The insulation procedure and the choice of materials must be approached very, very responsibly. Heat loss depends on this, which means the comfort and coziness of people living in this building. Insulation of a frame house with high-quality mineral wool is the most affordable and reliable method. This is confirmed by the reviews of those who used it, it is recommended to choose by experienced developers. 80% of all existing insulation methods are allocated specifically to mineral wool or other insulation based on it.

Functions performed by insulation

The thermal protection of the frame with mineral wool, in contact with cold air currents, performs several functions at once, preventing:

- Falling out of condensate from the inner space of the room;

- Dampness, mold or mildew formation;

- Temperature imbalance, which reduces comfortable living and coziness in the home.

That is why the correct insulation of a frame house from the inside with mineral wool is a mandatory procedure. In addition to thermal protection, it also extends the service life of the frame.

Wall insulation

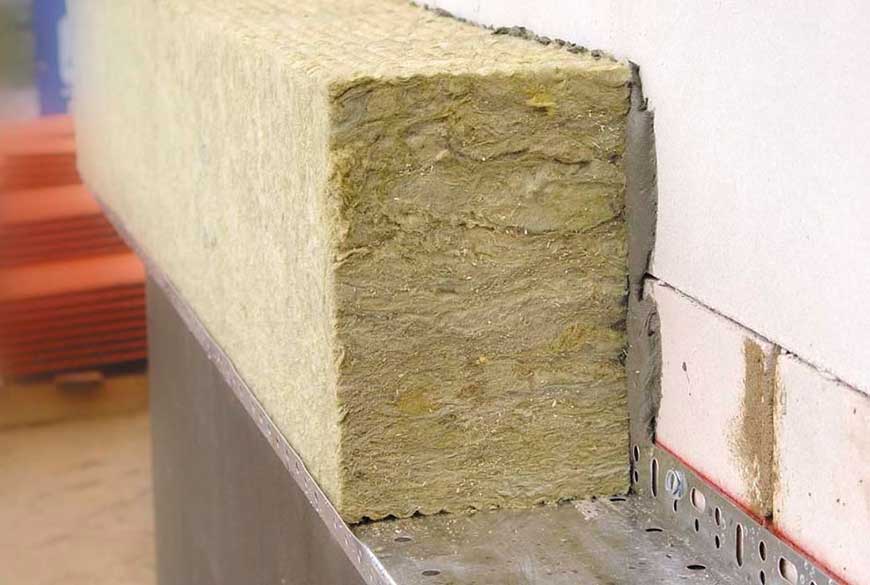

Mineral wool in the walls It is used to insulate a house inside living quarters, as well as as a soundproof warm material in internal partitions between rooms. Along the inner perimeter of the walls, the insulation ensures the creation of a comfortable atmosphere in the house, is a way to save on heating.

Thermal insulation of internal walls with mineral wool is done as follows:

- 1. A wooden lathing is installed on the walls. The width between the slats should be 10-15 mm less than the width of the insulation boards. The sheathing must be at least 25 cm thick.

- 2. A layer of insulation is laid in the crate between the slats.

- 3. Then - the second layer. In this case, it is necessary that the seams between the upper layer fall in the middle of the slabs of the lower layer.

- 4. A diffusion membrane is lined on top of the insulation, which prevents the penetration of steam.

- 5. The cladding can be installed from above.

- 6. If ordinary plastering or painting of walls is planned, slats are stuffed on top of the vapor barrier layer. Drywall or chipboard boards are stuffed on them.

What features should the insulation have and why

All materials that can be used for thermal protection must meet the following requirements:

- Have a low coefficient of thermal conductivity;

- Possess good indicators of fire safety;

- Have low water absorption;

- Have no shrinkage or shrink as low as possible;

- Have a good environmental friendliness.

- Why these properties are needed, we will figure it out in more detail.

Thermal conductivity

This indicator is responsible for the ability of the insulation to transfer heat. The lower this coefficient, the less the material allows heat to pass through. This means that in winter, the insulation does not allow the building to cool down quickly, in the summer, accordingly, it warms up.

Advice! Based on, when choosing, it is from this indicator, the user must take into account the coefficient of thermal conductivity when used in specific climatic conditions.

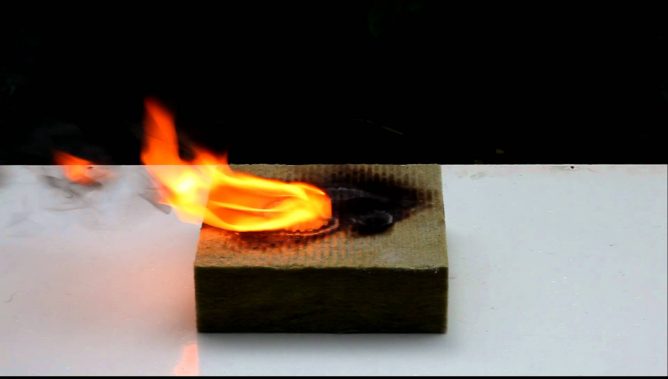

Fire safety

This indicator is responsible for the ability of the insulation to withstand high temperatures, without losing its functions, without deforming, without changing its structure. Insulation of frame houses with mineral wool is considered reasonable and correct because this indicator is regulated by GOST standards. Mineral wool has them and fully meets them.

Water absorption

The next important parameter after the previous one is responsible for the material's ability to absorb moisture and retain it.If the material strongly absorbs water, then it gives off heat faster and stronger. This is because the pores in the insulation are clogged with water, and, according to the laws of physics, it has a higher thermal conductivity than air.

And then, with too much moisture absorption, the material, at too low a temperature, can simply freeze, and when it turns into ice, it finally loses its properties.

Therefore, the smaller its parameters, the better the material.

Shrinkage

Choosing insulation of a frame house with high-quality mineral wool, this parameter is also worth paying attention to. This factor should be as small as possible. Otherwise, over time, after shrinkage, subsidence will appear in the places where the heat insulator is laid. And this means that cold bridges will appear there necessarily, and this is very bad. The cold bridge is an ideal zone for dissipating heat from the inside of the room.

Environmental friendliness

The basis of thermal protection is made by insulation, which is located along the entire perimeter of the building. It is very important that no harmful radiation and vapors emanate from it in the form of compounds and substances hazardous to health.

Benefits of mineral wool

Durability and strength are the fundamental advantages of the announced raw materials. Compared to glass and cellulose insulators, mineral wool has better thermal insulation characteristics. It creates favorable climatic conditions, delays from 15 to 20 decibels of external sounds. This is enough so that the person in the living room is not disturbed by the noise of an airplane flying by or a passing truck.

Minimum labor costs - the third positive quality of the announced isolator. It makes it possible to mount it without contacting specialists, but certain skills are required to work with it. Experts do not recommend resorting to installing mineral wool without personal protective equipment, with a lack of engineering skills. The reduced load on the house structure is the fourth plus, dictated by the relatively small dimensions.

Resistance to destructive influences, including sudden temperature changes, the influence of rodents, as well as small insects. The antiseptic substance in the original composition repels pests. The fire retardant prevents the formation of mold, as well as fungal deposits that can disrupt the operational integrity of the building material. Air space occupying 80% of the structure prevents the formation of cold bridges.

How to insulate a house outside: step by step instructions

In the exterior decoration of country cottages, loosened cotton wool is used that does not contain phenols, formaldehyde and other active compounds. The dense internal structure of the advertised building material guarantees uniform heating of the floors. Air runs along the millimeter layers. This prevents moisture stagnation. Wood, brick or concrete is not subject to destruction under the influence of man-made factors.

- Preparation

As part of the preparatory stage, clean the area from settled dust, dirt, sand, and other debris. Carry out the leveling, after removing the weathered layer of plaster, paint, varnish. Treat the walls with an antiseptic. Repeat the procedure after 30 minutes.

- Disconnecting the electrical wiring

Remove the electrical wires by undoing them with the available tools. Call an electrician if you do not understand the intricacies of dismantling the power supply at home. Errors at this stage are categorical and unacceptable.

- Surface finishing

Before starting work, check the floors for cracks, cracks, gaps. Use jute or other analogs to eliminate the existing errors. Observe the uniformity of the mixture during application. The surface must be perfectly flat.

- Vapor barrier

The pre-purchased film must be laid so that the smooth part touches the mineral wool, and the rough side faces the wall. Use an engineering stapler and adhesive tape to seal the joints.

- Lathing

Make a lattice base from timber or aluminum pieces. Take a dowel, nail or screw as a fastener. Try to avoid distortions. Use an automatic or manual level.

- Styling

Mount the mineral wool on the prepared frame according to the manufacturer's instructions. Secure the insulator with anchor nails with a cap. A wide part of the hardware used must be buried in the material.

- Decorative finishing

Mount the second framing base on top of the existing structure. Sew up the rough surface with plasterboard or other building material intended for exterior decoration of facades and walls of houses outside the city.

How to insulate a house from the outside with siding

Siding panels are the most common building material for exterior decoration of cottage houses made of rounded logs, laminated veneer lumber, brick or concrete. It is best to entrust the installation to experts in decorative finishes. The do-it-yourself approach is a risky method that compiles with potential errors, which in the vast majority of situations result in unplanned costs.

Nine out of ten homeowners do not see a fundamental difference between installing basalt or mineral wool slabs. This is the first mistake often made by consumers, the correction of which entails costs, waste of energy, time, and nerves. To avoid this, entrust the installation. A specialist will visit you, measure the area free of charge, make a detailed estimate, and give recommendations on preparation if you want to participate.

Briefly about the technology of siding insulation

Siding installation begins with the preparatory stage, including the dismantling of window construction elements, street lighting devices, platbands, as well as slopes. The second stage involves the installation of the lathing followed by the installation of steam insulation. At the third stage, a thermal insulator is mounted, which must be covered with a film and only then proceed to the installation of siding panels.

At first glance, nothing complicated, but the opinion is wrong. Technological processes contain subtleties and nuances. Engineers, architects, installers understand them. Without the skills and knowledge of engineering calculations, you run the risk of making a critical error, which will result in additional problems. Now ask yourself? Do you need it? Wouldn't it be better to delegate these matters to experts?

How much does it cost to insulate a house outside?

The average cost of insulating houses outside is 150 rubles per square meter. The time required to complete the work processes is 48 hours. Dismantling of an outdated insulator with removal of solid household waste, as well as construction waste - 50-60 rubles per square meter. To get accurate calculations, leave a request via the online feedback form or call the phone number listed on the website. Engineer's on-site visit is free of charge. All types of work are guaranteed for 10 years.

Reasons for the popularity of mineral wool

Insulation of a frame house is chosen very often with mineral wool. The popularity of the material can be explained by several reasons:

- Mineral wool is endowed with high levels of noise and vapor barrier;

- Has excellent thermal conductivity;

- It is considered a non-flammable and environmentally friendly material;

- Has an ideal water absorption rate;

- Eliminates condensation formation.

The material cannot be called cheap. But by choosing it, the user has the opportunity to save on the purchase of a vapor barrier film or specially designed membrane materials.

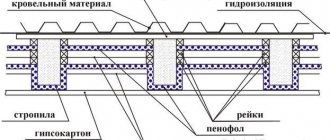

Roof insulation

Mineral wool is suitable for insulating a roof in an attic or mansard roof. This makes sense even if you do not plan to use the attic for permanent residence in the future. The attic, the attic are the most vulnerable parts of the house, since they are separated from the external environment only by a relatively thin roof. Heat loss here sometimes amounts to 25%. Therefore, it is so important to insulate the roof from the inside.

The choice of the width of the mineral wool slab depends on the region of Russia. In the middle lane, a heater with a width of at least 200 mm is used.

Installation of insulation is done as follows:

- 1. A hydro-windproof film is laid on top of the rafters. It protects the insulation from moisture penetrating through the roof.

- 2. The first layer of insulation is placed in the space between the rafters. The width of the blocks of mineral wool should be 10-15 mm larger than the distance between the rafter legs.

- 3. When laying the second layer of insulation, it is necessary to ensure that the seams of the lower layers are in the middle of the blocks of the upper layer.

- 4. Further, an additional lathing with a width of at least 50 cm is installed across the rafters. The distance between the slats should be 10 - 15 mm less than the width of the insulation.

- 5. Another layer of insulation is laid in the crate. This ensures that possible cold bridges between the rafters are covered.

- 6. From above, the insulation is covered with a vapor barrier film. It ensures that steam enters the insulation and gets wet as a result of condensation.

- 7. The film is fixed with a stapler.

- 8. At the junction of the edges, it is overlapped with a distance of 10 cm. The edges are glued together with a wide tape.

- 9. Further, the insulation, depending on the selected facing material, is sewn up with plasterboard, chipboard, wooden board.

Mineral wool analogues, their use, the best manufacturers

Fiber heat insulator, referred to as mineral wool, is used in 80% of all available cases. Other materials based on it are often used for thermal protection.

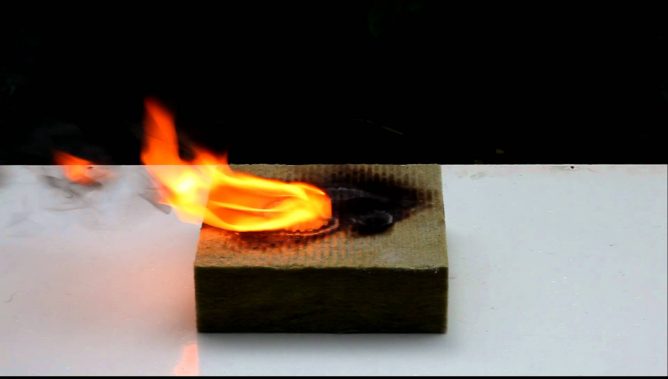

Basalt

The best mineral wool for insulating frame houses of the following brands:

- Isolight;

- Izorok;

- Isolight-L.

- As well as:

- Nobasil;

- Rockwall;

- "Paroc".

It is also called stone, it is made from raw materials of rocks, namely from:

- Basalt;

- Diarita;

- Porphyrite;

- Basalite.

Basalt is the leader in the list of raw materials. Cotton-stone slabs are used for insulation:

- Insulation of pipelines;

- Wall structures of frame frames;

- Heat and vapor barrier of technological equipment.

Basalt wool is a non-combustible material with:

- High rates of thermal conductivity. Refers to the list of durable heaters. Average service life is 50 years;

- For the entire time of use, it does not change its structure, valuable properties;

- Has a good indicator of resistance to chemical compounds;

- Non-hygoscopic;

- Has a high biological resistance;

- Resistant to deformation from high temperatures. It can withstand temperatures of 1000 0C.

In addition to all the listed advantages, stone slabs are endowed with negligible shrinkage. Cold bridges are not formed in the interplate joints.

Has a pronounced water-repellent effect.

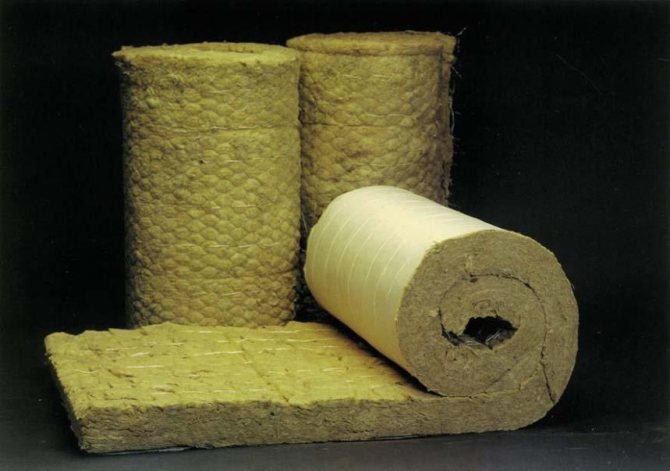

Glass wool

Much like the previous material. It differs only in that completely different raw materials are used in its production. The raw material base here is fiberglass, glass and its waste. It goes on sale not in the form of slabs, but in rolls, which are often called mats.

Standard parameters of one roll (in mm):

- Length - 1000;

- Width - 1200;

- Thickness - 100.

When choosing to insulate the walls of a frame house with mineral (glass-based) wool, use an insulation with a density of 15-20 kg / m3. It is with its help that you can achieve the expected result. It is used for thermal protection of horizontal surfaces of the frame, for example, floors.

The second difference between glass wool and mineral wool is the lack of environmental friendliness. That is why the mineral is preferred to her. It is unsafe to work with glass wool, therefore, before starting installation, the master should wear gloves and a respirator.

The best manufacturers of glass wool are the following brands:

- Ursa;

- Isover;

- Knauf (Knauf insulation).

Advice! When choosing glass wool, remember that it tends to shrink. Another disadvantage is the high coefficient of water absorption.

Slag

Slag heat insulator is rarely used. It is produced from metallurgy branches. It is characterized by low thermal conductivity, low cost. But they are not used in the production of thermal protection due to the fact that the material does not meet environmental requirements. The service life is short. Insulation of a frame house with slag wool is considered to be of poor quality also because the material has high fragility and fragility.

In case of accidental mechanical damage, it does not restore its shape. Its hydrophobic properties are also very weak, which means that the material can be safely attributed to the category of heat insulators with a high water absorption coefficient. Phenyl-formaldehyde compounds, which are part of the slag, are very harmful to human health.

Ecowool

Modern insulation made from cellulose. It differs from mineral wool:

- By appearance and styling technology;

- Flammability - very low. When burning, it does not emit harmful toxins;

- The increased rates of sound insulation. In comparison with mineral wool, they are 2 times more.

- Ecowool is used in heat protection:

- Office buildings;

- Shopping centers and shops;

- Residential home ownership;

- Manufacturing institutions;

- Children's, medical and educational institutions;

- Warehouses.

The use of ecowool is allowed in buildings with high levels of humidity or condensation. Ecowool has one drawback - the high cost of the material.

Raw materials for manufacturing:

- By-products of the paper industry (waste);

- Clippings and defective material from printing houses;

- Waste paper.

The latter refers to secondary raw materials due to severe pollution and obvious heterogeneity. 80% of the composition of ecowool is cellulose fibers, 12% is boric acid (to protect against bacteria and the formation of fungus), 8% is tetraborate (acting as a fire retardant). The latter serves not only as a component that increases fire resistance, but also as a substance that affects insecticidal properties, namely, it enhances them.

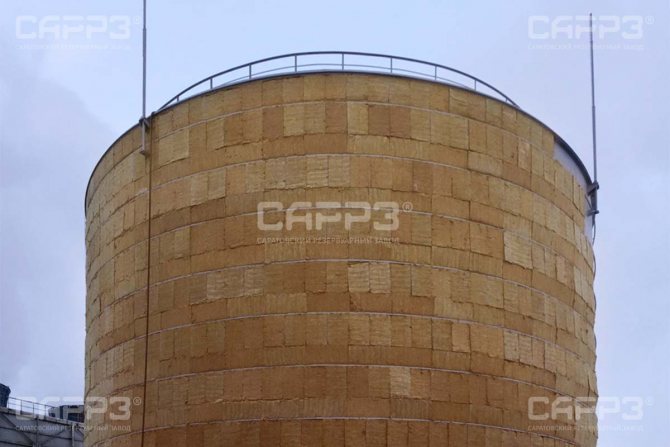

Insulation of the facade

Basalt mineral wool is also used to insulate the outer walls of a private house. A layer of insulation on the street side prevents the walls from freezing in the winter cold and getting wet in cold weather.

Insulation is placed under vinyl or wood siding, hinged panels. External insulation is performed as follows:

- 1. The walls are cleaned of dirt and debris.

- 2. The crate is attached to them. The distance between the slats should be 1 - 2 cm narrower than the width of the insulation boards.

- 3. Next, a vapor barrier is laid. You can use roofing material, factory-made films.

- 4. The first layer of insulation is lined.

- 5. Behind it, the second layer is laid so that the spacing of the joints is at least half of their length.

- 6. Although basalt mineral wool slabs are quite hard, they must be fixed with dowels with umbrellas.

- 7. From above, the insulation is covered with waterproofing.

- 8. Then additional rails are attached. Siding panels, facing slabs, and other cladding are attached to them.

Thermal insulation with basalt mineral wool for siding, the panel is a homemade ventilated facade. An air cushion is formed between the insulation and the cladding, due to which the insulation constantly dries out, does not fill with moisture.

Which wool is better, what methods of insulation exist

It is important to know how to properly insulate a frame residential building with mineral wool, because each of the modifications presented above (except for stone wool) loses its insulating properties when wet. To prevent such embarrassing situations, most developers insulate the frame strictly with mineral wool in a protective (polyethylene) sheath.

There are three methods for producing thermal protection:

- Sticky;

- Wet;

- Dry.

To carry out blowing using dry technology, the use of special equipment will be required. The material is fed through a hose to all planes and slots, completely filling them.

It is recommended to use the wet technique in cases where the frame is covered after thermal protection. Here the composition is diluted with water and also sprayed on surfaces. Drying, the wet composition transforms into a dense coating. The key advantage of this technique is the absence of shrinkage.

Adhesive is used when it is necessary to insulate a reinforced concrete or metal structure: walls or ceilings. The adhesive composition, if selected correctly, ensures the highest adhesion of the insulation to the base.

Important clarification! Due to the high strength and hygroscopic properties of the coating, no additional external cladding is required.

Warming the veranda

Often there is a need to insulate the veranda, since the threshold freezes in winter. By insulating the veranda, the owners of the house benefit doubly. First, the front door is insulated. Secondly, they get another relatively warm room where vegetables and preparations can be stored. On the veranda, walls and floors are subject to insulation. Insulation works are carried out using mineral wool. Insulation methods are the same as for other parts of the house.

Now you know how you can insulate a private house using mineral wool. And you will be able to use your knowledge in practice.

Self-production of thermal protection

Insulation of a frame house with mineral wool, namely its step-by-step scheme, will definitely require the installation of a protective layer against moisture - waterproofing. This is necessary in order to prevent moisture trapping on both sides. Due to its removal to the outside, the walls will get wet and deteriorate.

Waterproofing

The first step will be to measure the dimensions of the surface, cutting the waterproofing material. The material is fastened with a construction stapler to the racks. In this case, you need to ensure that the strength of the fastening is maximum, the frame is completely sheathed around the perimeter. The material should be overlapped, the layers should overlap each other by about 10 cm.

Vapor barrier

This front of work is mandatory if hydrophobic materials are used for thermal protection or those that tolerate any contact with moisture neutrally. In addition to them, the so-called cake can also consist of other materials that are more sensitive to getting wet. It will be right to choose (for internal and external thermal protection) foamed polyethylene or a special film. They are also attached to the racks, this will provide a good fit to the insulation.

Important note! Wrapping heat insulator blocks in a film is a gross violation of the standard method for arranging thermal protection. Until all areas of the frame, without exception, are covered from getting wet, the work cannot be considered completed.

Only after that it will be possible to safely begin work on laying the filler, strictly observing the safety rules.

Stitching

This is the final stage in the production of thermal protection. For internal surfaces, drywall sheets and particle boards remain out of competition. GKL is best used in cases where the frame is perfectly flat. OSB, due to the stiffness indicators, can be used in the presence of small irregularities. Then you can carry out the finishing.

Mineral wool insulation

Mineral wool is available in two formats - slab and roll (mats). On the packaging there is necessarily a two-digit number from 11 to 66 - density, that is, the main indicator of the constructive value of cotton wool. Rigidity and bearing capacity directly depend on it. In different cases, different indicators are relevant. Consider the main cases of using mineral wool in private construction and repairs in order of increasing density.

Noise insulation of floors

Mineral wool mats of the lowest grade - 11-14 are suitable for this. This is due to the fact that there are no temperature and humidity fluctuations in the internal floors of the building.

Noise insulation of partitions

For this, mats of higher density are suitable - from 30 to 37 gk / m 3 or plates with the same indicators. This is due to the requirement for vertical stability of the non-load-bearing insulation layer, which are imposed on partitions. It should simply stay in the cell under stable temperature and humidity conditions.

The thickness of the layer in these cases is determined by the design possibilities. The ideal option is to fill the entire thickness of the slab.

Roof insulation up to 45 °

The closer the slope is to the horizon, the less density is required to maintain the stability of the layers. The thickness of the insulation is usually equal to the width of the rafters (150-200 mm). In any case, you should never save on roof insulation - we are talking about blocking 40% of heat losses that pass through the roof. The money saved for one layer will be overpaid for heating within 2-3 years. You can use mats and boards with a density of at least 30 kg / m 3.

What is better basalt wool or mineral wool

The glass wool is soft and can be rolled up.

To understand in more detail how basalt wool differs from mineral wool, you need to consider the characteristics of these materials. Depends on them:

- installation;

- exploitation.

By and large, the installation of stone wool and mineral wool is no different, with the exception of minor points. Both materials can be installed on both horizontal and vertical surfaces. Stone wool is much denser, it is inelastic and brittle, practically does not absorb moisture and, even getting wet by 30%, continues to perform thermal insulation functions. This material does not shrink, all types of it can be laid under a screed or under plaster.

The first thing that distinguishes mineral wool from basalt is its density, which is much less. The material is soft, shrinks, very susceptible to moisture. Insulation strongly saturates water and removes it poorly, so it must be protected with special films (vapor barrier and diffusion membrane). Only some types of glass wool can be used for screed or plaster applications.

Installation of basalt insulation is made difficult by the fact that its fibers are short and fragile. They break, and as a result, there is a lot of dust in the air.

When it gets on the skin, it causes itching. Also, dust should not be allowed to enter the respiratory tract, since it settles in the lungs and is never removed from there. The problem of dust is also present during the operation of this thermal insulation. Small particles of basalt, which you breathe, can penetrate through the cracks in the cladding. Therefore, special attention should be paid to the tightness of the casing or to make a vapor barrier layer.

In terms of exploitation, glass wool is much better. First, an acrylic-based compound is used as a binder. Secondly, the insulation is elastic, its long and soft fibers do not break, so there is no dust at all. The material does not prick, some brands, for example, Ursa PurOne, look very similar to cotton in appearance. Therefore, in terms of environmental friendliness, glass wool is much better.

A two-pipe heating circuit with an electric boiler is no different from circuits with a gas or TT heater.

Read about the functions of a thermostat for electric heating boilers here.

Comparative table, which is better than mineral wool or stone wool:

| Basalt insulation | Glass wool | |

| Density | hard material | soft material |

| Fiber | short, brittle | long, elastic |

| Hygroscopicity | low | high |

| Thermal conductivity | 0.038-0.045 W / m * K | 0.036-0.042 W / m * K |

| Environmental friendliness | contains formaldehyde resins | acrylic based |

The main advantages of the product

- high fire resistance - non-combustible components of silicate rocks are used for production, which increases the fire resistance of cotton wool. It does not burn at high temperatures and does not lose its shape. A material with such properties is ideal for cladding warehouses with flammable substances;

- chemical resistance - cotton wool does not react to chemicals. Therefore, it is sheathed in production workshops, laboratories and chemistry classrooms in schools;

- resistance to bioorganisms - fungus does not multiply in mineral wool, rodents and insect pests do not live;

- minimal shrinkage - cotton wool does not lose its original volume and shape over time;

- lack of hygroscopicity - certain types of insulation do not absorb water;

- high level of vapor permeability - water vapors do not linger inside the cotton wool and pass through it. The room quickly loses unpleasant odors and the risk of condensation;

- excellent sound insulation - a layer of insulation protects the room from external noise;

- environmentally friendly product - it is hypoallergenic and safe for people;

- ease of installation - a special production technology simplifies the installation of mineral wool. A novice builder can also cope with the process of warming;

- long operational life - mineral wool will perform its functions and not lose useful properties for 70 years.