The design and thermal calculation of a heating system is an obligatory stage in the arrangement of heating a house. The main task of computing activities is to determine the optimal parameters of the boiler and the radiator system.

Agree, at first glance it may seem that only an engineer can do a heat engineering calculation. However, not everything is so complicated. Knowing the algorithm of actions, it will turn out to independently perform the necessary calculations.

The article describes in detail the calculation procedure and provides all the necessary formulas. For a better understanding, we have prepared an example of thermal calculation for a private house.

Norms of temperature regimes of premises

Before carrying out any calculations of the parameters of the system, it is necessary, at a minimum, to know the order of the expected results, as well as to have available standardized characteristics of some tabular values that must be substituted in the formulas or be guided by them.

Having performed calculations of parameters with such constants, one can be sure of the reliability of the sought dynamic or constant parameter of the system.

For premises for various purposes, there are reference standards for the temperature regimes of residential and non-residential premises. These norms are enshrined in the so-called GOSTs.

For a heating system, one of these global parameters is the room temperature, which must be constant regardless of the season and ambient conditions.

According to the regulation of sanitary standards and rules, there are differences in temperature relative to the summer and winter seasons. The air conditioning system is responsible for the temperature regime of the room in the summer season, the principle of its calculation is described in detail in this article.

But the room temperature in winter is provided by the heating system. Therefore, we are interested in the temperature ranges and their tolerances for the winter season.

Most regulatory documents stipulate the following temperature ranges that allow a person to be comfortable in a room.

For non-residential premises of an office type with an area of up to 100 m2:

- 22-24 ° C - optimal air temperature;

- 1 ° C - permissible fluctuation.

For office-type premises with an area of more than 100 m2, the temperature is 21-23 ° C. For non-residential premises of an industrial type, the temperature ranges differ greatly depending on the purpose of the premises and the established labor protection standards.

Each person has their own comfortable room temperature. Someone likes it to be very warm in the room, someone is comfortable when the room is cool - this is all quite individual

As for residential premises: apartments, private houses, estates, etc., there are certain temperature ranges that can be adjusted depending on the wishes of the residents.

And yet, for specific premises of an apartment and a house, we have:

- 20-22 ° C - living room, including children's room, tolerance ± 2 ° С -

- 19-21 ° C - kitchen, toilet, tolerance ± 2 ° С;

- 24-26 ° C - bathroom, shower, swimming pool, tolerance ± 1 ° С;

- 16-18 ° C - corridors, hallways, staircases, storerooms, tolerance + 3 ° С

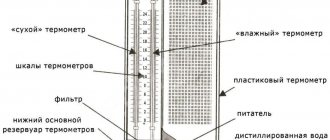

It is important to note that there are several more basic parameters that affect the temperature in the room and which you need to focus on when calculating the heating system: humidity (40-60%), the concentration of oxygen and carbon dioxide in the air (250: 1), the speed of movement of air mass (0.13-0.25 m / s), etc.

Calculation of heating radiators by area

The easiest way. Calculate the amount of heat required for heating, based on the area of the room in which the radiators will be installed. You know the area of each room, and the heat demand can be determined according to the building codes SNiP:

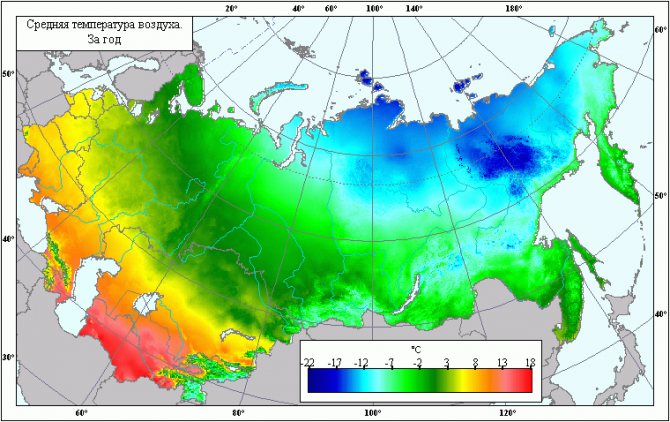

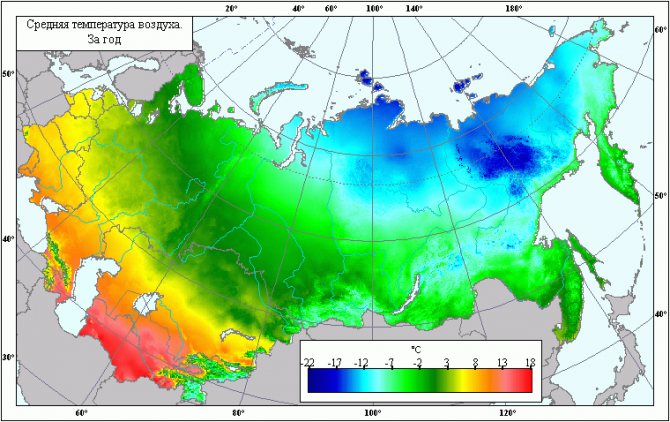

- for the middle climatic zone, 60-100W is required for heating 1m 2 of living space;

- for areas above 60 o, 150-200W are required.

Based on these norms, you can calculate how much heat your room will require. If the apartment / house is located in the middle climatic zone, 1600W of heat will be required to heat an area of 16m2 (16 * 100 = 1600). Since the norms are average, and the weather does not indulge in constancy, we believe that 100W is required. Although, if you live in the south of the middle climatic zone and your winters are mild, count 60W.

The calculation of heating radiators can be done according to SNiP standards

A power reserve in heating is needed, but not very large: with an increase in the amount of required power, the number of radiators increases. And the more radiators, the more coolant in the system. If for those who are connected to central heating this is uncritical, then for those who have or are planning individual heating, a large system volume means large (extra) costs for heating the coolant and a greater inertia of the system (the set temperature is less accurately maintained). And a logical question arises: "Why pay more?"

Having calculated the heat demand of the room, we can find out how many sections are required. Each of the heating devices can emit a certain amount of heat, which is indicated in the passport. They take the found heat demand and divide it by the radiator power. The result is the required number of sections to make up for losses.

Let's calculate the number of radiators for the same room. We have determined that 1600W is required. Let the power of one section be 170W. It turns out 1600/170 = 9.411 pcs. You can round up or down at your discretion. It can be rounded into a smaller one, for example, in a kitchen - there are enough additional sources of heat, and in a larger one - it is better in a room with a balcony, a large window or in a corner room.

The system is simple, but the disadvantages are obvious: the height of the ceilings can be different, the material of the walls, windows, insulation and a number of other factors are not taken into account. So the calculation of the number of heating radiator sections according to SNiP is approximate. For an accurate result, you need to make adjustments.

Calculation of heat loss in the house

According to the second law of thermodynamics (school physics), there is no spontaneous transfer of energy from less heated to more heated mini- or macro-objects. A special case of this law is the “striving” to create temperature equilibrium between two thermodynamic systems.

For example, the first system is an environment with a temperature of -20 ° C, the second system is a building with an internal temperature of + 20 ° C. According to the above law, these two systems will strive to balance through the exchange of energy. This will happen with the help of heat losses from the second system and cooling in the first one.

It can be said unambiguously that the ambient temperature depends on the latitude at which the private house is located. And the temperature difference affects the amount of heat leaks from the building (+)

Heat loss means the involuntary release of heat (energy) from some object (house, apartment). For an ordinary apartment, this process is not so "noticeable" in comparison with a private house, since the apartment is located inside the building and is "adjacent" to other apartments.

In a private house, heat “escapes” to one degree or another through the outer walls, floor, roof, windows and doors.

Knowing the amount of heat loss for the most unfavorable weather conditions and the characteristics of these conditions, it is possible to calculate the power of the heating system with high accuracy.

So, the volume of heat leaks from the building is calculated using the following formula:

Q = Qfloor + Qwall + Qwindow + Qroof + Qdoor +… + Qiwhere

Qi - the volume of heat loss from the uniform appearance of the building envelope.

Each component of the formula is calculated by the formula:

Q = S * ∆T / Rwhere

- Q - thermal leaks, V;

- S - area of a specific type of structure, sq. m;

- ∆T - temperature difference between ambient and indoor air, ° C;

- R - thermal resistance of a certain type of structure, m2 * ° C / W.

The very value of thermal resistance for actually existing materials is recommended to be taken from auxiliary tables.

In addition, thermal resistance can be obtained using the following ratio:

R = d / kwhere

- R - thermal resistance, (m2 * K) / W;

- k - coefficient of thermal conductivity of the material, W / (m2 * K);

- d Is the thickness of this material, m.

In older houses with a damp roof structure, heat leakage occurs through the top of the building, namely through the roof and attic. Carrying out measures for warming the ceiling or thermal insulation of the attic roof solve this problem.

If you insulate the attic space and the roof, then the total heat loss from the house can be significantly reduced.

There are several other types of heat losses in the house through cracks in structures, a ventilation system, a kitchen hood, opening windows and doors. But it makes no sense to take into account their volume, since they make up no more than 5% of the total number of main heat leaks.

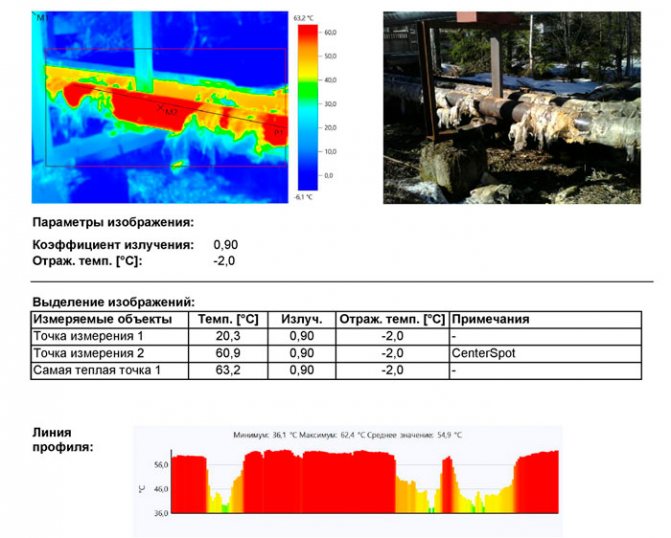

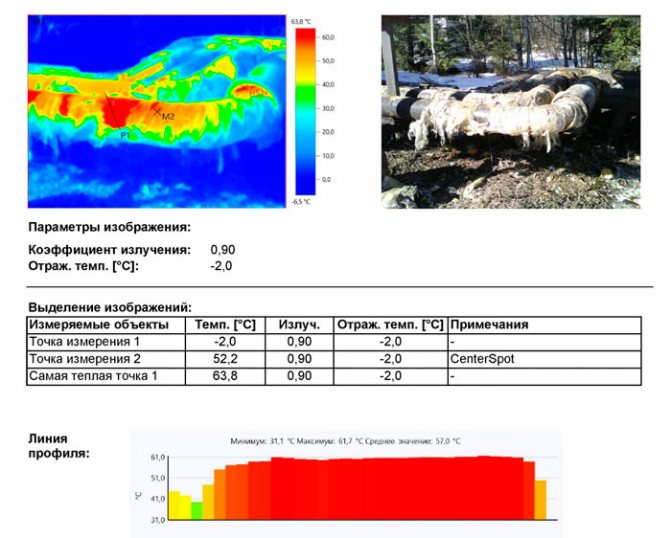

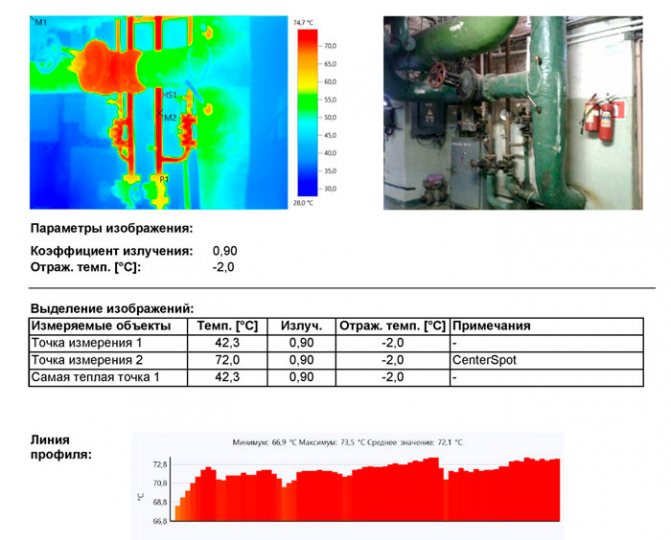

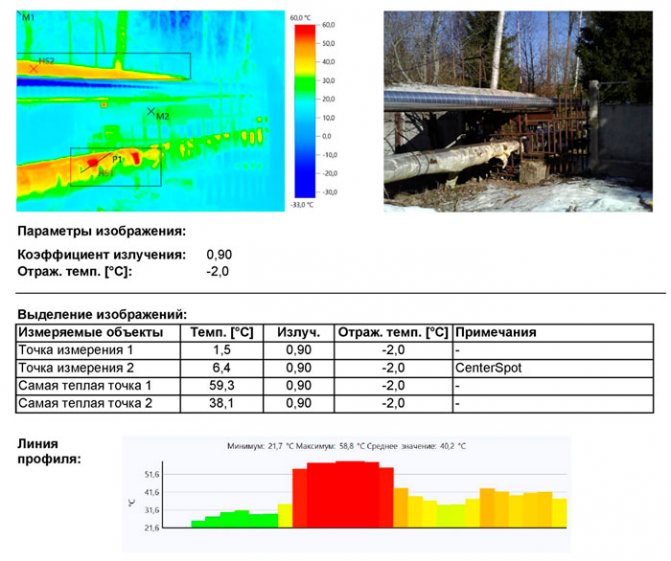

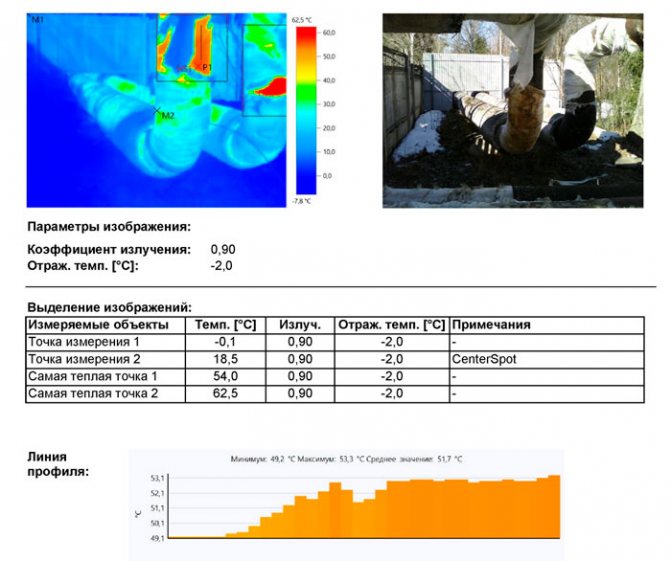

We determine the actual heat losses in heating networks

We proceed from the assumption that heat losses in heating networks do not depend on the speed of water movement in the pipeline, but depend on

- pipe diameter,

- coolant temperature,

- thermal insulation material and

- states of thermal insulation.

Stationary thermal conductivity of a cylindrical wall - description of the calculation method

A cylindrical wall is understood as a pipe of infinite length with an inner radius R1 (diameter D1) and an outer radius R2 (diameter D2).

Constant temperatures t1 and t2 are set on the wall surfaces. Heat transfer is carried out only by thermal conductivity, the outer surfaces are isothermal (equipotential) and the temperature field changes only along the pipe wall thickness in the direction of the radius.

The heat flux passing through a cylindrical wall of unit length is denoted by ql and is called the linear heat flux, W / m:

where λ is the coefficient of thermal conductivity of the material under study, W / (m ∙ K);

D1, D2 - respectively, the inner and outer diameters of the cylindrical layer of the material;

t1, t2 - average temperatures of the inner and outer surfaces of the cylindrical layer of the material.

Heat flux, W:

where l is the length of the pipe, m.

Consider the thermal conductivity of a multilayer cylindrical wall consisting of n homogeneous and concentric cylindrical layers with a constant coefficient of thermal conductivity and in each layer, the temperature and diameter of the inner surface of the first layer are equal to t1 and R1, on the outer surface of the last nth layer - tn + 1 and Rn + one.

The linear heat flux of the cylindrical wall ql is a constant value for all layers and is directed towards lowering the temperature, for example, from the inner layer to the outer one.

Writing down the ql value for each arbitrary i-th layer and transforming this equation, we have

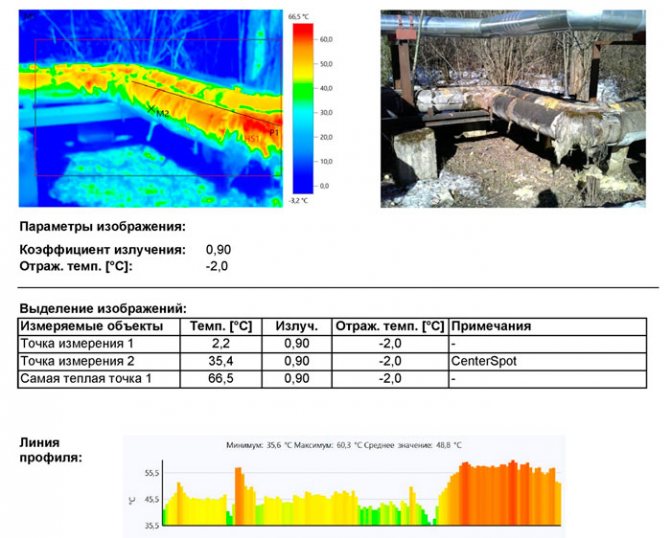

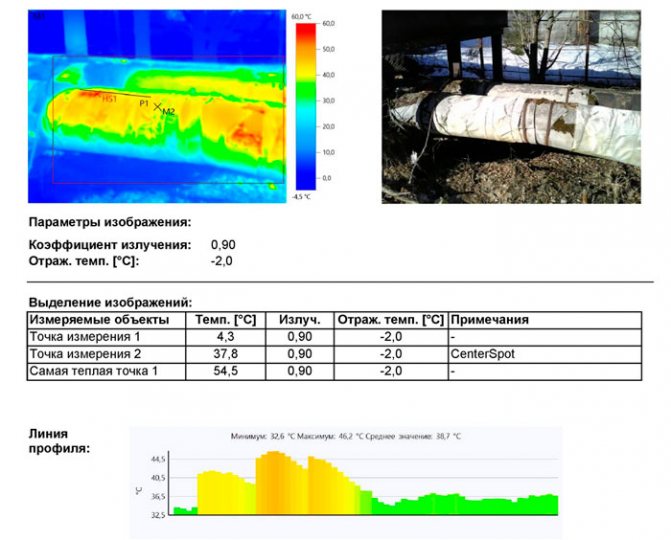

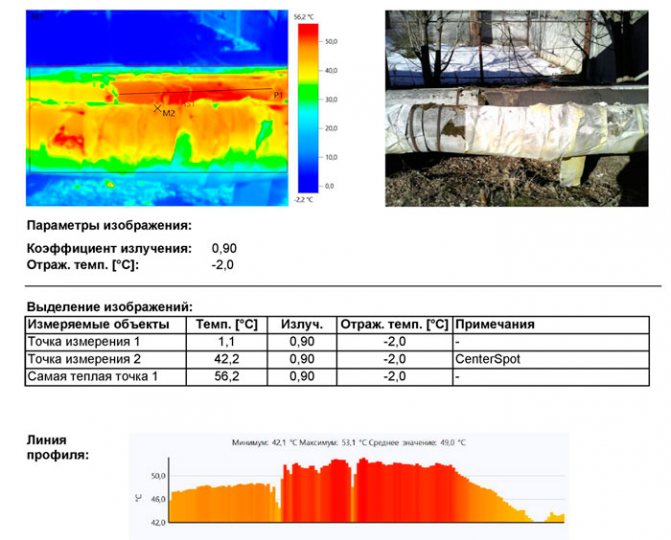

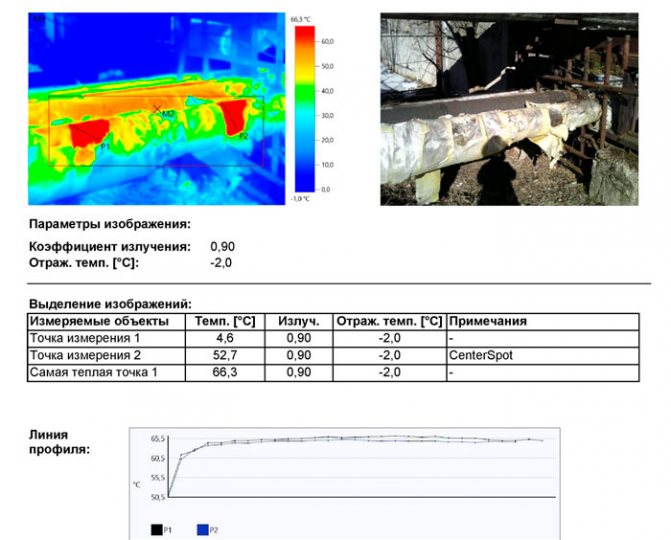

Since the heating network has three different types of insulation, we calculate the heat losses of pipelines for each type separately, as well as the case without pipeline insulation to assess heat losses in the damaged sections of the heating network.

Next, we calculated heat losses in heating networks with different types of thermal insulation.

In the example that follows, the calculation of heat losses in a heating network with polyethylene foam insulation.

Determination of boiler output

To maintain the temperature difference between the environment and the temperature inside the house, an autonomous heating system is needed that maintains the desired temperature in every room of a private house.

The basis of the heating system is different types of boilers: liquid or solid fuel, electric or gas.

The boiler is the central unit of the heating system that generates heat.The main characteristic of the boiler is its power, namely the rate of conversion of the amount of heat per unit of time.

Having made calculations of the heat load for heating, we will obtain the required rated power of the boiler.

For an ordinary multi-room apartment, the boiler power is calculated through the area and specific power:

Rboiler = (Sroom * Rudelnaya) / 10where

- S rooms- the total area of the heated room;

- Rudellnaya- power density relative to climatic conditions.

But this formula does not take into account heat losses, which are sufficient in a private house.

There is another relationship that takes this parameter into account:

Рboiler = (Qloss * S) / 100where

- Rkotla- boiler power;

- Qloss- heat loss;

- S - heated area.

The rated power of the boiler must be increased. The stock is necessary if you plan to use the boiler for heating water for the bathroom and kitchen.

In most heating systems for private houses, it is recommended to use an expansion tank in which a supply of coolant will be stored. Every private house needs hot water supply

In order to provide for the power reserve of the boiler, the safety factor K must be added to the last formula:

Рboiler = (Qloss * S * K) / 100where

TO - will be equal to 1.25, that is, the estimated boiler power will be increased by 25%.

Thus, the power of the boiler makes it possible to maintain the standard air temperature in the rooms of the building, as well as to have an initial and additional volume of hot water in the house.

General calculations

It is necessary to determine the total heating capacity so that the power of the heating boiler is sufficient for high-quality heating of all rooms. Exceeding the permissible volume can lead to increased wear on the heater, as well as significant energy consumption.

Boiler

The calculation of the power of the heating unit allows you to determine the indicator of the boiler capacity. To do this, it is enough to take as a basis the ratio at which 1 kW of thermal energy is sufficient to effectively heat 10 m2 of living space. This ratio is valid in the presence of ceilings, the height of which is no more than 3 meters.

As soon as the boiler power indicator becomes known, it is enough to find a suitable unit in a specialized store. Each manufacturer indicates the amount of equipment in the passport data.

Therefore, if the correct power calculation is performed, problems with determining the required volume will not arise.

Pipes

To determine the sufficient volume of water in the pipes, it is necessary to calculate the cross-section of the pipeline according to the formula - S = π × R2, where:

- S - cross section;

- π - constant constant equal to 3.14;

- R is the inner radius of the pipes.

Expansion tank

It is possible to determine what capacity the expansion tank should have, having data on the coefficient of thermal expansion of the coolant. For water, this figure is 0.034 when heated to 85 ° C.

When performing the calculation, it is enough to use the formula: V-tank = (V system × K) / D, where:

- V-tank - the required volume of the expansion tank;

- V-system - the total volume of liquid in the remaining elements of the heating system;

- K is the expansion coefficient;

- D - the efficiency of the expansion tank (indicated in the technical documentation).

Radiators

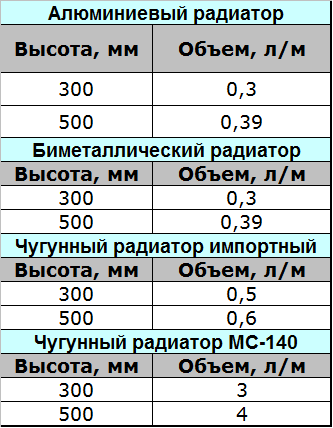

Currently, there is a wide variety of individual types of radiators for heating systems. Apart from functional differences, they all have different heights.

To calculate the volume of working fluid in radiators, you must first calculate their number. Then multiply this amount by the volume of one section.

You can find out the volume of one radiator using the data from the technical data sheet of the product. In the absence of such information, you can navigate according to the averaged parameters:

- cast iron - 1.5 liters per section;

- bimetallic - 0.2-0.3 liters per section;

- aluminum - 0.4 liters per section.

The following example will help you understand how to calculate the value correctly. Let's say there are 5 radiators made of aluminum. Each heating element contains 6 sections. We make a calculation: 5 × 6 × 0.4 = 12 liters.

Features of the selection of radiators

Radiators, panels, underfloor heating systems, convectors, etc. are standard components for providing heat in a room. The most common parts of a heating system are radiators.

The heat sink is a special hollow modular type structure made of high heat dissipation alloy. It is made from steel, aluminum, cast iron, ceramics and other alloys. The principle of operation of a heating radiator is reduced to the radiation of energy from the coolant into the space of the room through the “petals”.

An aluminum and bimetallic heating radiator has replaced massive cast-iron radiators. Ease of production, high heat dissipation, good construction and design have made this product a popular and widespread tool for radiating heat indoors.

There are several methods for calculating heating radiators in a room. The list of methods below is sorted in order of increasing computational accuracy.

Calculation options:

- By area... N = (S * 100) / C, where N is the number of sections, S is the area of the room (m2), C is the heat transfer of one section of the radiator (W, taken from those passport or product certificate), 100 W is the amount of heat flow, which is necessary for heating 1 m2 (empirical value). The question arises: how to take into account the height of the ceiling of the room?

- By volume... N = (S * H * 41) / C, where N, S, C - similarly. H is the height of the room, 41 W is the amount of heat flux required to heat 1 m3 (empirical value).

- By odds... N = (100 * S * k1 * k2 * k3 * k4 * k5 * k6 * k7) / C, where N, S, C and 100 are similar. k1 - taking into account the number of chambers in the glass unit of the window of the room, k2 - thermal insulation of the walls, k3 - the ratio of the area of windows to the area of the room, k4 - the average subzero temperature in the coldest week of winter, k5 - the number of outer walls of the room (which “go out” to the street), k6 - type of room on top, k7 - ceiling height.

This is the most accurate way to calculate the number of sections. Naturally, fractional calculation results are always rounded to the next integer.

How to calculate the heat output of a heater

The way to calculate the power largely depends on what kind of heating device we are talking about.

- For all electric heating devices, without exception, the effective thermal power is exactly equal to their rated electrical power.

Remember the school physics course: if useful work is not done (that is, the movement of an object with a nonzero mass against the gravity vector), all the energy spent goes to heating the environment.

Can you guess the heat output of the device by its packaging?

- For most heating devices from decent manufacturers, their thermal power is indicated in the accompanying documentation or on the manufacturer's website.

Often there you can even find a calculator for calculating heating radiators for a certain volume of a room and parameters of the heating system.

There is one subtlety here: almost always the manufacturer calculates the heat transfer of the radiator - heating batteries, convector or fan coil - for a very specific temperature difference between the coolant and the room, equal to 70C. For Russian realities, such parameters are often an unattainable ideal.

Finally, a simple, albeit approximate, calculation of the power of a heating radiator by the number of sections is possible.

Bimetallic radiators

The calculation of bimetallic heating radiators is based on the overall dimensions of the section.

Let's take the data from the site of the Bolshevik plant:

- For a section with a center-to-center distance of the connections of 500 millimeters, the heat transfer is 165 watts.

- For the 400mm section, 143 watts.

- 300 mm - 120 watts.

- 250 mm - 102 watts.

10 sections with half a meter between the axes of the connections will give us 1650 watts of heat.

Aluminum radiators

Calculation of aluminum radiators is based on the following values (data for Italian radiators Calidor and Solar):

- The section with a center distance of 500 millimeters gives off 178-182 watts of heat.

- With a center-to-center distance of 350 millimeters, the heat transfer of the section decreases to 145-150 watts.

Steel plate radiators

And how to calculate steel plate-type heating radiators? After all, they do not have sections, from the number of which the calculation formula can be based.

Here, the key parameters are, again, the center distance and the length of the radiator. In addition, manufacturers recommend taking into account the method of connecting the radiator: with different methods of inserting into the heating system, the heating and, therefore, the heat output may also differ.

In order not to bore the reader with the abundance of formulas in the text, we will simply refer it to the power table of the Korad radiator range.

The diagram takes into account the dimensions of the radiators and the type of connection.

Cast iron radiators

And only here everything is extremely simple: all cast-iron radiators produced in Russia have the same center-to-center distance of connections, equal to 500 millimeters, and heat transfer at a standard temperature delta of 70C, equal to 180 watts per section.

Half the battle is done. Now we know how to calculate the number of sections or heating devices with a known required heat output. But where do we get the very thermal power that we need?

Hydraulic calculation of water supply

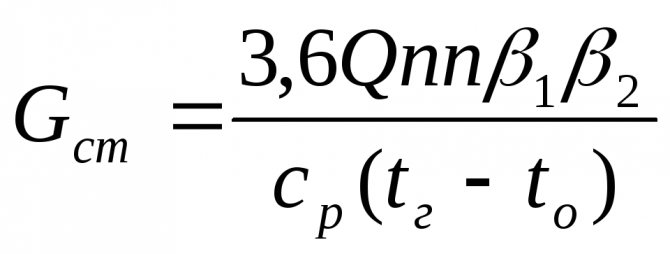

Of course, the “picture” of calculating heat for heating cannot be complete without calculating such characteristics as the volume and speed of the heat carrier. In most cases, the coolant is ordinary water in a liquid or gaseous state of aggregation.

It is recommended to calculate the real volume of the heat carrier through the summation of all cavities in the heating system. When using a single-circuit boiler, this is the best option. When using double-circuit boilers in the heating system, it is necessary to take into account the consumption of hot water for hygienic and other domestic purposes.

The calculation of the volume of water heated by a double-circuit boiler to provide residents with hot water and heating the coolant is made by summing the internal volume of the heating circuit and the real needs of users in heated water.

The volume of hot water in the heating system is calculated using the formula:

W = k * Pwhere

- W - the volume of the heat carrier;

- P - heating boiler power;

- k - power factor (the number of liters per unit of power is 13.5, range - 10-15 liters).

As a result, the final formula looks like this:

W = 13.5 * P

The flow rate of the heating medium is the final dynamic assessment of the heating system, which characterizes the rate of circulation of the liquid in the system.

This value helps to estimate the type and diameter of the pipeline:

V = (0.86 * P * μ) / ∆Twhere

- P - boiler power;

- μ - boiler efficiency;

- ∆T - the temperature difference between the supply water and the return water.

Using the above methods of hydraulic calculation, it will be possible to obtain real parameters, which are the “foundation” of the future heating system.

Example # 1

It is necessary to determine the correct number of sections for the M140-A radiator, which will be installed in the room located on the upper floor. At the same time, the wall is external, there is no niche under the windowsill. And the distance from it to the radiator is only 4 cm. The height of the room is 2.7 m. Qn = 1410 W, and tv = 18 ° C. Conditions for connecting the radiator: connection to a single-pipe riser of flow-controlled type (Dy20, KRT valve with 0.4 m inlet); the distribution of the heating system is top, tg = 105 ° C, and the flow rate of the coolant through the riser is Gst = 300 kg / h. The temperature difference between the coolant of the supply riser and the considered one is 2 ° C.

Determine the average temperature in the radiator:

tav = (105 - 2) - 0.5х1410х1.06х1.02х3.6 / (4.187х300) = 100.8 ° C.

Based on the data obtained, we calculate the heat flux density:

tav = 100.8 - 18 = 82.8 ° С

It should be noted that there was a slight change in the level of water consumption (360 to 300 kg / h). This parameter has almost no effect on qnp.

Qpr = 650 (82.8 / 70) 1 + 0.3 = 809W / m2.

Next, we determine the level of heat transfer horizontally (1r = 0.8 m) and vertically (1w = 2.7 - 0.5 = 2.2 m) located pipes. To do this, you should use the formula Qtr = qwxlw + qgxlg.

We get:

Qtr = 93x2.2 + 115x0.8 = 296 W.

We calculate the area of the required radiator by the formula Ap = Qnp / qnp and Qпp = Qп - µ trxQtr:

Ap = (1410-0.9x296) / 809 = 1.41m2.

We calculate the required number of sections of the M140-A radiator, taking into account that the area of one section is 0.254 m2:

m2 (µ4 = 1.05, µ 3 = 0.97 + 0.06 / 1.41 = 1.01, we use the formula µ 3 = 0.97 + 0.06 / Ap and determine:

N = (1.41 / 0.254) x (1.05 / 1.01) = 5.8. That is, the calculation of heat consumption for heating showed that a radiator consisting of 6 sections should be installed in the room in order to achieve the most comfortable temperature.

Thermal design example

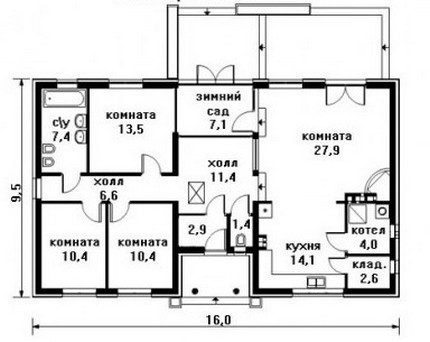

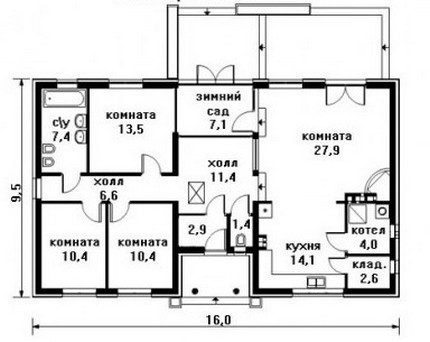

As an example of heat calculation, there is a regular 1-storey house with four living rooms, a kitchen, a bathroom, a “winter garden” and utility rooms.

The foundation is made of a monolithic reinforced concrete slab (20 cm), the outer walls are concrete (25 cm) with plaster, the roof is made of wooden beams, the roof is metal and mineral wool (10 cm)

Let's designate the initial parameters of the house, necessary for the calculations.

Building dimensions:

- floor height - 3 m;

- small window of the front and back of the building 1470 * 1420 mm;

- large facade window 2080 * 1420 mm;

- entrance doors 2000 * 900 mm;

- rear doors (exit to the terrace) 2000 * 1400 (700 + 700) mm.

The total width of the building is 9.5 m2, length is 16 m2. Only living rooms (4 pcs.), A bathroom and a kitchen will be heated.

To accurately calculate the heat loss on the walls from the area of the external walls, you need to subtract the area of all windows and doors - this is a completely different type of material with its own thermal resistance

We start by calculating the areas of homogeneous materials:

- floor area - 152 m2;

- roof area - 180 m2, taking into account the attic height of 1.3 m and the width of the run - 4 m;

- window area - 3 * 1.47 * 1.42 + 2.08 * 1.42 = 9.22 m2;

- door area - 2 * 0.9 + 2 * 2 * 1.4 = 7.4 m2.

The area of the outer walls will be 51 * 3-9.22-7.4 = 136.38 m2.

Let's move on to calculating heat loss for each material:

- Qpol = S * ∆T * k / d = 152 * 20 * 0.2 / 1.7 = 357.65 W;

- Qroof = 180 * 40 * 0.1 / 0.05 = 14400 W;

- Qwindow = 9.22 * 40 * 0.36 / 0.5 = 265.54 W;

- Qdoor = 7.4 * 40 * 0.15 / 0.75 = 59.2 W;

And also Qwall is equivalent to 136.38 * 40 * 0.25 / 0.3 = 4546. The sum of all heat losses will be 19628.4 W.

As a result, we calculate the boiler power: Рboiler = Qloss * Sheat_room * К / 100 = 19628.4 * (10.4 + 10.4 + 13.5 + 27.9 + 14.1 + 7.4) * 1.25 / 100 = 19628.4 * 83.7 * 1.25 / 100 = 20536.2 = 21 kW.

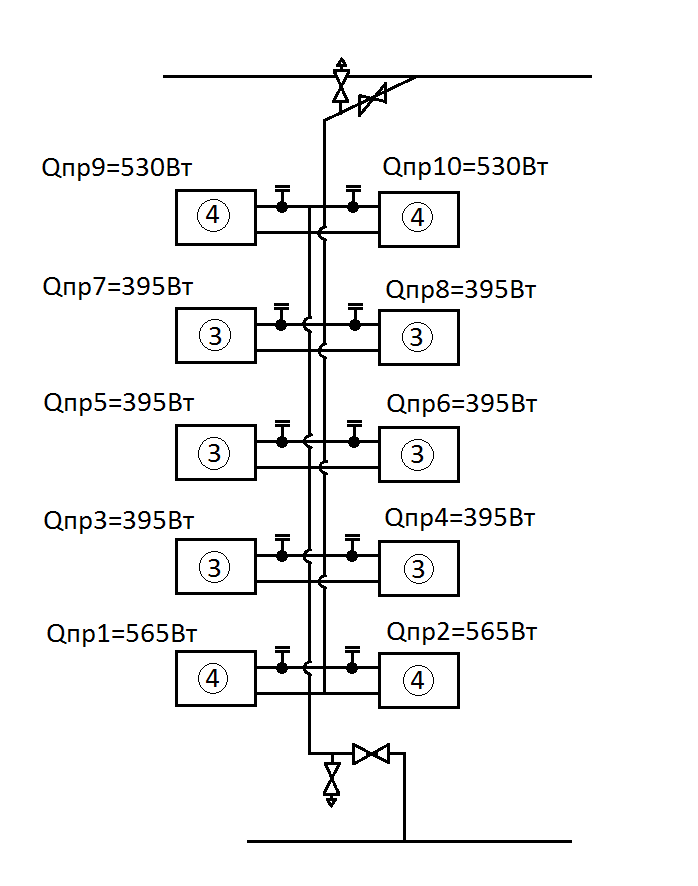

We will calculate the number of radiator sections for one of the rooms. For everyone else, the calculations are the same. For example, a corner room (left, bottom corner of the diagram) is 10.4 m2.

Hence, N = (100 * k1 * k2 * k3 * k4 * k5 * k6 * k7) / C = (100 * 10.4 * 1.0 * 1.0 * 0.9 * 1.3 * 1.2 * 1.0 * 1.05) /180=8.5176=9.

This room requires 9 sections of a heating radiator with a heat output of 180 W.

We turn to calculating the amount of coolant in the system - W = 13.5 * P = 13.5 * 21 = 283.5 liters. This means that the speed of the coolant will be: V = (0.86 * P * μ) / ∆T = (0.86 * 21000 * 0.9) /20=812.7 liters.

As a result, a complete turnover of the entire volume of the coolant in the system will be equivalent to 2.87 times per hour.

A selection of articles on thermal calculation will help determine the exact parameters of the elements of the heating system:

- Calculation of the heating system of a private house: rules and calculation examples

- Thermal calculation of a building: specifics and formulas for performing calculations + practical examples

Total heat losses in heating networks

As a result of the inspection of the heating network, it was found that

- 60% of pipelines of heating networks are insulated with glass wool with 70% wear,

- 30% extruded polystyrene foam of the TERMOPLEX type and

- 10% foamed polyethylene.

| Thermal insulation | Total losses of heat energy in heating networks, taking into account the percentage of coverage and wear, kW | Calculation of heat losses in heating networks, taking into account the percentage of coverage and wear, Gcal / hour |

| Glass wool | 803,589 | 0,69092 |

| TERMOPLEX | 219,180 | 0,18845 |

| Foamed polyethylene | 86,468 | 0,07434 |

| Total: | 1109,238 | 0,95372 |

The best formula to calculate

Table of examples of calculating the water of radiators in the heating system.

It should be said that neither the first nor the second formula will allow a person to calculate the differences between the heat losses of a building, depending on the building envelope and insulation structures used in the building.In order to most accurately make the necessary calculations, a somewhat complicated formula must be used, thanks to which it will be possible to get rid of significant costs. This formula is as follows: Qt (kW / h) = (100 W / m2 × S (m2) × K1 × K2 × K3 × K4 × K5 × K6 × K7) / 1000 (the amount of gas consumption for heating is not taken into account). In this case, S is the area of the room. W / m2 represents the specific value of heat loss, this includes all indicators of heat consumption - walls, windows, etc. Each coefficient is multiplied by the next one and in this case denotes one or another indicator of heat leakage.

K1 is the coefficient of heat energy consumption through the windows, which has values of 0.85, 1, 1.27, which will vary depending on the quality of the windows used and their insulation. K2 - the amount of heat consumption through the walls. This coefficient has the same performance as in the case of heat loss through windows. It can vary depending on the thermal insulation of the walls (poor thermal insulation - 1.27, average (when using special heaters) - 1, a high level of thermal insulation has a coefficient of 0.854). K3 is an indicator that determines the ratio of the areas of both windows and floors (50% - 1.2, 40% - 1.1, 30% - 1.0, 20% - 0.9, 10% - 0.8 ), the following coefficient is the temperature outside the room (K4 = -35 degrees - 1.5; -25 degrees - 1.3; -20 degrees - 1.1; -15 degrees - 0.9; -10 degrees - 0.7 ).

K5 in this formula is a coefficient that reflects the number of walls facing outward (4 walls - 1.4; 3 walls - 1.3; 2 walls - 1.2; 1 wall - 1.1). K6 represents the type of insulation for the room above the one for which this calculation is made. If it is heated, then the coefficient will be 0.8, if there is a warm attic, then 0.9, if this room is not heated in any way, the coefficient will be 1. And the last coefficient that is used when calculating according to this formula indicates the height of the ceilings in room. If the height is 4.5 meters, then the ratio is 1.2; 4 meters - 1.15; 3.5 meters - 1.1; 3 meters - 1.05; 2.5 meters - 1.