Coal is a very diverse and multifaceted compound. Due to its peculiarity of formation in the bowels of the earth, it can have very different characteristics. Therefore, it is customary to classify coal. How this happens is described in this article.

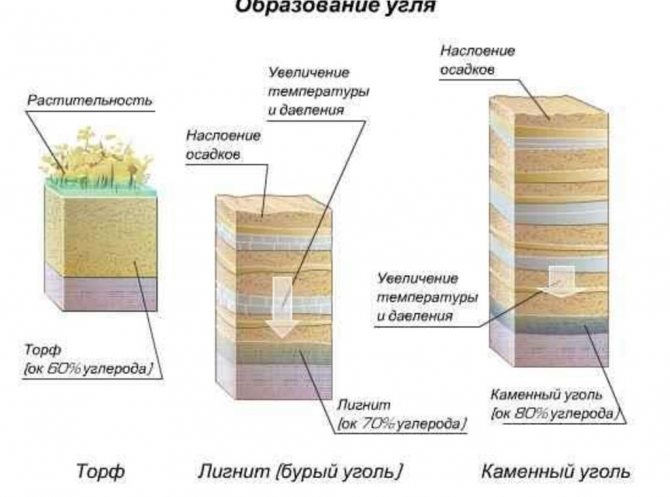

Fossil coal is mostly mined from the bowels of the earth, but sometimes as a result of seismic activity, coal seams come to the surface, where open pit mining is possible. But where does the coal in the earth's crust come from? Coal formation is a very long and complex process that originates from common plants. When plants die, peat is formed from them with a lack of oxygen and high humidity. Over millions of years, this peat settles into the ground, where, due to high temperature and pressure, it slowly turns into coal. This process is called coalification.

Fossil coal can be found by humans at various stages of coalification, so there are many types of this resource. In total, there are several types of classifications of coal: composition, origin, size, moisture content, the presence of impurities, as well as many other characteristics. Let's take a closer look at some of them.

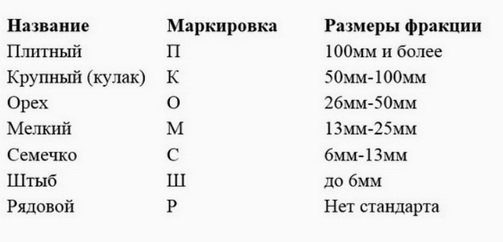

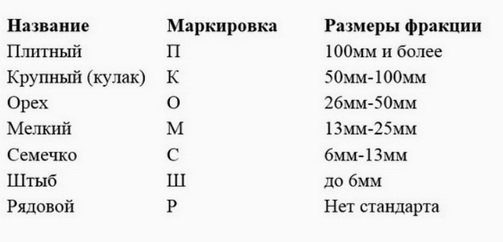

Coal classification by lump size

To extract coal from the ground, it must be crushed and brought to the surface. The resulting pieces can be of different sizes, which is important enough for further use. For this reason, there is a state standard (GOST R 51586-2000), which defines the classification of coal by the size of the pieces. These sizes are sometimes referred to as coal grades so as not to be confused with the grades discussed later.

| Class name (abbreviation) | Size in mm |

| Plate (P) | From 100 |

| Large (K) | 50-100 |

| Walnut (O) | 25-50 |

| Small (M) | 13-25 |

| Seed (C) | 6-13 |

| Shtyb (W) | Until 6 |

If the coal has not yet been sorted and has lumps of completely different sizes in its composition, then such coal is called ordinary (P).

There are also mixed grades, that is, mixtures of coals of different sizes within certain limits. But the percentage of coal of each class is not regulated in this case. The mixture may consist, for example, of 95% seed and 5% stem, in which case the variety will be called seed with stem.

| Class name (abbreviation) | Dimensions in mm |

| Large with slab (PC) | From 50 |

| Walnut with large (KO) | 25-100 |

| Small with nuts (ОМ) | 13-50 |

| Small seed (MC) | 6-25 |

| Seed with a spike (SSh) | Up to 13 |

| Small with a seed and a spear (ISSH) | Up to 25 |

| Walnut with small, seed and pine nuts (OMSH) | Up to 50 |

How to ignite self-igniting charcoal?

Fast-ignition charcoal is produced in the form of tablets with a diameter of 40 ml. Before lighting it, you should take specially designed tongs. By squeezing the pill in tongs, you can even set it on fire with an ordinary lighter.

The coal will spark for the first few seconds. It is worth not forgetting this in order not to jeopardize safety. Only after the tablet turns completely red should it be laid out on the hookah bowl.

Important: during burning, self-igniting hookah coals can crumble. Therefore, you should be very careful when placing them on the narghile bowl.

After complete burnout, white ash remains. The average burning time is about an hour. In the market for hookah goods, you can also find long-playing self-igniting coals. Their burning time is increased to 80 minutes. This is quite enough to enjoy the process of hookah smoking in the fresh air.

Coal classification by grade

As already mentioned, coal can differ in composition.It is extremely difficult to isolate specific compounds in the composition of coal, therefore, in order to characterize coal, only some of the characteristics are used: the concentration of volatiles, humidity, carbon content, heat of combustion, etc.

Usually all of these characteristics are related. The more carbon content in coal and less volatile matter, the more heat the fuel can provide. According to these characteristics, coal is divided into grades.

Brown coal (B)

It is the youngest and therefore the least useful coal grade. It looks like a brown mass of stone. Sometimes a woody structure is even noticeable on it. The heat output is only 22 MJ / kg. The reason for this is the low carbon content, a large amount of moisture, volatiles and mineral impurities. All this does not provide efficient combustion.

Such coal is formed directly from peat and lies at a shallow depth (from 10 to 200 meters). In Russia, it is mined at the Solton deposit, in the Tunguska and Kansk-Achinsk coal basins.

Long flame coal (D)

It is usually gray-black in color. It burns with a long smoky flame, which gave it its name. It contains 70-80% carbon, which makes it a slightly higher quality fuel than lignite. It is also affected by less moisture and impurities. But this is not the advantage of long-flame coal. This fuel can burn without blowing, which makes it easy to use in furnaces and boilers. This type of coal is very common. It is mined in Minusinsk, Kuznetsk, Donetsk and many other basins.

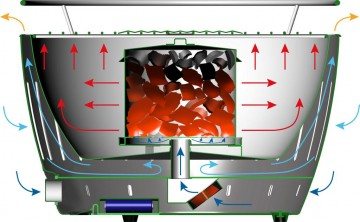

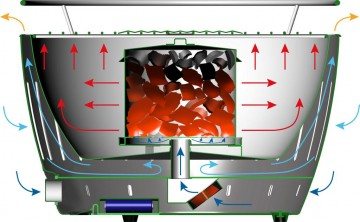

What is a smokeless grill

This name was given to a device with many functions, which provides great comfort when frying meat and vegetables. The coals in the original grill are ignited using a special gel. At the same time, you can start cooking - according to the promises of the manufacturers, you can already in 3-4 minutes after ignition.

The device is very economical in terms of coal consumption - it requires about 8 small briquettes for one hour of roasting meat or vegetables at a temperature of 204 degrees Celsius. You can use it almost anywhere, at any time of the year and in any weather - be it sun or rain.

There is also a built-in fan. It ensures uniform heating of the grate. Such a system also makes it possible to completely shield the heat from the coals by means of a turn located on the toggle-switch housing.

The small size and safety of the device during use allow you to take it on a trip to the forest or to the lake. Just imagine - a picnic on the boat! You can also turn on a smokeless charcoal grill in your home, on your balcony or terrace. The neighbors will stop complaining about smoke and you can enjoy the spell of summer.

Oily charcoal (F)

This is already a fairly high-quality coal. Despite the fact that it ignites heavier than the previous two brands, it has a high calorific value (35 MJ / kg). The disadvantage is the high content of volatile substances, which complicates the control of the combustion process, therefore, this grade of coal is rarely used as a fuel. The main areas of its use are the production of building materials, activated carbons and other useful substances, as well as in the by-product coke industry. Such coal is mined at the Osinovskoye, Baidaevskoye, Leninskoye and Tom-Usinkskoye deposits.

Coal types

There are several types, differing from each other in composition and specific calorific value. Some are used in production, others for heating household buildings. Coal types:

- Lignite - black with brown tints, is used in the energy industry. Unsuitable for storage in a domestic environment. Its distinctive feature is a minimum of humidity and a maximum of heat transfer.

- Subbitominose species - contains up to 30% moisture, easily crumbles, has a high calorific value. Coal is used for heating in residential buildings.

- Bituminous species is a dense material, more suitable for transportation. When burned, it releases a lot of heat; it is used for coking.

- Anthracite is a high-quality and expensive coal, characterized by hardness, density and high hydrocarbon content. Black or gray-black in color with a glossy sheen, with good electrical conductivity. It does not smoke when burning, it is suitable for heating living quarters.

- Long flame - with good calorific value, burns quickly, forming a long flame. It is used for heating public buildings and has a low cost.

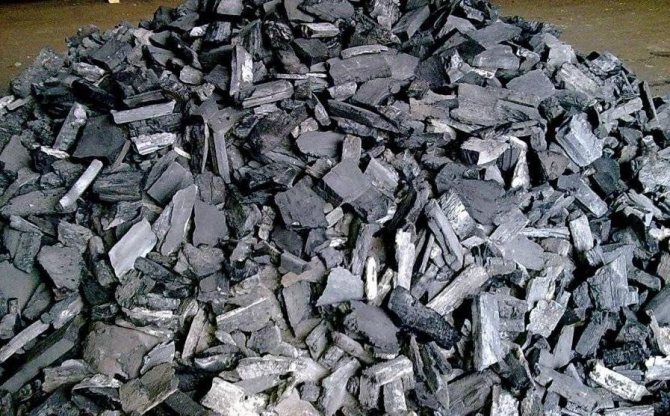

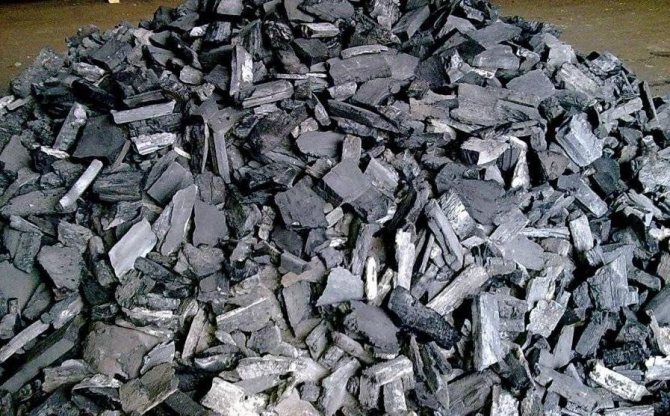

A separate group includes charcoal containing organic matter. It burns for a long time, giving off a lot of heat, it is suitable for fireplaces and barbecues. Wood ash is used as a fertilizer and plant nutrient. The woody species is used in the production of cast iron because of its resistance to corrosion.

Activated carbon is isolated, which has a porous structure and contains up to 97% carbon. It is used in everyday life to purify water through a charcoal filter, take care of furniture, remove unpleasant odors. In medicine, it is used as an adsorbent for poisoning and bloating.

Coke coal (K)

This is a very valuable type of coal due to its low prevalence. Very high quality coal coke is obtained from this brand, as the name implies. Such coal is formed at a sufficiently great depth (5500 m), where there is great pressure. The color of this coal is gray with a glassy sheen. It has a very uniform structure and a minimal pore count. The content of volatile substances is moderate (22-27%), and carbon already reaches 88-90%, which has a positive effect on heat transfer, although such coal is rarely used as a fuel. Coke coal is mined in the Kuznetsk coal basin, in Anzhersky, Tom-Usinsky, Prokopyevsko-Kiselevsky and other regions.

How to make charcoal at home

Making charcoal at home is done using improvised means. This is the simplest technology, although it does not guarantee the production of high quality charcoal.

Before making charcoal with your own hands, preparatory work is carried out, which necessarily include measures to ensure fire safety. To obtain high-quality charcoal, logs of the same type of wood are selected, they are cleaned of bark and chopped into approximately the same smut.

Before you start making charcoal with your own hands, the method of burning is determined. The most popular ways to get charcoal at home is by burning wood:

- in an earthen hole;

- in a barrel;

- in the oven.

The first two are performed on the street, the last one is carried out in two stages - the first in the stove (it is optimal if the stove was built outdoors), and the second on the street.

In the pit

This is the cheapest way to get charcoal at home. For this, a pit 0.8-1.0 m deep and 0.5-0.6 m in diameter is torn off in the ground. At the bottom, firewood is laid for starting a fire. After the fire is made, the raw materials are laid in the pit. Firewood is stacked to the top. After the fire covers the entire volume of the pit, and the wood starts to burn out little by little, the pit is closed with a metal sheet, and moist earth is poured on top, so as to completely block the access of oxygen.

12-16 hours after closing the pit, the lid is carefully opened. After about 1-1.5 hours, the smut can be removed. With this method of obtaining charcoal in the pit, the yield of the finished product is from 25 to 35% of the volume of the laid firewood.

In a barrel

You can also make charcoal at home in a barrel. For this, a metal barrel is taken.For a large volume, a large 200 liter barrel is required, for coal with a volume of 3-4 kg, a 50 liter barrel is enough. For work, it is advisable to choose a barrel with thick walls, with a large neck and, if possible, with a lockable lid. To get charcoal in a barrel, the technology does not change much, the only thing that is recommended is to put it on bricks in order to heat it up afterwards.

The barrel is filled with wood, ignited and, after it has ignited, is closed with a lid. After about 12-18 hours, for a 200 liter container, it is recommended to light a fire under the barrel and heat it up for 3-4 hours. After warming up, the barrel can be left to cool.

Remove the cover carefully so as not to inhale carbon monoxide. You can take out the material after 4-6 hours. When the drums are fully loaded, up to 40-50% of the volume of the finished fuel can be obtained.

In the stove

You can also make charcoal in the oven. The process consists of two stages. The first stage is burning wood in a stove. This is done until the firewood is completely burned out. Then the smut is removed from the furnace and transferred to a bucket or ceramic container and covered with a lid. The yield with this method of charcoal is small, only 2-2.5 kg.

Lean-sintered coal (OC)

This grade of coal does not differ much from coke oven coal: the content of carbon and inorganic impurities is approximately at the same level. Its main advantage is its high calorific value. It is 36 MJ / kg, so it is sometimes used as a fuel in power plants. But its main use is the by-product coke industry. True, this coal is coked with difficulty, so it has to be used in a mixture with other types of coal. Such a mixture of several brands is called a coal charge. Lean-caking coal is mainly mined in the Kuzbass, in the Kemerovo region and in the South Yakutsk coal basin.

Burning coal, how to heat it, long-term burning

The quality of coal determines the amount of energy that can be obtained from it, as well as the time for service, the amount of ash obtained, the ability to heat them ... Which coal is better suited for home heating? How to burn it correctly in order to achieve maximum energy output and minimum worries?

Coal combustion temperature and other characteristics

It is often asked - what is the combustion temperature of coal? - although this value has little effect. Other parameters are much more important.

- calorific value - the amount of heat generated per kilogram of fuel, kW / kg;

- ash content - the amount of ash that will remain after coal combustion,% of the total mass. It will reduce the total calorific value, we will have to clean it from the boiler and dispose of it,

Also important:

- Caking capacity is the ability of coals to create caked ash, which is very harmful.

- Humidity, both in-situ and introduced, is it wet coal? It is better to dry it wet beforehand in natural conditions than to burn it in a boiler with a loss of energy, which will be spent on the evaporation of this water.

- Emission of volatiles, tendency to coking - coking coal grades are not suitable for heating.

More about ash content

The ash content is as follows.

- Intra-layer - these are those mineral impurities, "sand and stones" that are inside the coal seam, in every piece of coal, and they cannot be extracted during enrichment. Good coals have this ash up to 10%.

- Technical is a rock that has mixed with coal during its extraction, including from large rock layers inside a coal seam, and which can be separated from coal by mechanical methods during its enrichment. Miners accidentally chopped up the roof and the soil of the seam, - here are the extra tons, even though the ash content is increased ... The rock mass from the mine may be 35% ash - it is not at all suitable for home combustion.

It should be borne in mind that rock bedding significantly enriches those selling coal. Therefore, buying coal is not easy.It is necessary to check the fuel for the presence of pieces of rock, including those powdered, directly in the carriage, in the car, before unloading. And refuse to purchase, if that ...

What is the calorific value of different grades of coal

How much heat can we get from coal, is it enough to heat a house?

The amount of heat in kilowatts that can be released from different grades of coal compared to dry wood is given below, kW / kg

- Dry firewood - 4.0

- Brown coals - 3.8 - 5.5

- Long-flame - 6.0 -7.0

- Gas and fatty - 7.5

- Lean-sintered 7.0 - 7.4

- Lean - 7.4 - 8.0

- Anthracites - 7.8 - 9.5

Mainly for domestic boilers, energy grades of coal are suitable - lean, anthracite and semi-anthracite. It is they that sinter less and form coke substances, have a minimum of ash inside the formation and a better calorific value.

In addition to the brand, you need to choose a coal size class.

For advertising purposes on the packaging, the seller writes only that ...

Coal size class, why they do not heat coal dust

Coal dust and coal fines are the cheapest, they burn perfectly, but only in special furnaces of power plants. There they burn in a cloud with fuel oil and air. And in a boiler, they simply seal the passage of air through them, so combustion inside their layer is impossible. Coal fines do not burn in stoves, except perhaps with small additives, poured over burning coal.

- You can heat with a sunflower seed, but it usually wakes up through the grates of all boilers ...

- For home heating, more expensive fractions are used - walnut and fist.

- Hot coal is even more expensive, but at home it is broken into smaller pieces.

A lot of unburned elements remain in coal ash. Ash, after burning, zealous owners sift on a 5 mm metal grate, and all large unburned ones are sent back to the boiler along with a fresh portion. This saves 10 - 15% of fuel.

Coal dust is tried to be moistened into cakes, which are dried, and fed into the boiler in the form of pellets.

How to properly heat coal

If oxygen is not supplied to the combustion zone, then carbon monoxide (CO) is formed instead of carbon dioxide, the efficiency from incomplete combustion decreases by 20 - 50%. Modern boilers provide secondary air supply for afterburning CO and soot particles at high temperatures. With old equipment, with stoves, you need a practical skill of supplying air over burning coals for better afterburning and preventing the release of unburned gases into the atmosphere.

The supply of a large amount of primary air directly to the burning coal can make a forge out of the boiler, entail the rapid combustion of a large mass of coal, a sharp increase in the temperature of the exhaust gases up to 1500 degrees and the melting of equipment, ignition of soot in the chimney, a sharp drop in efficiency several times, from - for the removal of energy into the pipe.

The efficiency of coal combustion can be monitored by the temperature of the flue gases, which should not increase. There should be enough air so that complete combustion of fuel without CO occurs and at the same time there is no increase in temperature in the chimney above normal. As a rule, modern coal-fired boilers are able to burn fuel in the right way with a maximum efficiency of about 78%.

How to make long burning coal

Normal long burning with high efficiency is better with modern equipment. But even on old boilers and furnaces, you can find the optimal approximate opening of the lower and upper dampers in order to ensure a normal air supply over the fuel, for CO afterburning on the heat exchanger.

For example, an ordinary old coal stove provided for the following adjustments:

- "Blower closed",

- "The two upper burners are slightly open",

- then a portion of coal smolders - there is a long burning, but the afterburning of gases, as a rule, is complete.

In modern boilers, the equipment itself monitors such modes.

Coal-fired boilers of increased power (large load is possible) from well-known manufacturers with secondary air supply are suitable as a cheap and versatile option for home heating. They can make long-term combustion of a large load of coal by redistributing the air supply.

Automated boilers are now more and more popular. Their combustion duration is provided by a coal bunker and constant supply of small portions to the combustion zone. Moreover, the equipment is not necessarily too expensive. Boilers with a bunker, from which fuel is loaded under its own weight, have a democratic price. Boilers with a screw feed are more expensive, but they can do a little more. Thus, the bunker allows you not to worry about fuel surging every day. Combustion, as a rule, takes place in small portions, but with full air supply without the formation of large volumes of CO - European environmental requirements for equipment.

In any case, the increased duration of coal burning will be provided primarily by equipment for a large load - into the bunker or directly into the furnace. The choice of a coal-fired boiler is based on this consideration.

Which coal to choose

Coal occurs in the earth's crust in the form of seams. Each of them is labeled and has its own quality characteristics. But even in the same seam, but in different regions, coal can vary greatly in quality - the degree of metamorphism, the amount of ash, volatiles, sulfur, moisture change ...

Coals with the highest degree of metamorphism, with the highest percentage of carbon C in the composition, are most valuable for power engineering. These are Anthracites and those close to them, which have been assigned the Semi-Anthracite and Skinny Coals brands.

The best for heating will be the coals related to anthracite and semi-anthracite from the processing plant, walnut and kulak fractions.

By regions of production, the best thermal coals were previously mined in the Donbass, but recently production has been greatly reduced, and it is difficult to find such coals on the market. In any case, anthracites of the Donbass layers H2 Removskiy, H2-1 Podremovskiy, N-8 Fominskaya were considered the best for home heating. There is a record of the calorific value of a kilogram of coal mined in the 70s from the Fominskaya seam with a value of 9800 kW / h - in fact, pure carbon ...

Now it is cheaper to purchase coal from Kuzbass and Ekibastuz, despite the long delivery. It is necessary to ask for coals from the energy layers of Kuzbass.

The purchased coal must contain a minimum amount:

- fines, dust, which practically do not burn and have a bad effect on the combustion process, filling the boiler, limiting the access of oxygen to large pieces;

- rocks - pieces of rock in coal - this is a marriage of beneficiation or a special mixture at different stages of the trade.

It is better to warn the seller right away that you refuse to purchase coal with spear and rock. Order coal of walnut and fist fractions in small portions, for inspection, as a rule, the seller has a supply for the entire season, and you can buy additional fuel if it is of good quality.

Lean coal (T)

This brand of coal received such a funny name because of the relatively thin layers with which it lies in the rock. This is due to the great depth (6600 m) and great pressure. Unlike the previous two types, lean coal does not have the ability to sinter, and it is almost impossible to produce coke from it.

But it has a very high heat of combustion up to 40 MJ / kg. This leads to its use as a fuel, as well as in metallurgy, where an extremely high temperature is required in furnaces for melting metals. The main areas for the production of lean coal are Aralichevsky, Baidaevsky and Kemerovo districts.

Is there coal that doesn't smoke?

Save an ordinary private trader

Combustion products emitted by coal-fired boilers and stoves of private houses, as a rule, contain underburning in the form of soot particles, fine dust, aromatic hydrocarbons and other compounds.Visually, such emissions are perceived as smoke - a stream of gray-black gas from the chimney. “Of course, when burning thermo-coke briquettes, gases are also formed (carbon dioxide, water vapor), but they are invisible to the human eye. Exactly the same gases, but in a different proportion, are formed when natural gas is burned. And they are invisible to the eye, which can be observed in an ordinary gas stove, ”says Sergey Islamov

.

As the main consumer of thermo-coke briquettes, coal miners see private sector ovens. But what real harm do they inflict on the city, heating with traditional coal, against the background of industrial giants - KrAZ, SGK thermal stations, etc.? Will the transition to briquettes help in the fight against the long-standing problem of the region - the “black sky effect”?

The annual volume of emissions in Krasnoyarsk is about 200 thousand tons in CO2-equivalent - these figures were recently announced by the acting governor of the region. Alexander Uss

... According to the calculations voiced by the leader of the local "green"

Sergey Shakhmatov

, in Krasnoyarsk coal is used to heat about 7300 private households and about a thousand unregistered autonomous heating sources of small commercial enterprises. Together, they generate about 2.3% (or about 4.5 thousand tons) of the total emissions into the city's atmosphere, burning from 130 to 170 thousand tons of coal per year.

It seems that 2.3% is insignificant? “Substantially!” I am sure Sergey Stepanov

: - Regions like the Krasnoyarsk Territory need smokeless fuel in the form of thermo-coke briquettes literally like air - in the literal sense. Private houses in the region are heated with coal - this is an established reality, a geographical feature. The chimneys of houses are located low, in calmness all the smoke and soot settle in the lowest atmospheric layer - one and a half to two meters from the ground - where people actually stay. Of course, no one denies the influence of coal-fired thermal power plants, but at least they have tall pipes that give a large scattering radius. The massive introduction of thermal coke as a fuel can dramatically improve the environmental situation in the coal regions of the country. "

Local ecologists confirm that up to 25% of Krasnoyarsk residents find themselves in the zone where the permissible concentrations of suspended solids in the air, generated by household stoves, are exceeded. This means that it is necessary to radically reduce the ecological footprint of coal, bringing its combustion closer to natural gas for environmental safety. Federal Research Center for Coal and Coal Chemistry SB RAS and its scientific advisor, Academician of RAS Alexey Kontorovich

, actively support the development of production and use of thermal coke and fuel briquettes from it, and propose to develop and launch the Federal Target Program “Low-carbon coal technologies”. According to Kontorovich, this will not only provide a technological breakthrough in coal energy, metallurgy and environmental technologies, but will also ease social tensions in the coal-mining regions of Russia, caused by a systematic reduction in the consumption of this solid fuel in traditional sectors of the economy.

According to Sergei Stepanov, the biggest pitfall of a new product is the need for complexity, which is not always possible to provide. “The fact is that the production of thermal coke is as environmentally friendly and rational as possible if the heat generated in the process is not emitted into the atmosphere, but is used. In other words, . The ideal consumers of this heat could be housing and communal services enterprises, but, oddly enough, they do not need it - they have their own generating capacities, a sales market, and there is no motivation to reconstruct the existing and functioning system. Therefore, the main task is not just to build a factory with hot-coke boilers, but to create a complex of the plant and its heat consumers ”. But it is not so easy to find “unconnected consumers” in the existing and stable system of the heat generation market.

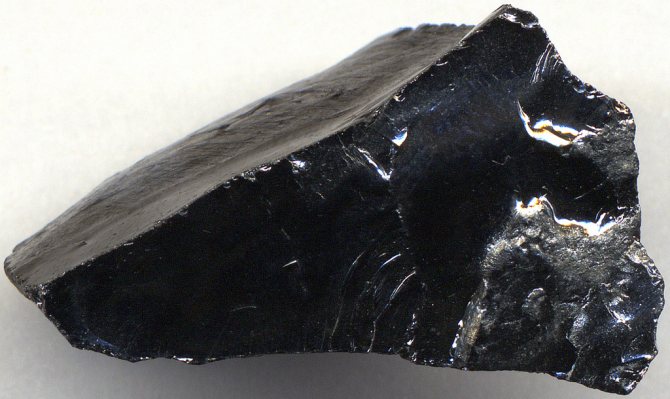

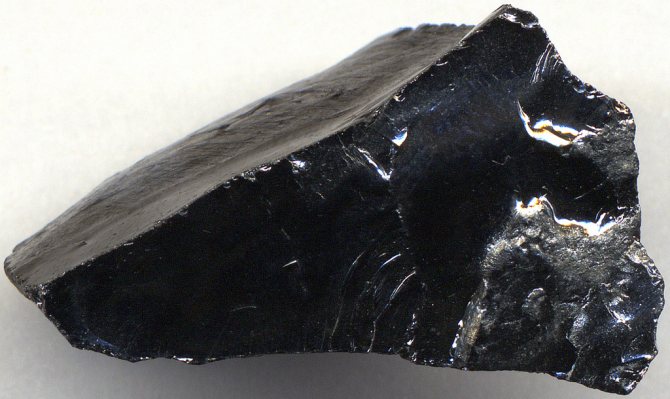

Anthracite (A)

This is the highest quality coal in terms of calorific value. The carbon content in it can reach 98%.Only graphite has more. And in appearance, anthracite is very different from other brands. It has a dark black color with a pronounced metallic sheen. It also has increased heat resistance and electrical conductivity. The combustion temperature of anthracite is quite high, so it cannot be used as a fuel in all types of furnaces. In addition, it is used in metallurgy, for the manufacture of filters, electrodes, calcium carbide, microphone powder. This coal does not sinter, so it has not found application in coking, although even without this process it can replace coke in some processes.

How to economically and efficiently burn wood and coal in a boiler

The most economical and environmentally friendly way to heat a house with solid fuel is the so-called top heating of the stove. This principle involves moving the coal layer from bottom to top. Thus, the smoke coming out of the still cold fuel layer must pass through the coals, where it is almost completely burned up. This ensures that toxic fumes do not enter the chimney and more heat is generated instead of smoke.

Rules to remember

- Place the fuel on an empty grate, from the thickest to the smallest pieces of charcoal or wood. Ignite the prepared fuel from above, not from below (as everyone usually does).

- Place thick wood on top - log by log. Add another layer of wood, but with thumb-width sticks.

- Light the workpiece and close the top door. It takes about 60 minutes to ignite.

- From the moment of ignition until the stage when the coals go down to the grate, the stove needs a constant flow of air.

- The oven temperature can be reduced by closing the door. Opening it will increase the temperature.

- Once ignited, there is no need to drop fuel until it gets hot.

- The stove will heat up for about 6-8 hours, depending on the amount of fuel.

Overhead heating can be used in various types of stoves, including kitchen, tiled, fireplace and simple stoves. This is a completely safe technique that has been proven in practice.

The most important advantages of this method:

- Saves money - By firing fuel from above, you can save up to 30%.

- Health - you emit much less smoke, noxious dust and odor.

- Thermal comfort - heating and thermal comfort up to 8 hours.

- Convenience and time saving - once the fuel is ignited, nothing else needs to be done with it. You do not need to add new portions of fuel and monitor whether the stove has gone out.

- Long service life of the heating system - you do not clog it with soot.

Other types of classifications

In addition to those grades that are presented above, there are many intermediate grades, for example, fatty coke (CG), sintered gas (GS), long-flame gas (DG).

Also, each grade of coal can have different lump sizes. In this case, the letter denoting the grade is placed after the letter denoting the brand. For example, anthracite-nut (AO), fat-plate (ZhP), coke seed (KS).

There is also a classification of coal by origin. All coal, as already mentioned, is formed from plants over millions of years. But plants can be of a different nature. So, coals are divided into humic (from wood, leaves, stems) and sapropelite (from the remains of lower plants, such as algae).