Vapor barrier tape and its types

The replacement of windows in the house is always accompanied by the installation of protection for the joint between the frame and the wall. Polyurethane foam is applied between the opening and the frame - a traditional and proven thermal insulation. Foam regularly performs its role, but with extreme exposure to moisture or ultraviolet radiation, its quality may change for the worse.

In order to exclude the possibility of such a situation in advance and save yourself in the future from replacing the polyurethane foam, you should think about sealing the seams. To do this, you need to install additional insulation.

Window butyl vapor barrier tape as an element of additional insulation

A complete set of insulation allows you to avoid freezing of the room and to maximally exclude the penetration of moisture and noise.

How and how to insulate

Window insulation measures are divided into two categories: temporary and conditionally permanent. Temporary ones are held annually with the onset of cold weather - these include insulation with paper, cotton wool, foam rubber. Conventionally permanent methods include methods using polyurethane foam, sealant, rubber or polymer seals. Let's take a look at each of the thermal insulation methods.

Newspaper (paper strips)

This method is very old, our grandmothers still used it. Over time, the method of insulating windows using newspapers or paper strips has undergone some transformation, and now there are several options for its implementation. A paper putty can be made to seal window holes and seams.

We level our site, and build a cellar, veranda and perlog.

It is necessary to grind paper or old newspapers, soften with water, and add clay or crushed chalk to the resulting mass. We cover the cracks with such a mass; for this it is better to use a knife or a metal ruler.

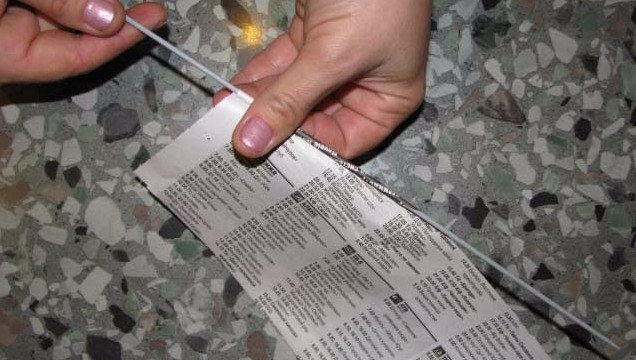

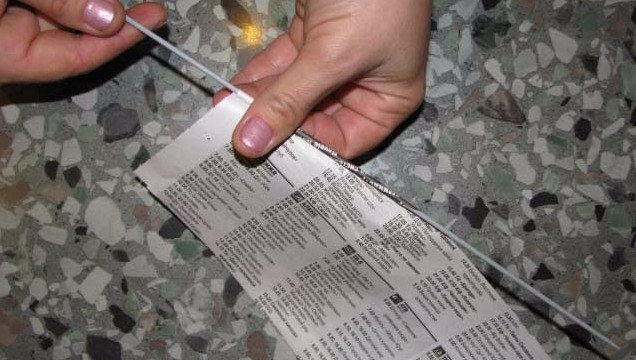

Such a tool penetrates well into hard-to-reach places. Window tape or paper strips are suitable for closing this putty. You can also use strips of fabric. You can glue them with soap and water: grease the pre-moistened strips with soap and cover them with paper putty.

Another variation of this method involves insulation with paper rolls. The cracks are sealed with twisted paper tubes soaked in water. The joints of the frame and glass are sealed with paper strips coated with soap.

Important! Old paint may peel off when using tape, so painting may be required.

This method is very effective, but it is only temporary protection from the cold. With the onset of warm days, the insulation must be removed. But at this point, a new problem arises related to thoroughly removing the paper.

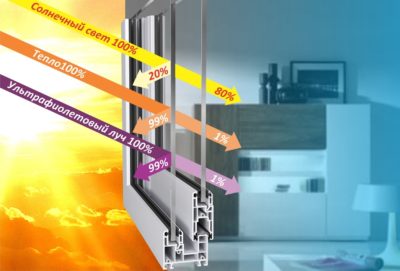

Energy Saving Film

A new trend in window thermal insulation is the use of energy-saving films. Its principle of operation is to reflect infrared rays and reduce heat loss. Such a film in winter will protect the house from the cold, and in summer it will prevent the room from heating. It is a good barrier for maintaining a comfortable climate in the house.

This protection can be applied to the entire surface of the window, and not just to the glass, which creates additional thermal insulation. Energy-saving film is also called the "third glass". There is a film that is glued to the window frame and forms an additional protection 0.5-1 cm wide. After its installation, the temperature in the room rises by 3 or even 7 ° C. The application of this method is convenient for both plastic and wooden windows.

Polyfoam, polyurethane foam, basalt wool, foam rubber, paraffin

Other materials are also used to insulate windows.For example, a foam sealant, paraffin wax, polystyrene or polyurethane foam. Consider the features of the use of each of these materials. The use of foam strips will help protect windows from drafts. This material easily penetrates the gaps between the sashes and the window frame. Narrow foam strips are perfect for gluing window sashes around the perimeter, they fit snugly and allow you to use the window in winter.

If you stick such a seal in several rows, this will improve the tightness of the room. Gaps larger than 2 mm can be sealed with flat foam rubber. To fill the cracks with foam rubber, use a thin and blunt object, for example, a screwdriver or a table knife. After filling the gaps, they are sealed with tape, which provides additional thermal insulation. It is convenient to seal small cracks with paraffin. Using a steam bath, it is heated to 60-70 ° C - in this state it is easy to draw it into a syringe - after which the slots are filled with it.

Store vegetables properly in your home.

Paraffin is an excellent draft barrier. If the gap is large enough, then use a clothesline in combination with paraffin. But such protection is only enough for one season. You can insulate wooden windows using a sealant (acrylic or silicone). These sealants are applied to the border between the glass and the frame, as well as between the window sill and the window profile. To seal the window frames, it is necessary to first dismantle the glazing beads, clean up the debris and apply sealant to the junction of the glass with the window frame.

The glazing beads can be mounted only after the sealant has completely dried. It should be borne in mind that after dismantling the glazing beads, you may need new ones, since they often break. Thus, you will not only insulate the window, but also carry out repairs.

Important! To fill up gaps in wooden windows, you can use wood putty or a mixture of plaster and chalk. After completing the insulation work, varnish and paint can be used as a topcoat. Unlike sealant or paraffin wax, this coating is easy to apply.

As insulation of slopes, foam plastic can be used, which is used for both external and internal decoration. Before using the foam, it is necessary to pre-treat the surface: remove dirt and old polyurethane foam. To insulate slopes, it is better to use sheet polystyrene, which is easy to use and has high thermal insulation properties. Styrofoam is glued to the slope and all cracks are closed.

A reinforced mesh is glued to the foam base, then you can apply plaster and paint. Basalt wool, like foam, is an excellent insulating material. The use of this material will allow you to insulate slopes and window sills. The advantages of this material include fire resistance. When using this material for external insulation of slopes, additional finishing is required, since this material easily gets wet and loses its thermal insulation properties.

Make a retaining wall at the site.

Sometimes a simple insulation or sealant is not enough to insulate windows. For example, when there are large gaps in the window frame or it comes through at the junction of the window opening and the frame. In such cases, it is better to use polyurethane foam. With its help, you can not only insulate the slopes, but also isolate the space under the windowsill. But in the course of prolonged contact of the polyurethane foam with the external environment, it degrades its insulating properties and may even partially collapse. Such insulation is a very effective and affordable solution to the problem of heat loss.

Important! For sealing, you can prepare your own putty. To do this, you need to mix 1 part of chalk and 2 parts of stucco with the addition of water. This putty will be an excellent alternative to polyurethane foam.

The window structure can also be sealed using a tubular profile. It is distinguished by high reliability and long service life, which will allow them to be classified as conditionally permanent methods of insulation. It is better to install such an insulator in the warm season, but it can be done with the onset of cold weather, the main thing is that the temperature does not drop below -10 ° C.

It is attached to the window frame with a self-adhesive strip. Such isolation is laborious, but the result will not be long in coming. The tubular seal is used for window thermal insulation using the so-called "Swedish" technology.

Before starting work on the insulation of windows, it is necessary to determine the size of the seal. To do this, use a piece of plasticine wrapped in polyethylene. It is placed in the gap between the sash and the frame and the window is closed. Depending on the size of the gap, a tubular gasket of sizes E, P, D is used. To install the gasket, a gap must be made in the base frame. Secure the seal with glue. The use of this method allows windows to be insulated for 20 years, or even more.

Vapor barrier

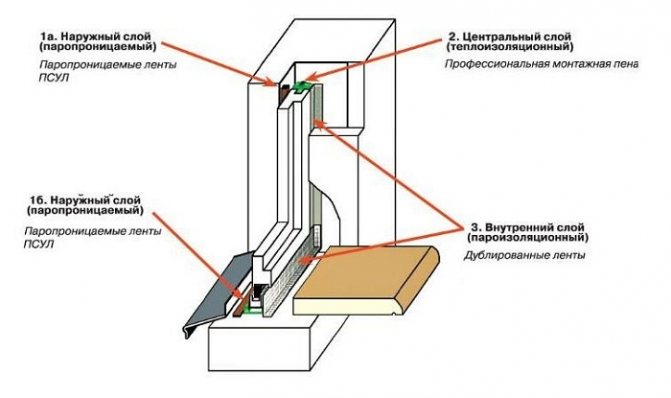

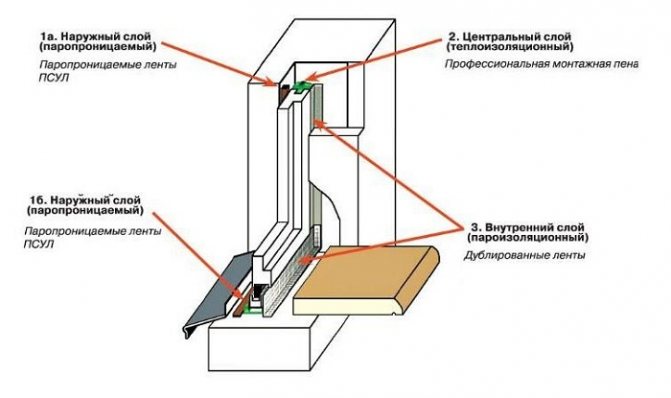

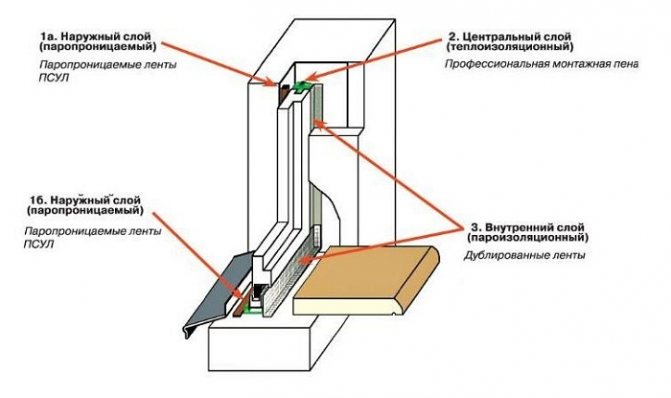

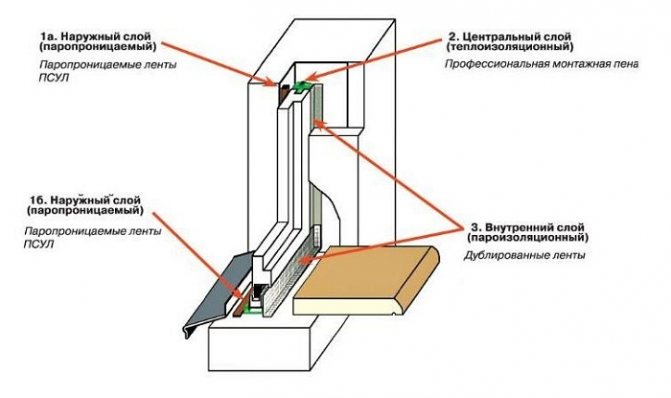

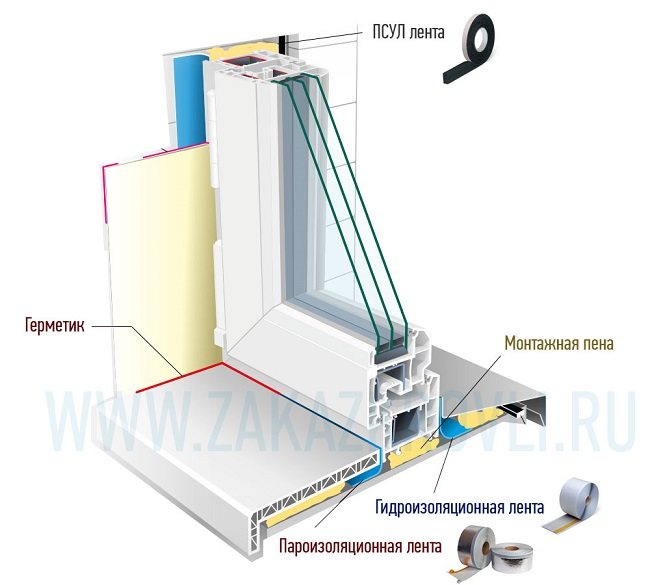

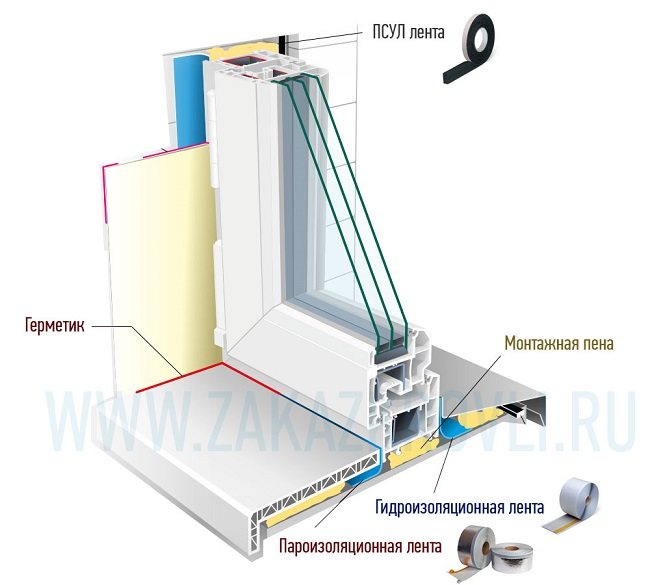

The insulation of the wall-window joint consists of three layers:

- Outer. Its function is waterproofing, which means protecting the room from any weather conditions - snow and rain.

- The bearing layer of insulation is located in the middle of the joint and is responsible for heat and sound insulation. Frost protection is provided by a porous material resembling polyurethane foam. The sealant prevents moisture from getting inside.

- The inner layer is also considered to be heat insulating. Here the mechanism of heat conservation is different. This layer does not allow heat to escape from the inside, in contrast to the outside, which protects the premises from cold air currents from the street.

Window insulation layers

Vapor barrier of windows refers to the inner layer, but is not always included in the insulation system. One-sided self-adhesive vapor barrier tape or double-sided vapor barrier tape is an additional protection. The need to use tape increases if the window is installed in a room with a high moisture content: kitchen, sauna, bathhouse.

Installation of vapor barrier tapes in complexity does not surpass the installation of other types of seam insulation. However, a vapor barrier can help avoid subsequent serious problems with the entire window protection system. When installing a vapor barrier, in some cases, you may need a couple of additional accessories, for example, a vapor barrier tape. It is worth considering.

Protective film on windows - features and reasons for difficult removal

To prevent damage to windows during transportation, installation and repair work indoors, manufacturers cover them with a special two-layer film. The outer layer is transparent, dense and strong enough - it is easily separated from the inner part without creating any special problems. Difficulties arise with a thin inner layer that is sensitive to sunlight and is very fragile. Reacting to ultraviolet light, a thin white film quickly "cakes" and adheres so firmly to plastic that it is almost impossible to separate them. These same rays disrupt the structure of the material, reducing the strength of the coating and making it even more difficult to remove.

For this reason, installers carrying out the installation must warn buyers about the presence of a protective film on the windows and the need to remove it as soon as possible. Unfortunately, this is not always the case (for example, if the windows are installed in a new house before the occupants enter it) and the owners often have to put the windows in order several months after the period recommended for removing the coating. It is quite difficult to do this, but it is necessary, because protection spoils the appearance of structures, especially if they have a colored decorative coating.

Laminated windows are even more difficult to clean - they cannot be washed with gasoline, acetone and other substances containing solvents.Methods of mechanical cleaning are also not suitable here, because the decorative layer is very easy to damage. There are several safe ways to clean your profile as gently as possible. And we will consider one of them right now.

Classification of vapor barrier tapes

Vapor barrier tapes are manufactured in two versions:

- tapes with one adhesive side;

- double-sided vapor barrier tapes.

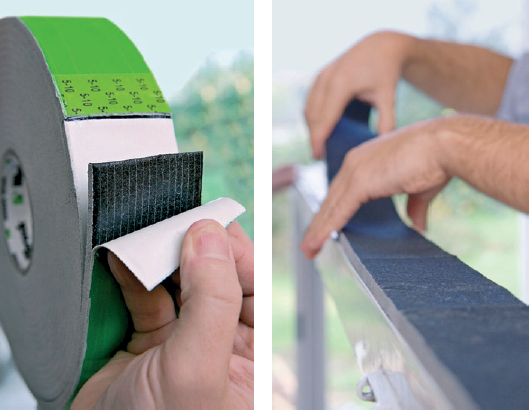

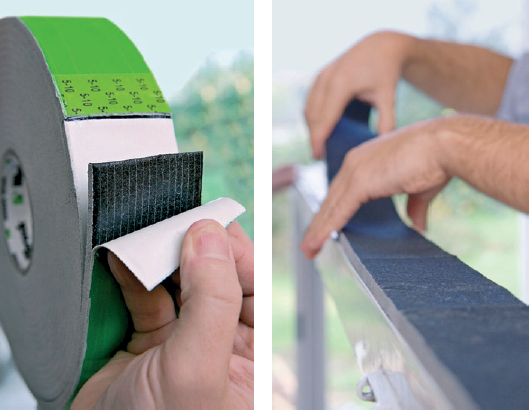

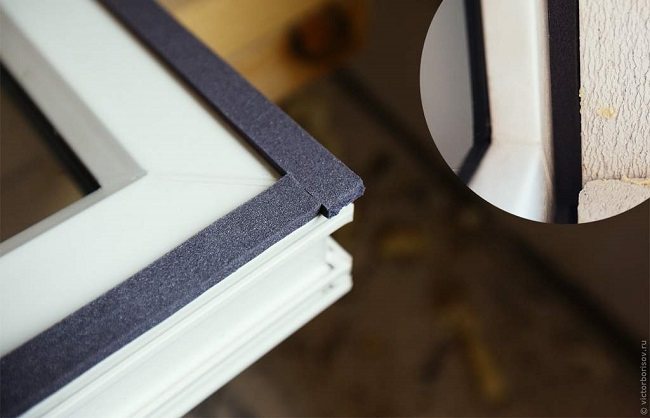

Butyl vapor barrier tape for window

The first type of tape is attached to the window frame of the window. The second makes it possible to choose the place of attachment: both on the frame and in the opening.

In addition to differences in adhesive structure, tapes are divided into two types according to climatic performance:

- for predominantly warm average annual weather, "summer" vapor barrier films are suitable;

- in the presence of subzero temperatures, "winter" tapes are used.

Prices for pasting windows with foil

| Film type | Price (work + material) |

| Sunscreen | from 800 600 rubles / m2 |

| Mirrored | 750 600 rubles / m2 |

| Matt | from 800 600 rubles / m2 |

| Protective | RUB 700 / m2 |

* prices are valid for orders of at least 10 m2. The price includes film and installation.

Discounts are calculated individually when ordering from 50 m2.

For a faster order, detailed information by phone

+7

Adhesive surface of vapor barrier tapes

All vapor barrier films are equipped with an adhesive strip. The absence of the need to independently apply glue eliminates the possibility of poor-quality fastening of the tape, as well as the ingress of moisture into the heat-insulating environment.

The material for the adhesive layer of the vapor barrier tape is butyl rubber or, in cases of high humidity, metal. Tapes containing rubber foil are used for windows, balconies and doors in almost all types of premises. The basis of such a vapor barrier is a non-woven fabric.

How is pasting done

Our masters do everything consistently and correctly, taking into account the recommendations of film manufacturers.

- A film coating is selected for a specific object.

- The film is cut to fit the window area.

- The surface is carefully prepared.

- Installation is carried out using tools and materials.

The step-by-step execution of operations allows you to guarantee the result and make the surface even, smooth, without bubbles, cracks and creases.

Customer Reviews

Types of vapor barrier tapes

The most common types of tapes, depending on the material:

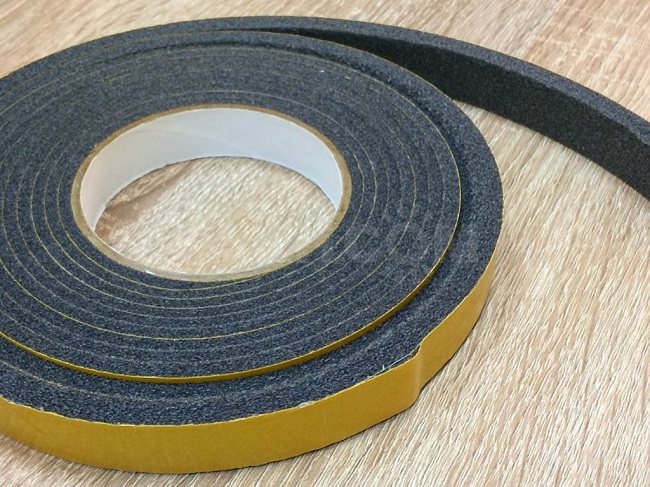

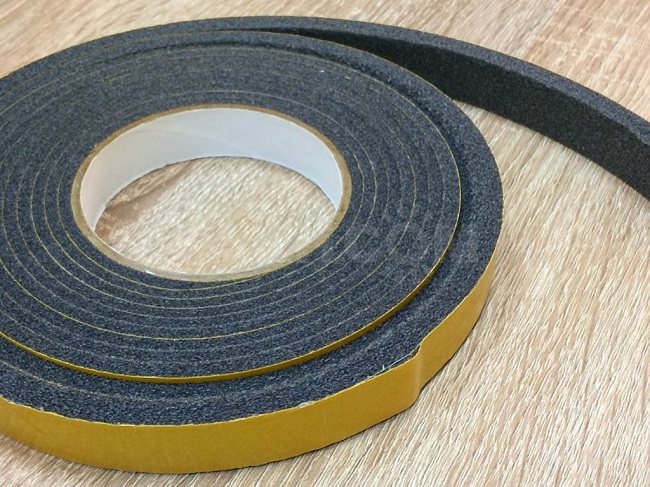

- Some of the most popular butyl rubber tapes are PSUL (pre-compressed sealing tapes), which are responsible for the external vapor barrier, finishing of the external joints and the tight connection between the frame and the wall.

- Polyethylene tape ГПЛ is made of foam material. On the one hand, it is processed by lamination. The strip contains metal inserts and an adhesive part along the entire length and width. Due to its well thought-out composition, it is practically universal and is recommended for insulating all types of door and window frames.

- Vapor barrier tape for VS windows. Suitable for insulating joints if a subsequent dry method of finishing slopes is planned. Usually applied on plastic or plasterboard elements. The bonding tape protects the surfaces from condensation. The wide adhesive strip makes the installation of the vapor barrier strip quick and easy.

- VM vapor barrier tape. As well as other types of tapes, it is perfectly attached to window and door frames. Installation is carried out in sequence from the frame. The strips of tape are overlapped in order to avoid possible heat leaks during the operation of windows or doors.

Butyl rubber tape has a high specific gravity. The PSUL tape weighs about 5 times more than the tape made with reinforced aluminum foil at the same width. The differences between the types of tapes also lie in the surfaces for which they are usually used.Thick rubber tape is able to adhere firmly to the wall, and there is no need to use heavy insulating materials for gluing with slopes. For this case, lightweight foil-reinforced strips are preferred.

Types of material

Depending on the place of application, the insulator can be external and internal. The first type is used for sealing assembly joints from the street, therefore it is highly resistant to weathering and mechanical damage. To do this, they most often use:

- a waterproofer on a polypropylene basis, which allows you to abandon expensive sealants, because due to its unique structure, the material well removes moisture formed on the foam and reliably blocks its flow from the street into the room;

- PSUL (pre-compressed sealing tape that looks like foam rubber). It removes moisture well from the polyurethane foam and, in addition, reliably protects it from the effects of ultraviolet radiation. The material is produced in two colors - gray and black (due to its excellent qualities, it allows the installation of windows even in winter).

Related article: Reflective roller blinds for plastic windows

To exclude the flow of vapors from the foam into the room, a special type of vapor-waterproofing material is used.

GPL tapes

GPL - steam waterproofing tapes that perform moisture protection as the main task. These tapes form the outer layer of insulation with an additional vapor barrier function.... Self-adhesive vapor barrier tape is made of foamed polyethylene.

Polyethylene foam has a porous structure, has good thermal insulation properties and practically zero hygroscopicity (does not absorb moisture). The presence of this material in the tape makes it elastic and provides high-quality sealing with any surface, including uneven ones.

Vapor barrier tape for PVC windows. What is it and how to glue it

Photos from the site: izollab.ru

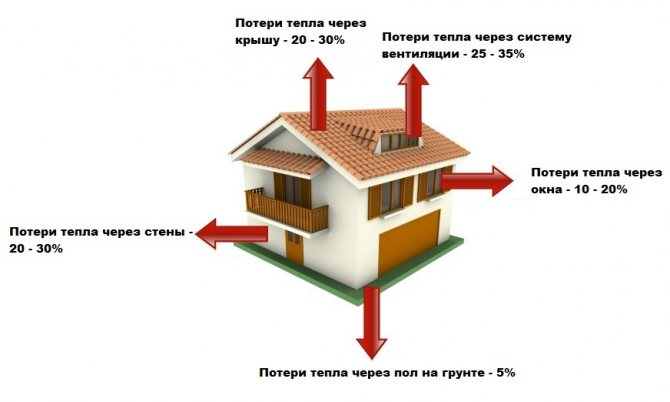

If we talk about the vulnerability of any building to a wide variety of influences, both from the inside and outside, then such places as, for example, the joints of the windows of the window frames themselves with openings in the wall immediately come to mind. The thing is that it is in these places, with improper installation of window structures, heat can be significantly lost, also outside, if there are cracks, noise and extraneous sounds can penetrate inside, and on top of that, there is also dust that is ready to penetrate through the smallest holes ... In order to keep the heat inside the house with high quality, as well as to ensure the long-term service of the structures, a vapor barrier tape for plastic windows was invented, which many simply do not install, thinking that this is simply an extra hassle.

Identification of problem areas

If examining common blowing spots does not help identify the problem area, you can use other methods. The first way is to run a damp hand around the perimeter of the window; there will be a feeling of a strong temperature difference at the place of blowing. Another option is to inspect the inside of the frame, but this method is only suitable for plastic windows.

If these simple methods do not allow you to identify problem areas, then you can use the flame of a candle or lighter. If you run a burning candle along the window frame, the junction with the slope and the window sill, the flame will begin to vibrate at the blowing points.

Properly equip your garden area, and add to it a fountain, waterfall, front garden, gabions, rockery, decorative fences, barbecue, gazebo and garden swing.

Mandatory three layers: vapor barrier for PVC windows

Photos from the site: izollab.ru

Whatever one may say, the correct vapor barrier from the inside, as well as waterproofing from the outside, really plays a huge role in preserving the walls and the window structures themselves, preventing cold air from getting inside, as well as warm air leaking out.Moreover, the places of the assembly seam are the most vulnerable, which is why they must be performed taking into account all technological nuances, one of which is the vapor barrier of window slopes, seams, openings, and so on. Moreover, professional builders distinguish three main layers, the quality of which must be monitored.

Correct installation of window structures that provide three levels of insulation, that is, when the seam is three-layer, which can be read about a little below, can completely exclude freezing through it during the winter cold. This also completely eliminates the appearance of condensation on the slopes, prevents their cracking and deterioration. That is, you can pick up a wide variety of materials for yourself, since the market provides such an opportunity, however, there should be three layers of embedding in any case.

- The middle seam, which is just under the window structure, performs the function of heat and sound insulation, and it can be safely considered the main one, as it were, load-bearing.

- The layer on the outside is considered waterproofing, since it prevents moisture from entering the inside, which can lead to the entire structure, a terrible black mold may appear, and so on.

- The inner layer is vapor barrier, which just does not allow the heat from inside the premises to leak out.

Which sealant to choose?

When installing windows, silicone-based products are most often chosen. To protect the material during work, an acrylic mass is applied. Also, a seal in the form of a tape is actively used on the frames.

Installation of plastic windows and waterproofing of their seams with the wall is equivalent to the installation of ordinary windows. After installing the plastic windows, the gap between the frame and the opening is filled with foam, after which the seams are carefully sealed and sealed. In this case, inside the room, you can only fill the joint, and work on its sealing must be carried out from the front side of the building.

Such a sealant is very resistant

Sometimes the technology of waterproofing plastic windows is violated, which leads to the following consequences:

- the thermal resistance of the seams is disrupted, as a result of which cold air enters the room through the gap between the frame and the opening;

- the service life of thermal insulation is reduced, since it will be negatively affected by UV rays, frost, moisture.

All this adversely affects the sealing and condition of the room itself. Moisture begins to seep inside, damaging surfaces, plaster, wallpaper. The room gets cold and uncomfortable.

To keep the room warm, PVC structures must be insulated. Misting windows and surfaces do not look aesthetically pleasing. Mold and mildew grows quickly on damp surfaces.

Incorrect installation of slopes provides 40% of heat loss, so slopes are not just decorative elements, but also, when properly installed, increase the level of heat in the room. In addition, improper installation of the slopes contributes to the fact that the foam will be filled with moisture and steam, as a result of which its properties will be violated.

With the wrong slope, you can lose up to 40% of heat

To eliminate the appearance of condensation on plastic windows, different manufacturers apply their own preventive measures for waterproofing. Some of them use a hydrophobic film. It is based on silicon, which is endowed with moisture-repellent properties. The cost of the film is not high. It has a long service life and helps to protect the seams and maintain a comfortable indoor climate.

Sectional slope trim

Other companies use bitumen-based liquid rubber for window installation and sealing. This mass is flexible enough and has high insulating properties. Its disadvantage is its high cost.

High-quality installation of windows is impossible without sealing. Sealing of window openings with errors uncontrollably leads to a violation of heat exchange.

Vapor barrier tape for PVC windows: general information

Photos from the site: izollab.ru

It is clear that if you really want to ensure the reliability and durability of a brand new PVC window, so that it will last the maximum period with the lowest cost, you should always do everything thoroughly and according to the technology. High-quality materials for embedding, high professionalism of the installers themselves, good quality of the window frame and glass unit, as well as a good vapor barrier tape for windows can guarantee high performance in all necessary parameters. Moreover, it is worth knowing that the higher the humidity inside the premises, the better such a vapor barrier should be, preventing moisture from entering the slopes, frames, and so on.

First of all, you need to know that all vapor barrier tapes can be conditionally divided into those that have only one adhesive surface, with which they will be attached to the frame itself, or double-sided. The second option can already be fixed not only on the window structure itself, but also in the opening. Among other things, before the vapor barrier of a PVC window is purchased and installed, it is necessary to find out what weather and climatic conditions it is intended for. Moreover, there is a summer version of films on sale, designed for temperatures from five to thirty-five degrees of heat, as well as from zero and below, that is, a winter version.

Films for euro windows

Euro windows include structures assembled from aluminum, plastic and wood profiles. An additional feature of these models is the presence of double-glazed windows, tightness contours and modern fittings. The film is applied to the euro-windows in exactly the same way as on the old-style joinery. In all cases, it is glued to the glass. That is, there is no fundamental difference between polymer coatings for different types of windows.

To avoid confusion when purchasing, it is recommended to use the correct names. It is advisable to voice to the seller the main characteristics that the protection should have. Only in this case, the tinted glass unit will perform all the necessary functions.

The best mounting tape for windows: what it can be

It is also worth knowing that the adhesive tape for vapor barrier can be made of butyl rubber, and this particular option is intended for insulation of balcony, window, as well as door blocks and interpanel joints. Inside such a tape, a reinforcing layer of non-woven fabric necessarily goes.

Photos from the site: gidroizolyaciya-pro.ru

The second option is a metallized tape specially designed for the insulation of seams and joints in rooms with high humidity. It also has an adhesive layer, which greatly simplifies the installation of the structure, as well as the subsequent finishing of the slopes, and so on. In addition, the width of the belts of this plan can also vary, depending on the manufacturer. You need to choose one that is several tens of millimeters wider than the assembly seam itself.

A full-butyl vapor barrier tape made according to the Robiband system has all the prerequisites to ensure high-quality ventilation of the assembly seam. Moreover, this system fully complies with all, without exception, the standards and requirements that apply to it.

Photos from the site: gidroizolyaciya-pro.ru

- First on the list is a material like PSUL tape that can really provide a secure fit for a door or window frame to a wall. Full-butyl vapor barrier PSUL tape is intended for external vapor barrier. It will help to qualitatively close up all joints and seams.

- The insulating tape VS is intended for sealing joints in cases where a dry finish is meant. For example, for drywall, sandwich panels, plastic and so on. It has a layer of adhesive coating along the width of the tape, which greatly simplifies installation, and is also able to prevent condensation from falling on the slopes from the inside of the room. Likewise, the version with BC + tape is also designed for interior work, for dry-type finishing. It is also glued over the entire surface, protected by an anti-adhesive film.

- Robiband VM vapor barrier tape is another extremely good quality option.It is also used for interior work, and wet plaster can already be applied on top of it. A more advanced version of such a tape is VM +.

- Hydro-vapor barrier tape, that is, GPL is made of high-quality foamed polyethylene, laminated on one side, and also equipped with a metallized layer, as well as with an adhesive surface in the entire width of the tape itself. This tape is completely universal and can be used in almost all cases. There are also variations on the theme, for example, the GPL-S tape.

It is imperative to understand that a vapor barrier tape with a protective polypropylene strip resists all kinds of mechanical damage quite well. Among other things, it has an enviable resistance to aggressive environments, that is, it is not afraid of acids, alkalis, or organic solvents.

The right solution is always at hand: how to make a vapor barrier for PVC windows with your own hands

Photo from the site: remoo.ru

When you somehow managed to figure out the materials, as well as their properties and purpose, it is worth thinking about how to glue the vapor barrier tape on the windows so that it provides maximum efficiency, both as a vapor barrier and as an insulator in general. Most often, a vapor barrier film or tape on PVC windows is installed where the humidity is steadily increased, for example, in bathrooms, saunas, swimming pools, and so on.

However, in an ordinary house, it also does not interfere at all and will only bring exceptional benefits and nothing else. Moreover, it takes all the burden of eliminating moisture loss on the slopes, which will help make your windows more durable, reduce the risk of fungal infections and similar risks.

Photos from the site: tremco-illbruck.com.ua

It is worth knowing that such tapes can be equipped with two or one adhesive strip, which greatly simplifies installation, it is actually elementary simple and even a small child can cope with such a task, not to mention an experienced adult man. Just choose the right width and temperature (winter / summer), and follow the instructions, which are ridiculously simple.

- First you need to thoroughly clean the window opening from all kinds of contamination, for example, from construction debris and dust.

- The PVC structure should also be wiped with a dry cloth before installation, and then put in place, marking with a pencil the places where the tape is attached to the frame and wall.

- We take out the window back, and then directly along the perimeter we glue the vapor barrier tape on the surface of the frame.

- Do not forget that before installing the window structure in the opening, you will also need to take care of the protective film, which must be removed from the tape.

Photos from the site: 1pooknam.ru

It is necessary to understand that for one window, door structure or balcony block, you need to use only one, single piece of tape, therefore it is better to cut a little more than less. It is completely unacceptable to allow the mosaic to fold. Moreover, the tape on the windowsill, which is placed at the very end of the installation, must be glued last.

The installation of a window structure must necessarily be carried out according to the developed technology, if you want it to serve faithfully and without failures and breakdowns, as well as for a sufficiently long time. Many people give a damn about vapor barrier and then suffer severely from all kinds of inconsistencies. It is worth thinking ten times before giving up the vapor barrier, so that later you will not complain about fate and your own stupidity.

Getting rid of old film is simple and effective

The simplest and most effective way to remove the protective film from windows is steam steaming. Yes Yes! This is how you can call the procedure for getting rid of the pasting of windows with film by exposing it to hot steam. The method is available to almost everyone and guarantees the safety not only of the profile, but also of the lamination layer on it.

For work, you will need a household steam generator.The simplest model can be bought in a regular hypermarket, but it is better to purchase an apparatus with a hose for attaching the attachment. Such a tool is more convenient than the option in which steam comes out directly from the nozzle, since they can reach hard-to-reach areas near the windowsill.

We fill the steam generator with water, plug it in and, as soon as the water heats up, we start working. First of all, we warm up a small area at the edge of the profile - it is easier to pick up the film there and start separating it. The device should be held close over the film and the nozzle should be directed towards the surface, practically touching it. It is very important to simultaneously warm up a small piece of film over the entire width and try to pick up the edge with a fingernail or a plastic (!) Scraper. If the coating is old and does not come off the first time, let it cool down, and then try again.

It is necessary to separate the film from the profile carefully along the entire width. Only after it has been possible to do this in a small area, it is possible to heat up the next segment and move on. In order for the coating not to tear and separate evenly over the entire area, it is necessary to act slowly and carefully, treating the film with steam from both sides - from the outside and from the inside (along the line of contact with the profile).

If the film is torn or a part of it is torn off, heat the remaining adhered fragment and try to pick it up again. Only when the edge has been captured and the separation line has been restored across its full width can the removal procedure be continued. At that moment, when the removed part of the film becomes too long and begins to interfere, it must be cut off, leaving a small strip (2-3 cm) to hold the coating during further cleaning.

After you can completely remove the old film from the window, you can proceed to the final stage - removing the white plaque left by the protective coating. Film traces are difficult to wash off with ordinary soap or powder, but any glass cleaner does an excellent job with them.

Vapor barrier tape for plastic windows

Vapor barrier tape, internal duplicated full-butyl, under a slope, Bauset ST-I 150 mm (15 m)

Vapor barrier tape, internal duplicated full-butyl, under a slope, Bauset ST-I 150 mm (15 m)

Vacation rate: 15 m

Cost per 15 m: 545 .55

Bauset tape internal duplicated 150mm (25m)

Bauset tape internal duplicated 150mm (25m)

Vacation rate: 25 m

Cost per 25 m: 429.25

Vapor barrier tape, internal duplicated full butyl, under a slope, Bauset ST-I 70 mm (15m)

Vapor barrier tape, internal duplicated full butyl, under a slope, Bauset ST-I 70 mm (15m)

Vacation rate: 15 m

Cost per 15 m: 277 .05

Bauset tape internal duplicated 100mm (25m)

Bauset tape internal duplicated 100mm (25m)

Vacation rate: 25 m

Cost per 25 m: 384.50

Bauset inner metallized MR tape 2x100mm, under the windowsill (12m)

Bauset inner metallized MR tape 2x100mm, under the windowsill (12m)

Vacation rate: 12 m

Cost per 12 m: 373.20

Vapor barrier tape, inner full-butyl metallized, under the windowsill, Bauset ST-bau 70 mm (15m)

Vapor barrier tape, inner full-butyl metallized, under the windowsill, Bauset ST-bau 70 mm (15m)

Vacation rate: 15 m

Cost per 15 m: 277 .35

Vapor barrier tape, internal duplicated full butyl, under a slope, Bauset ST-I 120 mm (15m)

Vapor barrier tape, internal duplicated full butyl, under a slope, Bauset ST-I 120 mm (15m)

Vacation rate: 15 m

Cost per 15 m: 443 .85

Vapor barrier tape, inner metallized, under the windowsill, Bauset MR 200mm (12m)

Vapor barrier tape, inner metallized, under the windowsill, Bauset MR 200mm (12m)

Vacation rate: 12 m

Cost per 12 m: 657 .96

Vapor barrier tape, internal duplicated full-butyl, under a slope, Bauset ST-I 100 mm (15 m)

Vapor barrier tape, internal duplicated full-butyl, under a slope, Bauset ST-I 100 mm (15 m)

Vacation rate: 15 m

Cost per 15 m: 389 .55

Vapor barrier tape, inner metallized, under the windowsill, Bauset MR 150mm (12m)

Vapor barrier tape, inner metallized, under the windowsill, Bauset MR 150mm (12m)

Vacation rate: 12 m

Cost per 12 m: 568 .08

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 100 mm (25 m)

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 100 mm (25 m)

Vacation rate: 25 m

Cost per 25 m: 462.00

Bauset inner metallized MR tape 2x70mm (12m)

Bauset inner metallized MR tape 2x70mm (12m)

Vacation rate: 12 m

Cost per 12 m: 346 .08

Vapor barrier tape, inner full-butyl metallized, under the windowsill, Bauset ST-bau 45 mm (15m)

Vapor barrier tape, inner full-butyl metallized, under the windowsill, Bauset ST-bau 45 mm (15m)

Vacation rate: 15 m

Cost per 15 m: 214.20

Bauset inner metallized MR tape 2x50mm (12m)

Bauset inner metallized MR tape 2x50mm (12m)

Vacation rate: 12 m

Cost per 12 m: 283 .08

Internal tape, duplicated, under a slope, Bauset MR 70mm (12m)

Internal tape, duplicated, under a slope, Bauset MR 70mm (12m)

Vacation rate: 12 m

Cost per 12 m: 390 .96

Internal double tape, Bauset MR 100 mm, under a slope (12m)

Internal double tape, Bauset MR 100 mm, under a slope (12m)

Vacation rate: 12 m

Cost per 12 m: 528 .36

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 150 mm (25 m)

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 150 mm (25 m)

Vacation rate: 25 m

Cost per 25 m: 549.25

Bauset MR tape 200 mm, internal duplicated, under a slope (12m)

Bauset MR tape 200 mm, internal duplicated, under a slope (12m)

Vacation rate: 12 m

Cost per 12 m: 729.24

Bauset MR tape 150 mm, internal duplicated, under a slope (12m)

Bauset MR tape 150 mm, internal duplicated, under a slope (12m)

Vacation rate: 12 m

Cost per 12 m: 631 .56

Tape, vapor barrier, inner metallized, under the windowsill, Bauset MR 45mm (24m)

Tape, vapor barrier, inner metallized, under the windowsill, Bauset MR 45mm (24m)

Vacation rate: 24 m

Cost per 24 m: 546 .96

Vapor barrier tape, isolon 3 mm, Bauset MR 250mm, sloped (12m)

Vapor barrier tape, isolon 3 mm, Bauset MR 250mm, sloped (12m)

Vacation rate: 12 m

Cost per 12 m: 1 186 .32

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 120 mm (25 m)

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 120 mm (25 m)

Vacation rate: 25 m

Cost per 25 m: 524.50

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 70 mm (25m)

Vapor barrier tape, internal duplicated, under a slope, Bauset ST-I 70 mm (25m)

Vacation rate: 25 m

Cost per 25 m: 433 .75

Bauset tape internal duplicated MR 1.5x120mm (12m)

Internal duplicated tape Bauset MR 1.5x120mm (12m)

Tapes for window installation in accordance with GOST

High-quality glazing requires a serious attitude towards itself and is impossible without proper isolation of the gap between the opening and the window. Often, organizations installing translucent structures are limited to traditional polyurethane foam, which is subsequently covered with plaster or other finishing materials. This approach has proven itself relatively well and in some cases does not cause complaints from the consumer throughout the entire life of the window.

However, glazing with one level of sealing of the opening does not meet the requirements of the state for the quality of the services or goods provided, that is, GOST. In order to comply with these requirements, additional insulation is required for the junction of the window to the opening both from the street side and from the side of the room. Such insulation is provided using special mounting tapes.

Scheme of using mounting tapes on windows

View from above

Mounting tape for windows is a self-adhesive material on a polymer or fabric base, designed for additional sealing of window or door openings.

Selection recommendations

The use of certain types of protective coating for glass units depends on the required characteristics of the wooden window. First, the parameters of the room openings are analyzed - their location relative to the cardinal points, number of storeys. Then the possible impact of external factors is taken into account.

The protective film is mounted in the following cases:

- Increased risk of glass breakage. Installed in sports, preschool and educational institutions;

- Ideal for families with small children;

- The risk of illegal intrusion into the premises is increased;

- Production and warehouse workshops.

Installation of tinting coatings is recommended for the following operating conditions:

- The amount of natural light in the room has been increased.As a result, furniture and interior items lose their original appearance;

- It is necessary to ensure that there is no street view. Mirror coatings are mounted;

- Improving aesthetic performance. Various designs and patterns can be created using tinting film.

In practice, the field of application of the additional coating is extensive. To choose the best option, it is recommended to consult with the specialists of a window company.

Varieties of mounting tapes for windows

The functions performed by the tapes are different and depend on the place of gluing, the state of the opening, the features of the future finishing of the slopes, as well as the requirements for the window block. Next, we will consider the most commonly used materials common in the modern construction market.

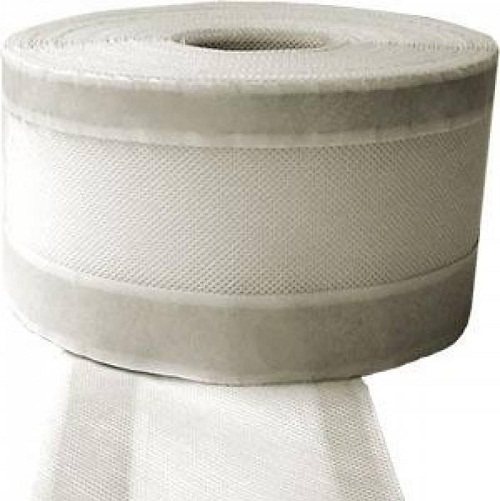

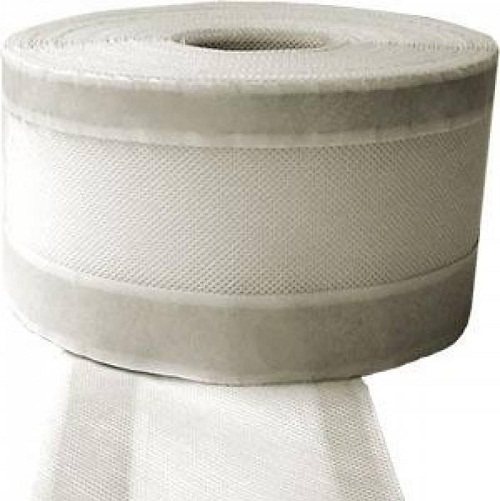

The pre-compressed sealing tape is mainly used on the outside of translucent structures. Its main purpose is to ensure unhindered drainage of moisture from the area where the trap joins the opening.

In fact, this is a tape product made of elastic polyurethane foam (it looks like foam rubber), as a rule, gray or black. One side of the material is covered with adhesive, insulated with a protective film. The tape is supplied rolled into compact bobbins or rolls (depending on the standard size), which need to be unwound only during the installation process, since the material loses its quality over time.

Example of tape expansion over time

The main feature is the ability to fill joints as a result of expansion, which occurs as a result of contact with air. The tape insulates the gap from moisture and external influences from the outside, while allowing excess liquid to evaporate from the inside.

Scope of PSUL application:

- Additional sealing of joints between elements of prefabricated structures;

- Sealing the gap between the frame and the opening when installing windows and doors;

- Insulation of joints between small-sized movable units of building facades;

- Filling the external seam between the slope and the frame during the installation of PVC windows.

How to avoid problems with the protective film?

It is quite simple to avoid difficulties when removing the protective film from PVC windows - you need to follow the manufacturer's recommendations on time. The operating instructions for window systems, as a rule, state that the protection from the profile must be removed within 10-12 days after the installation of structures. If it is not possible to do this on your own, you can ask the installers to do the work by prescribing this clause in the contract in advance or by negotiating with the installers in a private way.

In any case, when making such a valuable purchase, you should not ignore the manufacturer's instructions - this will help to maintain the impeccable appearance of the products without spending extra money and energy.

Installation features

The tape is glued both before fixing the window block in the opening and on already installed structures. The first option is more convenient in cases where external insulation is installed.

Let us consider the algorithm for using tape insulation using the example of gluing a pre-compressed sealing tape (PSUL) and an internal GPL-S with an additional strip of double-sided tape:

- We prepare the opening. If there is an old window block, we dismantle it as carefully as possible, without causing unnecessary damage. After dismantling, we align the surfaces adjacent to the future structure, clean them of extraneous contamination.

- We carry out a test installation of the block in the opening, temporarily fixing it. This is necessary to mark the edge of contact between the walls and the window, so that when gluing the tape is hidden behind the outer slopes.

- We measure the window block. In accordance with the obtained dimensions, we cut the PSUL for gluing on top and on the sides of the frame, prepare the diffusion tape to isolate the area of attachment of the casting profile.

- We proceed in the same way with the GPL-S (internal slopes) and butyl rubber tape (for the window sill profile).The material is measured for each side with a 10 cm allowance to form corner joints.

- We glue the tape, gradually removing the protective layer from the PSUL adhesive surface.

We glue GPL-S to the inner side of the window profile using a strip of double-sided tape (we do not remove the protective film from the main adhesive surface at this stage).

- We fix the window in the opening. We wedge it and then fasten it with anchors or by means of mounting plates. We fill the seams with polyurethane foam.

- After complete polymerization of the foam and rough preparation of the inner surface of the walls, we fix the GPL-S on them (remove the protective paper and glue it to the slopes).

It should be remembered that the tape must be selected in accordance with the weather conditions. Working in the winter, it is possible to glue only material intended for use in low temperatures.

Useful video on the topic:

Cons of material

Energy-saving film is not a source of heat, does not affect the heating of the room. Retains heat generated by central heating sources. The material maintains the existing air temperature.

Heat from the street does not penetrate through the window, pasted over with athermal protection

Disadvantages of the material:

- Protection does not transmit UV radiation, not recommended for use in rooms with indoor plants. Not suitable for tinting glass in greenhouses, greenhouses in the local area. Plants need ultraviolet light to grow. If there are plants in a room with an energy-saving coating, phytolamps can be used. However, you can forget about saving energy - for normal plant growth, compensation for the lack of sunlight, lighting must work at least 12 hours a day.

- The effectiveness of the film coating depends on proper adhesion. Large areas of glazing - for example, panoramic windows or portals, it is better not to paste over them yourself.

- The coating prevents the penetration of natural solar heat from outside into the room, in spring and autumn it will be uncomfortable in the apartment - damp, cold. It is necessary to turn on mobile heating devices.

- The ability to reflect radio signals. Radio waves from the outside, going to the indoor antenna, mobile phone, are reflected by the coating. Cellular communication interruptions are possible.

- If the room has window systems with two - or three-chamber double-glazed windows, it is not necessary to use a film.

Dimensions and approximate cost

Diffuse insulating tape for outdoor installation (under low tide):

- Width -70 mm;

- Length in a skein - 25 m;

- The price of a skein is 436 rubles.

PSUL for use at subzero temperatures:

- Width - 20 mm;

- Thickness - 8 mm (40 in uncompressed state);

- Length - 5 m;

- Price - 160 rubles.

Internal duplicated tape:

- Width - 100 mm;

- Length in a skein 25 m;

- The price of a skein is 377 rubles.

Internal metallized tape:

- Width - 45 mm;

- Length - 24 m;

- Price for 24 m - 523 r.

Window sill tape:

- Width - 200 mm;

- Length - 12 m;

- Price - 600 rubles.