Normal pressure in a closed heating system is very important. Firstly, this is a warm room in winter, and secondly, the normal operation of all components of the boiler. But the arrow is not always in the range we need, and there may be a lot of reasons for this. High and low pressure in the heating system leads to blocking of the pump and the absence of warm batteries. Let's take a closer look at how many atmospheres our pipes should have and how to fix common problems.

Some general information

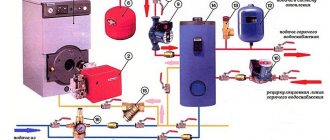

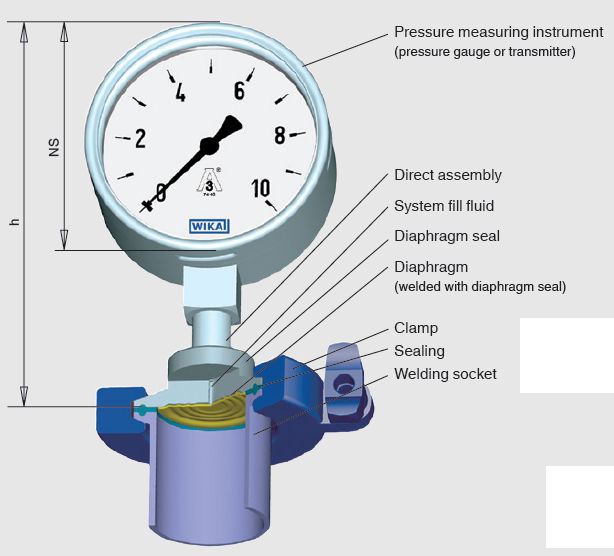

Even at the design stage of the heating system, manometers are installed in different places. This is necessary in order to control the pressure. When the device detects a deviation from the norm, it is necessary to take some action, a little later we will talk about what to do in a particular situation. If you do not take any measures, then the heating efficiency decreases, and the service life of the same boiler is reduced. Many people know that the most detrimental effect on closed systems is water hammer, for which expansion tanks are provided for damping. So, before each heating season, it is advisable to check the system for weak points. This is done quite simply. You need to create excess pressure and see where it manifests itself.

The reasons for the appearance of a pressure difference

Any change in the readings of the pressure sensors indicates a malfunction in the heating system. An increase in pressure can indicate such violations:

- the temperature of the coolant is higher than that established by the standard;

- pipe diameter is less than normal;

- the presence of blockages, deposits inside pipes and heating devices;

- the appearance of air congestion in the system;

- using a pump with greater efficiency than required;

- some of the nodes in the heating system are blocked.

A decrease in the pressure of the coolant in the pipes also indicates a malfunction in the heat supply. If the water pressure in the pipes has become weaker, then it is worth checking the system for such damage:

- emergency situations on pipes (damage to integrity, due to which a leak occurs);

- failure of the pump;

- breakdown of the safety unit;

- rupture of the membrane in the expansion tank;

- the formation of blockages in pipes and filters.

In the summer, that is, when there is no need to heat the premises, the water pressure in the heating pipes must be maintained at a pressure slightly higher than the static one. This is done to prevent air from entering the system. Under the influence of air, pipes can begin to corrode, and this will lead to the appearance of holes and constant leaks of the coolant.

In order to keep warm in the apartments in winter, heating specialists are required to timely diagnose the system, clean its components and elements, and monitor the state of all measuring devices.

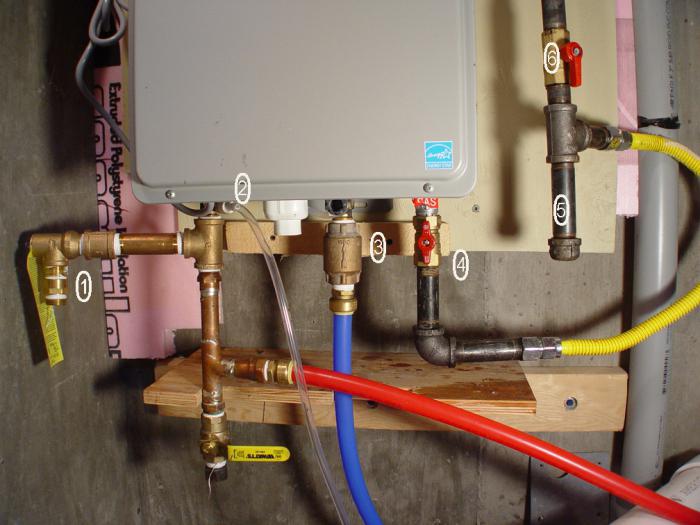

How to fix the situation with a drop?

Everything is extremely simple here. First, you need to take a look at the pressure gauge, which has several characteristic zones. If the arrow is in green, then everything is fine, and if it is noticed that the pressure in the heating system is dropping, then the indicator will be in the white zone. There is also a red one, it signals an increase. In most cases, you can handle it on your own. First, you need to find two valves. One of them serves for injection, the second - for bleeding the carrier from the system. Then everything is simple and clear.If there is a lack of media in the system, it is necessary to open the discharge valve and observe the pressure gauge installed on the boiler. When the arrow reaches the required value, close the valve. If bleeding is needed, everything is done in the same way, with the only difference being that you need to take a vessel with you, where the water from the system will drain. When the arrow of the pressure gauge shows the rate, turn on the valve. Often this is how the pressure drop in the heating system is "treated". For now, let's move on.

The reasons for the instability of the pressure in the network and how to adjust it

The most common cause of a drop in system pressure is water leakage. The "weakest" places are the joints of the pipeline with a heat generator or heating device. Less often, a pipe breaks through in an arbitrary place, if the owner did not keep track of its wear or if he purchased an initially defective product.

The surest indicator of a leak is a drop in static pressure, which can be measured by turning off the pump.

If the static pressure in the closed-type heating system is also normal, the pumps themselves must be checked. To search for a leak, different sections of the system are turned off one after the other, observing the pressure level. After identifying the damaged section of the pipeline, it is disconnected from the system for repair.

If the leak has not been found, and the coolant pressure continues to decrease, it is necessary to call specialists. Having freed the heating system from water and pumped air into it, they will quickly determine the "hole" by the stream of escaping air. If the pipes are hidden in the floor or in the space between the ceiling, specialists use a scanner to detect excess moisture, which allows them to detect an invisible crack in the pipe with an accuracy of several centimeters.

The second culprit for the pressure drop is boiler equipment malfunctions. Among the factors due to which the pressure in the gas boiler drops, there are four main ones:

- damaged expansion tank chamber;

- the destruction of the bithermal heat exchanger caused by a water hammer;

- the occurrence of microcracks in the heat exchanger (due to natural wear of the metal, factory defects or preventive flushing);

- an abundance of scale in the heat exchanger (an eternal problem in regions with hard water).

Any of the above problems are solved. The expansion vessel integrated in the boiler can be shut off by replacing it with an external equivalent. A defective heat exchanger can in most cases be soldered. Water hardness is easily reduced by using special additives. However, before raising the pressure in the heating boiler yourself, it is better to consult with a qualified engineer specializing in boiler maintenance.

Even more dangerous is the situation when the water pressure in the heating system of a private house rises uncontrollably. An increase in pressure is provoked by:

- stopping the coolant flow along the circuit;

- clogged sump or other filter;

- constant feeding of the system caused by a failure of automation or human error;

- the occurrence of air congestion;

- overlapping the valve in the direction of the coolant flow;

- erroneously performed pressure calculation for the expansion tank or its insufficient capacity (the pressure inside the tank should be 1/5 less than the system one, and the capacity should be equal to a tenth of the volume of the entire coolant in the network);

- the appearance of cracks in the expansion tank membrane (if the possibility of changing the membrane is not provided, the tank will have to be changed completely).

What should be the operating pressure in the heating system?

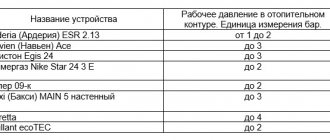

But to answer this question in a nutshell is quite simple. Much depends on which house you live in. For example, for autonomous heating of a private house or apartment, 0.7-1.5 atm is often considered normal.But again, these are approximate figures, since one boiler is designed to operate in a wider range, for example, 0.5-2.0 atm, and the other in a smaller one. This must be seen in the passport of your boiler. If there is none, stick to the golden mean - 1.5 Atm. The situation is quite different in those houses that are connected to central heating. In this case, it is necessary to be guided by the number of storeys. In 9-storey buildings, the ideal pressure is 5-7 atm, and in high-rise buildings - 7-10 atm. As for the pressure under which the carrier is supplied to the buildings, it is most often 12 atm. You can lower the pressure using pressure regulators, and increase it by installing a circulation pump. The latter option is extremely relevant for the upper floors of high-rise buildings.

Norm in an autonomous heating system

When, when autonomous heating is installed in the apartment, the coolant is heated by the boiler, usually of low power. Since the pipeline in a separate apartment is small, it does not require numerous measuring instruments, but normal pressure is 1.5-2 atmospheres.

During the start-up and testing of the autonomous system, it is filled with cold water, which gradually heats up, expands and reaches the norm at minimum pressure. If suddenly in a similar design the pressure in the batteries drops, then there is no need to panic, since the reason for this is most often their airiness. It is enough to free the circuit from excess air, fill it with a coolant and the pressure itself will reach the norm.

To avoid accidentswhen the pressure in the heating batteries of an apartment building rises sharply at least by the permissible 3 atmospheres, you need to install either an expansion tank or a safety valve... If this is not done, the system may be depressurized and then it will be necessary to change it.

In order for the heating system of an apartment building to always have working pressure, it needs:

- diagnose;

- clean its elements;

- check the performance of measuring devices.

How does media temperature affect pressure?

After the closed water supply system is installed, a certain amount of coolant is pumped in. As a rule, the pressure in the system should be minimal. This is because the water is still cold. When the carrier heats up, it will expand and, as a result, the pressure inside the system will slightly increase. In principle, it is perfectly reasonable to regulate the amount of atmospheres by adjusting the temperature of the water. Currently, expansion tanks are used, they are also hydraulic accumulators, which accumulate energy inside themselves and do not allow an increase in pressure. The principle of the system is extremely simple. When the operating pressure in the heating system reaches 2 atm, the expansion tank is turned on. The accumulator takes away the excess coolant, thereby maintaining the pressure at the required level. But it so happens that the expansion tank is full, there is nowhere for excess water to go, in this case, a critical excess pressure (more than 3 atm.) May arise in the system. To save the system from destruction, a safety valve is activated to remove excess water.

Features of autonomous heating

The normal value for a closed circuit is 1.5-2.0 bar, which is much different from the pressure in the central heating pipes. The reason for the downgrade may be:

- depressurization - when a leak or microcracks appears, through which water can escape. Visually, this may not be noticeable, since a small amount of water has time to evaporate;

- decrease in the temperature of the coolant. The lower the water temperature, the less its expansion;

- the presence of autonomous pressure regulators that bleed air.They are installed to remove air pockets. Leak frequently;

- changing the radius of the nominal pipe passage. When heated, plastic pipes can change their geometry - they become wider.

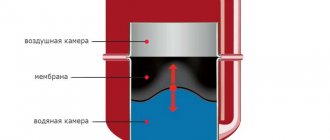

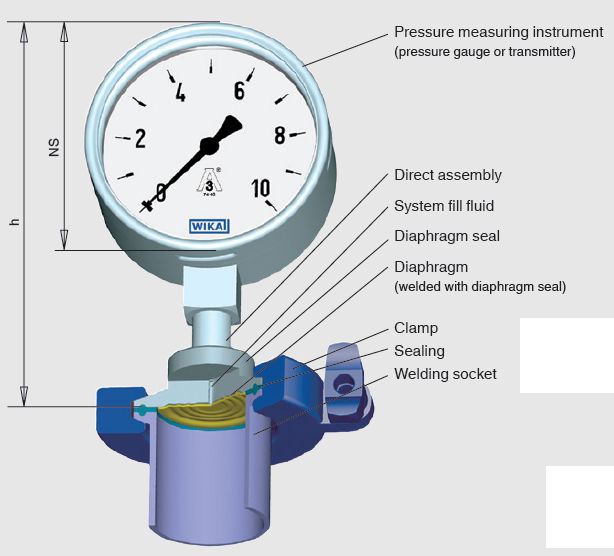

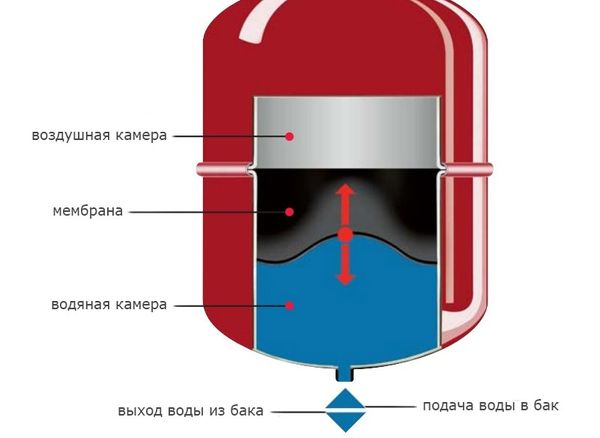

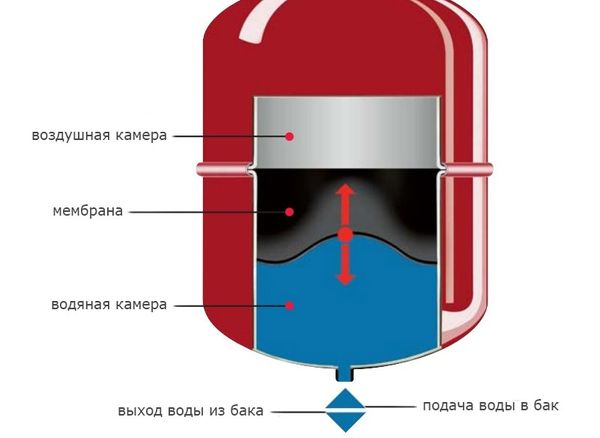

Not only the circulation of the coolant depends on the pressure indicator in the heating system, but also the serviceability of the equipment. To prevent a decrease and increase in pressure in any part of the system, an expansion tank is installed. It is a metal container with a rubber membrane inside. The membrane divides the tank into two chambers: with water and air. At the top there is a valve through which air exits at extreme pressure rise. It can occur due to excessive heating of the fluid. After the water cools down and decreases in volume, the pressure in the system will not be enough, because the air has escaped. The volume of the expansion tank is calculated based on the total volume of the coolant in the system.

Static and dynamic pressure

If we explain in simple words the role of static pressure in a closed heating system, then it can be expressed something like this: this is the force with which the liquid presses on the radiator and the pipeline, depending on the height. So, for every 10 meters there is +1 atm. But this only applies to natural circulation. There is also dynamic pressure, which is characterized by the pressure on the pipeline and radiators while driving. It is worth noting that when installing a closed heating system with a circulation pump, static and dynamic pressure is added, while taking into account the features of the equipment. So, a cast iron battery is designed to operate at 0.6 MPa.

Diameter of pipes, as well as the degree of their wear

It must be remembered that the pipe size must also be taken into account. Often, residents set the diameter they need, which is almost always slightly larger than the standard sizes. This leads to the fact that the pressure in the system decreases slightly, which is due to the large amount of coolant that will fit into the system. Do not forget that in corner rooms the pressure in the pipes is always less, since this is the most distant point of the pipeline. The degree of wear of pipes and radiators also affects the pressure in the heating system of the house. As practice shows, the older the battery, the worse. Of course, not everyone can change them every 5-10 years, and it is inappropriate to do this, but from time to time it will not hurt to carry out prevention. If you are moving to a new place of residence and you know that the heating system there is old, then it is better to change it right away, so you will avoid many troubles.

Pressure drop

In a closed heating circuit, the pressure drop can be due to three reasons:

- depressurization of the circuit, leakage in the boiler, through pipes and connections or radiators;

- the pressure in the air chamber of the expansion tank has decreased;

- the safety valve worked, the volume of water in the circuit decreased, which caused a drop in pressure when the temperature of the coolant dropped.

The most dangerous situation is associated with depressurization. This is a direct indication that an accident has occurred, which should be immediately resolved and the causes removed.

The pressure gauge readings change gradually downward, and the speed depends on the level of the leak.

Switch off the boiler and circulation pump immediately., reduce the pressure in the expansion vessel. It is important to check the integrity of the heat exchanger or boiler tank, all connection points along the piping route and radiators. Once the problem is identified, measures should be taken to eliminate the leak.

Heating starts only after replenishing the coolant volume, venting and pressure testing.

If the pressure drops very slowly, for example, by only 0.1 bar on average per month, then you should first pay attention to the expansion tank.

The air chamber and the nipple installed on it are similar in principle to a conventional wheel chamber of a car. Likewise, air can be vented, gradually decreasing the pressure in the circuit.

Often this problem is not noticed immediately, but simply manually or automatically supplemented with water into the circuit. If you run the problem, then the pressure will eventually begin to change strongly and quickly, as the expansion tank will simply overflow.

Diaphragm expansion tank device

If, for some reason, the safety valve has triggered, and part of the coolant has left the circuit, then after the temperature has returned to normal, the pressure in the circuit will drop, which will be signaled by the pressure gauge reading.

It is enough not to ignore the operation of the safety valve, eliminate the cause of the surge and top up the coolant to the nominal volume

About Leak Testing

It is imperative to check the system for leaks. This is done to ensure that the heating is efficient and does not fail. In multi-storey buildings with central heating, the cold water test is most often used. In this case, if the water pressure in the heating system drops by more than 0.06 MPa in 30 minutes or 0.02 MPa is lost in 120 minutes, it is necessary to look for places of gusts. If the indicators do not go beyond the norm, then you can start the system and start the heating season. The hot water test is carried out just before the heating season. In this case, the carrier is supplied under pressure, which is the maximum for the equipment.

How to raise the pressure

Checking the pressure in the heating mains of multi-storey buildings is a must. They allow you to analyze the functionality of the system. A drop in the pressure level, even by a small amount, can cause serious failures.

In the presence of centralized heating, the system is most often tested with cold water. A drop in pressure in 0.5 hour by more than 0.06 MPa indicates the presence of a gust. If this is not observed, then the system is ready for operation.

Immediately before the start of the heating season, a test is performed with hot water supplied under maximum pressure.

Changes in the heating system of a multi-storey building most often do not depend on the owner of the apartment. Trying to influence the pressure is a pointless undertaking. The only thing that can be done is to remove air locks due to loose connections or incorrect adjustment of the air release valve.

The presence of a problem is indicated by inherent noise in the system. For heating devices and pipes, this phenomenon is very dangerous:

- Looseness of threads and destruction of welded joints during vibration of the pipeline.

- The interruption of the supply of the coolant to individual risers or batteries due to difficulties with airing the system, the impossibility of adjustment, which can lead to its defrosting.

- A decrease in the efficiency of the system if the coolant does not completely stop flowing.

To prevent air from entering the system, before testing it in preparation for the heating season, inspect all connections and taps for water passage. If you hear the characteristic hiss during a test run of the system, immediately search for the leak and repair it.

You can apply a soap solution to the joints and where the tightness is broken, bubbles will appear.

Sometimes the pressure drops even after replacing old batteries with new aluminum ones. A thin film appears on the surface of this metal from contact with water. Hydrogen is a by-product of the reaction; due to its compression, the pressure decreases.

In this case, you should not interfere with the operation of the system. - the problem is temporary and goes away on its own over time.This happens exclusively in the first time after the installation of radiators.

It is possible to increase the pressure on the upper floors of a high-rise building by installing a circulation pump.

Attention: the most distant point of the pipeline is the corner room, therefore, the pressure is the least here.