What are pellet stoves?

Pellet boilers, or fireplaces, are constructions that heat the premises due to the combustion of a special type of fuel - pellets. The latter are small compressed pellets from wood waste. The fuel is completely safe - the absence of any harmful substances makes it environmentally friendly. Including glue.

There are two main types of pellets:

- industrial; they are made from different types of waste, therefore the consumption of granules is higher, and the efficiency of the furnace is lower;

- household; these are made from high quality raw materials, and therefore the thermal efficiency is much higher.

It is recommended to use only the latter type for loading boilers in private buildings. Moreover, it is advisable to select pellets based on the characteristics of a particular device - this will increase the heat transfer and the operating life of the furnace.

What are pellets?

Pellets are waste from the woodworking and agricultural industries compressed in the form of granules. Since the granules are produced without chemical additives, these products are hypoallergenic and environmentally friendly. Pellet heating is a relatively new phenomenon in our country. Due to the fact that the prices for diesel fuel and electricity have increased dramatically, the population began to look for alternative and economical sources of heating. So, pellets came to us from Europe.

New producers of pellets appeared, they became more accessible and cheaper. And if initially the pellets were wood or coal, later they began to be made from agricultural waste - husks, straw, corn.

Pellet classification

Due to the increased demand for alternative fuels, more and more varieties of pellets appear. Depending on the raw material, granules are:

- woody;

- peat;

- granules from solid household waste;

- coal

- from the husk.

Depending on the degree of purification, granules are of three types:

- higher (household or white pellets);

- standard (industrial pellets);

- economy (agropellets).

Household pellets

Household pellets belong to the highest grade fuel. This is the best choice for heating frame houses. Granules are made from sawdust. The raw material is soft and hard wood. They have extremely low ash content - less than 0.5%. This means that the boiler should be cleaned no more than once a month. Heat transfer is high, 17.2 MJ / kg. Household pellets are white. This effect is achieved by debarking wood, which is carried out before crushing and granulating. This also means a higher fuel efficiency. Household pellets are suitable for any type of boiler.

Industrial pellets

Industrial pellets are slightly lighter in color than agricultural pellets. They are mainly made from unbarked wood. The heat transfer of this category is 17.2 MJ / kg, the ash content is from 0.7%. The frequency of cleaning the boiler surface when using such pellets depends on how high their ash content is.

Types of pellet boilers

Heating equipment of this type is classified based on different criteria.

According to the materials from which the structure is made

Most fireplaces are made of high quality steel. Devices, the main material of which is cast iron, are much less common.

By type of burner

There are ovens:

- torch; the most popular "household" option; flare boilers are characterized by low power, ease of operation and adjustment, reliability; among the minuses of the type - sensitivity to fuel quality and unidirectional heating of the furnace walls;

- fireplaces; characteristic feature - the pellets are burned in a special pellet bowl; there are fewer regulation possibilities, and there is also a demand for fuel; but such stoves can be placed in rooms - the equipment is quiet and safe;

- volumetric combustion; much more often, similar burners are used in industrial-type devices, but they also have a place in household units; minus - increased bulkiness; advantages - higher power and undemandingness to granules (in Russian realities, the latter aspect is of considerable importance).

By type of fuel supply

Furnaces are divided into:

- mechanical; the operator of such a boiler turns into a stoker, forced to constantly monitor the combustion process;

- semi-automatic; manually only power is set here - the rest of the control falls on the shoulders of the automation; from the point of view of the ratio of cost and quality, this option is preferable to others;

- automatic; only a fuel load is required from the user - the automation will do the rest; but for the initial setup of the equipment, it is better to call specialists - they will make all the necessary calculations based on the size of the room, the required temperature and other parameters.

By type of fuel

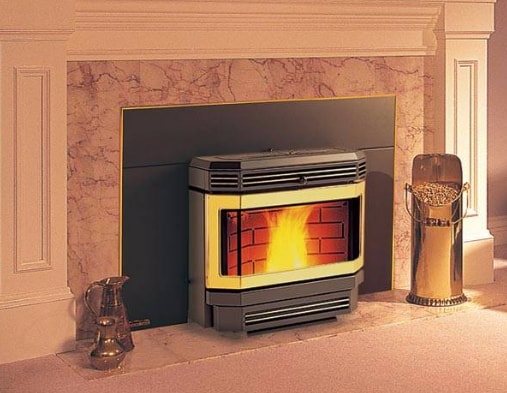

Picture 2. Pellet boiler

Pellet boilers operate on different types of fuel. There are ovens:

- working exclusively on wood pellets; in the absence of the opportunity to regularly provide oneself with pressed fuel, it makes no sense to purchase such equipment; even at the stage of choosing a furnace, it is necessary to think over options for supplying granules of a suitable type;

- partially combined; the use of briquettes and firewood is allowed - this is facilitated by the format of the firebox; but the main role of fuel is played by pellets, while other options are helpful in situations where there is no access to pellets; ignoring this rule leads to equipment failure;

- combined; these units have several furnaces of different formats; therefore, it is allowed to use both pellets and firewood with briquettes on a regular basis; the disadvantages of the combined devices are the high price and decent dimensions.

By appointment

Depending on the goals, the equipment is divided into:

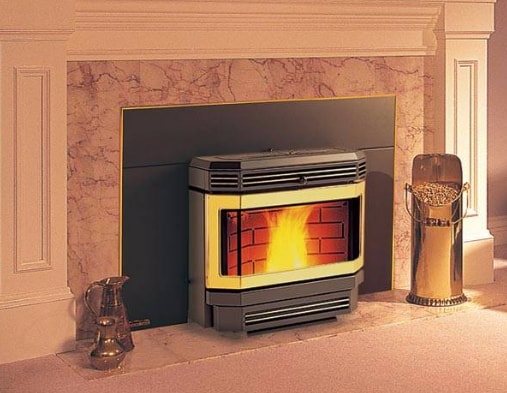

- fireplaces-convectors; their task is to heat the air; the most popular option - such stoves take up little space, have the "right" to be placed in residential premises and easily "get along" with any interior design;

- water heating boilers; differ in solid size and expressionless appearance; they are usually installed in utility rooms or basements;

- hybrid aggregates; the task of combined devices is both direct heating of air and heating of the coolant; in terms of design, they are close to convection equipment.

Types of equipment for the use of pellets

Pellets are used as fuel both in private country houses and in industrial premises. The choice of equipment depends on the heating area.

Basically today, boilers and pellet stoves are used, which sellers sometimes call fireplaces.

Pellet stoves (fireplaces)

Pellet fireplaces are usually installed to heat one single room or house with a small living space. The power of such devices ranges from 6-15 kW. Modern pellet stoves are divided into three types:

- convection ovens that are capable of heating exclusively the ambient air;

- devices additionally equipped with a water circuit for heating not only air, but also water;

- combined stoves, which, along with pellets, can also use briquettes with sawdust or ordinary dry wood.

Pellet boilers

In large country cottages, as well as in industrial enterprises, boilers are installed as heating devices using pellets.Their power varies from 15 to 100 kW. If the installation of pellet boilers takes place in a private house, then the optimal place for their placement is the basement. There are several types of such devices:

- boilers operating exclusively on wood pellets;

- systems that in emergency cases (in case of burner failure, for example) allow using sawdust or dry firewood as fuel; for such interchangeability, the equipment is equipped with a special grid;

- combined boilers that allow using not only wood pellets, but also firewood with briquettes.

The device of furnaces operating on fuel pellets

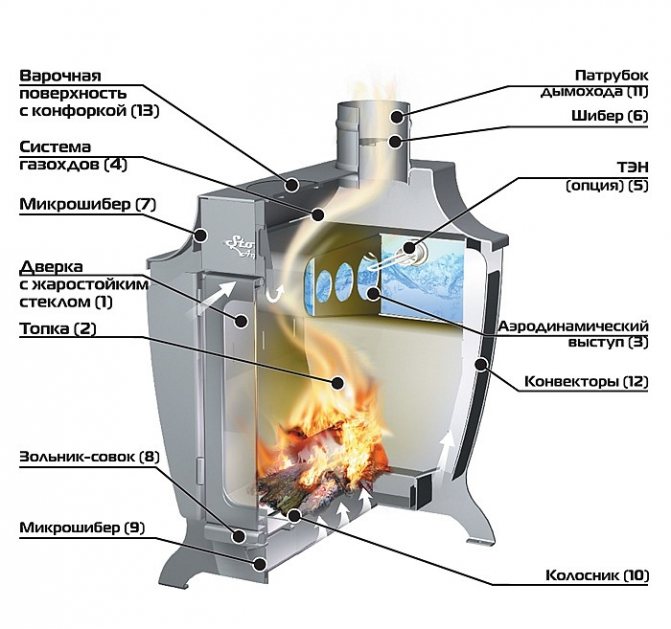

Figure 3. Pellet stove device

Pellet stoves have the following design:

- metal body - quality stainless steel or cast iron;

- bunker area for filling fuel; some models are designed for external silos;

- an electric screw feeding granules in portions into the combustion chamber;

- fan; its purpose is to supply cold air from the room to the device and to remove hot air (together with working off) to the outside;

- firebox;

- burner;

- ash pan - an element for collecting wood waste;

- a heat exchanger designed to circulate cold / hot air;

- thermostat and control panel.

Definition

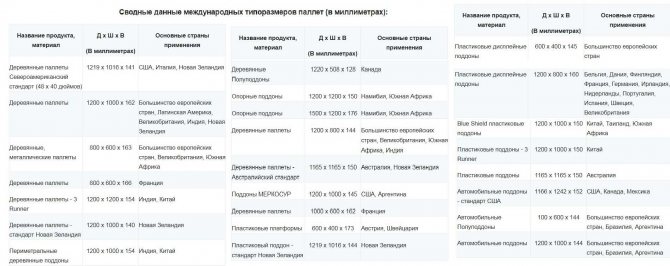

Pallets and pallets belong to shipping containers. The pallet has the simplest design. The bars are used as a basis, on which a platform of boards is attached. According to the generally accepted definition, a pallet or pallet is a container unit with a platform used for collecting and picking cargo.

With the help of such containers, goods are moved by specialized equipment (forklifts), as well as their transportation and storage.

The pallet has a more complex design and can be unified for specific requirements. But the functional purpose is the same. In fact, pallets and pallets can be considered as separate containers or as a basis for packaging.

Furnace working principle

Picture 4. Pellet boiler of industrial type

For the operation of pellet boilers, electricity is needed. Thanks to him, the control unit, fan and auger work. After loading the granules, they are fed into the combustion chamber in portions - by means of a screw. Due to the suction of air from the room, the fuel is ignited. It takes a maximum of 10 minutes to start the system.

Important! The independence of stoves from power systems is conditional. The operation of boilers is impossible without electricity

The gases formed during the combustion process enter the heat exchanger. From here, a fan distributes them around the room. The smoke goes into the chimney. Most modern models are equipped with a thermostat that sets and controls a certain temperature in the room.

The resulting ash goes to the ash pan. There is very little waste from the burnt pellets. The average cleaning frequency is once a month. Advanced models require even rarer attention to this aspect - even to the extent of disposing of waste every two months.

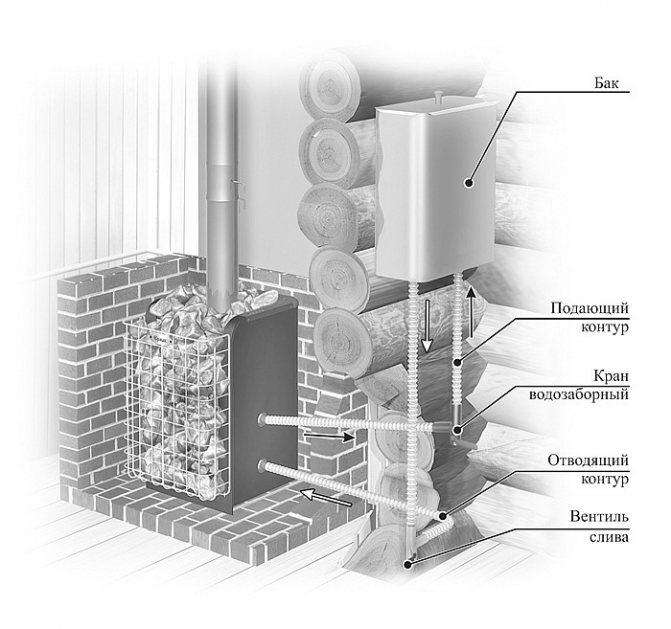

In the presence of a water heating system, along with air, the liquid also heats up. Water circulates through pipes, if necessary, entering special containers.

Automation greatly simplifies the interaction of the user with the oven. The computerized system makes every stage of the boiler more efficient and safer.

Figure 5. Boiler operation diagram

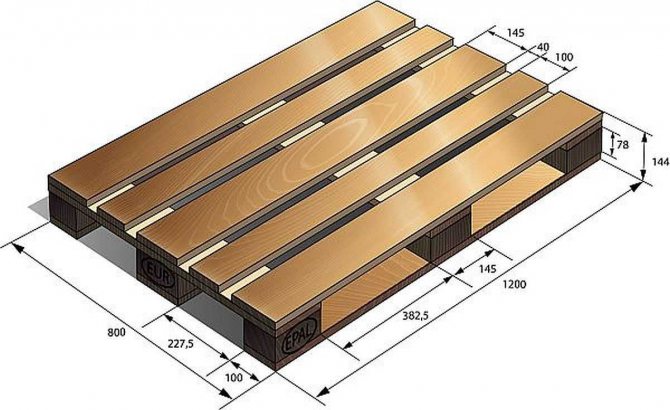

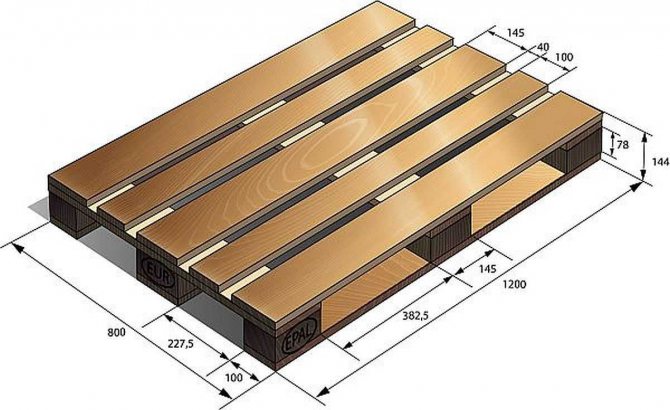

Euro pallet design and size (EUR)

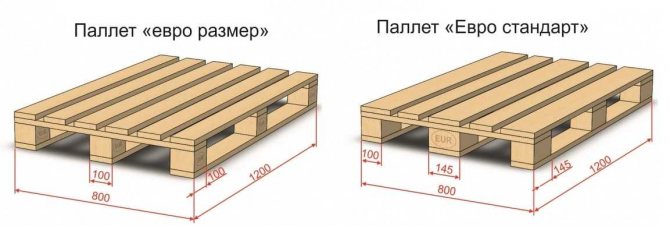

In general, in Europe several sizes of pallets are in use, but the so-called "standard" ones are most often used. The size of this type of Euro pallet in millimeters is 1200 * 800 * 144 mm, the weight of the Euro pallet is up to 35 kg. You can load up to 600 kg.

Structurally, the Euro pallet consists of an upper and a lower deck, consisting of five boards: two narrow - 100 mm wide and three wide - 145 mm, the thickness of the boards is 22 mm.The wide ones are located at the edges and in the middle, narrow between them.

Dimensions of the euro pallet and its design with dimensions

Two floorings are connected using pieces of timber (they also use MDF) - checkers. Their dimensions are 100 * 145 * 78 mm. They provide space for a forklift loading platform to enter.

The checkers are placed three in a row at a distance of 382.5 mm from each other. Three pieces of checkers are connected by the boards of the lower flooring in one row. The bottom deck requires two narrow planks (first and last row) and one wide plank. Their difference from the material for the upper deck is the presence of a chamfer for easier entry of the loading platform. The edges of the Euro pallet must be chamfered.

The rows are interconnected by intermediate strips. The parameters of these boards are 145 * 22 mm and a length of 800 mm. They form a rectangular platform from the rows and serve as a support for laying the top deck.

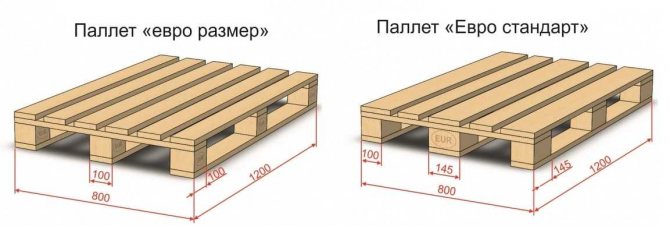

Dimensions of the Euro pallet type "size" and "standard"

This type of Euro pallet is called "standard". There is also a euro size. It differs in the smaller size of the checkers, respectively, has a lower carrying capacity - up to 400 kg.

Euro pallet marking

A few more words should be said about labeling. To designate the standard, a brand is burned out on the corner checker: the word EUR enclosed in an oval. Other checkers are also marked. It displays information about the manufacturer, series, batch number, and the passage of sanitation. Wooden containers do not pass customs without processing.

Advantages and disadvantages of pellet boilers

The popularity of pellet boilers is growing due to a series of advantages. Among them:

- efficient heat dissipation; The efficiency of such devices is comparable to the efficiency of gas heating devices and is significantly higher than the efficiency of wood-burning stoves;

- fuel economy;

- complete environmental friendliness; the absence of any harmful substances in the granules;

- autonomy; subject to the availability of an automated system, the user is deprived of the need to control the combustion process - the automation does almost everything for a person;

- independence from main power systems;

- almost complete zero waste - when burned, the granules leave a very small amount of ash; ash pan cleaning is rarely required;

- equipment safety and no need to coordinate the installation with the relevant services;

- aesthetic design of boilers-fireplaces - the ability to "fit" the unit into any interior.

Figure 6. Furnace with a modern aesthetic design

Not without its drawbacks. These include:

- the need for electricity, without which it is impossible to ignite fuel, the operation of the auger and the control unit;

- high cost of equipment; average price range - 100,000-1,000,000 rubles;

- dependence of European models on Russian energy systems and pellet quality; devices can be sensitive to power surges and demanding fuel; when choosing a stove, you should definitely consider protection against voltage surges and the possibility of purchasing granules suitable for a particular model.

If financially available, the advantages of ovens outweigh their disadvantages.

Comparison with similar devices

The cost of electricity and gas is constantly growing, which means that it is profitable to buy pellet stoves, first of all, from the point of view of benefits.

Since they are completely independent of external sources, the dependence of the system on suppliers automatically disappears - the owner of the house himself decides how many pellets he needs to purchase, for example, for one winter season.

The main differences

The main difference between wood pellet stoves and dry wood stoves is that they do not emit carbon dioxide. Wood, on the other hand, emits carbon dioxide when burning, and this is very dangerous for the health of the inhabitants of a country house.The ash that forms after the combustion of pellets can be used as fertilizer on the site or in the greenhouse.

Another distinctive feature of such devices is that they can be installed in homes when there is no gas pipeline nearby or the possibility of heating using an electric unit. Moreover, even if both gas and electricity are available, if they are turned off, the pellet stove will be a backup system for heating the cottage. This is especially true in severe cold weather. With proper operation of such furnaces, and timely maintenance work, they can serve for more than 20 years.

Application in institutions

The popularity of installing pellet stoves in restaurants, shopping centers, industrial premises, hotels and social institutions (hospitals, schools, kindergartens) is quite understandable.

The fact is that, compared to gas heating, heating rooms with pellets is approximately 2 times cheaper, and if we talk about electric heating, the economic benefit can grow by 3-4 times.

x-teplo.ru

How to choose a pellet stove?

Furnace selection criteria:

- power; the most important aspect - when choosing a device, you need to build on the volume of the room; average required power - 1 kW / 10 m2; the calculation scheme is valid for rooms with a ceiling height of up to 3 m;

- type and consumption of granules; the need for pellets is variable and tied to the design of the stove and the volume of the room; average consumption of pressed fuel - ton / month;

- manufacturer and distributor; it is recommended to buy equipment from a seller who provides comprehensive or at least service;

- heat exchanger material; branded manufacturers produce furnaces only with steel heat exchangers; less popular manufacturers allow the manufacture of elements from cast iron; the cast iron option is less preferable - it is heavier and characterized by greater thermal inertness.

Loading capacity of pallets and rules for placing goods on them

Today, a strange situation has developed: the possible loads on pallets and pallets have not been determined. Each manufacturer exposes its own figure. On the one hand, it is difficult to guarantee any specific figure, since the wood can be used in different ways. Also, the cargo may be different. The mass can be dispersed over the entire area of the cargo area, or it can be point. With a point load, of course, the mass should be less.

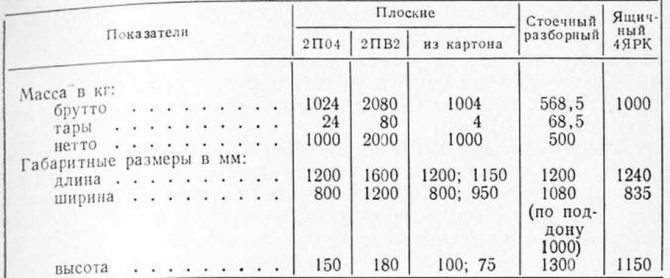

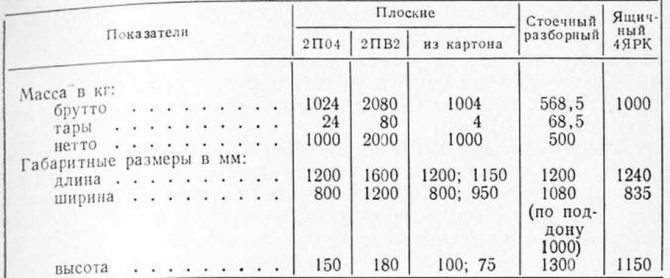

Excerpt from GOST

If you follow the GOSTs of the Soviet era, the maximum load on a pallet is up to 1000 kg. In real tests, it was found that it is possible to store and transport up to 1500 kg. But during transportation, overloading of vehicles is not allowed. So more than 700-800 kg are still not loaded. When placing loads on pallets / pallets, the following rules must be observed:

- It is necessary to distribute the load evenly over the entire area and fasten it well to each other.

- Pallet edges can be free, but the load must be placed symmetrically about the center. Each row of boxes must be individually secured to the pallet with twine or load straps.

- If the dimensions of the cargo exceed the dimensions of standard pallets, the edges should not protrude beyond the container by more than 2 cm.

- When laying rectangular boxes, it is better to fold the rows in a checkerboard pattern (as when laying bricks). Otherwise, with a stack height of 1 meter or more, the load crumbles.

In this form, goods are usually sent

The general order of packing is as follows: the cargo is placed, fastened with straps, fixed to the pallet. Then it is wrapped with plastic wrap or other material that prevents the load from shifting. Corners can be installed, which are also wrapped in foil. They serve as additional insurance for the displacement of goods during transportation. The strapped bag is fixed with plastic ties to the platform.

Errors in the operation of pellet stoves

A pellet boiler can be expensive and of high quality, but if the choice of the appliance was wrong, disappointment is inevitable. The main mistake lies in the general non-compliance of the boiler with the goals of consumers. You need to be clearly aware of your needs and how the oven is able to satisfy them. First of all, the equipment must be evaluated in terms of its type and selection criteria.

A common mistake is the incorrect calculation of the boiler power and the heat loss of the room. The result is too low or too high temperature. Better to spend more time, but make the right calculations. Better yet, entrust it to a specialist.

Poor oven performance is another annoying problem. It is usually connected (if we are not talking about low-quality equipment) with the realities typical for Russia - the mentioned unimportant quality of power grids and fuel.

Let's briefly list three more possible troubles:

- chimney sparking; the reason is the wrong choice of the latter;

- wood dust scattering around the room; the reason is the incorrect choice of a place for the oven;

- increased frequency of filling the ash pan; the reason is incorrect setting of the pellet burner.

Corrugated pallets

The pallet can be used both separately and integrated into the package, with corrugated board sides - box pallet. In this way, you can create quick-assembly containers that are easy to use and take up a minimum of storage space. This approach is considered to be quite profitable, since there is an opportunity to produce cheap containers intended for goods or processes of different types and different loads.

Advantages of corrugated pallets

- Corrugated pallets may not be tied to fixed dimensions. Any products with the required parameters can be made to order.

- Manufacturing is inexpensive, which is economically feasible for the production of containers in small batches or experimental samples. Corrugated board is the cheapest material.

- No disposal problem.

- The container is lightweight, which is preferable for air transportation. According to this parameter, corrugated cardboard pallets can be compared with plastic ones, but they are cheaper.

- They have various designs and strengths. Suitable for transporting a variety of goods.

- Eco-friendly and hygienic.

- Fully meet international export requirements. Does not require sanitization.

- Can be used in the food industry.

Corrugated pallets are convenient and cost-effective containers. They provide many advantages and have few disadvantages. Therefore, such products are gradually replacing wood products, which are more expensive and not so practical to use. For international exports, especially for air transportation, this is an ideal option, given that any structure can be made, integrated to specific requirements and conditions of use.

Corrugated pallets can be called the most relevant packaging option in the food industry, logistics, as well as to ensure trade processes. They fully meet the norms and requirements dictated by the established state standards.

Characteristics and features of pellets

Defining what pellets are, it is possible to describe the products as waste products from the production processes of woodworking, processing of coal, peat, and agricultural crops. Briquettes are formed under a pressure of more than 300 atmospheres at high temperatures.

The raw materials are mixed, processed, passed through the molds, as a result, capsules or granules are obtained. Adhesion of particles does not require the use of artificial adhesives, natural lignin is sufficient, therefore heating a house with pellets is the cleanest and safest from an environmental point of view. The granules can be 6-10 mm thick and 20-30 mm long.The peculiarity of the use of pellets is in their increased thermal efficiency. In comparison with other types of raw materials, 1000 kg of pellets will replace 500 kg of diesel, 480 m3 of gas, 1600 kg of firewood.

On a note! The property of 100% combustion and low ash content will help to make a choice in favor of pellets. The price of raw materials is higher than that of firewood, but when choosing sawn birch firewood, pellets turn out to be more profitable, even if you take wooden pallets for heating of the highest purity class.

Some manufacturers produce pellets from solid waste. Granules are very cheap, do not differ in thermal efficiency, but are suitable as a reserve stock for heating a house during the off-season or late spring frosts.

Weather thermostat for heating boiler regulation

What to make of pallets for a summer residence with your own hands?

and With just one pallet, you can make a wall-mounted mug rack. To do this, you need:

- pallet;

- water-based impregnation for wood;

- metal or plastic hooks;

- 2 wardrobe sheds;

- self-tapping screws;

- stencil letters;

- White paint.

Wash the pallet, cover with a water-based impregnation, let this solution dry. Using self-tapping screws, attach the hooks to the rails of the pallet.

With the stencil on the top board, write the word “coffee” in English or Russian. Pets will know that this is where to look for mugs for this drink.

The photo demonstrates how to turn pallets into flowerpots for giving with your own hands.

- For this, the pallets must be carefully disassembled. Then boards in good condition are sawn off to one size. These will be the same vertical bars. They are stuffed onto a pre-made base of beams.

- Attach the top horizontally to each side on the board to make the edging for the outdoor planter.

- It remains to paint it, wait a little, after which you can pour the earth and plant beautiful flowers.

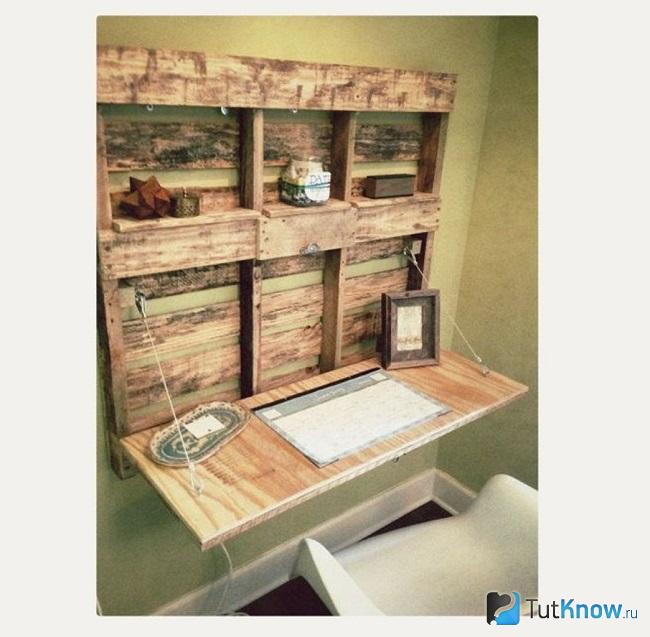

If you have another pallet, then make a convenient folding table out of it. In addition to it, you will need:

- board or wood panel;

- self-tapping screws;

- two chains;

- two carbines;

- two metal screw-in hinges.

Cover the previously washed listened pallet with wood stain or varnish. In the lower half of such a pallet, metal hinges must be attached to the bars. The same ones are fixed on a wooden board.

Attach the carabiners to the chains, fix these table cover limiting parts to the metal hinges.

If you want to fold the countertop sometimes, then you need to consider how to fix the lid. To do this, you can use a hook, magnet or latch.

Pellet production technology

Since the technology for the production of pellets consists in the mechanical processing of wood waste, it will be necessary to consider the whole process in order to find out what equipment is needed for the production of pellets from sawdust. At the very beginning, there is a preparatory stage and the first operation - crushing large pieces of wood or processing slabs and other woodworking waste into chips. The operation is carried out with the help of a special machine - a crusher, which produces chips of no more than 4 mm in size.

Crushers of small dimensions for use at home can be purchased in a retail network or made on their own. An example of the operation of a machine for crushing branches into a fine fraction, suitable in size and subsequently used for the production of pellets, is shown in the video.

The second operation of the preparatory stage is the drying of wet raw materials. As mentioned above, the upper threshold for moisture content is 12%, such waste occurs only after processing dry boards or logs, in other cases, options are possible (40-50% moisture). Sometimes people do not pay attention to this, believing that the sawdust is dry on its own. In fact, it happens in different ways, which the boiler plant will later let know about, working half-heartedly and covered with soot from the inside.Therefore, before loading the raw material into the pellet machine, it is advisable to dry it. The operation is carried out in dryers of various designs, for example:

- dryer drum;

- aerodynamic dryer;

- pneumatic dryer;

- tape type;

- dispersant.

Without going into the details and principles of operation of these installations, we note that in order to evaporate moisture from wood, it will be necessary to supply thermal energy to it. This is theory, but in practice, pressing properly prepared sawdust will cost you at least making a homemade dryer plus heating energy.

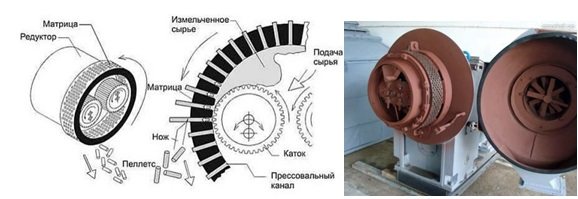

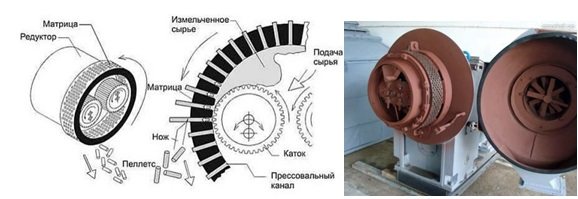

The next stage is the main one, the compression of raw materials and the formation of pellets from it. The operation is performed by a special machine - a pellet press. The main element of the unit is a matrix, it can be of 2 types: flat and cylindrical. In both cases, to rotate the shaft or the auger, the unit is equipped with a powerful electric motor with a belt or gear drive.

In industrial production, where production volumes are significant, a granulator for pellets with a cylindrical matrix is usually used. In it, the raw material fed into a cylinder with many holes is pressed by notched rollers moving inside it, as shown in the diagram:

Under high pressure, the sawdust takes the form of holes, turning into solid granules, and then pushed out. There is a cut-off knife that cuts off the product from the rotating die, ensuring that the finished pellets are of the same size. Such a design is difficult to manufacture and is rarely assembled on its own, although the performance of this machine is greater than that of the second type of units.

It is easier to make a pellet press with a flat die at home. Here, the raw material is poured from above onto a flat disc with holes, along which the rollers move, pressing the sawdust into the holes in the same way as described above. The finished granules fall down and are poured into the container along the chute.

The design is convenient for do-it-yourself assembly, which is what many craftsmen use. For this they buy 2 finished products: an electric motor and a matrix. And then, if you have access to turning and milling equipment, you can make die parts. Further, all elements are fixed on a metal frame, drive pulleys (or gearbox) and a receiving hopper are installed. All that remains is to connect to the electrical network and you can start producing pellets from sawdust.

For reference. Self-made installations for pressing granules have a low productivity. In order not to stand near them with a bucket to fill the bunker, some craftsmen additionally install a screw conveyor that feeds raw materials from a large container at a given speed.

DIY pallet furniture

If you have a large family or frequent guests, then make a large table that will accommodate a lot of people. Those wishing to relax and sunbathe can sit on the sofa, which is also made of pallets.

These blanks can be pre-sanded with a grinder, the loan is applied with a primer for wooden surfaces, and then coated with rainbow-colored paint. All those present will certainly cheer up from just one look at this pretty country furniture. You can plant petunias in balcony boxes, fix them on the table bar, and an open-air cafe will turn out to be even more cheerful.

If you like bar counters, these can also be made using wooden pallets.

For such an impromptu bar, you will need:

- wooden pallets;

- self-tapping screws;

- saw;

- varnish;

- metal corners;

- paint.

Crafting workshop:

- Place two or three pallets on the narrow side. This is the front of the bar counter.To fix these elements, attach a long bar to them from below, and boards from above, which at the same time will become a table top.

- Perpendicular to the data, place one more pallet on both sides, fixing them in the same way, also with metal corners.

- To make a stool, join four small beams at the bottom and top with the same number of slightly larger vertical beams. From above, stuff the boards tightly against each other, but leave a gap of 5 mm so that water can drain off when it rains.

- Using the same technology, make other stools with your own hands or with the assistance of assistants. Cover the table-top and seat of the stools with moisture-resistant varnish, and their legs and bar counter with paint intended for outdoor use.

Pallet furniture is very durable. You will be convinced of this when you make a spacious sofa and a coffee table for it.

To do this, take:

- wooden pallets - 5 pieces;

- grinder;

- paint;

- self-tapping screws;

- furniture legs;

- brush.

- As you can see, the pallets must first be sanded and painted in the desired color. When 2-3 layers of it stop sticking to your hands, you can start assembling the furniture.

- Place two pallets side by side, attach them to each other using self-tapping screws or nuts and screws. Place another pallet on top, which will become the seat of the sofa, the fourth will turn into its back.

- Attach the furniture legs to the fifth pallet so that the coffee table can be moved.

You can also make wonderful swing out of pallets for giving, which will practically cost nothing. You will only need to spend money on:

- nails or screws;

- impregnation for wood;

- brush;

- rope rope.

Place two pallets side by side. Nail it from the outside or attach two long thick boards with self-tapping screws.

It is better to connect the structure inside with metal elements. To do this, you can straighten the corners and fix the resulting blanks between two pallets.

Tie the ropes at the corners. At the top, attach them to a powerful tree or metal pipes, which must first be dug into the ground, and fixed here with concrete mortar. It is better to use a welded structure, similar to the letter P. If you like antique furniture, then make a cabinet out of pallets. It does not even need to be painted to show the raid of time. But mechanisms for opening drawers will certainly come in handy for you, as well as carpentry skills.

For the next craft, much less experience is needed. After all, even novice craftsmen, women, teenagers can build such a table.

Let's dwell on two more ideas in more detail, since they imply the creation of buildings.