In most European countries, they are abandoning the use of cast iron radiators in favor of aluminum or bimetallic ones, which have more compact dimensions, high efficiency and an attractive design. But they are characterized by two significant drawbacks:

- High price;

- Increased wear due to poor-quality heating agent of the centralized system.

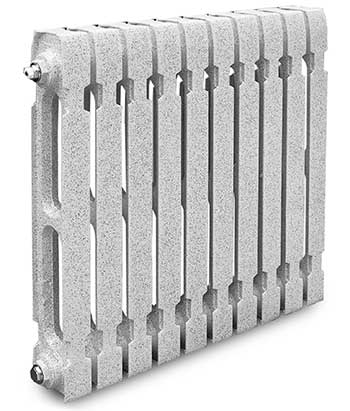

Therefore, for the CIS countries, cast iron heating devices are still relevant and in demand. They are characterized by:

- Long service life;

- Corrosion resistance;

- Compliance with existing heating systems.

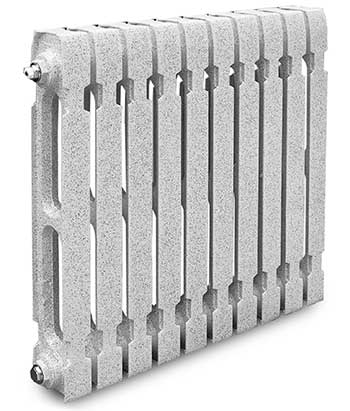

Design features of cast iron radiators

Cast iron devices are made from an alloy of cast iron, which has high strength and is homogeneous.

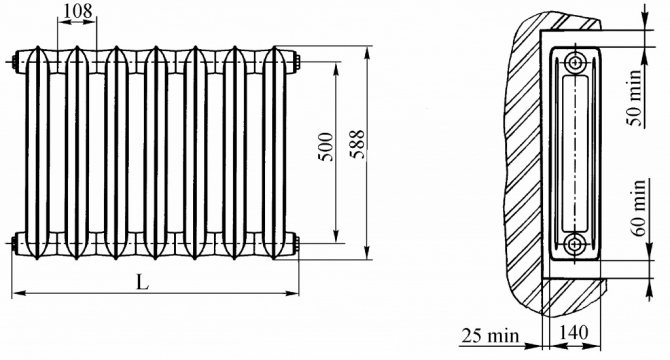

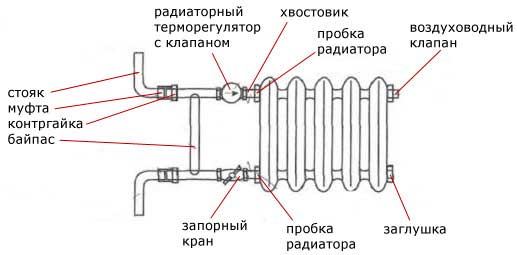

Battery sections are produced separately by casting, then connected to obtain the required thermal power. The tightness of the joints is achieved by using sealing elements made of various materials.

There are three types of cast iron radiators: single-channel, two-channel and three-channel.

The principle of operation is very simple, it is as follows: the heated coolant circulates inside the device, gives off heat to its walls, which is then transferred to the surrounding air.

- Heating equipment of this type is characterized by the following features:

- Internal ribs are vertically positioned in order to increase the heat exchange surface;

- Good strength and ability to withstand high pressures;

- Relatively low coefficient of linear expansion of the material and high temperature resistance;

- Thermal power ranges from 100 to 150 W;

- A high degree of inertia of products, in connection with which their heating and cooling occurs rather slowly, thermoregulation practically does not make sense.

Types of aluminum radiators by manufacturing technology

According to the production method, they can be sectional (cast) and solid (extrusion).

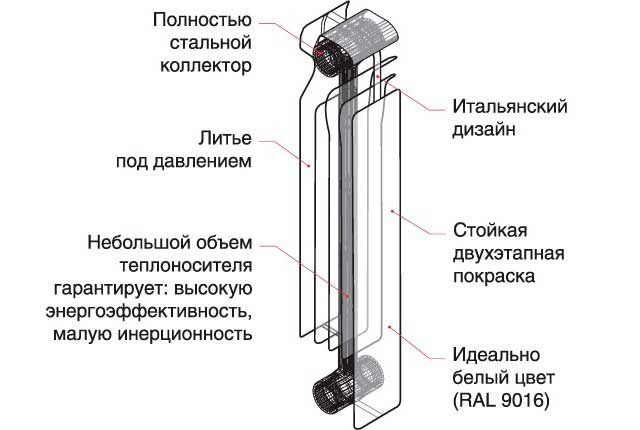

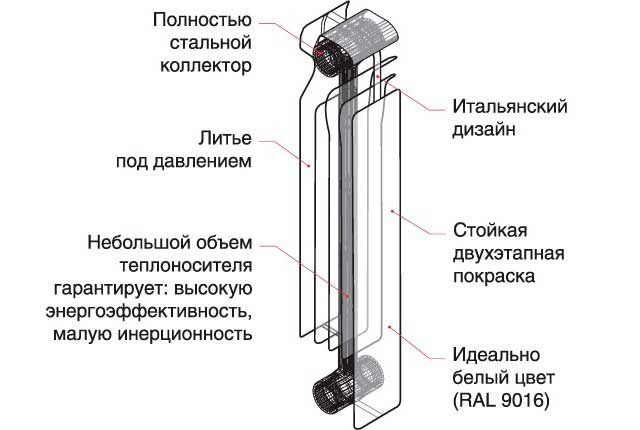

Cast

Each section of the radiator is manufactured using injection molding. This method guarantees precise dimensions and a smooth surface of the product.

The connection of the sections into a block is carried out by means of nipples. Such batteries are more expensive than extrusion ones, but their reliability is also higher.

Extrusion

One-piece models are extruded from recycled aluminum. It consists in forcing the material melt through the forming heads (dies) to obtain the desired profile.

Steel profiles are used as dies. The workpieces obtained in this way are welded together. The result is solid products that cannot be increased or decreased.

Sometimes, to reduce the cost of their cost, individual parts are not welded, but glued together with composite adhesives. However, such a replacement significantly degrades the performance of the products.

Advantages and disadvantages of cast iron batteries

Like any heating devices, cast iron radiators have both advantages and disadvantages. Among the advantages are the following:

- Resistance to the effects of chemically active components in the composition of heat transfer fluids. Unlike the materials used in the production of other types of radiators, cast iron practically does not rust.

- Long service life. Some cast iron batteries that have served 50-60 years still function today.

- It is not required to connect a circulation pump, since cast iron radiators create a small hydraulic resistance for the coolant.

- Do not require cleaning for a long time due to the large diameter of the channels;

- Thermal inertia, which acts as an advantage and a disadvantage at the same time. Radiators are able to keep warm for a long time, but temperature control is not possible.

Disadvantages:

- Large dimensions, mass of devices, which significantly complicate their installation;

- Difficulty adjusting temperature conditions;

- Slow warming up when the system is turned on;

- Intercostal joints are quite complex, which interferes with cleaning and painting the product.

Design and principle of operation

Aluminum batteries can be solid or sectional. For strength and corrosion resistance to aluminum, silicon, zinc, titanium are added during the manufacturing process.

The sections are connected with threaded connectors. The connections are sealed with silicone gaskets. To prevent tearing, the inside of the radiators is covered with polymer materials.

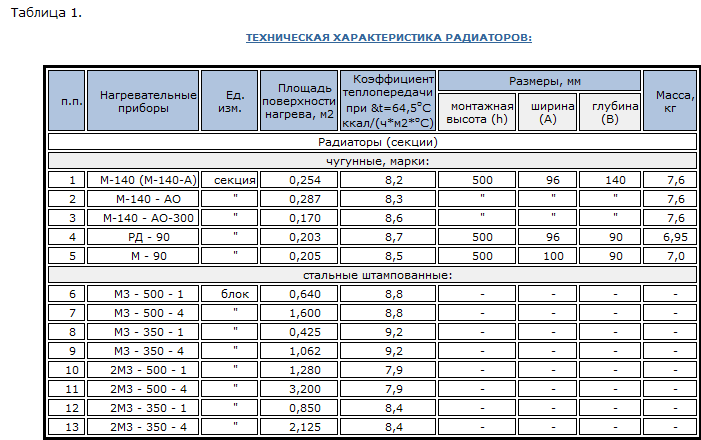

How to choose a cast iron radiator - selection options

The main selection criterion is the heat output of the device.

Each model is characterized by a certain amount of heat energy released. Its amount is largely influenced by the color of the coating. Black products emit 25% more heat energy than white products.

When choosing a cast-iron radiator, you should also pay attention to the method of installation, connection, permissible coolant temperatures and pressure.

Main technical characteristics

Aluminum batteries are attractive precisely for their high technical characteristics at an affordable price. Wherein:

- the weight of one section is 1 ... 1.5 kg;

- capacity - 0.25 ... 0.46 l;

- the distance between the axles is 20/35/50/80 cm;

- guaranteed service life 10 ... 20 years.

The manufacturer indicates all the main characteristics in the passport of the device.

Thermal power

Thermal power (heat transfer) is understood as the amount of heat that is given by one section of the radiator.

The recoil factor for the standard section is 82 ... 212 watts. It depends on the temperature of the coolant. The total heat output depends on the number of sections in the battery.

Operating pressure

There are two types of aluminum radiators:

- normal - with a working pressure of up to 6 atmospheres;

- reinforced - up to 16 atmospheres

Since the working pressure in multi-storey buildings is 10 ... 15 atmospheres, and in houses with an autonomous heating system - less than 1.4 atmospheres, the first option is suitable for installation in private houses, and the second - in "high-rise buildings".

Pressing pressure

To maintain the efficiency of the system, it must be subjected to pressure testing annually, the pressure of which is 20 ... 50 atmospheres.

Heat carrier parameters

The temperature of the heat carriers in aluminum radiators can reach 120 ° C, but usually it does not exceed 70 ° C, and it is this temperature that is taken when calculating the heat output.

How many kW in one section - calculation of heat transfer

In the data sheet for the device, the manufacturer indicates the main characteristic of the battery section - thermal power (heat transfer).

The actual and declared values are often very different. This is possible in the case when the actual temperature of the coolant differs from that indicated in the passport for the device.

To calculate the actual heat output, use the following formula:

Q = K * S * dT

Where:

- S is the area of the heat exchange surface;

- dT is the temperature head expressed in degrees Celsius;

- K is the heat transfer coefficient of cast iron.

To calculate the temperature difference, you need to know three parameters:

- Coolant temperature at the inlet (tinlet);

- Coolant temperature at the outlet of the radiator (tout);

- Average room air temperature (tair).

We get the formula:

dT = 0.5 * (tinput + toutput) - tair

The difference between the actual and the declared result can be caused by the following factors:

- The underwater pipes are too long;

- Low head of the coolant;

- Insufficient coolant temperature.

To calculate the required number of sections, it is necessary to find out the required amount of heat for heating the room. There are two calculation options: by the area of the room and by the volume of the heated space.

For any of the options, a normalized value of the amount of heat required to heat a unit of area and volume of space, respectively, is selected.

Then, the total amount of heat required to heat the entire room is obtained as the product of the normalized value by the area or volume (depending on the chosen calculation option).

The required number of sections is equal to the quotient of dividing the required amount of heat by the amount of heat generated by one section of the device.

Heat dissipation property

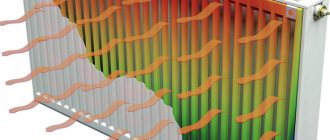

The power of steel heating radiators, as well as all other types of heaters, is based on the principle of their operation:

- The coolant, getting into the battery, circulates through the tank (for steel panel models, these are channels), while in a hot state it is directed upward, while when it cools down it goes down. In an autonomous or centralized heating system, the boiler is engaged in heating the carrier.

- During the time that hot water comes into contact with the radiator, it gives off its heat to it, heating its walls. This point is very important, since the length of its path depends on the size of the heater, and the longer it is, the hotter the radiator.

- The heated walls of the structure give their temperature to the air, which spreads through the room under the influence of heat fluxes.

- In order to increase the level of heat transfer, the heater is equipped with heat exchangers, as can be seen from the steel radiators of types 11, 22 and 33.

The presence of heat exchangers significantly increases the power of steel radiators, working according to two heating principles: radiator, which uses the heat from the walls of the device, and convector, which forms the movement of heated air.

As a rule, the manufacturer indicates the power indicators in the data sheet, so you can navigate by it, but it is even better to independently make calculations taking into account the area of the room, the air temperature and the amount of heat loss.

The consequences of an incorrectly selected heater are:

- The so-called overheating, when the room is so hot that you have to keep the window open. This creates a microclimate that is harmful to the body, forces you to pay more for energy costs or install thermostats to reduce the load on the system.

- If the power of panel steel heating radiators is below the required level, then the room is cold even at their maximum load.

- Strong pressure drops in a heating system equipped with weak batteries will lead to an accident, as they will not withstand such "stresses".

All of these problems can be avoided if you know what exactly affects the heat transfer of heating batteries, and how to increase their efficiency.

Which manufacturer to choose?

Cast iron radiators are now made by not so many manufacturers as aluminum and bimetallic models, but we will consider three main brands on the Russian market.

Konner

Cast iron batteries of this company have the following advantages:

- Long service life;

- Low hydraulic resistance;

- Compliance with centralized heating systems;

- The declared high level of heat transfer from the section (up to 150 W);

- Ease of installation;

According to some consumers, these devices actually produce less thermal energy than stated in the passport. Another disadvantage is the rather high cost.

Exemet

Advantages of devices from this manufacturer:

- Environmental friendliness and reliability;

- High heat output produced by one section;

- Able to work in one- and two-pipe heating systems;

- Powder coated;

- Unique design stylized as 19th and early 20th century.

In the production of cast iron radiators, the art casting method is used, which increases the cost of the devices. Also, their unique design is not suitable for every interior.

GuRaTec

Advantages of radiators of this brand:

- High quality of products, the control of which is carried out in a pressure chamber and hydraulic tests;

- Long service life;

- Environmental Safety;

- Sufficiently high thermal power of the sections (up to 150 W);

- Unique design.

The devices are decorated with various decorative elements that give them an attractive appearance. However, this also affects the cost of products.

4.9 / 5 ( 37 votes)

Features of steel batteries

The design of panel radiators is such that they are made of two stamped steel sheets connected together, inside which there are 2 horizontal channels at the top and bottom and 3 vertical channels for every 10 cm of length.

The weak "link" of such heaters is the narrowness of these channels, therefore it is so important that the coolant is free of impurities. In a centralized heating system, this is impossible, therefore, having made a choice in favor of steel radiators, you need to install a filter at the inlet of the coolant supply to the supply pipe of the apartment.

As a rule, kW of steel radiators depends on their type and averages 0.1-014 per section:

- For type 11, which consists of one section and a convector with a depth of 63 mm, the power is 1.1 kW.

- For 22 type, consisting of two sections with two convectors at a depth of 100 mm - this is 1.9 kW.

- 33rd type recognized as the most efficient, as it consists of three sections with three convectors at a depth of 150 mm. The power of this type of steel panel radiator is 2.7 kW.

For example, structures with convectors were taken, since without them steel panels are ineffective and suitable for small autonomous heating systems.

To make the right choice, you should familiarize yourself with the following parameters before buying:

- How many kW in 1 section of a steel radiator.

- How does the height and length of the product affect its power.

- How many sections and convectors there are.

Only having received answers to these questions, you can choose the best option for a heater for each room separately.

When installing a heating system, the focus is on the quality of the radiators. Aluminum batteries have the best price / quality ratio.

It is their pros and cons that we will consider in the following - varieties, calculation, connection options, technical criteria and tips for choosing.

What you need to know when choosing aluminum batteries

Aluminum radiators are very afraid of the acidic environment in the heating system. Therefore, reliable long-term operation is only possible at pH 6.5… 8.

You should also know that:

- the inner surface must be carefully processed, an oxide film applied;

- the radiator must have a passport with the characteristics indicated in it, it is desirable that there is a test report;

- factory assembly is more reliable, therefore, if possible, you should buy a ready-made battery from the required number of sections;

- do not install a battery for more than 15 sections, it is better to install two;

- an unusual design of the radiator can degrade its performance;

- radiators made in China NF / 68 should be avoided. They may contain asbestos, which is hazardous to health.