Panel houses have never been famous for their warmth because of the thin walls - both outer and ceilings, therefore, the owners of the apartments carry out the insulation of the panel house from the outside at the slightest opportunity. Thermal insulation of concrete panels helps not only to make an apartment warmer in winter, but also to keep it cool in summer, therefore, insulation of panel houses can be considered a universal means of ensuring comfort in a home. You can carry out work independently if your apartment is not higher than the second floor - otherwise you will have to seek help from industrial climbers or high-rise builders.

Insulation of a panel house with foam

Warming options and methods

When insulating the walls of a panel house from the outside, you can use a variety of materials, including expanded polystyrene, glass wool, stone wool or foam. In order to make the premises more comfortable for living, you can not install insulation sheets at all, but simply trim the outer seams. They are not only filled with building material, but also additionally waterproofed so that moisture no longer gets inside through them, which begins to expand when freezing, reducing the thermal characteristics of the walls. Joints can also be sealed with polymers.

If we consider the methods of attaching a layer of insulation, then it is possible to highlight the gluing of sheets or their mechanical fixation, and further finishing can be continued only three days after the foam is on the wall. If you choose mechanical fasteners, you should purchase mushrooms, which consist of a plastic sleeve. For them, you will additionally need to drill holes, and then cover the heads with plaster.

Thermal insulation technique for exterior walls in panel houses

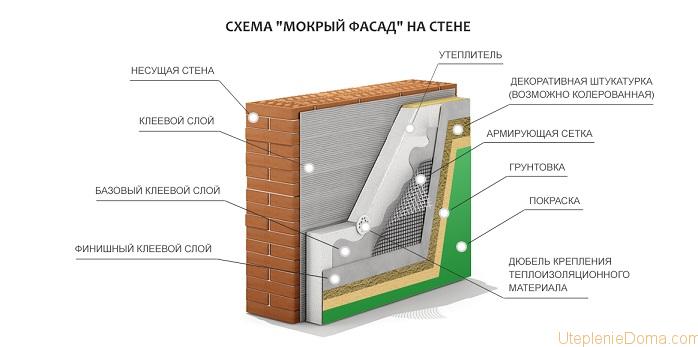

The method of insulation of external walls with polystyrene "Wet facade".

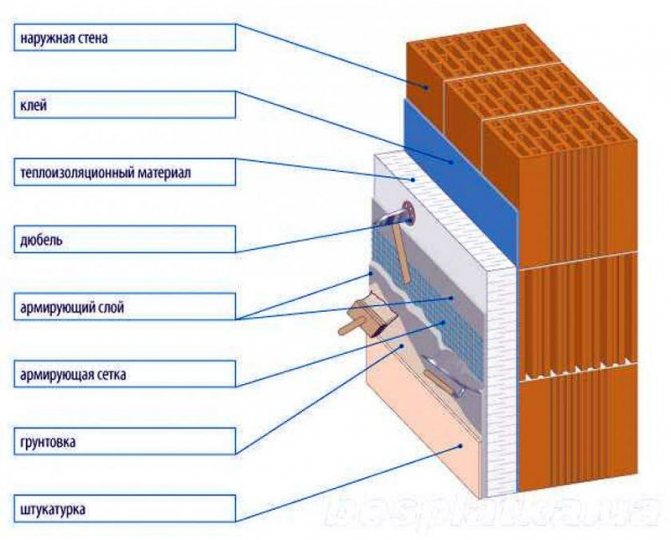

Let's consider how to insulate a panel house from the outside using the wet facade method. Everything is quite simple:

- we apply the adhesive to the foam plates and press them against the wall;

- after the glue hardens, the plates are fastened with dowels;

- the first layer of putty is applied over the foam;

- until the first layer has dried, the reinforcing mesh and plastic corners are sunk into it;

- a finishing layer of putty is applied;

- a visor is installed on the upper edge of the insulation;

- the finishing putty is primed and painted.

The slabs are laid according to the brickwork principle, with the joints shifted to the side by half of the slab. If the work surface is perfectly flat, then the adhesive can be applied with a notched trowel over the entire surface of the foam sheets. If the surface is uneven, then the flat cakes are dotted. How to apply the glue foam is indicated on the bottle.

We examined how to insulate a wall from the outside in a panel house correctly, in practice you can observe a picture when foam panels are attached only to dowels. Such craftsmen must be driven in the neck - this is a gross mistake, because of which there will be no sense in warming. When there is no glue, there is a single air gap under the insulation layer. It will not be possible to completely seal the ends of the insulation, as a result, air will circulate through the air gap, as in a ventilated facade.

Cold outside air will take away all the heat from the walls, and the insulation layer in this case will simply hang on the wall. Even heat engineers calculate the degree of heat loss of materials to the ventilation gap, that is, everything behind the ventilated gap does not perform any insulation function.Therefore, there must be glue in any case, at least to separate one plate from another, so that air cannot circulate under the foam layer.

How to choose insulation

When insulating the facade of a panel house, it is imperative to choose the right material. In this case, one should take into account not only the prevailing direction of the winds and the climate of the region where the house is built, but also the available funds, as well as the features of the facade of the building. Among other solutions, mineral wool should be highlighted, which, although well suited for outdoor work, provides waterproofing and protection from external influences. For this purpose, the insulation is closed with a vapor-permeable membrane, which copes with the task perfectly. You can also arrange a ventilation gap in which the membrane is not needed.

External insulation of a panel house can also be carried out with polystyrene foam, as well as extruded polystyrene foam. These materials have low thermal conductivity, so they can be used to insulate such buildings. If you choose between these two solutions, then you should think about foam. It is lightweight and easy to install. The apartment after such work will also be soundproofed. This is especially true if your windows open onto a playground. By installing additional plastic double-glazed windows, you will be less likely to hear screams from the playground on summer evenings.

It is better to insulate the outer walls of a panel house with material marked G1, which indicates the inability of the canvases to maintain combustion. By choosing the fibrous structure of stone wool, you get insulation that has a low density, but does its job well. Although this solution is inferior to the first two above-described options in terms of thermal conductivity, it does not ignite or rot. The layer will not remove the ability to breathe from the wall That is why, when choosing a material, one should take into account the fact that among the main characteristics there is a wind and steam capacity.

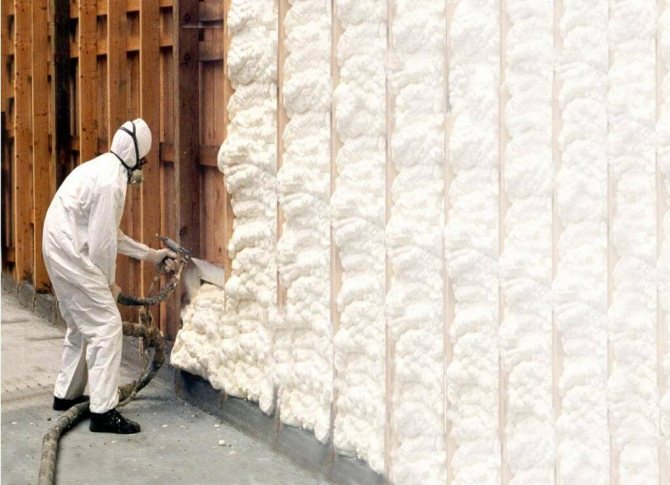

Another option for insulating the walls of a panel house is a relative novelty in the construction market - foamed polyurethane. It is known today as foam rubber or polyurethane foam. In the latter version, the material is used to fill the gaps.

You can choose a convenient application option by choosing a spray-on method of insulation or installation of plates.

When insulating apartments in panel houses, polyurethane foam sheets should not be used if you plan to equip a wet facade, since the canvases have a low degree of retention capacity for peel. But this material forms the basis of sandwich panels, and is also used in the manufacture of thermal panels, which are suitable for outdoor installation. But the wet facade system is almost always used in apartment buildings with partial insulation, but in the case of a private house, the choice of external cladding is somewhat wider.

If necessary, you can use sprayed PU foam to form a seamless layer. This requires professional installations that ensure the mixing of the components during the application process. For domestic use today, the production of one-component foam has been established, which is sold in an aerosol can. The apartment can be quite effectively insulated with another new material, which is created on the basis of cellulose fiber. Application is carried out using a special installation. Thermal insulation can be placed between the wall and the outer sheathing or on the batten. In the latter case, adhesive binders must be present in the mixture. At the final stage, the facade panels are installed.

Types of insulation for panel houses

Insulation of the facade of a panel house can be carried out with one of the types of thermal insulation. It can be represented by slabs or rolls when it comes to mineral wool.If you prefer to work with foamed materials, then rigid or liquid versions should be distinguished among their main types. For example, when insulating joints in panel houses, foam is used, which, after application, begins to increase in volume, filling the hollow space.

Mineral wool

Insulation of facades of panel houses is often carried out with mineral wool. This material is divided into several varieties, among them it should be highlighted:

- glass wool;

- slag wool;

- stone wool;

- basalt wool.

The first has characteristics of strength and elasticity. When working with this material, you should wear protective clothing and protect your eyes and breathing. Thermal insulation of a panel house with mineral wool is less often carried out by its slag variety, since it has lower heat resistance rates. In order to create better conditions in the room, a thicker layer of insulation should be installed. If you want the walls to continue to breathe after insulation, you can choose stone wool, which copes well with high temperatures. Insulation of the facade of a panel house will be most effective if you use a basalt variety of cotton wool. It differs from stone in that there are no harmful inclusions in the composition, which allows the material to endure temperatures up to 1000 ˚С. The layer does not burn, which is important when working with the facades of private houses.

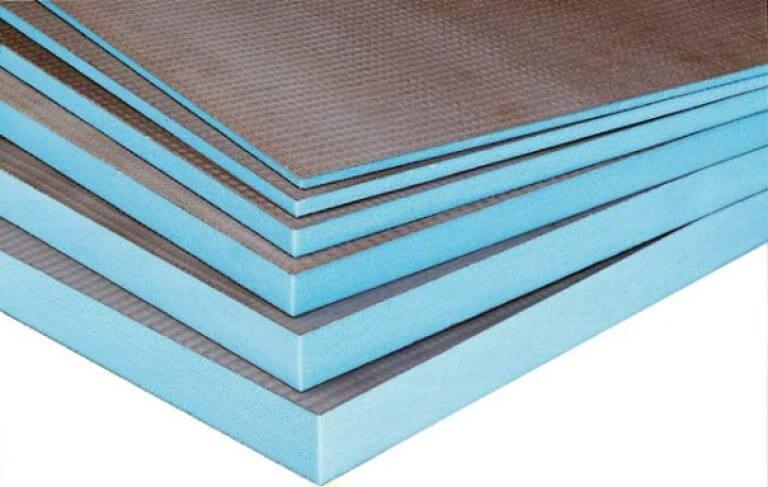

Extruded polystyrene foam and foam

External insulation of an apartment in a panel house can be carried out with rigid polystyrene foam plates or polystyrene foam. The advantage here is the cost savings for the installation of the ventilation façade. The structure of the canvases is very dense, the walls after insulation do not stop breathing, which eliminates the need for a ventilation system.

The materials are very fragile, but have many other advantages such as low weight and ease of processing. Microorganisms do not form on the surface, moisture does not affect it, which does not penetrate inside. The service life is not limited, and the installation is very simple. The materials are affordable and able to withstand all weather conditions.

These solutions, however, have two important drawbacks, which are the ability to burn and melt.

If we compare these two options according to the principle of moisture absorption, then extruded polystyrene foam does not have as high moisture absorption capacity as foam. In terms of sound insulation, these materials are not inferior to each other. If density is important to you, then foam is 4 times lower than that of its competitor. If you still cannot decide what material to use when insulating a corner room outside in a panel house, you should pay attention to the global trend that involves replacing foam with extruded polystyrene foam. Today it is more popular, modern and has more outstanding quality characteristics.

Speaking about specific manufacturers, the extruded polystyrene foam from Technonikol is a material with unique qualities. Not only is it affordable, but it can also be used on a variety of surfaces. When purchasing material for walls, you can use it in the future for plinths, roofs and foundations. The canvases do not absorb moisture, which means they do not swell or shrink over time. Chemicals can attack their surface without damaging the structure.

The material has high strength. The layer will be resistant to rodents and insects, and heat retention will be 1.5 times more effective than foam and twice as effective as glass wool or stone wool.There is no formaldehyde among the ingredients, the material does not emit odor and provides a high speed of installation. The service life can be up to 50 years. During the entire period of use, the material will not be hazardous to health.

Stages of the facade insulation process

Insulation of the walls of a panel house is sometimes a necessary procedure, since such buildings have never been famous for comfortable living conditions in the cold. This is especially true if the building is old and the heating system no longer meets the requirements for normal operation.

First you need to pick up the material. If you are guided by price, then choose foam, since it is the most affordable today. The canvases are lightweight, which means they can be easily lifted to a height and held during installation. The disadvantages here are known to everyone, they lie in the fragility of the material and fire hazard. These disadvantages can be eliminated by overlapping the layer using the plastering method.

It is best to insulate a panel house with foam plastic with a material whose density exceeds or is equal to 18 kg / m3. Mineral wool is more durable, it does not burn and is environmentally friendly. But it costs more, and when working, you will have to additionally use special clothing and glasses. When choosing this material, it should be borne in mind that its density should be equal to or greater than 85 kg / m3. It is also important to consider the thickness of the roll, which should be 100 mm or more. This applies to mats and slabs.

Preparatory stage

When insulating an apartment in a panel house outside, it is necessary to prepare everything for work. The boards are usually installed with construction adhesive. You can purchase it ready-made or dry. For mineral wool and foam, there are different types of compositions, but if you wish, you can purchase a universal mixture.

The walls will need to be freed from contamination, for this you should also arm yourself with some tools. Seams should also be repaired, which are filled with foam or liquid polyurethane foam. When insulating panel houses with foam and mineral wool, mechanical fasteners in the form of plastic dowels are used.

Before starting work, it is recommended to treat the walls with a primer, which is necessary to increase adhesion. After installing the material, it is covered with a mesh. It can be steel or fiberglass. Insulation of panel houses with polystyrene means the use of perforated corners. You can choose those made of aluminum or galvanized steel. For finishing work, you will need decorative plaster or paint, everything will depend on what your budget and finishing preferences are.

When buying insulation, you should determine the surface area of the wall and the area of one slab. The first value is divided by the second, which will allow you to get the number of sheets that will be needed for insulation. To this value should be added about 15%, which will be used for pruning.

Insulation of a panel house begins with the preparation of the walls. Old coatings are removed from all surfaces, be it plaster, whitewash, ceramics or paint. The base should be cleaned of dust and dirt. If necessary, the surface is washed with water and left to dry. Then you can proceed to the insulation of the joints of the panel house between the plates. The seams are filled with foam. If their space is too narrow, then it is better to decipher so that the seam itself does not increase when used under a layer of insulation. The surface of the seams is cleaned and moistened, then construction foam is poured into it. Alternatively, concrete putty can be used. After these materials have dried, the excess will need to be knocked down. Outer walls are well cleaned.

Insulation installation

The technology of insulating panel houses at the next stage provides for the installation of thermal insulation. In order to ensure a more economical consumption of glue, you should purchase it dry. Mixing is easy, just add water and stir. The mixture is applied to the reverse side of the insulation with a notched trowel.

If the walls are uneven, they can be leveled with plaster. The composition is applied in lumps, and then distributed. To insulate a room from the outside, you need to start from the corner, moving to the side, and then up. The position of each sheet is controlled with a building level. The second sheet is glued on the opposite side of the surface. A cord should be pulled between the canvases, along which all other sheets will be attached. To maintain horizontality and verticality, corner beacons are installed on the wall. They are fastened to plaster or alabaster. According to this algorithm, the first row is installed. The layer of glue should not turn out to be too thick, otherwise you will be faced with its overuse. All subsequent sheets in other rows must be stacked with an offset so that cold bridges and long seams do not form.

At the corner of the house, you need to ensure the binding of the sheets along the edge. The material should be reinforced with umbrella dowels. There should be 5 of them on one sheet. One should be placed in the center, the others along the edges. For fasteners, holes are additionally drilled in the sheet.

Preparation for reinforcement

The layer of plaster on the insulation must be leveled. The fastener caps are overlapped with the mixture. A perforated corner is installed on the outer corners. It is fixed with glue. The gaps between the sheets must be filled with polystyrene, placing it on the same glue.

Finishing

The reinforcement mesh must be fixed to the slopes of the windows. Apply 3 mm of glue to the same surface. As soon as the first layer of mortar is dry, you need to apply another one and level it with a spatula. Once the reinforcement of the slopes has been completed, you can begin to install the mesh over the rest of the surface area. The walls are primed and painted as needed. After applying the primer, plastering can be done. The first layer is rubbed with a small piece to give the surface a patterned texture. At the last stage, the walls can be painted with an acrylic compound, which is pre-tinted if necessary. The paint is applied with a roller.

Insulation of apartments outside

With the onset of cold weather, the problem of keeping warm in the apartment comes to the fore. You can, of course, put on warmer clothes or turn on several heaters at once and then go broke on electricity bills. But it is better to once correctly and thoroughly insulate the walls from the outside of your apartment and save yourself from significant heat loss, as well as prevent the appearance of various types of mold and mildew outside, as well as insulate corner apartments, insulate the walls of a corner apartment, insulate an apartment on the ground floor ... And in the hot season, thermal insulation will protect the outer walls of the house from heating by the sun's rays and help keep the rooms pleasantly cool. At the same time, there will be no need to evict the inhabitants of the apartment during the thermal insulation work. That is why additional insulation of the facade will come in handy at any time of the year. It will also be necessary in an apartment where dampness on the wall is present even during warm periods, especially if it is corner in the house.

Therefore, this procedure can be called simply necessary, especially in old panel houses.

So, the process of facade insulation consists of several main stages:

- Preparation of materials

- Preparing walls

- Insulation installation

- Preparation for reinforcement

- Reinforcement

- Gunting

- Decorative plastering

- Painting

Thermal insulation material is attached to the building facade, covering all the outer walls of the apartment. Externally insulating walls of an apartment has several advantages:

- the area of the dwelling will not decrease;

- all work will take place outside the window, you will not have to move furniture or move to relatives for a few days;

- the walls will not freeze through, thaw, which will exclude the appearance of cracks;

- the humidity in the apartment will decrease.

Tips from the masters

- End freezing of panel slabs in an apartment building can be a serious problem. Some also carry out internal wall insulation using the drywall installation method. For this, a frame is installed, between the elements of which insulation plates are placed, for example, mineral wool. GKL is installed on top, which is then covered with a decorative layer.

- When insulating a panel house from the outside with foam, according to experts, the material should be purchased only from trusted manufacturers. The company must have a manufacturing license. This is due to the fact that the production technology is very simple, it attracts not very conscientious entrepreneurs. The market is filled with less quality goods today.

- When insulating a panel house with penoplex and then finishing it with plaster, the cladding procedure should be performed in one go. Otherwise, you may be faced with the fact that the joints may be visible to the eye.

- If you decide to carry out insulation with foam, you should take care that condensation does not form between the insulation and the wall. It can appear due to the fact that the glue was applied in separate lumps and is not distributed. This allows the formation of air pockets, which are subsequently filled with moisture coming from the premises of the apartment.

Cost of materials

If you are already fed up with end freezing, it's time to start insulation work. But first you need to ask about the price of the material. For example, Rockwool mineral wool will cost 495 rubles. per packing. The dimensions of each sheet are 50 x 600 x 800 mm. The material is presented in slabs, and its density is D35. The package contains 12 canvases. Knowing the area of each of them, you can calculate how much is needed to carry out the work.

Prices for polystyrene are slightly lower compared to expanded polystyrene. So, you can buy extruded polystyrene foam "TechnoNIKOL" for 1174 rubles. for one package. The length, width and thickness of the material are 1180 x 580 x 50 mm. The canvases are connected to each other by an H-shaped profile, which eliminates cold bridges and reduces installation time. The package contains 8 sheets of 5, 475 m2.

How is the work done?

There are many options for materials with which you will achieve the optimal result. The specialist who will perform the work will be able to determine the level of the problem while examining the walls of the housing and suggest ways to solve it, depending on your capabilities, requirements and requests. You yourself decide what materials should be used to repair the walls, because not only the cost of the work, but also their durability will depend on your choice. The manufacturer specifies the service life of each material. For example: mineral plaster will last, without losing its qualities, for about ten years. Acrylic, silicate or silicone have a service life of twenty to thirty years - in general, under the guidance of a professional, we are sure that you will make the right choice.

Sealing interpanel seams of a typical house

The complex of repair measures, conscientious performers begin with the repair of interpanel seams. If they are destroyed or begin to deteriorate, their integrity must be restored. This will allow you to achieve the best result and protect you from worries about re-insulating the walls.

The actual insulation of the walls is carried out with expanded polystyrene plates, which are attached to the walls using dowels with plastic or metal nails. For a better fit of the plate to the wall, its inner part is coated with a special thermal glue, and the slots (if any) are filled with foam. Reinforced mesh is applied to the reinforced panels, which becomes the basis for applying the plaster to the surface. It should be noted that the work is carried out in such a way that all interpanel seams (horizontal or vertical) overlap and are reliably protected by panels, and the joints of insulation and window openings, joints of windows and new ebb tides must be properly treated with a sealant. When the main work is completed, the insulation is primed and painted.

It will not be superfluous to remind you that work at heights is of increased complexity and therefore striving to save money by performing the necessary measures on your own can be extremely dangerous! Do not trust amateurs who offer you low prices by calling the amount of work and their cost. Without a thorough inspection of the site, only scammers can make an estimate!