Driving in winter is seriously complicated by the adhesion of snow and ice to the car windows, which the wiper blades cannot always cope with. Because of this, the view of the road is significantly reduced, and the risk of getting into an accident increases.

To ensure that the windshield always remains clean and does not freeze, it must not only be cleaned, but also constantly washed while the vehicle is in motion. Ordinary water, which is poured into the wiper tank in summer, is not suitable for winter conditions - it quickly freezes, clogs the spray nozzles and can tear the tank itself. Therefore, in winter, an anti-freeze windshield washer fluid is used to wash the windshield - "anti-freeze".

In what cases antifreeze can not be used

Why is the question posed in this way? Everything is very simple - you can easily familiarize yourself with the specific positive qualities of antifreeze of any brand. Such information is actively disseminated by manufacturers. For our part, we want to present those features of this technical fluid, which they are trying to keep silent about:

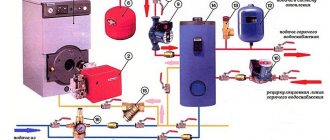

- Antifreeze cannot be used in double-circuit boilers - it is possible to mix the coolant from the heating circuit into the water supply circuit. As you know, non-freezing liquid is poisonous by its physicochemical properties.

- In open systems, it also cannot be used - evaporation of the coolant is possible.

- The use of antifreeze in a system with a galvanized pipeline is unacceptable - it is fraught with chemical changes and the loss of its original properties.

- The heat capacity of the non-freezing liquid is lower than that of water, which means that more powerful radiator batteries will be required.

- The viscosity of antifreeze is also higher - more powerful circulation pumps are needed.

The tank for antifreeze must be large enough, and correctly calculated according to the project

Volume calculation and filling

In order to avoid accidents, it is necessary to pour liquid into the heating system in a strictly defined volume. It is calculated taking into account the following factors:

- type of heating system;

- her material;

- internal volume of the boiler;

- the area of the room that is planned to be heated.

It is recommended to carry out the calculation according to the instructions for the equipment, and also take into account whether antifreeze can be used in it at all. But there are situations when there is no information on this in the technical documentation, then the calculation is carried out by studying the relevant literature. And in some cases, you will need the help of a specialist who will help you carry out all the calculations and get the system into operation.

After pouring, do not forget to test the equipment

You also need to know how to properly fill the coolant into the system. If it already contains old media, then it will need to be drained. It is also necessary to check the degree of contamination, perhaps the system will need to be cleaned first, otherwise the mixing of the two non-freezers will cause an unexpected chemical reaction.

We suggest that you familiarize yourself with the correct installation location of the water pressure regulator in the apartment

In a closed system, the filling point must be below other heaters. Antifreeze is poured through pumping equipment, but it is necessary that the pressure in the pipes be no higher than 3 atmospheres. And if it is open, then the filling must be carried out through the upper expansion tank.

After that, the operation of the equipment is tested. The temperature in the system rises, during which the tightness of the units is checked and the absence of unnecessary noise during the circulation of the coolant.

Propylene glycol antifreeze

Propylene glycol in the heating system is not as toxic as the previous type. The composition of such antifreeze may contain food additives that are not dangerous even to human health.

True, the composition of such a coolant may contain various additives that can affect the materials from which various elements of the heating system are made. The way in which additives work depends on the material from which the components of the heating system are made. Some additives are needed so that various oxidations or foaming do not appear inside the heating system.

Propylene glycol antifreeze

Features when starting the heating system

The different composition of the solutions affects the operation of the heating system. This is how the presence of ethylene glycol influences the initial start-up phase of the system. The heating process must be started at low power, then gradually brought to the required level. This method will reduce the toxic effects of this substance.

The propylene glycol-based product does not need such adjustment of the heating equipment start-up.

When all the requirements are met, then there is no need to be afraid of using "anti-freeze" as a coolant. It will solve a lot of problems with skillful use.

The prices for antifreeze liquid are different, and the quality, accordingly, is also different. The policy here should be as follows: when there is no way to buy a good product, it is better to stay on the water. In this case, it is imperative to make sure that the coolant is drained from the system before the onset of frost, or turn on the heating devices on time.

The main criteria for choosing antifreeze

Buying an anti-freeze fluid for a windshield washer does not require special knowledge from the driver, but buying the first product that comes across is not recommended in order to avoid health problems. Much depends on the base of the liquid, which we will talk about later. Other parameters are also important, including:

- Foaming. If the product is of good quality, moderate but dense foam will appear after shaking the bottle or canister. If there is too much of it or it does not appear at all, you have a fake in your hands.

- Clarity and sediment. An important indicator of quality that you can determine yourself is the sediment at the bottom and transparency. The liquid should not contain any impurities and foreign inclusions. It is desirable that the composition is transparent. Flakes, sandy sediment, liquid stratification are all signs of chemical reactions that can worsen the quality of non-freezing.

- Aroma. It largely depends on the base used - methanol, ethanol and others. We will dwell on them further. High-quality anti-freeze does not have a sharp unpleasant odor. Also, the lack of scent is also a bad sign.

- Availability and quality of labels. Good manufacturers pay special attention to the quality of anti-freeze liquid packaging. The presence of defects or the absence of a label is a reason to refuse a purchase.

- Price. For many drivers, it is this indicator that becomes fundamental, but it is not recommended to save on anti-freeze.

- Information on the packaging. Examine the label to find the fluid manufacturing date, manufacturer information, batch number, composition, and other details.

- Temperature Range. One of the main indicators of an anti-freeze liquid is the freezing point. Unscrupulous manufacturers overestimate the indicators, so it is better to always buy products with a temperature range with a margin.

Other components

The recipes for factory anti-freeze liquids necessarily contain surfactants.They are designed to remove dirt, grime, grime, oil and anything else that can obstruct your view from the glass surface.

For the liquid to be effective in cleaning glass, very few surfactants are required. Flavors are also used in the manufacturing process. They serve to impart a pleasant aroma to the product. Manufacturers often use the smell of apples, citrus fruits or any other product with a persistent and “tasty” aroma. Dyes color the liquid in different colors. This makes it easier for the buyer to identify the desired product. Separately, it is necessary to say about water. For the manufacture of products of the highest class, distilled is best suited. In some cases, it is allowed to use artesian water with a minimum of salts. But the most ordinary (from the tap) is not suitable for making anti-freeze.

The best inexpensive anti-freeze fluids

Many users believe that buying an expensive washer is not a rational decision. After all, budget products are of the same good quality, but you do not need to overpay for a promoted brand.

To compile the rating, we selected inexpensive products based on more than 500 reviews of real buyers. The best anti-freeze products presented in the review are not only affordable, but also meet the necessary quality requirements.

Net Mile (-25 ° C)

Pure Mile is a good windscreen washer fluid. The products are provided by the domestic company Tosol-Sintez. The composition is used for cleaning side, windshield and windshields. You can use the product at temperatures up to -25 degrees. At lower values, the product solidifies.

The composition contains fragrances and detergents. Non-freezing allows you to efficiently remove mechanical particles, oil stains and snow embankments. Long-term use does not provoke destruction of paintwork and elements made of polymers and plastic.

Benefits:

- Cleaning quality;

- Does not harm health;

- Safety for all kinds of coatings;

- No oil stains, streaks or reflections are left during use.

Disadvantages:

- The presence of a specific smell;

- Increase in viscosity at temperatures above -20 degrees

According to reviews, this tool is in demand due to its affordable price, along with the absence of complaints about quality. The convenience of packaging is also noted.

Taimyr (-30 ° C)

The composition includes water, perfume and isopropyl alcohol. The products are produced in different colors depending on the dye. The color can be yellow, pink, blue or green.

The liquid is used to remove ice and snow in the winter and insects in the summer. The product is sold in a volume of 5 liters. In addition, the liquid does not crystallize at temperatures close to -30 degrees. Taimyr is intended for surface treatment using special washers or manually. The product has a caramel smell, which some consider pleasant, while others do not.

Benefits:

- Special components in the composition help get rid of lime deposits in the washer hoses;

- There is no methanol in the composition;

- Use is safe for humans and the environment.

Disadvantages:

- The smell is not for everybody.

Users are pleased with the presence of safe components in the composition, which is atypical for a low price. The product washes the glass thoroughly and does not harm the headlight coatings.

The best antifreezes

Ice Drive (-30 ° C)

A good anti-freeze for a car, which does not have an unpleasant odor, and also does not emit toxic components. The washer is made on the basis of isopropyl alcohol, which is a clear liquid. Such a component is safe for health and does not harm various elements of the car. Of the advantages, it is worth noting the absence of methanol.

When using the cleaner, there are no traces and grease stains on the windows. Under the influence of active ingredients, the frost leaves quickly and easily.

Benefits:

- Harmless composition;

- The lowest price in the rating;

- The ability to clean glass and headlights manually;

- The efficiency of the liquid is even up to minus 30 degrees.

Disadvantages:

- Not all stores are on sale.

Some users note that the manufacturer indicates false information about the composition of the product. In some reviews, you can find that the anti-freeze does not use the declared isopropyl alcohol, but methanol.

If you take an anti-freeze, what brand

Heating fluids

The market today offers a variety of offerings for this specific product.

However, there are also leaders here. Heating fluid called "Warm House" is in great demand among consumers. This product is produced in Russia.

"Warm House" has been successfully used for many years, so we can say with confidence that the liquid has passed the test of time. And best of all, this antifreeze is characterized by reviews of homeowners who have considerable experience in operating heating systems using antifreeze liquid.

According to them, this brand does not lose its characteristics over ten heating seasons.

This fully corresponds to the service life declared by the manufacturer. As you know, reviews from satisfied consumers are the best proof of quality.

Also on hearing are such brands as "Energos Universal", "Energos Lux", "Thermagent", "Dixis", etc.

On the basis of ethylene glycol, Russian manufacturers produce antifreezes in two versions: with a freezing temperature of up to -30 ° C, and also with a freezing temperature of up to -65 ° C.

The aforementioned manufacturers are actively expanding the range of non-freezing heat carriers made on the basis of food-grade propylene glycol, ecologically safe raw materials. And this is not in vain, because the demand for heating antifreeze is growing, which means there should be a supply.

Cases in which it is strictly forbidden to use antifreeze

When you can't use antifreeze

It is not difficult to get acquainted with all the advantages of antifreeze from any manufacturer.

This information is actively advertised by trademarks. On the other hand, we should talk about the features of this liquid, which manufacturers try not to emphasize:

- It is forbidden to use antifreeze in double-circuit boilers. After all, the design features of this heating system are such that the coolant can leak from the heating kennel into the water supply circuit. And by its chemical properties, the non-freezing liquid is poisonous.

- It is strictly forbidden to use antifreeze in open systems, in which case it may evaporate.

- Also, do not use antifreeze in heating systems with galvanized pipelines. When interacting with them, loss of original properties and chemical changes are possible. It is not recommended to pour antifreeze into cast iron boilers. At the very least, you need to make sure that paronite gaskets are present in your unit, which can prevent the harmful effects of antifreeze. The technical data sheet of the product will help you with this.

- The heat capacity of antifreeze is lower than water, as a result, radiator batteries of greater power are needed.

- Since the viscosity of the non-freezing liquid is higher, more powerful circulation pumps will be required.

In any case, the final decision is always yours. It is impossible to say unequivocally which is better, water or non-freezing liquid.

It all depends on the individual heating parameters. Before making a final decision on the choice of a particular coolant, you should seek the advice of specialists.

Selection recommendations

Water, unlike any antifreeze, is an environmentally friendly liquid. However, it can cause scale and corrosion. However, if the family lives in the house permanently, water is a more acceptable option for heating.

But it is better to use special fluids when, in the cold season, the heating is turned on from time to time. The fact is that if the heating was not started at the onset of cold, there is a risk of pipe breakage due to an increase in the volume of water during the transition to a solid state. With antifreeze, this problem is excluded.

The elements for the heating system themselves must be chosen taking into account what exactly will be used - water or antifreeze, then the risks will be much less. But if the heating system has been working for a long time and it was decided to change the water to an anti-freeze, then when choosing one or another of its types it is recommended to consider the following:

- a certain type of anti-freeze for heating a private house should be selected, focusing on the very design of the heating system. It is important here what metal its parts are made of, what power the pumps and radiators have, and what type of boiler is used;

- the composition must be reliable and of high quality;

- navigate the properties of the additives that are contained in antifreeze in order to know how it can affect the material of the equipment;

- it is necessary to dilute the non-freezing liquid strictly according to the instructions;

- when using, do not forget about the service life of antifreeze (in most cases it can be used no longer than 5 years).

If the liquid is purchased for the first time, you can contact a specialist in the store who will advise the most suitable option for each individual case. The correct choice is a guarantee that the heating system will work fully.

Antifreeze classification

There are many types of this product on the market. Non-freezing liquid for heating boilers can be made on the basis of an aqueous solution of glycerin, ethylene glycol, propylene glycol, and so on. Since all substances are highly corrosive, special additives are present in the composition of fluids.

Each species has certain specific characteristics:

- ethylene glycol-based liquid - common among buyers, since it has the most affordable cost. But it is the most toxic and cannot be used for double-circuit boilers. May be hazardous to health if released into the water supply system. If the boiling point rises above 110 degrees, the substance can form a precipitate that can interrupt the operation of a number of elements of the system;

- from propylene glycol - the properties of the composition are almost similar to the previous one, but it is less harmful and safer;

- based on glycerin - an environmentally friendly antifreeze, non-toxic, protects the system from corrosion. When going into a solid state, it does not increase the volume, and in order for the system to start, you just need to warm it up;

- from a natural solution of bischofite - has a high level of heat transfer and heat capacity, the freezing point is low, and the boiling point is high;

- salt carriers - made on the basis of solutions of sodium, calcium and other mineral salts. They are highly corrosive to pipes.

Which one to choose, how do they differ?

Serg3515

A lot has been written and rewritten on this topic, but I never saw a clear answer (and preferably from a user with experience). In this regard, if I may, questions. So, after all, what to fill? (what antifreeze liquid). Electric boiler, two-pipe system, metal-plastic pipes.

It can be very difficult for the uninitiated person to understand the abundance of offers and the range of prices.

The key factor in choosing a coolant is its base, i.e. basic chemical raw materials. The following are traditionally used as a basis:

- ethylene glycol is a toxic dihydric alcohol;

- propylene glycol is a non-toxic substance acceptable for use in the food industry.

The second selection criterion is the additives used in the coolant. Distinguish between organic additives (carboxylate) and inorganic. Additives affect the life and quality of the coolant. The coolant with organic additives has a longer service life, and during operation it more reliably protects the system from the effects of corrosion.

The third indicator is how the manufacturers of heating equipment relate to this product, in other words, is it permissible for a particular heat carrier to be used in a system where this type of equipment is used.

Rating of coolants in terms of a set of quality characteristics:

- Heat transfer fluid based on propylene glycol with organic additives and manufacturer approvals. Such a coolant provides the widest range of indicators: it is environmental friendliness with safety, and service life, and physical and chemical indicators, and versatility of use, from kindergarten to food production.

- Heat transfer fluid based on ethylene glycol with organic additives and manufacturer approvals. Such a coolant already has limitations in its application. You can determine its purpose: industrial facilities and systems, reliably isolated from human life.

- Heat transfer fluid based on propylene glycol with conventional inorganic additives. Although such a product has a shorter service life, it is harmless enough for the neighborhood with people and animals.

- Heat transfer fluid based on ethylene glycol with inorganic additives. Poisonous, short service life. Its use is often driven by the need to save money. If the system is well insulated from contact with human life, such a decision is quite logical.

P.S. Glycerin-based heat carrier. Glycerin is the simplest trihydric alcohol, which is a viscous transparent liquid, also used as a food additive. The product has a high density, kinematic and dynamic viscosity. Equipment manufacturers provide indicators several times lower than those present in a glycerin-based coolant. The product does not have operational and physical advantages, although it is quite easy to manufacture, therefore it is inexpensive. European manufacturers of chemical compositions are very negative about the use of glycerin as a base for antifreeze liquids.

How to do an anti-freeze: the main points

Whatever composition you prepare, it should:

- clean the windshield from dirt and ice;

- remain liquid at low temperatures;

- be safe for both humans and machine parts.

All, perhaps, nothing more is required from the washer.

As a rule, the base of antifreeze liquid includes ordinary distilled water, alcohol and some additives for flavoring, coloring and improving cleaning properties. Methyl, ethyl and isopropyl alcohols are used in production.

Methyl alcohol is harmful to health, therefore, non-freezing based on it is prohibited in Russia. And even if you have a canister of this substance lying around in your garage, you should not pour it into the car.

Isopropyl alcohol is extremely rare among the people; this technical liquid has a pungent smell. It can be asked from the one who repairs and cleans office equipment at home. True, such a master usually does not have more than half a liter in stock. And by the way it costs much more expensive than the same ethanol.

Ethyl alcohol is the most affordable option. Many have a bottle of medical, technical, or even food grade ethanol at home. However, no one canceled our favorite vodka either, because in essence it is an aqueous solution of ethyl alcohol.

To make anti-freeze in the washer at home, many also use salt, acids, detergents. But first things first.

Anti-freeze washer fluid recipe

There is far from the only recipe for non-freezing. Below are some of the most common ones:

- Based on an alcohol-based preparation for cleaning windows. To make such a liquid with your own hands, you need to mix a similar agent with water in a ratio of one to two. For example, a liter of anti-freeze is obtained by diluting 330 grams of the drug with 670 grams of water.

- With the use of ethyl alcohol. The liquid poured into the washer reservoir contains twenty percent alcohol, eighty percent water, they mix with each other. Now you need to add a little dish detergent and shake everything. You can assume that you managed to make the anti-freeze yourself.

- Using vodka. This is the simplest way to produce such a liquid on your own. It is necessary to add a little detergent to the vodka and shake everything thoroughly.

- Alcohol based (methyl, isopropyl). It is diluted with water (1: 3), the detergent is added to the mixture, and the anti-freeze is ready.

These are not the only recipes for making a washer with your own hands. The main difference between the other options will be at its core. In this capacity, vinegar, ammonia or any other substances that do not freeze at low temperatures and do not have a destructive effect on car paintwork, plastics and rubber parts can be used.

Non-freezing allows the driver to keep the windshield clean at a low temperature. However, the rather high price of the finished product often forces many drivers to make such a liquid with their own hands using available suitable components.

Can antifreeze be used

heat supply circuit with antifreeze instead of water

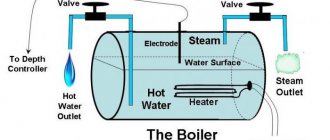

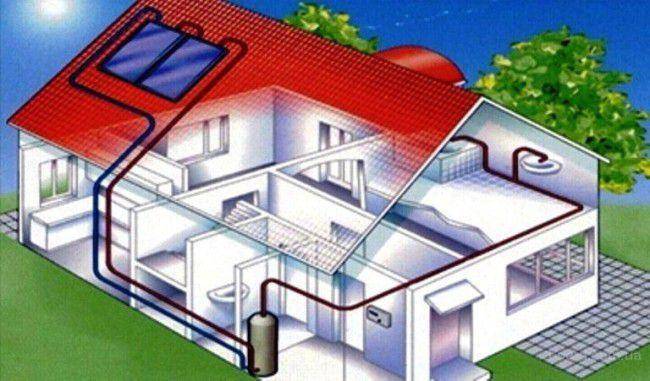

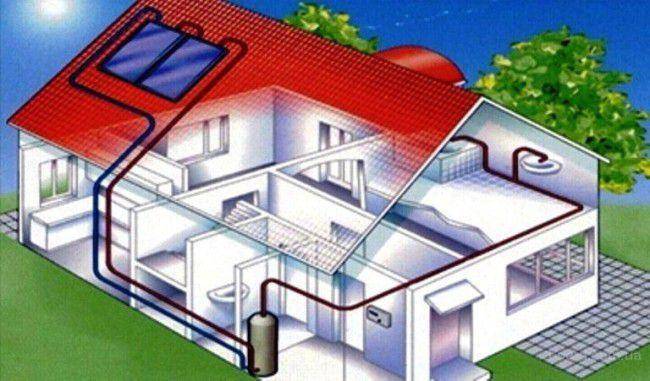

Antifreeze or antifreeze liquids are known to almost everyone. They are widely used in vehicle cooling systems in winter. In a car engine, antifreeze transfers excess heat from the engine, cooling it down. Moreover, even in the most severe frosts, it does not freeze. It is these properties - the ability to transfer heat even at the lowest temperatures and have led to the use of antifreeze for the construction of heating systems. It is especially important to use such a coolant in a system, part of the pipeline of which runs through an open area.

A good feature of "non-freezing" is that it provokes less corrosion on the inner surface of pipeline systems than ordinary water. Another undoubted advantage is the absence of suspended limestone solutions in non-freezing liquids - so you don't have to worry about possible scale formation.

There are several modifications of antifreeze fluids that can be used in heating systems. The choice of a specific type is made taking into account the climatic conditions and the configuration of the heating system of your home.

What is heating system flushing fluid and should it be flushed?

In addition to the heat carrier itself, when operating the heating system, you will also have to purchase a liquid intended for flushing with a pipeline and heating radiators.

Of course, as a last resort, you can rinse the inner surface of the pipes with ordinary tap water, but it is better to do this all the same with the help of special fluids, in which special chemical additives are introduced.

heating flushing

An alternative flushing option can be the use of water with a caustic soda solution added to it. Such a mixture is poured into the heating system and remains inside it for about an hour.The soda solution comes into contact with scale on the inner surface of the system and dissolves it. In addition, the baking soda solution will dissolve the corroded areas.

How to choose a liquid for a heating system?

First of all, it is necessary to determine the operating parameters of the system. Here two extreme values will be important to you - the maximum temperature of the coolant when heating in the boiler and the minimum temperature of the ambient air. Next, you need to carefully study the technical characteristics of your heating system.

Actually, the main attention should be paid to the characteristics of the heat exchanger in the boiler. Some manufacturers may not allow the use of anti-freeze fluids. And, finally, after determining the permissibility of using an anti-freezing liquid and its possible temperature parameters, proceed directly to the choice of the brand of liquid, focusing on its lowest toxicity

All the same, the heating system will be located in a residential area, and possible fluid leaks should not lead to poisoning.

Using alcohol as a heat carrier

No matter how blasphemous it may sound for a man's ear, it is allowed to use alcohol as a heat carrier. The alcohol does not freeze and can be used over a wide temperature range. Naturally, industrial alcohol is used in this capacity, which is a deadly poison for humans. However, many manufacturers of boilers and heat exchangers are critical of the use of fluids such as bischofite or ethylene glycol as a heat carrier.

bischofite

The disadvantage of using pure alcohol as a heat carrier is its high volatility - about five liters per year will evaporate through microscopic pores in the system.

Advantages and disadvantages

The special fluid has a number of features. It has both pros and cons. Antifreeze benefits:

- the composition retains its characteristics and properties, even if it is constantly in the heating system;

- does not freeze at sub-zero temperatures;

- no scale builds up in equipment and pipes;

- does not affect the condition of seals and gaskets: they will not dissolve, dry out or swell.

But when pouring non-freezing liquid into the heating system, there are also disadvantages:

- it has less heat transfer properties;

- acts aggressively towards metal;

- in the event of a leak, harmful substances will be released.

Types of low-freezing liquids

Non-freezing liquid for heating a house is the same antifreeze or antifreeze. no difference. More precisely, there is a difference, but it is more about the composition of the anti-freeze than the main properties. And their main property is not to turn into ice when the temperature drops, down to -60 degrees. In this case, the cooled composition thickens.

Propylene glycol is part of the eco-friendly anti-freeze

Any non-freezing liquid for heating, a warm house in particular, is made according to the same principle. Their composition:

- glycolic (alcohol) base;

- the main active ingredient;

- substances that prevent corrosion (inhibitors);

- substances responsible for the characteristics of the composition (additives).

So, it is already clear that non-freezing liquid for water heating is an alcoholic substance. Glycol by itself is not dangerous, but some additives can be very harmful to health. The following can act as an active component in anti-freeze:

Ethylene glycol liquid, in which ethylene glycol acts as an active substance, is strongly discouraged from using in homes of permanent residence. It is very toxic and causes burns when it gets on the skin. The ingestion of the composition into a person in the form of a liquid or gas leads to serious consequences, up to and including death.

Low-quality antifreeze and the well-known machine antifreeze, which is also sometimes poured into heating, are made on an ethylene basis. If there is even the slightest possibility of human contact with ethylene glycol, then it is better to refuse its use:

- evaporation from an open-type expansion tank;

- a leak;

- mixing into the DHW circuit in double-circuit boilers.

Do not use ethylene glycol antifreeze liquids for heating, where a double-circuit boiler acts as a heater.

Propylene glycol liquid for heating boilers, non-freezing, is completely non-toxic. This does not mean that you can drink it, but accidental contact with minimal doses on the skin or even inside will not lead to health complications. This anti-freeze can be used safely.

Glycerin antifreeze liquid has been poured into the heating system since the middle of the twentieth century and is still successfully used. Glycerin is, in general, a universal remedy. What is characteristic, unlike the above two types of non-freezing, glycerin does not dry the rubber, but, on the contrary, restores it, gives a second life. That is, it acts on it like a silicone lubricant, so there is no need to worry about the condition of the sealing gum.

The problem of heating the winter greenhouse has been solved, everything is quite simple.

Non-freezing liquid for the heating system of a private house on propylene glycol

Non-freezing liquid for heating the house "Warm House ECO-30" environmentally friendly

Antifreeze is environmentally friendly and ready to use. The base is propylene glycol (green). The composition can be diluted with plain tap water up to -20 degrees... If you have a double-circuit or heating boiler, dilution is a must.

It is better to use non-freezing liquid on propylene glycol where there are increased requirements for environmental safety (heat pumps, double-circuit boilers), but it is excellent friends with any heating systems.

The liquid is characterized by good temperature range from -30 to +104 degrees... The composition includes a special set of additives. This gives protection against corrosion, foaming, scale. Antifreeze is not aggressive to metal-plastic and plastic, paronite, rubber, flax. With such characteristics, the possibility of leaks is excluded. The price of a canister for 20 liters is from 1.6 tr.

Pros:

- environmental friendliness;

- explosion and fire safety;

- works in any systems;

- excellent set of additives;

Minuses:

- does not work with galvanized systems.

How to choose the right liquid for heating

It is difficult to imagine comfortable living in an apartment or a private house without high-quality heating. Residents of urban high-rise buildings with centralized heating are lucky. After all, you don't have to think and worry about the safety of pipes during the cold period. Maintenance falls on the shoulders of housing maintenance offices. But the proper operation of the autonomous heating system in the private sector has to be monitored independently.

A heat carrier is used as a heating element in the heating network. It is a heating fluid that circulates around the circuit. It can be of different types. It is on what fluid is used that the operation and maintenance of the system depends. Therefore, this article will be devoted to the coolant, its types and application rules.

How to make an antifreeze liquid

Knowing the recipe, making a similar product yourself is quite simple. It is necessary to mix the necessary components in the right proportion, after which the liquid can be used for its intended purpose. From what substances are used, the properties of a homemade anti-freeze may differ from the standard one.

Related article: How to properly bleed the brake system with ABS?

It should be borne in mind that in some cases, knowing how to make a frost-resistant liquid yourself may be necessary.

Characteristics of antifreeze heating fluids

The way a low-freezing liquid for heating systems behaves in the circuit is primarily influenced by the quality of the additive package and, of course, the operating conditions. Regardless of which main active element is added to the glycol base, all formulations have anti-corrosion and anti-foaming properties.

Without these additives, the heating fluid is very corrosive. All non-freezing liquids foam, but especially glycerin anti-freezing liquids for heating systems of houses. Foam is an air-containing substance, and air leads to impaired circulation, the formation of air pockets, as well as water hammer in the heating system.

The additive package has its own time resource. After a certain time, the additives disintegrate at the molecular level.

This will form a precipitate and release acid. It turns out that nothing already smoothes the aggressiveness of the coolant for heating the house, moreover, everything is aggravated by the release of acid. Service life of antifreeze liquid:

- based on ethylene glycol - five years;

- based on propylene glycol - five years;

- glycerin-based - up to ten years.

This is the service life of the compound under favorable operating conditions. The main requirement is, of course, temperature. When the temperature of the coolant rises to 90 degrees, the non-freezing liquid begins to disintegrate and loses its properties. This only happens if the boiler starts up incorrectly after a long period of inactivity, or errors during installation.

Direct contact of the heat exchanger with the flame is undesirable if antifreeze is poured into the circuit

For example, when a heat exchanger is built into a conventional oven. Some people install it so that it is in contact with an open flame. If you plan to use antifreeze for stove heating, then this should not be done. It is necessary that there is a layer of brick between the heat exchanger and the flame. He and the coolant will protect from too hot tongues of flame, and distribute the heat evenly. In this case, the non-freezing liquid for stove heating will not overheat.

Characteristics influenced by the quality of the additive package:

- thermal conductivity;

- density;

- viscosity;

- fluidity;

- thermal expansion.

The higher the quality of the additives, the higher the characteristics will be. That is, as close as possible to the characteristics of water. In the case of the coefficient of thermal expansion, then it should be as small as possible.

Considering the fact that the volumetric expansion of the anti-freeze is greater than that of water, it is necessary to provide for an expansomat of 40% more volume.

The thermal conductivity of antifreeze is lower than that of water. The lowest thermal conductivity of glycerin antifreeze liquids. In relation to water, it is only 85%; in other non-freezing systems, the indicator can reach 90%. As you can see, the difference is not that great.

Non-freezing liquids are half as dense and viscous as water. These qualities impede circulation. In order to pump the coolant along the circuit, a pump of greater power will be required; it would also be nice to assemble a heating circuit from pipes with a cross section larger by one step. For example, when it comes to polypropylene pipes. then instead of 25 in diameter, it is better to take 32.

Despite the fact that the non-freezing liquid is denser and more viscous, it has a lower coefficient of surface tension, that is, it is more fluid. Do you know that you can draw water into a glass "with a slide"? The slide, of course, will be small, but even visually it is visible that the liquid rises above the edge of the vessel. With anti-freeze, this will not work. Due to this high fluidity, it flows out where water does not penetrate due to surface tension. In other words, if there are microcracks and even very small holes, then the non-freezing liquid will find a way out there.

Therefore, often, after there was water in the circuit and it was decided to pour an anti-freeze into it, leaks appear. Major leak points:

- pipe joints;

- connections between radiator sections;

- places for connecting additional elements;

- in the boiler itself.

Water has another useful property, thanks to which a minor leak can disappear by itself. Metal particles settle at the edges of the cracks and seal them. Of course, this is just scale, which, in the case of flushing and further pressure testing of the system, will be removed and flow will resume.

Antifreeze additives for concrete mortar

To help the reader understand the specifics of concrete work in winter, this article will consider one of the ways to reduce the minimum operating temperature of a liquid mortar, namely an antifreeze liquid for concrete, as the most acceptable solution to the problem.

Also, a brief instruction will be presented here, which describes in detail the technology and recipe for the preparation of winter mortar.

Pouring a monolithic base in the winter.

Difficulties of winter concreting

The concrete solution is a mixture of a binder (cement M300 - M500), fine aggregate (river or quarry quartz sand), coarse aggregate (gravel, limestone or granite crushed stone) and water, which are thoroughly mixed with each other in a certain proportion.

After being laid in a mold or formwork, over time, the cement reacts with water, which is called hydration, resulting in its setting and gradual hardening.

The normal course of this process is possible only at positive temperatures, therefore, in the event of frost in the liquid solution, the following changes may occur:

- When the ambient temperature drops below +5 ° С, the hydration time increases significantly.

- A decrease in temperature below 0 ° leads to the formation of an ice crystal lattice in a liquid solution. Ice crystals, increasing in volume, create hotbeds of local stress in the immature solution, which leads to a violation of its structure and multiple ruptures of the bonds of cement particles, which have just begun to adhere to each other.

- In the event that the concrete is frozen, an ice crust forms around the metal parts of the structure, which pushes the mortar mass away from the elements of the steel reinforcement strapping, violating the integrity of the reinforced concrete product.

- The transformation of free water into ice reduces its amount, as a result of which it will not be enough for normal cement hydration.

It should also be noted that all these phenomena are dangerous in the case when freezing of concrete occurs at an early stage of hardening, that is, when it has not yet had time to gain critical strength, which conventionally is 50% of the design strength.

The photo shows the casting of the strip foundation using an anti-freeze additive.

Ways to combat solution freezing

Based on the above, we can conclude that the main task of concreting in winter is to protect the solution from freezing for as long as possible and keep the water in a liquid state.

To prevent concrete from freezing during the hardening process, there are several ways, each of which has its own advantages and disadvantages.

- The so-called thermos effect is the use of concrete formwork from materials that have good thermal insulation properties.... During the preparation process, the components of the solution are heated, after which it is poured into the formwork in a heated form, and then covered with heat-insulating materials. Together, these measures prevent concrete from freezing before it reaches the critical strength value.

- Heating of the liquid solution in the formwork is carried out either by heated steam, or by passing an electric current through special electrodes... This method is very energy intensive and requires the use of special equipment.

- The introduction of special modifying additives into the solution accelerates the hydration reaction and protects the water that is part of it from freezing.

Thermoelectric mats for external heating of concrete surfaces.

Advice! An alternative method is to construct a closed shed or hut over the construction site, which is heated with electric or diesel heat guns.

The main advantages of antifreeze

Of all these methods, the most acceptable for individual construction is the use of liquid antifreeze additives.

Among the advantages of this method are the following positive qualities:

- Thanks to its antifreeze properties, the freezing point of free water, which is part of the solution, is reduced.

- The plasticizing properties reduce the density and increase the mobility of the finished solution without the addition of excess water, which contributes to a better formation of the concrete product.

- As a rule, high-quality liquid anti-freeze in concrete contains corrosion inhibitors, which protect the steel elements of the reinforcement strapping from oxidation and destruction.

- A balanced set of components ultimately helps to accelerate critical strength development, and also increases the water resistance and design strength of the finished product.

- Due to the low cost of liquid additives, the price of this method of combating frost is much cheaper than the others, moreover, it does not require the use of bulky and energy-intensive equipment.

The use of modifying additives makes it possible to carry out concrete work at temperatures down to -25 ° C.

Advice! It is not recommended to use fluids without corrosion inhibitors in structures with metal reinforcement strapping due to their high corrosiveness.

Features of working with antifreeze additives

In order not to think about the question during construction in winter: what to do if the concrete is frozen, it is enough just to use the necessary anti-freeze modifying additives in a timely manner.

The technology of their use is quite simple:

- Pour the required amount of water into a working concrete mixer, and then add an anti-freeze liquid in strict accordance with the instructions for use.

- Let the mixer run for a while to completely mix the water and the modifier.

- After that, load into the bucket half the volume of sand, then the entire volume of cement, and then the rest of the sand.

- Finally, load the required amount of coarse aggregate into the mixer and leave to work until the components are completely mixed and a homogeneous mixture is obtained.

Table 1 shows the average proportions of antifreeze liquid for concrete and the rate of development of design strength.

| Average design temperature of concrete hardening | Dosage of the additive in %% of the cement mass | Compressive strength in% of design, at age, days | ||

| 3 | 7 | 28 | ||

| - 5 C | 1 | 20 — 30 | 40 — 50 | 55 — 70 |

| - 10 C | 1,5 | 15 — 25 | 25 — 35 | 50 — 65 |

| - 15 C | 2 — 2,5 | 10 — 15 | 20 — 30 | 45 — 55 |

Self-preparation of winter concrete mortar.

Advice! Competent use of antifreeze additives, due to an increase in the design strength of concrete, allows the use of lower grades of cement for the preparation of concrete mortar.

How to choose the right fluid

Today, there are hundreds of product options on the market for heating devices and consumables.

It is quite difficult to choose high-quality and safe antifreeze among them, because each brand uses all kinds of marketing tricks to attract the attention of the buyer to their product.In order not to fall for the fishing rods placed by advertisers, the homeowner needs to understand what requirements the liquid for heating boilers, poured into the circuit, must meet.

Before you buy heating fluid. the owner needs to find out some of the technical characteristics of the boilers, as well as familiarize himself with the list of antifreezes that are compatible with radiators and pipelines connected to the circuit. In addition, it is necessary to clarify the operating parameters of the heating system and the features of operation. Next, you should study the specific requirements of specialists for antifreeze that can make the heating system productive, stable and safe.

Pay attention to the following parameters:

- Operating temperature range;

- heat capacity;

- inertness of the chemical composition;

- the presence of anti-corrosion properties;

- no sediment in the liquid when heated;

- stability of chemical properties - density, viscosity, heat capacity;

- no toxic emissions during use.

Functional heating boilers liquid fuel, gas and solid fuel will last much longer if they are filled with antifreeze with a maximum operating temperature range, stable chemical composition and acceptable performance, guaranteeing the protection of heating devices from corrosion, scale and solid sediment. You can buy such a liquid only from a trusted manufacturer. But the use of the wrong antifreeze can lead to a number of undesirable effects.

Negative effects that may appear:

- the formation of foam inside the circuit when the coolant is heated;

- precipitation, which provokes overgrowing of pipes and clogging of the boiler heat exchanger;

- corrosion formation;

- the appearance of leaks;

- violation of the boiler tightness;

- the release of toxic substances.

The best non-freezing fluids of average cost

Our review also presents a rating of the best quality options at an average price. Domestic and imported cleaners were selected based on real feedback from experienced drivers. When choosing such products, users analyze the composition and freezing point.

Motul Vision Black Currant (-20 ° C)

Motul winter washer fluids are based on water and isopropanol. Aldehyde-free substances are used as part of a good anti-freeze solution. The products have an original aromatic composition with a black currant scent.

The balanced composition promotes thorough cleaning of the windshield surfaces. The products have been tested for compatibility with windshield surfaces and headlamps. The manufacturer provides the necessary certificates for the product.

Benefits:

- Excellent cleaning of glass from dirt, icing reagents and salt;

- The composition contains a special component that allows you to keep the product on the glass;

- Ergonomic packaging;

- Convenient to fill in the washer tank;

- Quality compliance with strict European standards.

Disadvantages:

- It thickens in severe frost.

Fin Tippa Premium (-20 ° C)

Non-freezing of a domestic manufacturer. The tests carried out show that the temperature of the onset of crystallization corresponds to minus 18 degrees, which almost corresponds to the data in the marking. This product is sold in soft packs.

Anti-freeze is suitable for maintaining cleanliness on polycarbonate surfaces, since it does not react with this material. The freezing process of a liquid can begin at a temperature of minus 27 degrees, which is a confirmation of good quality at a low price.

Benefits:

- There is no methanol in the composition;

- Safe for paintwork, rubber, plastic and metal car parts;

- No defective products in the series;

- Affordable price.

Disadvantages:

- The presence of an unpleasant odor.

The fluid is suitable for use in areas with relatively warm climates and light frosts.

Liqui Moly Antifrost Scheiben-Frostschutz (-25 ° C)

Manufactured from proven German components. Even athletes who take part in rally competitions choose such an anti-freeze. Designed not only for cleaning glasses, but also headlights from reagents, snow and salt contamination. Non-freezing does not harm the paintwork, and also has additional protective properties.

The composition does not contain harmful components such as methyl and ethyl alcohol. The package contains 4 liters of yellow liquid. A melon-scented fragrance is used as a flavoring agent.

Benefits:

- Safe for polycarbonate coatings;

- Nice smell;

- Protection of surfaces from cracking and abrasive wear;

- Compliance with European standards.

Disadvantages:

- The price does not suit everyone.

Users love that the composition does not leave marks and streaks after use, and also provides a smooth gliding of the wipers. Regular use of the product prevents clouding of the headlights.

The best gear oils

CoolStream (-25 ° C)

CoolStream is recognized as the best odorless anti-freeze for cars, practically has no pronounced aroma. The liquid is made on the basis of special components produced by the German company Wigo.

Purpose - use in windscreen washer tanks at temperatures up to minus 25 degrees. Non-freezing effectively removes deicing agents, dirt and snow. After application, there are no films or streaks. The fluid can also be used in headlight washers. With regular use, protects surfaces from clouding.

Benefits:

- Economical consumption of funds;

- Does not harm plastic coatings;

- The crystallization process starts at minus 26 degrees;

- Complete freezing does not occur;

- Harmless composition.

Disadvantages:

- Not everywhere you can buy.

Buyers report improved visibility when using this tool with systematic use. The frost resistance of the anti-freeze components also attracts.

Frozok Cold Star (-30 ° C)

It is included in the TOP of the best non-freezing agents at an average price and a liquid of the Frozok brand. The products have an optimal balance of quality characteristics.

The tool well cleans car windows from all kinds of contaminants. The composition contains only high-quality components, so that the use of the purifier does not harm health, even if the vapors are inhaled. To ensure the best effect, a complex of surfactants is used. It also contains isopropyl alcohol, dyes and flavors.

Benefits:

- Harmless components in the composition;

- Effective cleaning of surfaces;

- The liquid does not destroy polymer, paint and varnish and rubber coatings:

- The crystallization process begins at a temperature of minus 30 degrees.

Disadvantages:

- Not very convenient packaging.

The conducted surveys indicate that the maximum temperature declared by the manufacturer does not correspond to the real indicators. Non-freezing begins to thicken already at a temperature of minus 25-27 degrees.