How to seal a leak

In connection, threads and joints

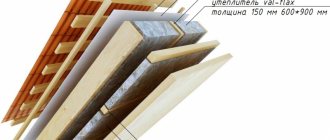

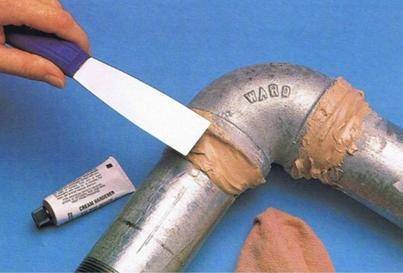

All heating elements are assembled into a single system using threaded, welded, soldered and fitting connections. Any of them is the least reliable place and happens to flow. Leaks in the joints of pipes, even if metal or polypropylene, can be eliminated with an epoxy-based glue. To do this, the surface of the metal pipe, together with the damage, must be cleaned from old paint and rust. You can do the cleaning with a wire brush, sandpaper, or scrape off with a knife.

Prepare fiberglass or medical bandage. If the pipe is 15 to 32 mm in diameter, the length of the fabric is about 30-35 cm. Then add the hardener to the glue base in the proportion indicated in the instructions. It is possible to add more hardener to increase the curing speed. The main thing is not to overdo it, or even before you have time to finish, the glue will harden. Saturate the fabric with glue and wrap the damaged area. After hardening, heating can be started. Wear rubber gloves. Likewise, you can eliminate leaks at the joints of polypropylene pipes.

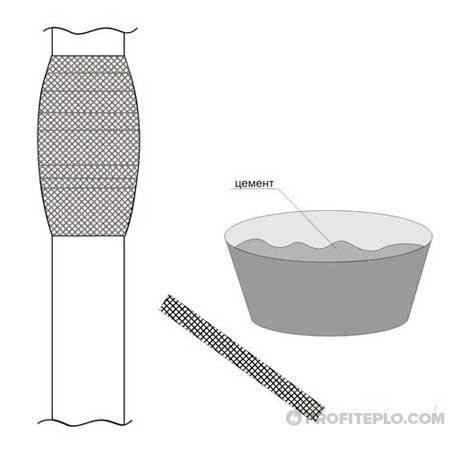

Most often, the threaded connections of the radiator and pipes leak. In these places and at the joints, in addition to epoxy glue, cold welding and cement-gypsum dressings can be used. The method is old, but quite workable. Ready-made dressings on sale are rare. Therefore, they are prepared independently. Cement is mixed with alabaster (plaster of paris) in a ratio of 1 to 0.5, diluted with water to a state of thick rustic sour cream, the bandage is cut into strips of 30-35 cm, and lays down in a bowl with cement-gypsum mortar, then impregnated, applied in layers over the threaded connections, smeared on top with the remaining solution. Sometimes salt is added to the composition.

In the radiator and in the pipes

There are damages in the radiator sections. It is often not possible to close the hole in the radiator without dismantling it. It can only be repaired where there is access. If you are "lucky" and the hole is available, you can repair it with a roofing screw, bolt or chopik. Well, everything is clear with the chopik, sharpen and hammer into the hole, carefully cut off the excess.

If the battery has a large hole, you can put the bolt in. To do this, you need to drill a hole and cut a thread with a tap and, dipping the bolt body into the paint, screw it into place. This is easy to do only on paper; in reality, everything is much more complicated. The same techniques can be applied to pipe repairs. If, the pipe is thick-walled (3 mm or more.)

Between battery sections

The leakage between the sections of the battery can be eliminated if it is cast iron. For aluminum and bimetallic, the sections are very close and you cannot get there.

Repair using cold welding or epoxy glue, in addition, a narrow clamp can be installed over the glue band or cold welding. He will press everything under him to the body of the battery. A heat-resistant sealant can also be used in combination with the clamp.

Hidden wiring

Hidden, this is a part of the heating system, which is covered with a concrete floor screed, insulation or decorative boxes. In all these cases, the most difficult thing is to find and get to the place of damage. And after that, evaluate which repair method to choose. There is no way without professionals.

On a straight section

On straight and accessible sections, you can use any method that you like and work best for. But the most reliable will be the mechanical method using clamps or bandages.

Eliminate a leak in a heating pipe without draining water

How to proceed in this case if it is necessary to eliminate the leak? After all, in this case, cold welding will not help. There is a way out - this is the same "plug" that was discussed above. The material impregnated in the composition of the sealant is able to adhere even to a damp surface.

The mixture can be purchased at a hardware store. Wipe the pipe surface dry and then wrap the cloth with sealant. This method of repair helps with not strong digging.

If the leak in the pipe increases, then a piece of rubber is used as a temporary sealant. For example, cut to the required size from a bicycle or car camera. The piece should be with a margin.

Wrap the prepared rubber tightly around the crack. For fixing, it is advisable to use one worm clamp or several pieces. You can use car clamps, which are designed to connect the pipes. Press down with a clamp and screw on the rubber gasket with a screwdriver. Such a simple method will help eliminate the leak or slightly reduce it.

You can buy ready-made pipe repair kits from the hardware store in the event of a leak. It includes a prepared clamp with a rubber gasket and a small valve. Thanks to him, it is possible to drain the accumulated water from under the clamp while the installation is taking place.

After the clamp is securely fixed, the valve closes tightly and the flow stops. Such kits for the repair of heating and other types of pipes help prevent an undesirable situation with a strong leak. Other means are unlikely to save.

In addition, if it is not possible to drain the water from the heating system, you can use another simple method. Using a special tool, dry and freeze the crack section of the pipe, and then glue it with glue or sealant.

The most relevant funds are "Apparatus Frost", "FRIZ PACK" and others. Such treatments contribute to the freezing of water in a damaged heating pipe. At this moment, in the damaged area, the water pressure decreases, which makes it possible to cut a piece of pipe and weld a new one. You can also put a "plug" on this area.

It should be understood that the methods given in our material to eliminate leaks in pipes using cold welding, sealant, adhesive, ready-made repair kits are just a temporary measure. Over time, the crack will begin to widen, rust can show itself again and the flow will resume.

It is advisable to do a thorough repair of pipes in the summer, namely, drain the water and completely replace the area with a crack or rust. If this is not done, then unpleasant surprises can again be expected in winter. It is best to invite specialists for repair work.

What to do if there is a leak in an apartment or a private house?

This manual is suitable for use as a guide for both private homeowners and apartment owners in multi-storey buildings.

The difference can only be at the preparatory stage - private houses are equipped with more complex internal networks, and therefore, in order not to drain all the water from the system, the regulator must be cut off with shut-off valves on both sides when dismantling it.

For work you will need (depending on the type of regulator):

- adjustable wrenches;

- socket wrench;

- hexagon;

- slotted screwdrivers: wide and narrow;

- repair kit for o-rings;

- fumlenta or sanitary flax with sealant;

- rust converter or equivalent.

After the water is shut off, the pressure regulator is removed from the pipeline and disassembled. Although repairs are allowed without removing the device from the pipe.

Disassembly of the diaphragm if dripping from the adjusting hole

Step-by-step instruction:

- It is necessary to loosen the fixing nut and loosen the pressure spring.Depending on the design, use a wide slotted screwdriver or hexagon. In this case, the spring is loosened with an adjustable wrench - turned counterclockwise.

- Unscrew 4 bolts and detach the housing cover. Below it is a pressure spring and a diaphragm. The beginning of spring corrosion is observed in the device - the membrane allows water to pass through. Possibly depressurization is caused by the ingress of dirt between the diaphragm and the working compartment.

- Unscrew the lower nut of the gearbox in order to get to the spool and remove the working mechanism, use an adjustable wrench.

- Now the spool is unscrewed - for this, holding the nut in the body from below (it is more convenient to hold it with a spanner wrench), unscrew the nut from above, the one that is under the pressure spring. You can unscrew it and vice versa - as it is more convenient. After that, the spool and diaphragm are removed from the body.

- The elements of the pressure mechanism are cleaned of dirt - a soapy water solution can be used for this purpose. It is strictly forbidden to clean with abrasives - you can violate the integrity of the diaphragm. The housing must be rinsed - a rust converter is used for cleaning. It is recommended to polish the body grooves (where the diaphragm is pressed).

- If the elements are not deformed, there are no cracks or other defects, then they are installed in the case in the reverse order.

In this case, the leakage through the control hole was caused by the loose contact of the gearbox membrane with the grooves of the working chamber. Removing the dirt completely eliminated the leak.

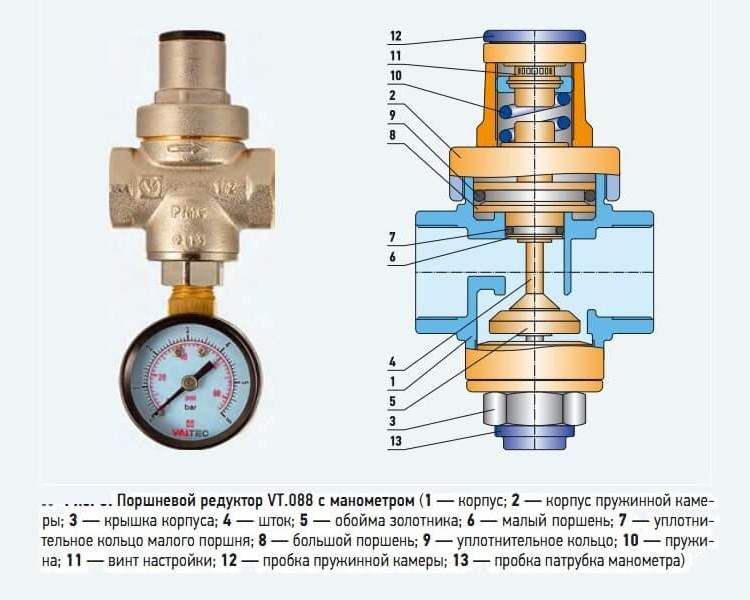

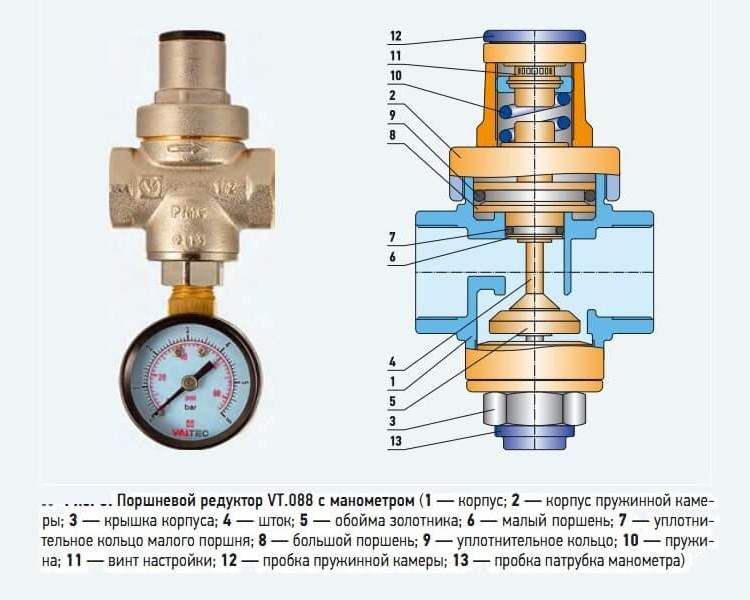

Elimination of leakage in the piston

A piston reducer is slightly different from a diaphragm one - instead of a diaphragm, it uses a piston with two platforms: small and large. The latter isolates the working chamber from the spring compartment.

If the sealing is broken, then water fills the spring compartment and flows out through the thread of the adjusting screw - this is how a leak occurs. To eliminate it, you need to disassemble the gearbox.

Disassembly is allowed without removing the regulator from the pipe:

- As with the diaphragm type, first loosen the hold-down spring - usually with a wide slotted screwdriver, turning counterclockwise.

- Unscrew the top cover of the adjustment compartment from the body - use an adjustable wrench.

- Unscrew the bottom plug or pressure gauge, if provided.

- Take out the piston mechanism - for this, hold the spool nut (with a socket wrench), and unscrew the nut from above.

- The piston mechanism is washed, using a soft brush. Clean the spring with a rust converter.

- The pressure rings are replaced with new ones, and the pressure regulator is assembled in the reverse order.

These measures should completely eliminate leakage through the adjusting screw.

To improve the sealing of the working chamber, it is recommended to polish the inner cylindrical surface of the regulator with a soft nozzle using a drill, and rubber seals should be treated with graphite grease.

These measures will help to reduce the friction of the piston in the device body, which will significantly increase the service life of the seals.

In the event of a leak through a plug in the hole or a pressure gauge, the connection is sealed again, - the rubber seal is changed, or simply the plug is insulated with fumlent or sanitary flax with sealant.

If the plug in the hole is defective, then it must be replaced., - as a replacement, use brass, suitable in size.

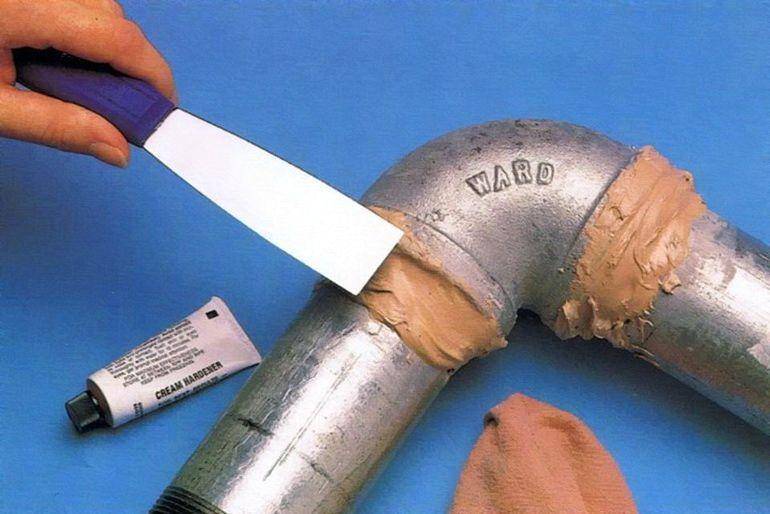

The essence of the cold welding method

The idea proposed by the inventors of this method of joining parts is quite simple. The composite material is thoroughly mixed, after which complex chemical reactions are triggered, imparting new properties to the mixture.Over time, the soft composition hardens, penetrates into the structure of the materials to be bonded and becomes comparable in strength to metal surfaces.

Excellent performance makes it possible to use cold welding to solve a wide range of household tasks:

- Elimination of leaks in metal and polymer water-pressure structures.

- Sealing cracks in heating radiators.

- Sealing places of damage to metal elements of the car body.

- Strengthening problem areas of pipeline networks.

The material can become indispensable in those situations when the problematic section of the pipeline is in a hard-to-reach place, where, with all the desire, it will not be possible to use a welding machine or other bulky device.

Water supply pressure standards

Official documents SNiP 2.04.01-85 and SNiP 2.04.02-84 determine the optimal indicators of water pressure in the pipeline. In houses with a height of less than 10 meters, 1 atmosphere is considered an acceptable value. If the structure exceeds 10 meters, the permissible pressure will be considered to be 2 atmospheres or more.

Pressure standards:

- cold water - 0.3–6.5 atmospheres;

- hot water - 0.3–4.5 atmospheres.

Measurements are carried out at the point of draw-off during the morning hours (from 7.00 to 9.00) or evening maximum (from 19.00 to 22.00).

If the indicators in the dwelling do not meet the requirements of the documents, it is necessary to find out the reason and, if necessary, contact the responsible authorities.

Heating radiator leak

If a leak is found in the heating battery itself, you can plug the hole with a simple self-tapping screw. This is done to reduce the flow of water, which will make it easier to carry out subsequent repairs, even if the taps are not turned off.

If a hole forms in the joint of the heating radiator, the problem is eliminated with a piece of cloth glued with epoxy. It wraps around the damaged area. The leak has been repaired, and you can calm down until the end of the season.

When using a dense piece of cloth, electrical tape, scotch tape and salt, you can also eliminate the leak in the heating battery:

- pour salt on the fabric and wrap the damaged area;

- we fix everything with tape.

If a leak is not found, it is worth temporarily shutting off the taps of the heating system, removing the battery, and lowering it into a container of water. Then we determine the damaged area at the place of air passage. A sealant is used for repairs. After filling the damaged area, we additionally apply a fabric winding and attach the heating batteries back.

There are usually air outlet valves at the top of the heating radiator, which can be used during its operation. After the end of the operating season, the heating radiator or its damaged sections are replaced with new ones.

If a radiator section is leaking, the procedure is the same as for a radiator leak.

Batteries and heating pipes can be both plastic and aluminum, it is a little more difficult to repair them, and special skills are needed to eliminate leaks in them. If a cast-iron battery has flowed, then cold welding will be required to repair it.

It is necessary to worry in advance about the availability of the necessary materials for the repair of the heating system, and to repair everything more thoroughly after the end of the heating season.

How to solve the problem yourself?

There are several ways to independently adjust the water pressure in the tap:

- Cleaning pipes and mixers or replacing them.

- Installation of a special electric pump. The equipment must be turned off after closing the water supply valve.

- The use of pipes with a large diameter, so that there is a decrease in resistance to flow.

If neighbors in a house or plot have the same problems with low water pressure, the issue cannot be resolved privately. Please contact your service provider.

Leak prevention

In order to prevent the formation of leaks on the sewer, water supply and heating systems, you should follow the simple recommendations of specialists:

- do not block the drain pipe;

- make sure that condensation does not form on the cold riser;

- for an external pipeline, its freezing is unacceptable;

Each of the proposed solutions to the problem does not cause technical difficulties. The only exception can be considered a malfunction of the metal or plastic system on the drains. In this case, it will not be possible to simply cover up the damaged area; this will require the help of specialists and the use of technology.

Pipe connection leaking

It is possible to eliminate the leak at the joints of the pipes with the same home-made or factory clamps. If there is a difference in diameter, you can first wind up the rubber band and then make or put on a clamp.

If the connection is threaded and drips from under the winding, you can pour alcohol on the tow, and then spread it with BF glue. It is alcohol-soluble. Once on the alcoholized tow, it liquefies and can leak into the compound. Then, when the alcohol evaporates, the glue dries up, the "drops" stop. But this method works only if you have exactly "drops", and not a "fountain". And one more thing: such a processed connection is very difficult to disassemble later.

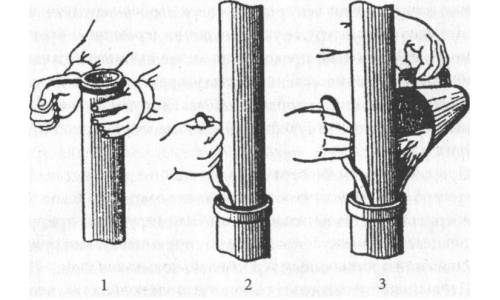

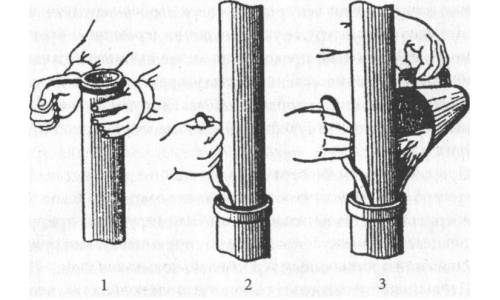

If it is possible to stop the system or turn off the radiator (if it leaks at the point of connection with it), it is better to repack the threaded connection. To do this, carefully and slowly unscrew the nut (locknut). It needs to be turned away and then wrapped. Do not make significant efforts - there is a great chance to break, and then you will definitely have to stop the system and redo everything. Having tightened the nut, remove all tow or fum tape, remove the remnants of the sealant, in general, thoroughly clean the thread. Wipe it to a clean state, you can treat it with a degreaser (acetone or pure gasoline).

If it leaks under the locknut, it can be repacked

Please note that there is no excess tow - just a little, and on top there is a paste. Take a roll and paste (sealant), wind up flax and grease everything with paste

Now you can spin. First with the hand, then with the key. But here, too, you need to work carefully: it is very easy to break the thread. Therefore, do not hold the key by the edge, but in the middle - this makes it easier to calculate the efforts. Do not overdo it with the amount of tow. If cast iron, in principle, no matter how much winding you wind, then aluminum and bimetallic, as well as steel from a large amount can crack. A microcrack first appears in the collector, into which water seeps. Metal corrodes, paint swells, a section (or the entire radiator) is damaged

Take a roll and paste (sealant), wind up flax and grease everything with paste. Now you can spin. First with the hand, then with the key. But here, too, you need to work carefully: it is very easy to break the thread. Therefore, do not hold the key by the edge, but in the middle - this makes it easier to calculate the efforts. Do not overdo it with the amount of tow. If cast iron, in principle, no matter how much winding you wind, then aluminum and bimetallic, as well as steel from a large amount can crack. A microcrack first appears in the collector, into which water seeps. Metal corrodes, paint swells, a section (or the entire radiator) is damaged.

But this is all in those cases when the threaded connection is flowing. If the fitting has leaked under the press (metal-plastic pipes), you can try to simply tighten it. In the case of copper pipes, only the option with soldering will work. If there is a leak at the junction of polypropylene pipes, there is also only one option - cut out the damaged piece and weld a new one.

It doesn't matter what you use. The result is important

How to protect threaded connections from leaks?

The best way to avoid leakage is to make the threaded connection correctly initially.

Choice of compaction roll

- A versatile material used as a seal is tow (linen fiber). It is able to withstand high temperatures and pressures. However, since flax is a natural material, it is susceptible to rotting. To prevent this process, in combination with linen winding, accompanying materials are used: oil paint, Unipack ointment, some use lithol or solid oil. Companion formulations can become a serious obstacle when dismantling the connection. In brass and bronze joints, flax fiber must be used with caution, as a thick layer can cause cracks in the threads.

- FUM-tape and thread are made of synthetic materials, therefore they do not need protection from decay. They are cleaner to work with, but cannot be used for foot nuts and locknuts.

When using steel pipes, these types of windings have no distinctive advantages from each other. The main thing is the correct winding. For plastic and metal-plastic pipes, synthetic sealing materials are usually used. However, when laying such a pipeline with a diameter of more than 20 mm, FUM tape is less effective than flax fiber.

Stages of manufacturing a threaded connection

- The winding is applied against the direction of the thread. It should lie between the turns, be tight, so that the material does not scroll and does not move outside the thread.

- If the threads have sharp edges that can cut through the winding, then the occurrence of a leak in the thread is a very likely option. To solve this problem, sharp places are filed with a file. Modern fittings are often made with this in mind.

If the threaded connection flows strongly and it is impossible to do without professional intervention, it is necessary to put a piece of raw rubber in the place of the defect and wind it tightly.

How to fix a pipe body leak

How to repair a leak in a pipe if there is a crack in the body? To eliminate the malfunction, you can use one of the following methods:

- install a clamp;

- apply a bandage;

- apply cold welding.

Clamp installation

The easiest way to fix a leak on a pipe body is to install a repair clamp. The special device consists of:

- metal case;

- a rubber seal located inside the body;

- fixing bolts.

Special device for eliminating pipe leaks

You can install the clamp with your own hands in the following way:

- the place of the leak is cleaned of dust and rust;

- the pipe is wrapped with a clamp;

- the device is fixed.

Elimination of leaks with a clamp

Applying a bandage

How to seal a leaking pipe if there is no clamp? To eliminate the leak, you can use a rubber, adhesive or cement bandage.

The rubber band is:

- a piece of rubber. A cut from a bicycle tube or medical tourniquet used to stop bleeding works best. It is necessary to wrap the cracked section of the pipe with a rubber cut;

- small straps, wire or other fixing straps to secure the rubber to the pipe.

Bandage for pipes made of scrap materials

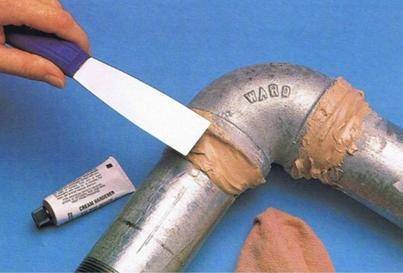

The adhesive bandage is installed according to the following scheme:

- the section of the pipe on which a leak has formed is cleaned of dirt with a solvent;

- fiberglass or medical bandage are impregnated with special glue;

Special formulation to eliminate leaks

- the pipe is wrapped with prepared material in several layers;

Installing an adhesive bandage in place of a leak

How to cover a current pipe with epoxy, see the video.

Cement bandage is analogous to adhesive bandage. A bandage or fiberglass is impregnated with a cement mortar prepared in a ratio of 1:10.

Cold welding of pipes

A relatively new way to eliminate leaks is the use of a composition of the so-called cold welding. How to cover the pipe so that it does not flow? For different types of pipes (metal, plastic, metal-plastic, etc.), different cold welding compositions are used.

Composition for plastic pipes of various types

Detailed instructions for using the mixture are given on the bottle with the active substance. Here is a general algorithm:

- before applying the mixture, the damaged section of the pipeline is cleaned of dirt. If the composition must be applied to a metal pipe, then the crack is additionally cleaned of paint and rust;

Stripping the pipe before cold welding

- a special composition is applied to the damaged area. If liquid cold welding is used in the form of glue, then it is advisable to apply it with a brush. If a plasticine-like composition is used, then before application it is necessary to knead it thoroughly until a homogeneous mixture is obtained;

- the substance for cold welding is evenly distributed over the entire section of the cracked pipeline, capturing 3-4 cm more than the crack itself;

Coating the damaged area with a cold welding agent

- the composition is left to dry completely, which takes an average of 2.5 - 3 hours.

All the methods given in the article to eliminate leaks on the pipe body, except for the use of cold welding, are only a temporary measure. To completely get rid of the problem that has arisen, it is necessary to completely replace the damaged section of the pipeline. To carry out this operation, it is advisable to involve qualified specialists.

general information

Before disassembling the causes and remedies, you need to consider in detail the nature of the problem itself - why hot water flows from a cold tap.

There are two main types of mixers in use today:

- Hot and cold water is regulated by rotating two valves.

- Water regulation is carried out with one lever, the movement of which in one direction increases the supply of cold water and decreases - hot, when moving to the other side, the opposite process occurs. The opening of the water is carried out by lifting the lever up.

Modern mixers are equipped with cartridges. These devices provide water supply and control the degree of pressure and mixing.

The cartridge consists of the following parts:

- Housing.

- Sleeve.

- Ceramic top disc.

- Ceramic bottom disc.

- Washer for the upper disc.

- Rubber compressor.

How the cartridge works:

- The cartridge has three holes on the lower disc: two for piping supplying hot and cold water. A third hole with a larger diameter is connected to a faucet, from which liquid flows into the sink.

- The upper disc has one hole and is designed in such a way that when tightly coupled with the lower disc and various changes in position during rotation, the diameter of the inlet holes changes in one direction or another. So, with a smooth turn towards the cold water hole, the hot liquid hole is gradually closed, until it is completely closed. In the opposite direction, the principle is similar.

- The upper disc, due to the bushing, which is connected to the lever, moves when turning. Thus, the supply, mixing and regulation of the liquid flowing from the tap takes place.

How to fix a leak in a heating pipe

Ways to eliminate leaks in heating pipes depend on a number of factors:

- the material from which the pipe is made;

- the place where the leak is formed (flat area or junction).

The best way to fix a leak is to call a technician who can fix all the problems. If this cannot be done for some reason, then there are other methods that you can use to repair the pipe yourself.

Many have already figured out the question of why a leak in the heating pipe can form. There are several ways to fix this common defect.

If a leak occurs on a flat section of the pipe, then you need to determine the location of the damage. Then put on this place a piece of rubber, larger than the hole, and tighten the entire structure with soft wire. There are ready-made materials for this procedure on sale.

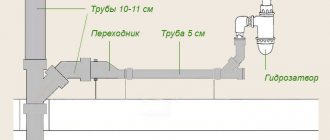

If a leak appears at the junction of the heating pipe with a radiator or tap at the threaded joints, then in this case the task becomes somewhat more complicated. At the joints, pipes of different diameters can be located.

You can also wind a long piece of soft rubber around the leak and use a clamp to squeeze the damaged section of the pipe. This option is not the final way to eliminate the breakdown, since the connection point must be disassembled, if necessary, redo everything. And this can only be done with the heating system turned off.

In a city apartment, you still need to call a specialist for this, but in a private house with an autonomous system, you can do it yourself. Therefore, before the heating season, just in case, it is necessary to have spare parts or new couplings for connecting pipes.

If the cause of the leak in the heating pipe is the pressure drop of the coolant, then this problem must be eliminated.

Due to the fact that pipes of different diameters are used in the heating system, hydraulic shocks can occur, especially at a time when the owner of an apartment or house is trying to bleed air from the system. To eliminate this problem, it is necessary to create special expansion devices or compensation loops.

If a leak occurs between the sections of the heating radiator, you can temporarily wrap this area with a dense cloth, which is impregnated with a sealant or moisture-resistant glue. When the glue is dry, you can turn on the radiator. Then you should definitely invite a specialist for the final elimination of the leak.

A special cold weld heating pipe sealant can be used. From the name it is clear that this material has high drying strength. Therefore, this sealant is often used for repairs in heating systems and even in the repair of car radiators.

Sealant Cold Welding

All methods of eliminating leaks in heating pipes are good. However, they are temporary. Only a specialist can completely eliminate all the reasons.

When is it necessary to repair the heating system?

Naturally, overhaul of the entire heating system must be carried out in a timely manner before the onset of the cold season. If it drips from the heating pipe in winter, this means that the appropriate measures were not taken in summer.

If the heating system has been installed for a long time and with the help of steel pipes, then it is time to think about replacing the metal elements of the system with reinforced polypropylene pipes. Recently, German REHAU plastic pipes have been popular, which are the leader in reliability and strength. They are adapted to heating systems in our country and, if installed correctly, the heating pipes will not leak.

All plastic products are non-corrosive and have a high degree of strength. Therefore, the replacement of old worn out metal pipes is a necessity. Patching holes will not lead to a sufficient level of comfort, because more and more damage will occur every year.

It is much easier and cheaper to repair and replace heating systems and communications in the summer when the heating system is off. All work must be carried out in a timely manner, otherwise in winter, during severe frosts, you will have to turn off the heating in the house.

Why does it flow badly from the tap in the apartment: reasons

A decrease in water pressure can occur due to various circumstances.Studies should be carried out separately for hot and cold water supply, since the factors that caused the pressure drop in the pipes may differ.

Cold

Reasons why cold water flows poorly:

- Improperly designed plumbing. When developing a scheme for laying pipes in a private or apartment building, mistakes were made and water does not flow in full to the consumer.

- Reducing pressure in the main pipeline. Sometimes industrial organizations relieve pressure due to poor state of communications in order to avoid disruption.

- Repair of main pipes.

- Excessive development of the residential sector. New multi-storey buildings are being erected and connected to old utilities, which are not designed for a large volume of users.

- Defective or low-power pumping station in homes.

- Clogging of the water supply system with various deposits and debris, which complicates the passage of the resource into the apartments of the residents.

- Poor condition of the pipes in the house.

- Dirty, oxidized valve-box, clogged aerator (mesh in the mixer, which retains small particles).

- Clogged fine filter. The structure is installed in front of the water consumption meter. Another name is an oblique filter or sump. Before entering the apartment, the water is purified so that rust, sand and other impurities do not reach the consumer.

Hot

Hot water enters through the main water supply system, heats up and goes the same way as cold water. Therefore, the reasons why the pressure in the hot pipeline has become weaker may be the same as described above.

Additionally, a decrease in pressure can cause:

- Malfunction of water heating equipment in an apartment building.

- Breakdown of a column, a boiler for obtaining hot water in an apartment or a private house.

- After the planned summer prevention of pipes and the shutdown of hot water supply, utilities resume the supply of the resource to the house with reduced pressure, and therefore there may be a poor pressure in the tap for several days.

Read more about the pressure standards for cold and hot water, as well as measuring the pressure in pipes here, and the reasons for turning off the water can be found in this article.

We solve legal problems of any complexity. # Be at home and leave your question to our lawyer in the chat. It's safer this way.

Ask a Question

Leaking joints

If the heating battery is leaking, what to do and how to fix this problem?

First you need to decide on the reason, find out why the pipes are leaking.

Joint leakage can occur for 2 reasons:

- loose connection of threaded connections;

- cracked pipe body.

Consider what to do in such a situation and how to seal the leak at the joints. This will require the following materials:

- rubber chambers;

- wire;

- materials for similar welding - sealants;

- several fasteners, clamps;

- rubber bandage.

First, using a rubber chamber, block the leak, fix it using 3 clamps or iron wire. We close the leak with one clamp, place the other 2 along the edges of the chamber or use a plumbing bandage, which is also a thick piece of rubber attached to the pipe with a clamp. It is bolted together to provide a seal.

If a leak occurs at the junction of the pipe with the battery, we tie a piece of rubber to the detected leak. We fix it with clamps directly at the place of the leak and on the pipe itself. Factory band or tube rubber can also be used here.

In such cases, cold welding can be used. It is performed using a sealant, which, after kneading, is applied to the damaged area, pressed firmly and smoothed. Hardening occurs within 3 hours.

Regularly, at least once a year, in the summer, it is worth calling a specialist for a thorough inspection of the entire system and replacement of parts in places of possible leakage.

Finding the cause of the malfunction

Before making any decision, it is worthwhile to determine the source of the problem. First you need to understand whether the cause of the malfunction is in your own apartment or it is outside of it. It is not difficult, you just need to touch the pipe supplying cold water to the apartment, if it is also hot, then the neighbors are most likely to blame.

If cold water flows from a hot tap, the first thing to do is to understand the causes of what is happening and eliminate them without waiting for the consequences. Boiling water in a cold line is not only discomfort, it can lead to a number of problems:

- failure of the cold water meter;

- damage to plastic pipelines;

- violation of the drain tank mechanism;

- failure of household appliances designed to supply cold water.

There are often situations in which water heating occurs spontaneously, for no apparent reason, then, in addition to checking your system, you should talk to your neighbors, find out if they have a similar phenomenon. If the same situation is observed in all apartments of the entrance, but no one can name the reason, you cannot do without a master.

When everything is fine with neighbors, and a sudden heating of cold water occurs only in one apartment, you need to start by checking the mixer, you should also make sure that the shut-off valves at the inlet are working, and test the operation of the check valves.

Options for repairing holes in a plastic pipeline

When carrying out repairs, it is not always possible to use the technology of high-temperature connections and therefore you have to use other methods:

- Clamp application. A temporary measure that solves the problem of how to eliminate a leak in a polypropylene pipe is the use of clamps (for more details: "Types of repair clamps for pipes and the rules for their use"). The screw-clamped part is supplemented with a layer of plastic, waterproof material, due to which it is possible to almost completely eliminate the leak. This method does not interfere with the fluid movement through the system, so there is no need to turn off the water supply. But it also has a drawback - after a while the clamp attachment points weaken and the connection loses its tightness.

- Cold welding technology. Before sealing a leak in a plastic pipe, you should prepare the required amount of a component for work: knead it in your hands or mix it in a certain proportion. Then the composition is applied to the damaged area, the crack in the pipeline is closed up and the required time is waited until the mixture completely solidifies.

- Application of an adhesive bandage. Using a pair of clamping clamps along with a material that is impregnated with glue will help to quickly cope with a leak with your own hands. It can be a two-component compound plus rubber for polypropylene pipe products or bandage plus cement for sewer pipes. The advantage of this method is that there is no need to shut off the water flow. But for systems operating under high pressure, the use of such a bandage is not allowed.

- Covering the sealing tape. The method allows for quick repairs if there is no possibility to cover a small leak with a sealant. Adhesive tape is wound in several layers over the damaged area.

- Using a special sealant. It will be possible to eliminate the leak if the plastic pipe bursts quickly. But this solution is temporary.

There are three types of sealant commercially available:

In cases where the water supply or heat supply system is partially laid by a concealed installation method, before proceeding with the repair of the plastic pipeline, it is necessary to find out exactly where the damage to the pipeline occurred. To do this, unfortunately, you will have to either dismantle the decorative trim, or open the wall covering.

Repair and maintenance of mixers

For faucets, regardless of whether they are wall-mounted or mortise, for a bathroom or for a kitchen valve or cartridge, water often flows at the junction of the swivel spout (spout) and the mixer body when water is opened. The main reasons are the wear of the gaskets during operation or the unwinding of the sleeve or sleeve.

1. To accurately determine the cause, you will have to unscrew the spout (spout) and check the condition of the gaskets and nuts. To do this, you will need a wrench and a rag if you do not want to scratch the chrome or nickel-plated surface of the nut. Although it is best to first try unscrewing the nut by hand. As a rule, it is not very tight. An adjustable wrench or a gas wrench will not work here, usually the nut that secures the spout to the body is not very wide (indicated by a red arrow in the photo):

When unscrewing with one hand, you need to hold the key, and the second body of the mixer, so that the mixer does not rotate. The most difficult thing to unscrew the nut on the in-line valve mixers, as this is often interfered with by the valve handles.

1a. Remove the handles.

2. Remove the spout by pulling it straight up or down if it is a wall-mounted mixer.

3. After removing the spout, you will see 2 rubber gaskets (marked in the photo with blue arrows), ensuring the tightness of the joint and 1 plastic (shown in the photo with a yellow arrow). With a large number of turns of the spout, the rubber gaskets are erased. This happens especially quickly if the gaskets were not lubricated when installing the mixer.

4a. It is easy to change the gasket; it is enough to buy an analogue at the nearest hardware store or on the construction market. In order not to delve into the geometric subtleties necessary to describe the gasket, just put it in a matchbox or somewhere else and take it with you.

When installing a new gasket, be sure to lubricate it with a good lubricant. This will extend the life of the gasket several times.

4b. There are times when it is not possible to find a gasket of the required diameter. In this case, 2 options are possible:

- If the gaskets are not very worn out, then you need to remove them and reel in 2-5 layers of plumbing synthetic winding, then put the gaskets in place, lubricate and put the spout in place.

- If the gaskets are completely out of order, then in order not to completely change the mixer, you will have to abandon such a function as turning the spout. Wrap 15-20 layers of plumbing synthetic tape around the bottom of the spout. Insert the spout and tighten the nut. If the water still leaks, then you need to add several layers of winding.

4c. If the rubber gaskets are normal, then most likely the sleeve on which the rubber gaskets are put on has spun:

You can tighten the sleeve with a hexagon; as a rule, there is always the right one in the set of hex keys.

In some models of mixers, the foot can be unscrewed, to which the spout nut is screwed:

You can tighten the footwear with any key.

If the matter was not in the gaskets and not in the bushing or case, for example, in the mixer body or in the lower part of the spout tube there are cracks or cavities causing leaks, then only change the mixer.

How to fix the leak and how to fix it

How to repair a leak in a heating pipe depends on where it was formed: at the junction of the sections, at the connection of the radiator with the pipe, on the pipe itself. Repairs are made in different ways, consider the main methods.

The heating pipe flows at the junction

Cold welding

As a rule, it is applied at the junction of two sections of the battery, it helps to temporarily close the damaged area. It is made using a sealant adhesive that can be purchased at a hardware store. It has a special composition that crystallizes upon drying and fills the hole.

Application of "cold welding" to a metal pipe

Procedure

:

- thoroughly clean the damaged area of paint and rust using a brush with metal bristles or sandpaper;

- degrease, alcohol, solvent, acetone are suitable for this;

- cut off a piece of sealant, knead with wet hands until smooth;

- press well into the damaged area on the heating battery and smooth it;

- until the composition hardens completely, it must be pressed tightly to the surface;

- curing time approx. 20-25 minutes, complete polymerization after 3 hours.

Cement-plaster cast

If a hole is found on the heating pipe or the junction of the battery sections, you can make a cement-plaster bandage, for this, prepare the following consumables:

- medical bandage, piece of gauze or thin cotton fabric;

- alabaster (gypsum);

- cement;

- a bucket or basin of water.

Elimination of leakage with a cement dressing

Procedure

:

- dissolve cement in water, mixing it with gypsum, the consistency should be like fat sour cream;

- take strips of fabric or bandage 25-30 cm long, soak with the resulting composition;

- wrap the damaged section of the pipe with a cloth;

- onlays are made until the bandage is strong and tight.

Clamp and rubber application

If you notice a leak in the heating pipes, you can apply a purchased or homemade clamp, as well as a rubber pad, as a temporary measure. If a factory-made clamp of a suitable diameter is available, it must be applied to the leak and secured tightly with a bolt. If there is none on the farm, you will have to make a rubber pad yourself.

Procedure

:

- cut a rectangle from a piece of rubber, which will be 2-3 centimeters wider than the hole, the length should be the same as the diameter of the pipe;

- Wrap the overlay tightly around the pipe, and fasten the edges with wire or metal clamps, you can make a wire winding along the entire length of the bandage.

Eliminating leaks with rubber and a clamp

Application of welding

If a heating battery is flowing in a house or apartment (not a metal-plastic one, but a cast-iron one), welding will help to eliminate the defect. It can be used anywhere on the radiator. Therefore, after you have made minor repairs yourself or cut off the water supply to the battery, call the emergency service or a private company that provides hot welding services.

Repair of a metal heating pipe by welding

What to do if cool water flows from a hot tap

What if instead of hot water comes cold? Where to go in this case?

First of all, we call the management company and invite its representatives in order to fix deviations from the norm. Remember, you can talk about recalculation only if there is an act in which this deviation is recorded.

In the event that specialists have recorded deviations from the norm, then, starting from the day of drawing up the act, the requirement of the law on a reduction in payment comes into force. This procedure for calculating hot water will continue until the commission draws up the next act, which clearly indicates that the supplied water meets the required parameters.

This procedure corresponds to the ideal state of affairs.... But what to do if the dispatcher in the management company does not want to respond to the request? Or is the act still drawn up, but it did not lead to a positive reaction?

In this case, there is only one answer - we go to the State Housing Inspectorate, the State Housing Inspectorate. The latter has its own levers of influence on a negligent communal organization - a decision on a fine, revocation of a license, a court case, etc.

You can, bypassing GZI, directly go to court on your own... In this case, the court will consider the statement of claim with the recovery of material damage in favor of the plaintiff. In this case, you can count on both material and moral damage.But get ready for the fact that there will not be a quick court decision, the case will be considered for more than one week. As a rule, the court considers such cases in favor of the plaintiffs.

Another option to record violations of the temperature regime of the supplied water is to install meters with temperature sensors. It is expensive and not always justified, but the temperature is recorded automatically around the clock. But keep in mind, these testimonies will not become evidence of violations, this is just a reason to contact the management company.

If you do not have a meter with a thermal sensor, you can take measurements in another, cheaper way.... Open the tap, drain the water for 3-5 minutes, fill the water in a small container and lower the thermometer into it, evaluate the result in a few minutes. If there are deviations from the norm, call the dispatcher. These measurements must be recorded. Please note that in accordance with Decree No. 354 of the Government of the Russian Federation, clause 108, measurements must be carried out no later than two hours after the application is received.

The commission's visit should result in several copies of the act. One of which remains in the hands of the resource consumer. The commission can come after a longer period of time, but with mutual consent.

In the event that specialists refuse to go to the address for taking measurements, the owner of the apartment can independently draw up an act, this document must be signed by at least three witnesses. This act has exactly the same force as drawn up by specialists and also serves as the basis for recalculation.

In this case, the period of the end of the violation also ends with the corresponding fixation... Self-compiled acts can be sent to the management company, to Rospotrebnadzor, the prosecutor's office, and the magistrate's court.

There is only one conclusion - if you are regularly supplied with a low-quality resource - do not leave this situation without due attention and solve the problem. In this case, the result will definitely be achieved.

How to fix a leak in a metal pipe

Below we will consider the simplest method for eliminating a crack formed in a metal pipeline. Plumbing services are not required for this.

Remember that the appearance of cracks can cause ordinary forgetfulness of a person. For example, in the summer cottage, the water was not drained from the system before winter. The water in the pipes will freeze, causing them to burst in some places.

Let's go directly to our actions, namely, sealing the crack. What do we need for work?

- Small size galvanized sheet metal.

- Cold welding such as epoxy glue.

- Metal plate - clamp.

- Metal scissors, screwdriver.

- A vessel in which you need to stir the composition.

Looking for a crack

Inspect the pipeline for cracks and make markings with a margin. If the pipe is full of water, drops or drips will be visible. If it is hollow, fill it with water for testing.

Dry the crack. Then remove rusty deposits and layers of old paint.

Preparing a patch - a clamp

Measure the length of the crack, add a few centimeters to it on both sides. Cut the patch to the desired length from sheet metal. The clamp must be bent in your hands so that it takes an arched shape. Try on so that it fits snugly on the pipeline.

Preparing the composition

We prepare cold welding for work - we dilute it in a separate container if it is watery. Or knead it with your hands if the composition is of a dense consistency. You shouldn't feel sorry for the glue mixture, but don't pour it too much.

Eliminating the crack

Protect hands with protective gloves. On the marked crack formed on the metal pipeline, we apply the composition of the prepared cold welding.

Cover the leak with a piece of sheet metal on top. Bend the clamp as much as possible, attach it to the pipe and fix it with any ties.Withstand a day so that the cold welding seizes firmly, then you can use the pipeline for its intended purpose.

On a note! After cold welding has solidified, it is advisable to process the area with fine sandpaper. The last stage is painting.

In the second option, you need to apply an arcuate piece of a metal plate, abundantly greased with glue, to the crack. Secure with ties. In appearance, such a fix may not look very aesthetically pleasing, but reliable.

What the legislation says

Before taking further steps, you should clearly understand what Russian legislation says about this in 2020. It clearly regulates the temperature of the water that must come from the hot water tap.

All requirements are indicated in two documents:

- "Rules for the provision of utilities to owners and users of premises in apartment buildings and residential buildings", approved by the Government of the Russian Federation of May 6, 2011 N 354. The necessary information on the parameters of water are spelled out in Appendix No. 1.

- Sanitary and Epidemiological Rules and Norms SanPiN 2.1.4.2496-09 "Hygienic Requirements for Ensuring the Safety of Hot Water Supply Systems". This information is prescribed by the decree of the Chief State Sanitary Doctor of the Russian Federation dated April 7, 2009 No. 20 "On the approval of SanPiN 2.1.4.2496-09".

If you do not go into details, then the essence of these two official papers boils down to the following parameters that hot water must meet:

- The temperature at the points of draw-off should not be lower than 60 ° C, but also not exceed 75 ° C. It does not matter what kind of water supply system is used in apartment buildings.

- Be prepared for the fact that before determining the temperature of the water flowing from the tap, it still has to be drained. According to the regulations, it is necessary to drain within three minutes.

There are small deviations that are permissible when supplying hot water:

- at night (from 0:00 to 5:00 hours) a slight deviation in temperature is permissible, but not more than 5 degrees;

- in the daytime (from 5:00 to 00:00) the deviation can be no more than 3 degrees.

The legislation prescribes not only the requirements for the quality of the water provided, but also the procedure for paying for water in the event that it does not meet the requirements.

For water that is supplied below the required temperature, the supplier is obliged to recalculate. But you need to take into account some of the nuances:

- provided that the water is below 40 degrees, payment for it is carried out at the rate of cold water. Please note that this payment will only be made for the hours when the water was actually supplied at a reduced temperature. The hours of low temperature water supply are summed up, this is in the event that the calculation is carried out according to the standard. If there are meters in the apartment, then the calculation is carried out by indicators.

- provided that the water temperature is below 60 ° C, but above 40 ° C - the calculation is carried out at a reduced rate.

The mechanism in this case is as follows, for every 3 degrees of deviation from the norm, there is a decrease in payment by 0.1% for every hour in which a decrease in water temperature was recorded.