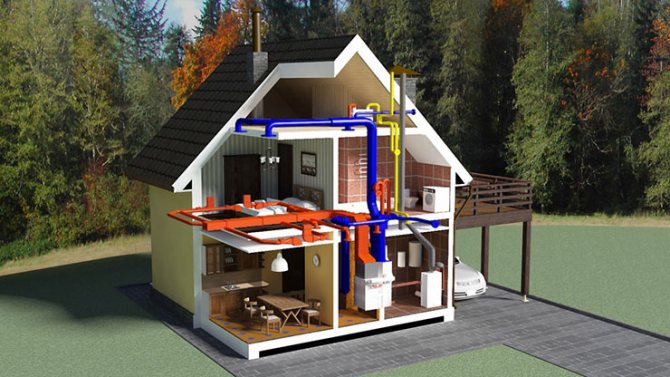

When creating a heating system in a house with your own hands, care should be taken to ensure that it is efficient, safe, economical, and easy to use. A dead-end heating system meets all these requirements. The installation scheme is quite simple, so there are no special problems during installation.

Types of heating systems

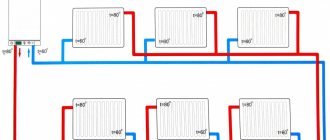

Heating in a home can be done in a variety of ways. For example, a radial (or manifold) method is a system in which each radiator is connected to a distribution manifold via a supply and return pipe. In some cases, radiators located in the same room are connected in pairs. This independent circuit makes it easy to disconnect one battery without stopping the entire line. Disconnection may be necessary in the event of a breakdown of any element or to save money.

When installing the beam system, pipes of the same diameter and approximately equal in length are used. This ensures a uniform pressure drop and each radiator consumes the same amount of coolant. Connecting pipes are often hidden in floors, walls, or behind a stretch ceiling, leaving only the radiators in sight. This makes the heating circuit more aesthetically pleasing.

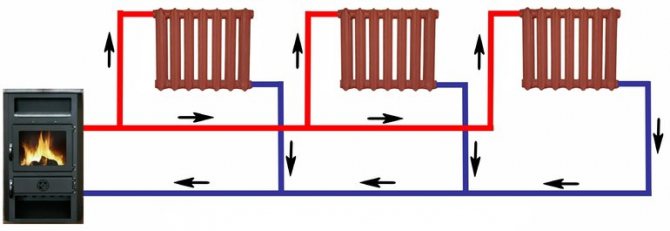

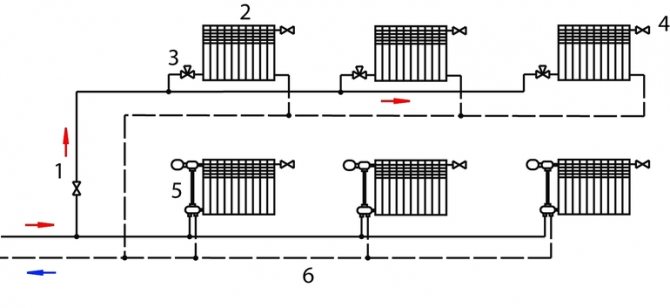

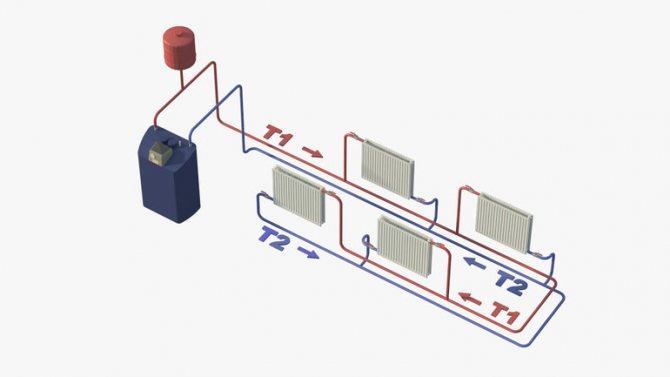

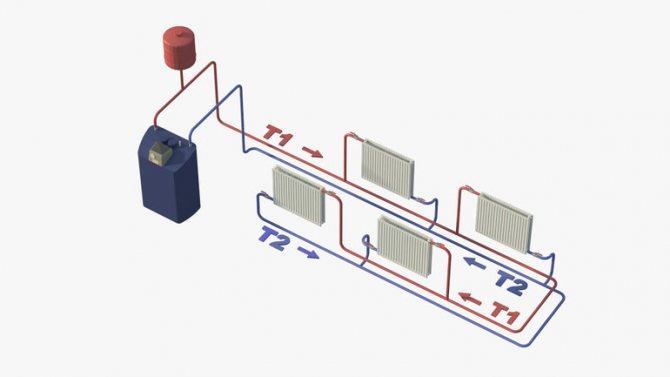

Passing routing is implemented differently. The supply pipeline in it runs in series from the boiler to the last radiator, and the return pipe connects the batteries from the first to the last and returns to the boiler. The coolant in both lines is transported in the same direction. The efficiency of such a heating scheme depends on correct pressure balancing. If it is more in one circulation ring than in others, the coolant will flow into it, and the pressure in the remaining batteries will significantly decrease.

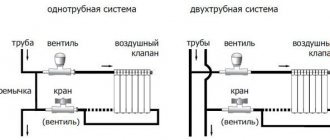

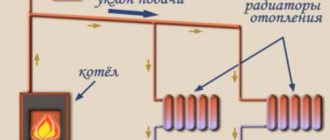

Another system - one-pipe - is the easiest to implement, but far from the most effective. It is devoid of water return pipes, the batteries are connected in series in it. Because of this, it is not possible to regulate the heating of individual radiators.

For such a wiring to function, a higher pressure is required. Its feature is vertical filling, which is carried out using an expansion tank installed in the attic. The installation of one-pipe heating in multi-storey buildings is unprofitable, since the heating of the batteries from the upper floor to the lower one is provided unevenly.

The most common is a dead-end heating scheme, which is simple and inexpensive to install, as well as characterized by long and stable operation. When creating heating in houses, it is chosen in 90% of cases.

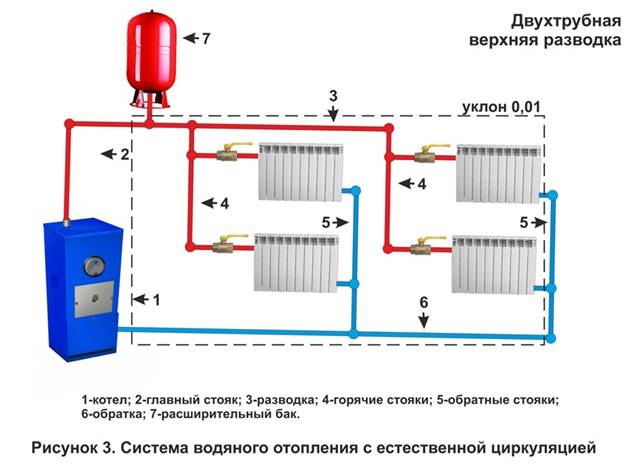

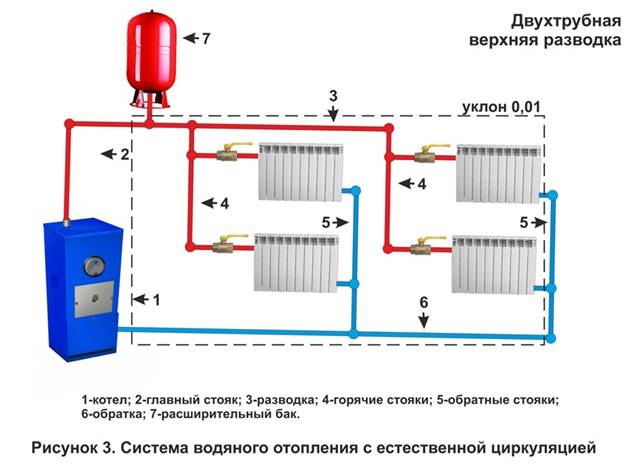

Varieties of a two-stream heating system

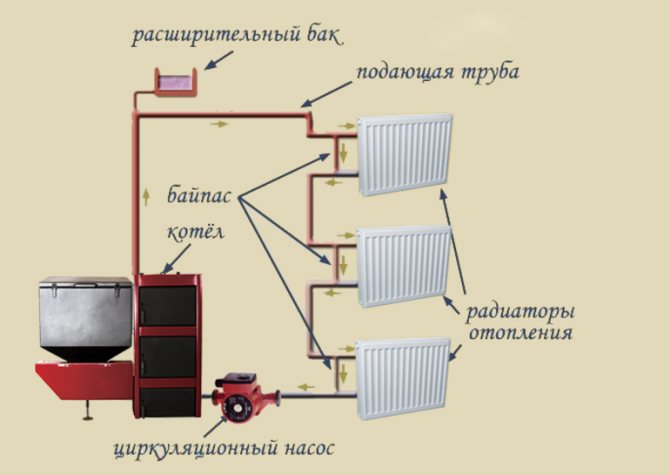

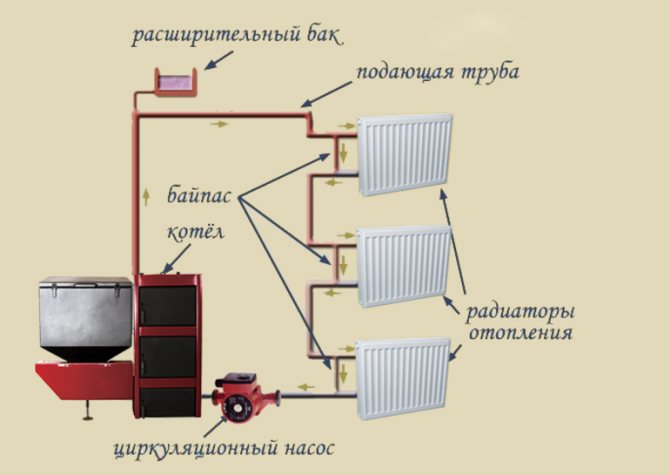

As noted above, there are two main types of two-pipe heating: gravitational (moving by gravity) and forced displacement. A feature of CO with natural circulation is the design of the pipeline and the absence of a circulation pump. Lines (supply, return) are made of large diameter pipes. From the boiler, the coolant rises along a vertical riser, after which, to create pressure in the system, it is lowered to the supply pipeline. The supply is mounted with a slope of 3-5 ° towards the direction of movement of the coolant. Two-pipe CO with natural circulation can differ in the way of wiring: with bottom and top wiring.

Correctly assembled gravitational CO is reliable, durable and works without additional energy sources. The disadvantages of this CO is a large inertia, a small radius of the contour (up to 30 m),

The principle of operation of CO with forced circulation differs from gravitational circulation, by the presence of a pump in it, which is responsible for the transportation of the coolant. When using a pump in CO, there is no need to install a pipeline with a slope.

Advice: despite the fact that the pump creates sufficient pressure for the movement of the coolant, most experts recommend building a CO with a slope in case of an emergency power outage.

There are closed and open heating circuits in two-pipe CO. The only difference is in the design of the expansion tank, which is atmospheric in an open heating system, and a membrane one in a closed one that does not communicate with the atmosphere.

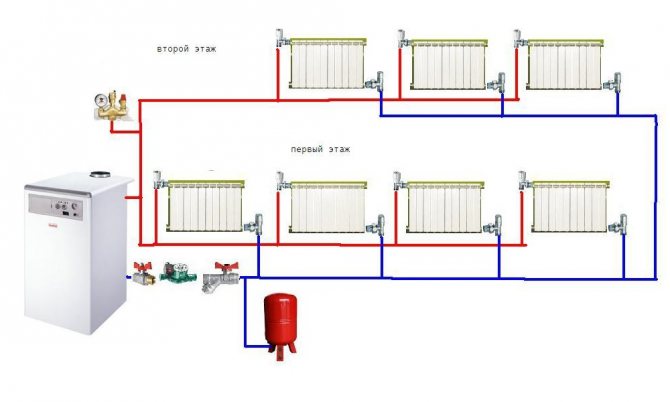

All heating systems differ in the way the batteries are connected. A vertical two-pipe heating system involves the connection of all heating equipment to vertical risers; in schemes with horizontal - to the main branches. The former are most often used in multi-storey construction. The two-pipe horizontal heating system is mainly used by private developers. Their advantage is the possibility of placing risers in non-residential premises or staircases. The disadvantage is the frequent airing of CO.

Dead-end wiring device

The main feature that distinguishes the dead-end system from others is that the length of the supply and return pipelines in it is not the same. Its use is suitable for those cases when it is necessary:

- Divide one dead end into several branches with a complex room configuration.

- Install an increased number of batteries on one shoulder, ensuring deep balance. With this balancing, the hydraulic resistance of the first radiators and short arms is increased.

- Hide pipes under the floor or under the headliner (for upper floors).

- Divide one dead end into several branches with a complex room configuration.

- Install an increased number of batteries on one shoulder, ensuring deep balance. With this balancing, the hydraulic resistance of the first radiators and short arms is increased.

- Hide pipes under the floor or under the headliner (for upper floors).

This method of organizing heating implies the presence of two pipeline circuits, due to which the coolant circulates in opposite directions. The water heated in the boiler goes to the radiators through the supply pipe. Having given off thermal energy, the cooled water moves along the return line towards the hot flow and goes back to the boiler, where it is reheated.

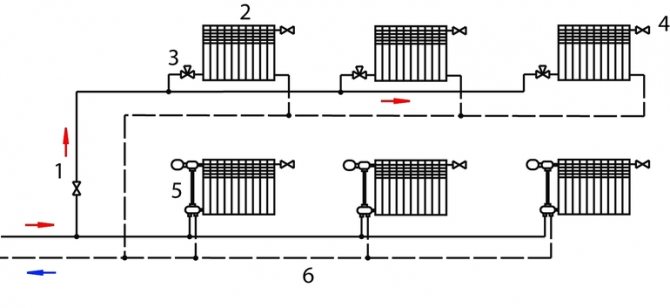

Radiators can be connected to the heating circuit in different ways. Depending on the installation method, a two-pipe dead-end heating system is:

- Vertical. The batteries are attached to the riser. The circulation rings closer to it are smaller than the others. For this reason, the movement of the coolant is uneven. The air in rooms located at a distance from the heat source warms up worse and longer. The vertical scheme is most often used to heat multi-storey buildings.

- Horizontal. Consists of pipelines of equal diameter, provides uniform heating of the entire area. The use of reinforced plastic pipes with sliding sleeves allows you to hide the contour in the floor screed without disturbing the design of the premises. An important advantage of the horizontal installation method is the ability to connect heated towel rails and additional lines for floor heating to a common circuit.

If secondary circulation rings are provided in a dead-end system, it must be equipped with a pump and a mixing circuit with a temperature sensor. Without this equipment, the additional line will affect the heating system as a whole.Natural circulation can only be used in rooms with a small area.

How to competently make heating for two wings. In a small house

A very significant advantage of a gravity water heating system is its independence from the availability of electricity. Gravity heating can also be created at a remote cottage on the basis of a non-volatile solid fuel boiler. The system is quiet and reliable, it will undoubtedly be in demand in the future.

We have gained extensive experience in the creation of gravity heating systems, because earlier all water heating was created on the principle of gravity. The system can be created according to the "typical folk scheme" and with your own hands.

The disadvantages are restrictions on power, heated area, the possibility of connecting additional circuits, with an increased cost of creation.

Gravity heating is more expensive, about 2 times compared to forced circulation systems, since it requires a large diameter of pipes and a special placement of the boiler. The difficulty in creating is that large-diameter pipes must have a common slope, which means that their position is fixed and therefore they often do not fit into the design of the room, cluttering the interior.

How a gravity system is calculated

You can order thermal and hydraulic calculations from specialists, in licensed organizations, but this will not be cheap. You can do these calculations approximately using known programs or manually.

In any case, the speed of fluid movement through the system is not high. The larger the inner diameters of the pipeline and radiators, as well as the boiler, the more liquid will pass through them, the more energy can be transferred.

It is important to answer the question - will there be enough energy to carry the coolant to heat a particular building? This is the essence of the calculations. But if there are no calculations, then you need to turn to the experience of creating such heating and insulation of buildings.

Energy loss and fluid movement

First, you need to determine the degree of building insulation, whether it meets the requirements of regulatory documents. If not, then the capacity of not only the gravity system may not be enough ... .. It is more expensive to heat a cold building, you need to insulate, and not increase the heating power.

After the building is insulated, you can turn to the experience of creating such systems, from which it is known that the usual maximum area of gravity heating is 150 square meters. on each floor of the building, while it is desirable to distribute the radiators for 2 arms on each floor, and the length of the supply pipeline of each arm should not exceed 20 meters.

A prerequisite for creating a system is the excess of the hot coolant (usually the center line of the radiators is taken) over the cold one (the center line of the boiler heat exchanger).

With a greater length of pipelines, a calculation would be desirable, or you need to put up that it is possible that in frost peaks the throughput of the system (speed of the coolant) may not be enough to make it hot in the building.

Let's consider why the performance of the gravity system will depend.

Features of the natural circulation heating system

The pressure in a gravity system will directly depend on the height of the water column with the difference in water density (temperature difference) and on the very difference in water density. The head formula is shown below.

The greater the difference between the supply and return temperatures, and the higher the water column with this difference, the faster the water circulates, the more heat will be transferred, the more reliable the system and the larger the area can be heated.

The fact is that water cools down most significantly in radiators, before them it is considered hot.After the radiators, cold water moves along the return line to the boiler heat exchanger, where it is heated. Therefore, the lower the heat exchanger is in relation to the radiators, the greater the pressure in the system.

In addition, the water cools down in the very pipe leaving the boiler, which means that the higher the hot pipeline is raised, and the longer and more heat it gives off, the more pressure will be.

However, this heat transfer will have a low efficiency for heating the house if the hot pipe is located under the ceiling. It is better if it is located along the floor of the heated massandra and is a heating device for it.

It is not correct to just make a high column of hot water, carrying the expansion tank above the roof. The greatest difference in height is needed, at which the temperature difference would occur, and this is easier to achieve by lowering the boiler.

A typical mistake when creating a gravity system for 2 floors is connecting radiators on both floors to the same risers. As a result, it will still be cold on the 1st floor, when it is already very hot on the 2nd floor. It is correct for the attic to provide a separate independent heating arm with its own control valve.

Feature of the system: - liquid in a gravity system usually cools down significantly, due to the low speed of its movement. The difference in supply and return temperatures is more often in the range of 25 - 30 degrees. The temperature regime, for example, is 75 degrees. exit from the boiler and 45 deg. return. Therefore, it is unacceptable to create a circuit with one pipeline with serial connection of radiators. Only passing and dead-end two-pipe wiring schemes are suitable.

How does the coolant (water) move

The design features of a gravity heating system follow from the above.

The boiler is located in a pit, in the basement, in any case, it is desirable that its heat exchanger be below the centerline of the radiators.

All pipelines are made with a common slope in the direction of fluid movement:

- water from the boiler rises along a vertical riser to the highest point;

- from the vertical hot riser always down to the entrance to the boiler;

- the difference in heights between the start and end point of the pipe is at least one percent, but the slope can change as you like along the length;

- it is always best to maintain the maximum slope.

What pipes to use

The diameter of the pipes for supply and return on one wing of the pipeline must be at least 32 mm, while the radiators can also be connected with pipes with an inner diameter of 20 mm. And for the riser and feed to the wing - not less than 50 mm. However, no one forbids increasing these diameters, which will only make the system more powerful.

Until now, ordinary steel pipes are considered the optimal variant. With large diameters, they become competitive with plastics. In addition, a large-diameter steel pipe is itself a heating device, due to the significant heat conductivity of the metal.

Boiler, radiators, pipeline

A special boiler (both gas and solid fuel) with its own small hydraulic resistance is used, designed for a gravity system.

Radiators with low hydraulic resistance are used, with a large diameter of internal holes - usually either cast iron or aluminum.

At the highest point of the pipeline, a valve is installed to bleed air (pressurized system with a closed expansion tank (hydraulic accumulator)). A safety group is built into the system at the boiler outlet - a pressure gauge and an emergency valve. Or an open-type expansion tank is located at the highest point.

The drain valve is located in the boiler area at the lowest point of the pipeline; a drain is made either to the sewer or to the container.

The selection of the boiler by power is carried out as usual - depending on the heat loss of the building, and radiators - on the heat loss of each room where they are installed.

In this case, they often use the rule - radiators in total are slightly more powerful than the boiler (it is taken into account that the passport temperature of the liquid is usually higher than the real one, i.e. radiators are purchased even more powerful by 20 - 35%), after which the total power of the radiators is distributed among the rooms.

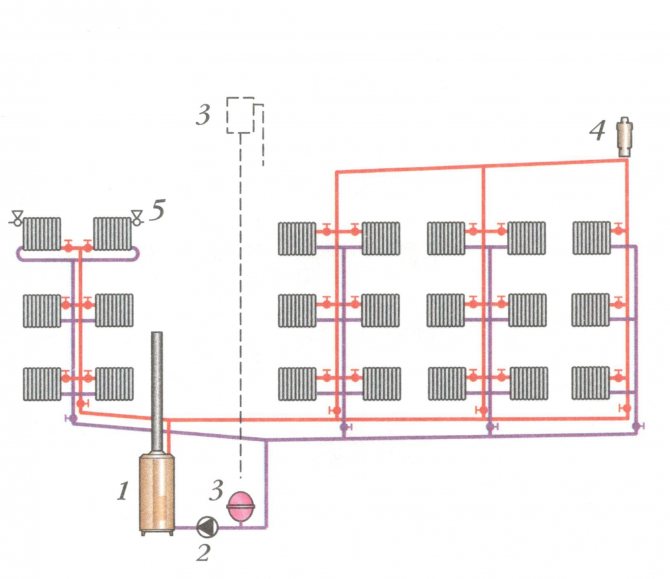

Gravity heating schemes for one wing

Typical water circuit from

us-okna.ru

Installation features

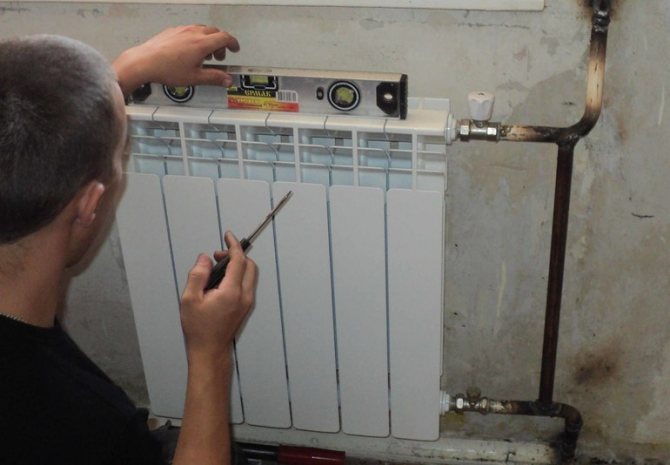

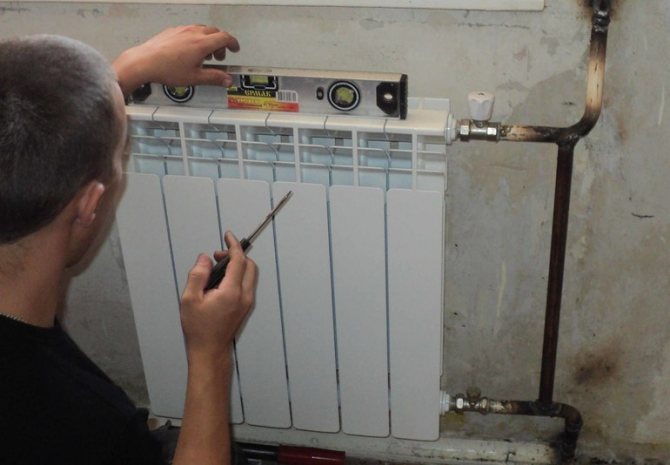

Features of the installation of the heating circuit depend on how the heat carrier will be supplied - top or bottom. Top routing is used in natural circulation applications. For maximum efficiency, the connecting pipes should be installed with a mandatory slope, and the expansion tank should be fixed at the top of the system. Radiators must be connected diagonally, equipping each of them with a Mayevsky crane or an air vent of another type.

In the case of bottom routing, both pipes are mounted above the floor surface, the supply pipe is located above the return pipe. A closed membrane-type expansion tank and a circulation pump are indispensable elements of the heating circuit and are located inside it. Usually they are implanted into the return pipe at a short distance from the inlet of the heat source. The lower wiring is hidden in the floor screed or masked by a small box behind a wide baseboard.

A significant disadvantage of such a system is the need to connect it to the electrical network. In the absence of electricity, the built-in pump will not work. To solve the problem, it is necessary to purchase an electricity generator.

In order for double-circuit heating of a dead-end type to meet the requirements of efficiency and safety, certain rules must be observed during its installation and commissioning.

When calculating the throughput and power of the circuits, it is necessary to take into account the inner diameter of the pipes used.

The connection should be made in accordance with the diagram. You need to be well versed in the notation that it contains. To avoid errors during start-up, it is important to know which icon indicates the internal size of the pipeline, and which is the external one.

It is also important to distinguish between modifications of radiator thermostats. Appliances designed for gravity systems have a capacity greater than those suitable for forced circulation.

For the pipeline through which water will flow from the boiler to the radiators, pipes of different diameters should be selected. In the direction from the first to the last, they should gradually decrease. Their slope with forced circulation should be 2-3 mm per 1 meter of length, with natural - 5 mm per 1 meter.

Vertical and horizontal system diagrams

Two-pipe heat supply structures are of two types:

- Vertical

... It is usually used in multi-storey buildings. A two-pipe vertical heating system requires the use of a large number of pipe products, but the connection of radiators on each of the floors can be easily performed. Its main advantage lies in the automatic removal of air - it rushes to the top and there it goes out through the drain valve or expansion tank. - Horizontal

... This system has found application in one-story, maximum two-story buildings. To bleed the air out of it, the so-called Mayevsky cranes are mounted on the batteries.

Shoulder connection

One of the varieties of dead-end mains is the shoulder heating system. The scheme of its implementation involves the lateral connection of radiators. The supply pipe is connected to the upper branch pipe, the return pipe to the lower one, both are located on the same side of the battery.In this case, the coolant can serve the entire system at the same time, and each arm can function separately. As a result, it becomes possible to regulate the temperature in each specific room.

The shoulder connection shows good efficiency only when using batteries with a small number of sections. Large radiators will not fully warm up. If there is no other option for installing long heaters, the water flow extension will help solve the problem.

This layout allows fewer pipes to be used than other layouts and is convenient and easy to install. It is easy to organize a bypass between the lines for the installation of control equipment.

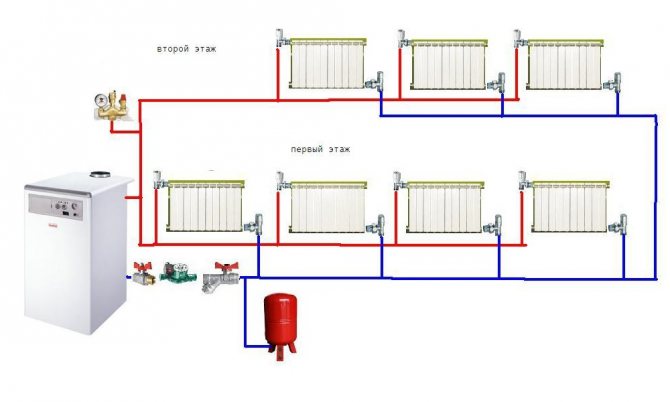

Most often, the shoulder system is used to heat multi-storey buildings. To achieve maximum effect, a certain number of batteries are placed on each floor. For example, in a two-story house, the common heating main is divided in such a way that there are two dead-end arms on the first and second floors. On the first one, 9 radiators are installed (5 on the right shoulder, 4 on the left). At the top, 3 batteries are mounted (2 on the right and 1 on the left). Tees are used to divide the general contour into the shoulders. They are located in the supply and return pipelines.

Sometimes a dead-end heating system contains only one pipe circuit. With such a scheme, the coolant sequentially passes from the boiler to all heating devices in the forward direction, and is discharged in the opposite direction. To achieve uniform heating, forced transportation of the coolant is organized and the number of sections of distant radiators increases.

One highway pros and cons

The single-pipe heating system of a two-storey house - the "Leningradka" scheme - consists of one main line laid horizontally along the perimeter of the building, above the floor of each floor. Heating devices are connected to the main line with 2 ends, alternately. This type of heating network is well suited for houses where two floors occupy a small area (up to 80 m² each). There are reasons for this:

- The coolant entering each subsequent radiator has an ever lower temperature due to the addition of chilled water from the previous batteries. Therefore, the length of the ring is limited to 4-5 heaters.

- In order to heat well the second floor and the rooms where the last batteries are located, their heat transfer should be increased by adding sections.

- The horizontal network of a two-story house with natural circulation should be performed with a large slope (up to 1 cm per 1 m running pipe). The boiler is installed in a recess, and an expansion tank is located in the attic, which is in communication with the atmosphere.

The Leningrad distribution of heating a two-story house with forced supply of a coolant works much more stable and efficiently than by gravity. For natural circulation in a private house, it is better to make vertical risers piercing the ceilings and distributing heat to the radiators near the windows. The supply of water to the risers is carried out from a horizontal collector laid in the attic, the return to the boiler is carried out along the same line running above the floor of the 1st floor.

As in the first case, an open expansion tank is placed in the attic of a 2-storey cottage, and the lines are laid with a slope. If the heating system is closed, then the slopes are required minimum (3 mm per linear meter of the pipe), and the membrane tank is placed in the boiler room.

Single-pipe heating wiring of a two-story house, although inexpensive to install, is difficult in calculation and execution.

And not every owner will like it when large-diameter pipelines pass through part of the premises, they have to be hidden under boxes.

Advantages and disadvantages

The prevalence of a dead-end heating scheme is due to certain advantages that it provides.With its help, you can organize a comfortable temperature regime in houses with a large area. The shoulder connection makes it possible to set different temperatures in separate rooms.

The creation of a two-pipe dead-end wiring does not imply any special difficulties, therefore it can be carried out without the involvement of expensive specialists. To install it yourself, you will need:

- Install the boiler, which will act as the main source of heat.

- Bring the supply pipe to the boiler by connecting it to the expansion vessel. The tank must have a signal connection and a device for draining the liquid.

- Cut the radiator taps into the upper line extending from the tank.

- Lay a pipe line for the cold water return. It also needs to provide for the connection points for the batteries.

- Connect the return circuit to the boiler.

- Fix the heating devices in the designated places, equipping them with thermostats and drain valves.

Upon completion of the installation work, it remains only to carry out a pressure test. The system will then be ready for use.

The main disadvantage of such heating is the need to use elongated pipelines, shaped joints, valves and fasteners. In comparison with a single-circuit, the installation of a double-circuit will cost more. However, the funds invested at the first stage will be justified as the system is used.

In contact with

Two-pipe system for a two-story house

Two-pipe heating of a two-story house is perfect for a country house in which it is necessary to heat not one, but several floors. It is enough to supplement the system with several devices (circulation pump, expansion tank, heating control valves) so that it helps to create the most cozy, comfortable atmosphere in the house. In addition, the creation of this system is a fairly easy process that does not require the involvement of outside specialists. A do-it-yourself two-pipe heating system is a great way to save a fairly large amount.

The two-pipe heating system of a multi-storey building has an important advantage - a large number of auxiliary elements can be connected to it. Most often, the "warm floor" system and heated towel rails are connected to it.

It is important that these elements can be connected both directly during the installation of the entire system, and later - after it has been functioning for a certain time.

Most often, the "warm floor" system and heated towel rails are connected to it.

It is important that these elements can be connected both directly during the installation of the entire system, and later - after it has been functioning for a certain time.

It should be understood that the most suitable moment for installing a heating system is the period of building a house. That is, in the process of building a building, it is necessary to create a plan for the most efficient heating system and immediately implement double-circuit heating of a private house.

A two-pipe heating system is a proven and effective way to heat a private house. Such a system allows you to regulate the heating of any room without changing the temperature in the rest of the house. The two-pipe heating system can be used in houses of any number of storeys. The main feature of the two-pipe system is the separation of the direct and return coolant circuit. Heated water from the boiler enters the system through the supply, the so-called pipe, from which the coolant is disassembled into radiators, coils, floor heating system. After passing through them, the cooled liquid is discharged using another pipe - a return one.

Two-pipe heating system of a private house

The two-pipe system has several advantages:

- Ease of regulating the flow of coolant to any of the radiators;

- The ability to use in a house of any number of storeys;

- The possibility of installing systems of considerable length.

Among the shortcomings, it is worth noting the doubled number of pipes compared to a single-pipe system. which makes the installation of the system more expensive and reduces its aesthetics - pipes for direct flow of water should be located above the level of radiators, usually they are laid under the ceiling or at the level of the window sill.

Types of heating wiring diagrams

The burden of providing heat in private housing construction falls, apart from fireplaces and stoves, on heating boilers. They are single- and double-circuit. Single-circuit heating devices are used only for heating the house, and boilers with two circuits additionally provide hot water.

When creating a heating system, the type of boiler equipment does not matter. To transfer the coolant and transfer heat energy to the premises, two options are used: one- or two-pipe. This is taken into account even when thinking over a building project.

Output

In addition to the above methods of routing the main pipes that supply the coolant to the batteries and deliver the cooled water back to the boiler, the connection diagram of heating radiators itself (bottom, side, diagonal) is no less important. Correct connection not only increases the rate of circulation of the coolant and increases the efficiency of the batteries, but also prevents the occurrence of air congestion.

For more details, see the video in this material.

Did you like the article? Subscribe to our channel Yandex.Zen