What to drown with?

The stove-potbelly stove is efficient, small-sized, unpretentious in operation. Its installation does not cause difficulties, and kindling is a process that does not require special training. Firewood (or dry chips) is used as fuel.

Expert opinion

Pavel Kruglov

Stove operator with 25 years of experience

When using firewood, it is recommended to use logs, the length of which does not exceed half a meter, and the thickness is 8-10 centimeters. This will allow them to burn out efficiently and evenly, avoiding sharp smoldering. You can also take a closer look at wood briquettes, which in their properties are no different from firewood. At the same time, in storage, they are more capricious and, when kept for a long time in conditions of high humidity, break down into sawdust.

Wood is one of the most demanded fuels. But how to heat a potbelly stove except firewood?

What to use besides firewood?

You can take:

- Peat briquettes, like wood briquettes, do not tolerate direct wetting, but they are less critical to storage conditions. However, when they are burned, a lot of ash is formed. Peat does not like long-term burning, emitting bad smell.

- Coal is no less popular for kindling than firewood. It burns longer, has a higher efficiency. But due to the high combustion temperature of the stove, coal-fired stoves impose special requirements on the design of the chimney.

- Pellets are granules made from compressed waste from the woodworking industry. The economic benefit of such fuel lies in the fact that it is produced from real waste and does not need special processing - cutting, splitting.

What can not be used to heat?

The stove should not be heated with raw fuel, this leads to the fact that during combustion, moisture is converted into steam. Steam, passing through the channels of the furnace, cools them and settles on the walls of the structure. Mixing with soot, the droplets form condensation, which leads to damage to the metal components of the unit and the destruction of the potbelly stove. So, firewood must dry out for at least a year before use.

General information

Fuel briquettes, or as they are also called eurowood, are made from pressed natural materials, most often sawdust, sometimes peat or straw, rarely from seeds or nut shells. During the pressing process, most of the moisture comes out of the wood, which allows obtaining high calorific characteristics. Unlike firewood, whose maximum dryness is determined by 20% moisture, the same parameter for fuel briquettes is 8-9%.

The version of the briquettes can be different:

- Eurobriquettes RUF - made exclusively by pressing without additional processing.

- Eurobriquettes Nestro are compressed briquettes with a cylindrical shape, sometimes with a hole in the middle.

- Pini-Cay Eurobriquettes are compressed sawdust fired with a gas-air mixture to create a more durable shape, which increases storage time and protection from moisture.

Regardless of the type of fuel briquettes, their density is higher than wood, which allows them to burn well and generate a large amount of heat. Thermal characteristics differ for Euro briquettes made from different materials, usually they use high-quality types of wood, cereal seed husks, straw, peat.

Direct use of fuel blocks

In the production of all types of Euro briquettes, no glue additives are used, since wood and similar materials contain a suitable lignin component that can glue together all the sawdust.

Due to the fact that fuel briquettes are made of drier wood, their calorific value is significantly higher than that of ordinary firewood or brown coal and is remotely comparable to the characteristics of black coal. For example, dry birch firewood during combustion emit 2500 kcal / kg, brown coal about 3800 kcal / kg, and fuel briquettes 4500 kcal / kg. Thus, for heating premises, an option with such a fuel is quite acceptable, but are fuel briquettes suitable for a bath, is it possible to heat a stove in it using this fuel.

Good to know: How firewood is chopped manually and mechanically

How to maintain a constant temperature?

When the wood or coal burns out, the heat transfer rates of the furnace are significantly reduced, and after a while the structure cools down altogether. To reduce fuel consumption and maintain a given temperature, experienced stove-makers advise using the following methods:

- next to the stove (no closer than 5-6 cm), place side metal screens in order to additionally heat the room due to the circulation of warm air;

Protective screens - it will be possible to keep the heat in a metal casing for much longer;

- to reduce air circulation, it is important to stack the logs in the oven as tightly as possible. If coal is used as fuel, the ash should be agitated as rarely as possible;

- placing a metal box or a bucket of sand on top, even after extinction, the accumulated heat will be evenly distributed throughout the room;

Pour sand into a bucket or box and place on top of the stove - to preserve heat, you can overlay the potbelly stove with bricks (in 1-2 layers), but not tightly, but at a distance of 5-7 cm, leaving gaps for ventilation.

How long can you heat continuously?

Several factors affect the duration of the furnace:

- the ability to retain heat at home;

- what type of fuel is used;

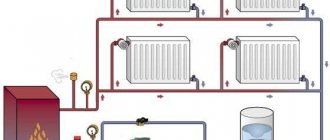

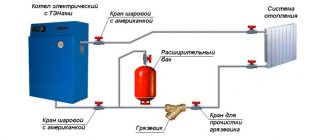

- if heating is carried out, then what kind;

- and finally the owner himself, and his preferences for indoor temperature.

If the winter is not very cold, then the house is 6x6 in size, it is enough to heat it once a day, while the temperature indicators will be within 20 ° C. For example, having flooded the stove in the morning, it will be hot in the house (about 24 ° C), then by the next morning it will drop to about 18 ° C.

The principle of operation of the apparatus

The combustion of fuel in the stove during processing occurs in two main stages. Initially, the filled oil burns out in the tank, after which the gases are mixed with air, enter the second chamber, where they are burned out and ensure the maximum possible heating efficiency of the room. At the same time, fuel consumption is significantly reduced, there is no need to constantly refuel the unit.

A properly assembled oil stove will consist of two separate compartments. The first chamber is a small tank where waste oil is poured. Fuel combustion occurs at a relatively low temperature. Above is the afterburner, where the formed gas mixes with air and burns at a temperature of about 800 degrees. The metal walls of the potbelly stove are heated, and the thick metal effectively retains heat, quickly heating a small area.

In this video you will find out useful information in the manufacture of a stove stove:

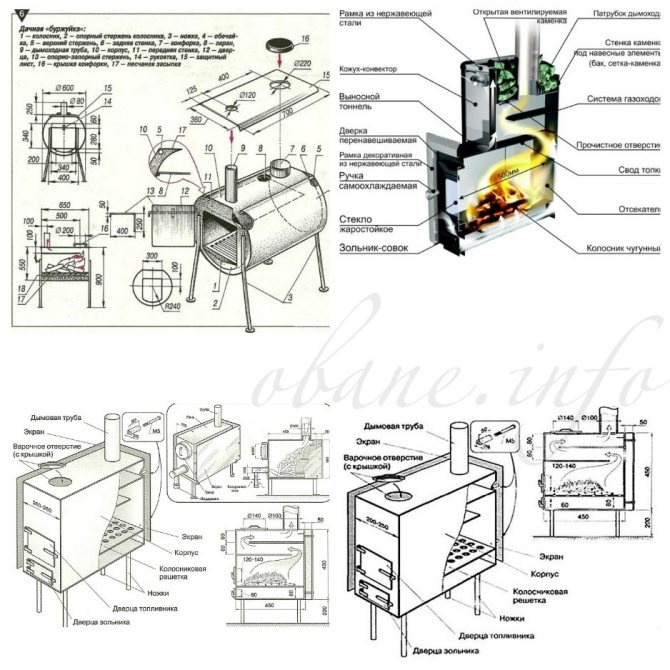

What are the stove stoves?

For the manufacture of the case, one of two metals is used:

- Cast iron.

- Steel.

Cast iron stove stoves on wood for a summer residence will have an impressive mass. Its heating takes a little longer than steel.

But inertia pays off when attenuation occurs. The steel walls are hot while the combustion process is in progress, and then cool down just as quickly. Cast iron, on the other hand, retains heat for some time after damping.

In addition, cast iron has a longer service life, such a stove will not burn out for a long time.But at the same time, it can be damaged, for example, by dropping or hitting with a heavy object - there is a possibility of cracks and the apparatus will become unusable.

Other differences in models. Potbelly stoves can be:

- With legs.

- Without legs, on a flat base.

The first ones look more elegant, but they are safer to use.

- rectangular;

- barrel-shaped.

Barrel-shaped potbelly stove

The latter are most often done by hand, for example, from a piece of pipe.

Coal as a fossil fuel

Coal is a type of fossil fuel. The process of its formation takes place from ancient plants deep underground without oxygen access, for quite a long time. Coal is primarily carbon containing non-combustible impurities. Coal is generally classified as follows:

- Lignite is the lowest-aged type of coal; it has a brown color, up to 45% moisture content, high sulfur content, and is the most loose in relation to other types of coal. It is mainly used in power plants.

- Brown coal is also a fairly young solid fossil. Carbon content up to 70%, humidity about 40%, volatiles 38-50%. It is used as a local fuel, sometimes as a chemical raw material.

- Coal is a sedimentary rock formed by the decomposition of plant debris. Here the composition is more saturated with carbon (from 75% to 95%) and contains less water (8-20%) and impurities that form ash.

- Anthracite - coal of the most ancient origin, has a high density and luster. The carbon content is 95%. Solid fuel from such coal is poorly flammable, having the highest degree of combustion heat.

How to light a stove with raw wood - no special means

Many people mistakenly think they can handle raw timber with kerosene, diesel or gasoline. One has only to splash some liquid into the hearth. This will lead to fatal consequences, including setting the premises on fire. You can also get poisoned by combustion products if you do not open all windows and doors wide open. There are other ways, you just have to be patient, because the procedure will take a lot of your time:

- It's good if you have dry logs left over from last year. Then you should first divide them with an ax or a knife into thin chips. Crumple more paper, put prepared torches on it, light it. Let the fire burn. At this time, beat the wet bars as thin as possible. And carefully put them on the hearth with a "hut". Do not try to speed up the process, do not add all the logs at once. This will lead to smoke in the room, the formation of soot and soot in the chimney. As soon as red coals appear, you can place thicker dies there. It is only necessary to ensure that there is a small distance between them for oxygen to enter the fire. Then proceed according to the method: the hand does not tolerate heat over fire, then it is time to put the rest.

- How to heat the stove with raw wood? A little harder and longer. Many stokers know from experience that smoke and soot will accompany it. But as soon as the first batch of brushwood flares up, you can add wet wood. There will no longer be any difference between dry and wet fuel. The heat transfer from the fire will be the same. Even people deliberately prolong the course of combustion by throwing raw material into the furnace in order to increase the time interval for throwing up a new batch. Because dry dies light up quickly, but they also burn out instantly. And you will constantly think about keeping the house warm, and run to the unit over and over again.

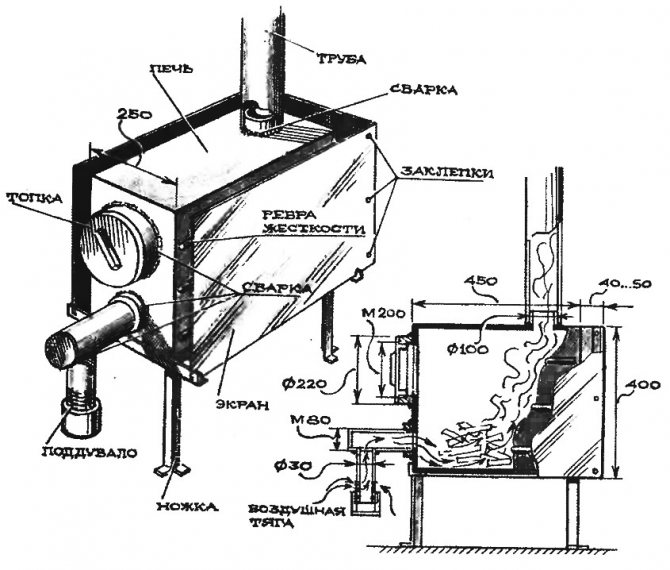

How to make Loginov's stove with your own hands?

The manufacture of Loginov's stove does not require special tools or materials. The master must be able to cook, cut and rivet metal, adhere to the scheme exactly.

Instruments

When working with metal, you will need the following tools:

- Grinder for cutting metal.

- Welding machine, accompanying protective equipment.

- Gun for riveting metal.

- Tool for cutting threads of different diameters.

- Drill and drill bit for metal.

Materials (edit)

Materials for making Loginov's stove:

- Metal sheets with a thickness of at least 3mm, with a total area of 1.35m2.

- Iron bars 45 cm long - 6 pcs.

- Chimney pipe 100mm. The length depends on the height of the room.

- Pipe 80mm and 30mm for blowing and venting.

- A 200mm pipe, about 10 cm long, for the firebox door.

- Plug 220mm.

- The metal corner for the legs is about 1.2 meters, depending on the planned height of the structure.

- Rivets 6pcs.

Step-by-step instruction

- Cut the metal into the desired pieces in the form of a rectangle according to the scheme (above, in p. Scheme and drawing).

Prepare leafy chunks

- Cut openings in the pipes and metal sheet for the front part of the stove for the furnace door and blower, and also make a hole for the chimney pipe in the top sheet.

- Cut threads at the ends of the pipes 200mm and 30mm, inside the firebox door and the blower plug.

Make pipe threads

- In a 30mm pipe in the thread area, drill holes in a circle in a staggered manner. There should be no holes outside the thread.

- Weld a blower from 80mm and 30mm pipes according to the scheme, weld the pipe edge by 80mm. Make a cap for the blower.

Also, the blower can be upgraded as in this photo.

- Weld the sheets of metal together, weld the chimney outlet, the fuel door and the blower to the holes.

Weld the body

Weld the rest of the parts to this body.

- Weld iron rods onto the walls of the furnace.

- Put the stove on its feet by welding a metal corner. Cut and bend the legs of the corner as in the diagram.

- Weld the screen. Using a special pistol, rivet the sheets together as in the drawing, bending the sheet of metal on the back of the screen.

- Weld up the chimney pipe at the smoke outlet.

Weld the chimney

- Check for defects, assemble and lead the chimney outside.

- Carry out a test furnace. If the stove does not smoke, has good draft, then the work is over. The oven is now ready for use.

Possible problems and how to fix them

The main problem that can arise when firing coal is smoke.

There may be several reasons for this:

- lack of draft in the chimney - blockage in the pipe or in the flue outlet;

- poorly insulated chimney;

- a large amount of moisture in the fuel, due to which the smoke becomes wet;

- cracks in the furnace body.

In each case, you need to identify the cause individually. It is best to consult a specialist for this.

Another question is whether it is necessary to pour the remaining coals from the furnace after kindling? The answer depends on the situation:

- If the coals have died out and do not give out flames, then they can be safely left in the fuel compartment. The next day, you will melt the stove faster. In this case, it is better to complete the kindling 1.5 hours before bedtime or before leaving the house.

- If the fuel does not have time to burn out, then pour it into a metal container and fill it with water.

Other problems can arise due to improper installation of the stove and chimney. To avoid them, we recommend that you carefully study the instructions for the heating equipment and entrust the installation of the stove to the master.

Advantages and disadvantages

The popularity of this type of heating units is largely due to the simplicity of their design, reliability and durability. The advantages of a potbelly stove during mining include:

- Simplicity of design.

- Reliability and safety.

- Efficiency.

- The possibility of using free fuel.

- Lack of unpleasant smell and sensation of burnt air.

- Complete environmental friendliness.

The operational characteristics of the oil stove and its power will directly depend on the choice of a specific manufacturing project. On the Internet you can find various drawings of a stove on used oil with their own hands, which will differ in their design, power and a number of other parameters.

Furnace under development - drawings and manufacturing scheme:

Preparing the stove for the first kindling after a summer shutdown

In the warm season, which is at least 3-5 months, heating equipment is not used at all. It is important to understand that after such a break, you cannot immediately heat the stove. First, you need to check the entire system and prepare it for work:

- Make sure that there are no cracks in the oven casing, the door is tight when closed. Otherwise, even through the minimum gap, carbon monoxide and smoke, dangerous to humans, can pass into the living space.

- Check the chimney structure, in particular, the integrity of the seams and the quality of the draft. If necessary, clean the pipe from soot and foreign objects.

- Remove objects that can catch fire from the firebox area. All flammable liquids and flammable objects must be kept at a distance of at least 0.5 m.

- The furnace of the stove should also be cleaned, as well as the ash pan should be emptied. To keep the ash from dusting, you can sprinkle it with water. Use a dry cloth to clean the interior walls.

In the cold season, when it's freezing outside, it can be especially difficult to melt the stove after a break. In this case, you can first warm up the firebox with an industrial hair dryer. It is also worth observing the interval between fireboxes of about 4 hours.

It is imperative to check the quality of the fuel. The charcoal should be firm, not crumbling when pressed. It is better to remove dust, otherwise an unpleasant odor may appear during the combustion process.