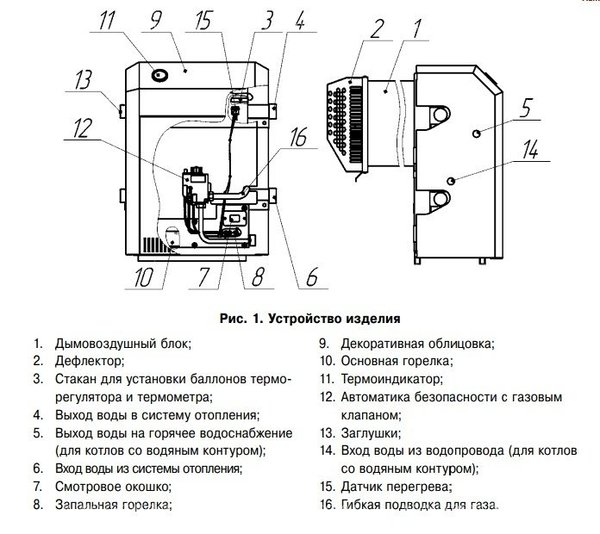

BOILER CONSTRUCTION …………………………………………………………………………………………………………………………………………………………… 9

6.

INSTALLATION, PREPARATION FOR WORK …………………………………………………………………… 10

7.

OPERATING PROCEDURE …………………………………………………………………………………………. fourteen

8.

OPERATING RULES, MAINTENANCE ………………………………. sixteen

9.

WARRANTY …………………………………………………………………… 16

10. RULES FOR PACKING, TRANSPORTATION, STORAGE ………………………………… .. 17 11. CERTIFICATE OF ACCEPTANCE ………………………………………………………… ………………… 18 12.POSSIBLE MALFUNCTIONS TROUBLESHOOTING ……………………………… .. 18 13. NOTES ON THE ANNUAL TECHNICAL

AND PREVENTIVE MAINTENANCE …………………………………………………… 19

14. CHECK CARD FOR BOILER INSTALLATION ……………………………………………… .. 20 15. SERVICE CENTERS …………………………………………… ………………………………………… 22

ATTENTION, READ!

when buying a boiler, you need to make sure that its capacity meets the design for heating your premises.

the Lemax premium series boiler effectively operates in open and closed heating systems, with and without a circulation pump.

when filling or replenishing the heating system, the water pressure should not exceed 2.0 kgf / cm

2

... to comply with this condition, install a relief

safety valve 1.5-1.7 kgf / cm

2

at a distance of no more than 150 mm

from the point of connection of the valve for filling the heating system.

Do not install shut-off devices on the signal pipe in an open heating system.

It is forbidden to make up the heating system during operation of the main burner and when the water temperature in the heat exchanger is more than 50 ° C.

We strongly recommend that you strictly follow the requirements for the room used for the installation of the boiler and the requirements for the construction and insulation of the chimney.

It is not recommended to operate the boiler at a coolant temperature below 50 ° C.

when buying a boiler, ask the dealer to fill out a warranty repair coupon. check the completeness and presentation of the boiler.

The boiler may only be transported in an upright position.

STOP

STEEL GAS BOILER "LEMAX" OF "PREMIUM" SERIES WITH AUTOMATION 820 NOVASIT

STEEL STEEL LEMAX PREMIUM 7,5 N WITH AUTOMATION NOVA 820 SIT

More details

Additional benefits:

- The temperature regulator is placed on the front panel of the boiler with the designation of temperatures, which allows you to accurately select the optimal temperature regime;

- Connection of a room thermostat, with which it is possible to regulate the boiler temperature in relation to the temperature inside the room;

- Working in conjunction with the Lemax turbo nozzle for the forced removal of exhaust gases;

- Soft start system.

Specifications:

Before using the heating boiler, read ...

Page 5

- Picture

- Text

Premium-M B. 1.03

5

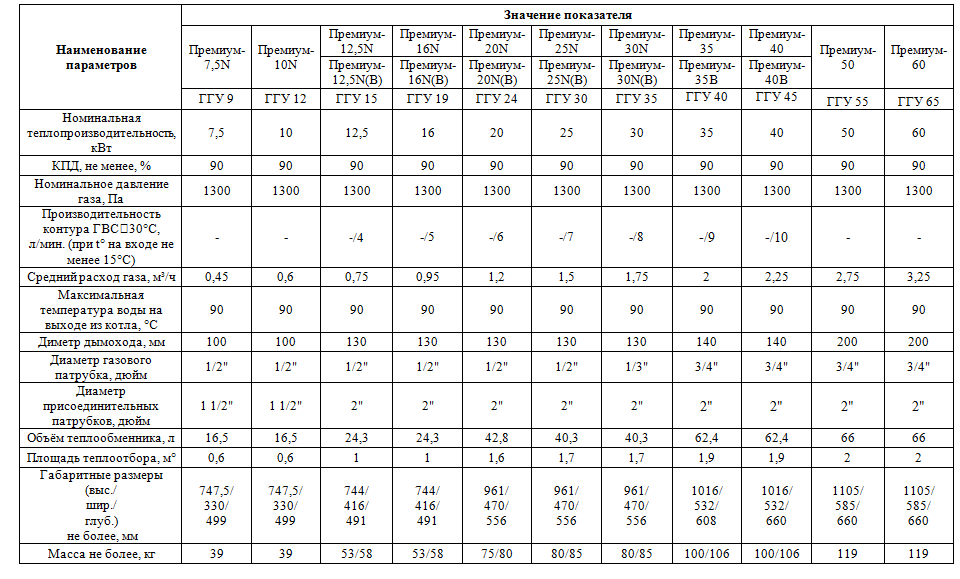

1.

GENERAL INSTRUCTIONS

1.1. Read this manual before using the boiler.

estom.

1.2. installation work, instruction in operation, commissioning, professional

lactic maintenance and repairs of the boiler are carried out by a specialized organization and the local administration of gas facilities in accordance with the “safety rules for gas distribution and gas consumption systems” approved by the State Technical Supervision of the Russian Federation, and building codes and regulations SNip 11-35-76; SNip 2.04.05-91 Gosstroy of the Russian Federation, according to the project for the installation of the boiler and the mandatory filling of the control card.

1.3. The assembled boiler can only be put into operation after its acceptance

by gas experts, instructing the owner and obligatory filling out of the control coupon for the installation (p. 21)

1.4. Checking and cleaning the chimney, repairing and monitoring the water heating system

are made by the owner of the boiler. When replacing an old boiler with a low efficiency with a modern one, you should pay special attention to the design of your chimney. When the boiler efficiency is below 80-85%, the flue gas temperature is about 200 ° C, which ensures good draft even with a poorly insulated chimney. With an efficiency of 90%, the temperature of the flue gases drops to 110-120 ° C, and, in the case of an outdated chimney, the draft disappears, which leads to the operation of the automation and shutdown of the boiler. Failure statistics show that 94% of problems with boilers arise from an incorrectly executed chimney.

1.5. In the room in which the boiler is installed, it is necessary to provide

natural ventilation. It is forbidden to cover the grilles of the ventilation ducts.

1.6. The use of boilers at hazardous production facilities is prohibited.

2.

SET

2.1. A heating boiler with a gas burner installed on it. 2.2. Packaging containers. 2.3. Boiler operation manual.

3.

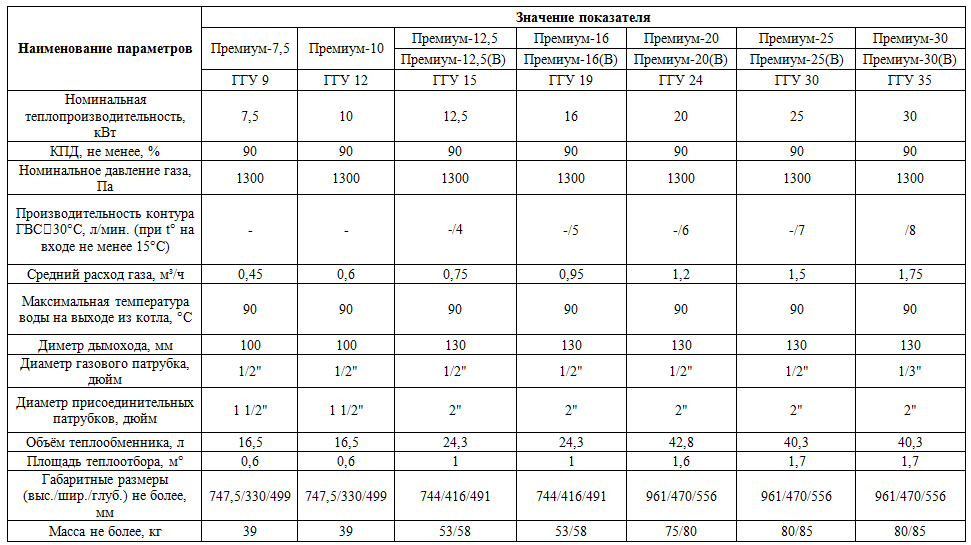

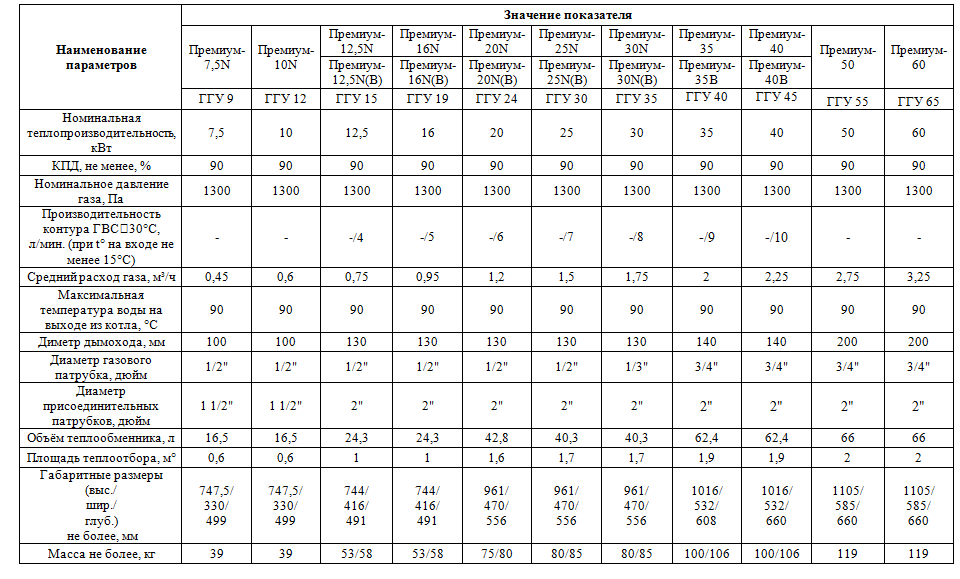

specifications

3.1. Steel heating boilers premium series

designed for heating and

rye water supply of apartments, residential buildings, cottages, buildings of administrative and domestic purposes, equipped with a water heating system with natural or forced circulation. the boiler meets all the safety and environmental requirements established for this type of product. GOST 20548; TU 4931-011-24181354-2011.

3.2. The boilers run on natural gas GOST 5542-96 and are delivered assembled

with gas burner

3.3. Working pressure of water in the heating system is not more than 2 kgf / cm

2

, in a closed system

heating, it is necessary to install a safety system with a safety valve for a pressure of no more than 1.5-1.7 kgf / cm

2

.

Series Models

The Patriot line consists of 6 models:

- Patriot 6... Floor standing gas boilers with a capacity of 6 kW. Designed for rooms with an area of about 60 m2. Additional heating due to its own convection increases the efficiency of the work. The best option for heating a small private or country house, office.

- Patriot 7.5... Gas floor units designed for heating areas up to 75 m2. Thermal power dissipated is 7.5 kW. It shows itself well when heating apartments, small private or country one-story houses, office or industrial premises.

- Patriot 10... Floor standing gas single-circuit units with a capacity of 10 kW. They are capable of heating houses or premises up to 100 sq. m. They are distinguished by high efficiency and low gas consumption.

- Patriot 12.5... The power of the installation is 12.5 kW, which allows heating up to 125 m2. The non-volatile design makes it immune to unexpected power outages, line failures, surges or undervoltage. Has the ability to connect an external indirect heating boiler for hot water supply.

- Patriot 16... Floor standing gas boilers with a capacity of 16 kW. Designed for heating areas up to 160 m2, which allows them to be used in the corresponding houses, industrial or public premises, including two-storey ones. They can be used in systems with both natural and forced circulation of the heat carrier. It is possible to connect an external water heater.

- Patriot 20... The most powerful units of the entire Patriot line. They give out 20 kW of useful (thermal) power, which allows them to be effectively used in rooms up to 200-250 m2. At low gas consumption, stable maintenance of the specified heating mode is ensured. Completely safe, they can work in conjunction with external water heaters for domestic needs.

With a noticeable difference in power, the Patriot series boilers have the same design and work on the same principle.

Installation and adjustment are described in detail in the user manual, safety is ensured by a closed burner with a coaxial chimney that does not require connection to the common smoke channel of the building.

This increases the capabilities of the boilers and allows them to be used both in private houses and in apartments, provided they are installed near an outer wall..

IMPORTANT!

Installation and connection must be carried out by employees of the gas or service department. Self-connection poses a threat to the safety of people and property.

INSTALLATION, PREPARATION FOR OPERATION ...

Page 10

- Picture

- Text

10

Premium-M B. 1.03

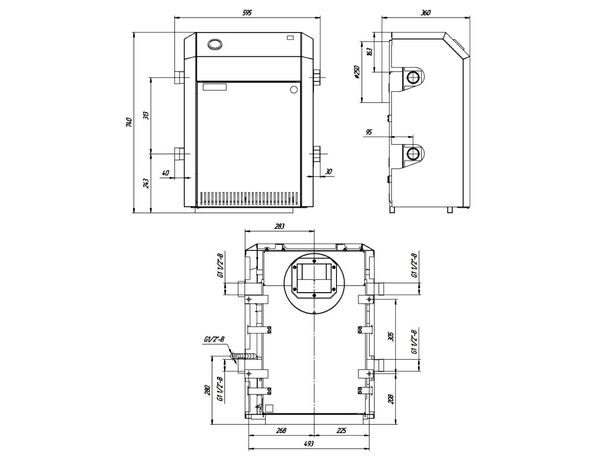

6.

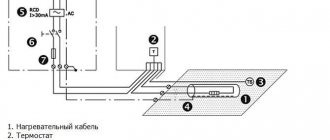

INSTALLATION, PREPARATION FOR OPERATION

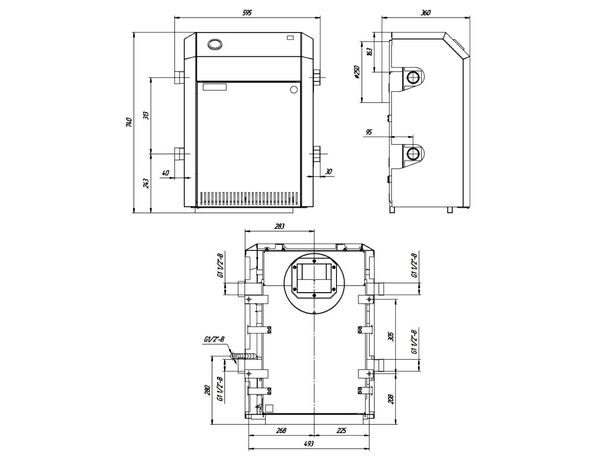

6.1. The volume of the room in which the boiler is installed must be at least 8 m

3

... Ras-

the distance between the boiler lining and the walls must be at least: - 150 mm behind; - 100 mm right and left; - 1000 mm at the front.

6.2. In the room in which the boiler is installed, it is necessary to provide for natural

proper ventilation.

6.3. When installing the boiler to the heating network, it is necessary to lay a non-combustible sheet on the floor

insulating material, on top - a sheet of iron, install a boiler on it.

6.4. The connections between the boiler and the heating system and the gas main must be threaded.

secondary, allowing, if necessary, to disconnect the boiler. If the boiler is installed instead of an old boiler, it is imperative to flush the pipelines and radiators of the heating system to remove rust, scale and sludge deposits. If these requirements are not met, the products of deposits (rust, sediment) are transferred to the boiler, which significantly complicates the circulation of the coolant and reduces the heat transfer from the boiler. In this case, claims regarding the temperature indicators of the heat carrier during the operation of the boiler are not accepted by the manufacturer.

With increased heat consumption of the room (the thickness of the outer walls of the house, the integrity of windows and doors, the routing of pipes of the heating system in attics, attics that are not insulated, its area is exceeded or the capacity of the heat carrier is significantly exceeded - the number of radiators, pipes) from the established standards, temperature the heat carrier may not reach 80 ° C, which does not mean that the boiler is defective.

6.5. The capacity of the coolant in the heating system should not exceed: Premium 10 - 150

liters, Premium 12.5 - 180

liters, Premium 16 -

240

liters, Premium 20 -

300

liters, Premium 25 -

375

liters, Premium 30 -

450

liters, Premium 40 -

600

liters.

6.6. For correct filling and replenishment of the system, be sure to install a waste

safety valve 1.5-1.7 kgf / cm

2

at a distance of no more than 150 mm from the place

valve connection for filling the heating system.

6.7. The expansion tank is installed at the top of the main riser, preferably

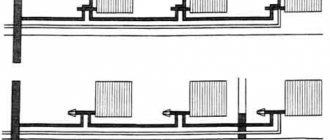

in a heated room. Do not install a valve on the signal pipe (see Fig. 2, 3).

6.8. Horizontal sections of pipelines of the heating system must be performed with

with a slope of at least 10 mm per 1 m towards the heating radiators and from them to the boiler. This is done in order to ensure free air outlet when filling the system with water and eliminates the formation of air pockets.

6.9. Pipelines, heating radiators and their joints must be sealed

no water leaks are allowed.

6.10. For a closed heating system it is necessary to install a security system with

safety valve for pressure no more than 1.5-1.7 kgf / cm

2

.

6.11. The chimney device to which the boiler is connected must comply with SP42-

101-2003 "General provisions for the design and construction of gas distribution systems" (see Fig. 4).

6.12. After connecting the boiler to the gas supply system and filling with a coolant

the heating system, employees of a specialized service center or local gas administration must adjust and check the safety automation and temperature control for operation, as well as check the tightness of all threaded connections on the boiler gas pipeline and before it.

6.13. Before igniting the gas burner, check the presence of draft according to item 4.3. With absence

draft, it is prohibited to ignite the gas burner device.

Comments (1)

Highlight → I found instructions for my water heater here! #manualza

- Click →

From the instructions for using the gas mask: - Pull on until the goggle is opposite the eye!

Manualza! Manualza.ru

Still not with us?

Choosing a place to install a parapet-type boiler

Parapet-type boilers are installed only in non-residential and non-office premises, that is, they cannot be installed in living rooms and offices, but they may well be located in kitchens, halls, corridors and other utility rooms.Gas boilers of this type do not require constant supervision.

Parapet gas boilers are installed only on the outer wall of the building so that there are no combustible structural elements near the place of their installation. If the wall includes combustible elements, then the distance from the pipe to such elements must be at least 20 cm, and these elements themselves must be protected by refractory material from the side of the pipe and the gas boiler. On the facade itself, there should be no combustible elements closer than 30 cm from the pipe. If such elements are present, they are either removed or protected with a refractory material.

The pipe should not go out into the loggia, onto the balcony, under a canopy, and even more so into the entrance or arch. It is worth immediately making sure that the pipe does not interfere with passers-by, if the boiler is installed at a low height relative to the ground, and does not throw combustion products out the window to neighbors.