When heating a private house, a rather important issue is the stabilization of the pressure in the boiler. If the pressure is low, the boiler will not be able to function. If the pressure is high, the heating equipment will wear out quickly. In order to stabilize the pressure, connect to the boiler expansion tank.

Expansion tank

The purpose of the expansion tank

An expansion tank is needed to compensate for the pressure of the coolant in the heating system. The pressure difference arises due to a change in its temperature during the heating process, since its volume changes depending on the temperature.

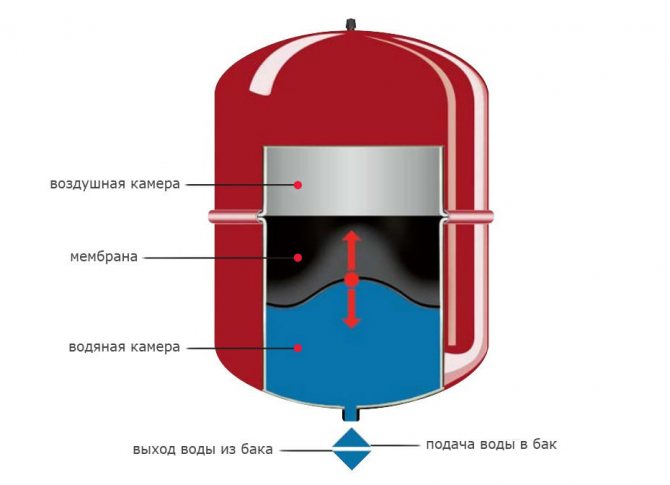

IN closed heating systems an expansion tank of a closed sealed design is used. Inside the tank there is elastic membranewhich divides it into two parts. One of the parts of the tank contains air under pressure, the second part is penetrated by the coolant.

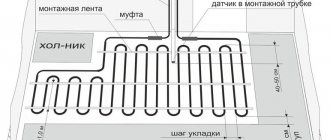

The circulation of the coolant in a closed heating system is provided by a circulation pump. IN open heating system the pump is not needed, and therefore any container can act as a tank, the coolant into which will be drained directly from the heating pipes.

Expansion vessel in a closed heating system

Expansion tank device

The work of the expansion tank is to compensate for the change in the volume of the coolant in the boiler and the circuit. When the boiler heats up, the liquid increases in volume, and part of the liquid goes into the expansion tank. Thus, the equipment is protected from a sharp increase in pressure and rupture.

See the same: calculation of the volume of the expansion tank.

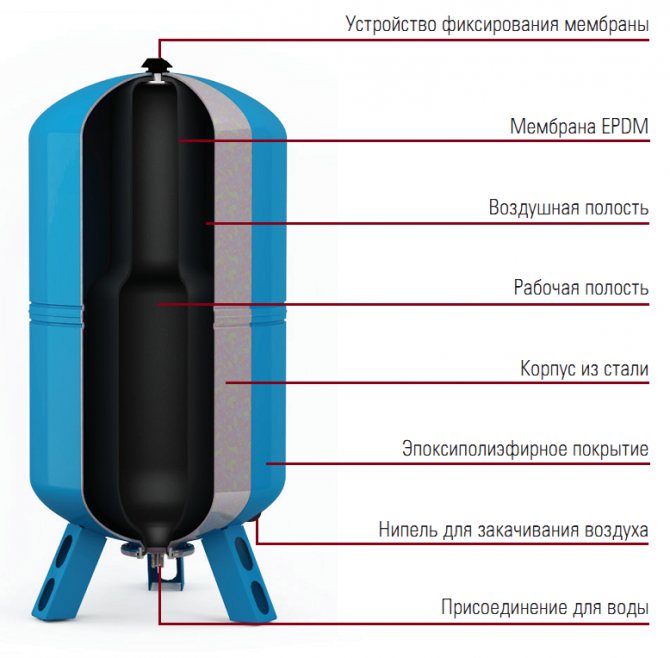

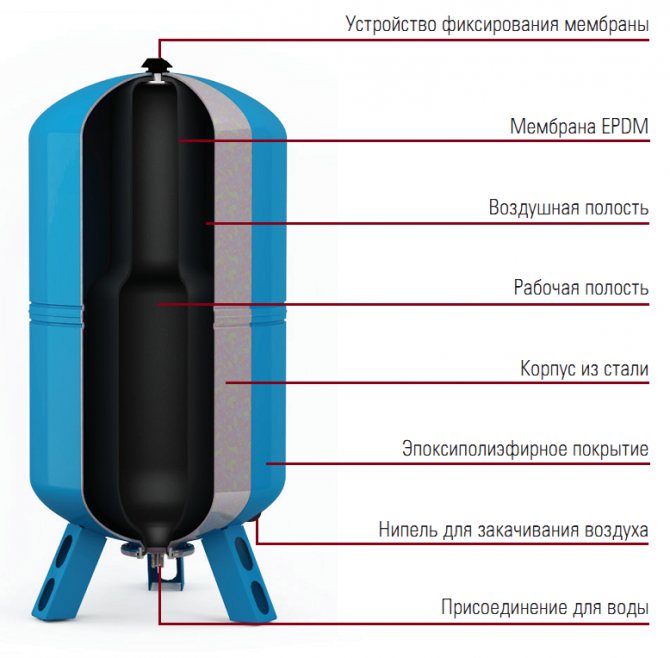

Structurally, the tank consists of a body, divided inside by a membrane into two chambers. The air chamber has a nipple for pumping or bleeding air. A pressure gauge is also connected here. This device allows you to monitor what pressure will be in the expansion tank of the heating system. The water chamber is connected with a pipe to the heating system. With thermal expansion, water enters the fluid chamber and compresses the membrane, increasing the pressure in the air chamber.

When the liquid cools down, the volume decreases, and the membrane squeezes it back into the system.

When choosing the size of the tank, it must be borne in mind that its volume must be at least 15% of the volume of all liquid circulating in the system. When using antifreeze, the volume of the tank must be at least 20% of the total liquid.

Advantages of a closed heating system

- The first plus of a closed heating system is that the tank can be installed where it is convenient for you, in an open one, only in the attic or at some other high point of the system. And due to the tightness, the coolant practically does not evaporate.

- The heating medium is always saturated with air in an open heating system, which leads to corrosion in heating pipes and radiators. In a closed one, as you know, this cannot happen.

- In a closed system, losses in the tank are less than in an open system, which heats up very quickly and has increased sensitivity. Plus, the difference in temperatures in a closed system is less, which allows longer use of equipment for heating.

- The closed system is suitable for a variety of radiators, convectors and air curtains, you can connect the “warm floor” system. Plus, an indirect heating boiler for DHW can be added to a closed system.

Calculation of the volume of the expansion membrane tank

In order to determine the volume of the expansion membrane tank, it is necessary to determine the total volume of the heating system, which consists of several volumes:

- pipeline;

- heating device;

- boiler.

The easiest way to determine the required volume of the tank is calculate 10% of the total volume of the heating system. If it is 500 liters, then you need a tank with a volume of 50 liters.

If the volume of the expansion membrane tank is less than necessary, this will lead to bad consequences. Cracks will begin to appear, hot water will leak through the threads, and the tank itself can deteriorate very quickly and it will have to be changed.

The membrane tank is selected individually for each heating system.

Advice... If safety valves are installed in a closed heating system, pressure build-up can be avoided and the entire system protected.

Expansion tank design

The tanks can be either with the possibility of replacing the membrane with a new one, or generally non-separable. To fix the tank on the wall, brackets and clamps can be supplied with it, for installing the tank on the floor - special legs. The tank membrane, in turn, can also be of different designs.

Non-disassembled models are equipped with a membrane in the form of a diaphragm, less commonly a membrane in the form of a balloon. It stretches under pressure, so it can be considered an independent water chamber. A special flange is used to replace this type of membrane.

Expansion tank design

Calculation of the volume of the tank

To determine volume of the tank you can follow the simplest path. That is, take 10% of the volume of the heat carrier used, which is calculated at the stage of the heating system design. Or you can drain the old coolant and fill in a new one by measuring the volume with a meter.

You can also find out the volume of radiators and pipes, so you get the volume of the heating system, from which you will need to take 10%.

There is also a way to calculate the tank using the formula:

V = (E * C * (Pmax + 1)) / (Pmax + Pmin), where

E is the coefficient of expansion of the coolant indicated on the package,

Pmax and Pmin are the maximum and minimum working pressures of the system, respectively.

It should be said that no calculations need to be made for an open heating system, but for a closed one it is still worth it. Moreover, if the boiler already has a built-in tank, in case of a shortage of its volume, a new one is installed.

In the event of a shortage of tank volume, the volume of the coolant decreases and the pressure in the heating system drops, since it begins to drain into the sewer. With a critical shortage of coolant, the operation of the boiler may simply stall.

If at this moment you are at home, it will be enough for you to simply add the coolant. If you are not at home, the heating system will begin to defrost. And there is nothing good in the operation of a boiler in a critical state either.

Therefore, it is better to always carry out such calculations and purchase a slightly larger tank than required.

Types - Open tanks

Open expansion tanks are characterized by the fact that they must be installed exclusively at the highest point of the heating system. Such a place could be, for example, an attic. But the obstacle to the expansion of the coolant is not the only function of this type of device, since they also prevent water from boiling in the pipes and replenish its reserves in cases where a leak has occurred for any reason.

The tank can be used with both natural and forced circulation.

- If the circulation is natural, then the tank must be connected to the main line, which is why it will also be an air collector "in combination".

- If the coolant moves through the system forcibly, then the tank is connected to the return pipe so that the water in the system does not boil.

In general, an open tank is a reservoir from which four tubes emerge:

- Expansion.

- Circulating.

- Overflow.

- Signal.

An expansion pipe leads to the heating system, which is located at the top of the tank. There is also an overflow tube, which is necessary in cases where the tank is overfilled and you need to drain the water into the sewer. At the bottom, respectively, there is a signal tube equipped with a lock, and the circulation tube is needed so that the coolant in the tank does not freeze, and the overall temperature is maintained permanently. If you wish, you can take one more additional measure that would “secure” the circulation pipe - insulate the tank with thermal insulating material.

Important! Today, such tanks are practically not used in heating systems due to the large number of disadvantages.

Among these shortcomings, I would like to highlight the following:

- Such systems are not designed for high pressures.

- Their design is very bulky and bulky.

- Due to the fact that the system is open, along with water, air also enters the pipeline, which has the most negative effect on the surface of the pipes - soon corrosion will form on them. The same applies to other metallic elements.

- Such tanks should be installed only at the highest point, and this, you see, is an additional cost.

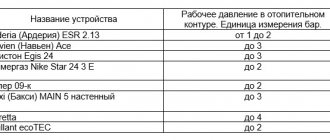

Expansion vessel pressure

Some boilers have the function of manually setting the pressure using an expander. Otherwise, it should be about 0.3 atmospheres lower than the operating pressure of the heating system in a country private house. And it is usually equal to from 1.5 to 1.8 atmospheres, we end up with about 1.6 atmospheres maximum or 1.2 minimum.

To measure the pressure in the tank, connect a pressure gauge to the nipple at the top of the tank, under the plastic cap. Under the cover there is a spool through which excess pressure can be relieved. You just need to bend the plate and release the air to the normal pressure.

To increase the pressure, the pump for the car together with the pressure gauge should be connected to the nipple, then pump to the required level. Do not forget that all these operations must be done when the tank is disconnected from the heating system! In this case, the coolant must be completely drained.

Installed expansion tank

Closed tank (membrane)

The membrane expansion tank for heating is devoid of all those disadvantages that the previous system literally boils over. However, it also has some requirements, without which the installation would not be possible. Firstly, he needs a pressure gauge, and secondly, he also needs a device in order to regulate the pressure manually, otherwise the pressure will exceed all permissible norms (which is about three to four bars, depending on the specific conditions and features of the model).

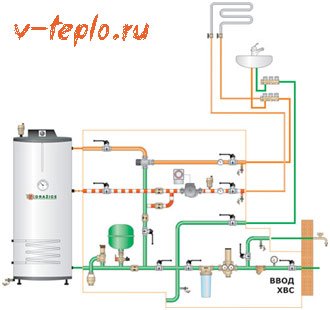

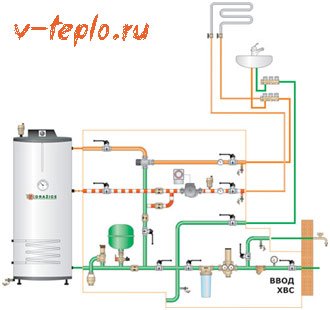

This kind of tank is installed in close proximity to the boiler and is fed to the return pipe. This is necessary so that the coolant does not boil. During installation, special attention must be paid to the reliability of the fasteners, since during operation the weight of the tank can significantly increase.

In fact, this expansion tank for heating is a metal container, which can be either flat or cylindrical in shape. The inner cavity of the tank is divided into several zones by means of a rubber membrane. In one of these zones there is compressed gas or air (the degree of its compression should be indicated in the data sheet). Consequently, in the inactive state, the entire volume of the reservoir is filled with gas. Before starting the system, the pressure in the tank is made the same as the pressure in the entire heating system.

Then, when the temperature rises, the water enters the specially designated area in the tank, and in the "gas" part, the pressure increases to the value of the heating system.If there is a sufficiently large amount of coolant in it, then the air pressure should be carefully controlled. For this, the systems are equipped with special compressors that maintain the preset value.

As you might guess from the name, the main part of such a tank is the membrane. She, by the way, can be of two types:

- The diaphragm membrane can often not be replaced in the event of a breakdown, but it is used mainly in tanks of small volume.

- In contrast, the bladder diaphragm can be easily changed in the event of failure. It also differs in that the coolant in it does not directly contact the surface of the tank, due to which the service life of the latter increases significantly.

The position of the expansion vessel in the heating system

In a closed heating system, the tank should be installed after the boiler, but in front of the pump, in order to create a flow in the opposite direction. To connect the pump, a tee must be installed in the pipe, the tank is screwed onto the perpendicular outlet, which must have a vertical upward direction.

We recommend that you install the next tee after the tank, so that a shut-off valve was installed on it. Thus, you can check the tank without draining the coolant. Turn off the tank and check the pressure, which should be at zero.

Summing up all of the above, we can conclude that a closed heating system with an expansion tank is an almost universal solution for most types of boilers, radiators and other heating equipment.

It is also highly recommended to make calculations for the installation of the tank. An open heating system is basically an option for a village house with an attic and a solid fuel boiler; in other situations, such a scheme is not very suitable.