Underfloor heating options for tiles

But, despite such an ancient and urgent need, there are not so many fundamentally different demanded heating systems (which theoretically can be filled with a solution):

- Electrical. Foil and cable materials for creating a heating circuit are available both in a prepared form (a complete set is meant), and in the form of separate elements.

- Air. The oldest and most controversial option.

- Water. The most cost-effective way to heat floors in multi-apartment buildings.

Features of screed reinforcement

To properly install the heating cables, make sure that the floor does not crack during drying. When cracks form, so-called cold zones appear, due to which heat is unevenly distributed over the base.

At the moment, there are several options for reinforcement:

- Additives. When preparing a solution, one should not forget about fiber - a special additive based on polypropylene. Fiber improves the technical characteristics of the screed: resistance to spreading, cracking and various damage. At the same time, the material increases the indicators of frost resistance and fire resistance;

- Reinforcing mesh. A special plastic mesh is found in various system installation recommendations. Manufacturers complete them with special stands that allow the net to be raised above the floor.

When arranging a warm floor in large rooms, there is a possibility of cracking due to the fact that compensation pockets were not provided. The procedure necessarily requires the use of a compensating damper tape.

Pros and cons of available floor heating systems

The advantages, as well as the disadvantages of underfloor heating, are not decisive when choosing them. After all, this is not the main, but only an auxiliary system.

Therefore, first of all, one should take into account the characteristics of the room (humidity, the main heating circuit, the expected load on the floor, furnishings, frequency of residence). On the scale of an individual building, the availability of local electricity, gas and water supplies is of considerable importance for prioritization.

Electric

Heating electrical equipment in a screed or a layer of tile adhesive has an impressive list of advantages over other systems.

- quick achievement of the desired effect;

- the ability to adjust temperature and time modes;

- parallel connection of heating elements ensures the operability of the system, even if some sections of the circuit cease to function;

- ease of installation and the possibility of equipping a unit with protective equipment (shield with RCD).

Of the significant disadvantages of this method, only significant energy consumption and a relatively short period of operation are known.

Water

In the case of the underfloor heating water system, the low cost, coupled with the outstanding efficiency, is very often forced to turn a blind eye to:

- the probability of freezing of the coolant in the pipes (private sector and balconies of high-rise buildings);

- possible problems during periodic testing of the centralized system (typical multi-apartment buildings);

- the need to develop a special project for the apartment and obtain permission to perform work from local authorities.

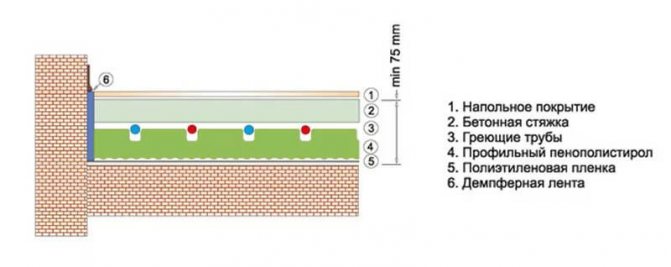

The procedure for installing pipes on polystyrene mats

It is easy to make a warm water floor without a screed with your own hands. First, the rough surface is cleaned of construction debris. The base must be leveled if necessary.

A plastic wrap is laid on the prepared surface. Its thickness must be at least 200 microns. Polyethylene waterproofing sheets are laid with an overlap (10-15 cm). The joints must be firmly fastened with tape.

A damper tape is laid out around the perimeter of the room. It compensates for possible expansion of the system during heating. Then the polystyrene mats are laid out. If their thickness is small, the joints must be greased with glue. Metal slats are laid out between the ledges. Pipes are put into their grooves. On top of them, another layer of waterproofing is laid out.

Then you need to lay out 2 layers of GVL sheets. The joints of the first layer should not intersect with the previous layer. The thickness of this flooring should be 1 cm. The joints should be coated with PVA glue. The layers must be fastened with self-tapping screws. It is important not to damage the pipes during this process.

After that, the topcoat is mounted. A special underlay must be placed under the laminate. When installing tiles, you should choose the right adhesive. It should be acrylic based.

What kind of underfloor heating works best for tiles? The main thing is not to miss anything

Again, the final choice of the underfloor heating design for tiles will be optimal only with a correct analysis of the existing conditions.

For example, a water heat-insulated floor in a country house that is empty for most of the winter period is unacceptable, even if there is an autonomous water supply system. While the heating mats are in a layer of tile adhesive, under the same conditions, the floor will warm up quickly.

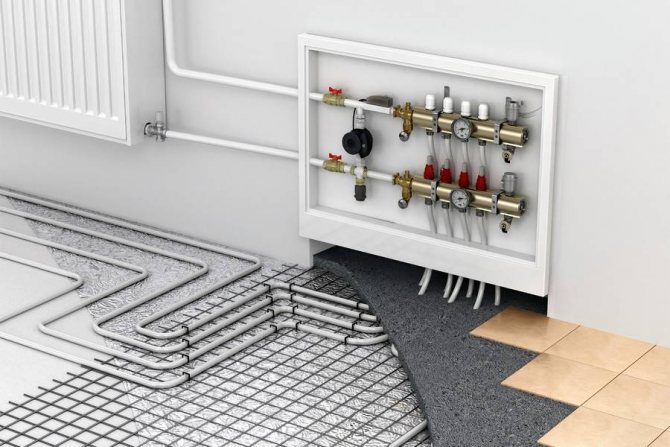

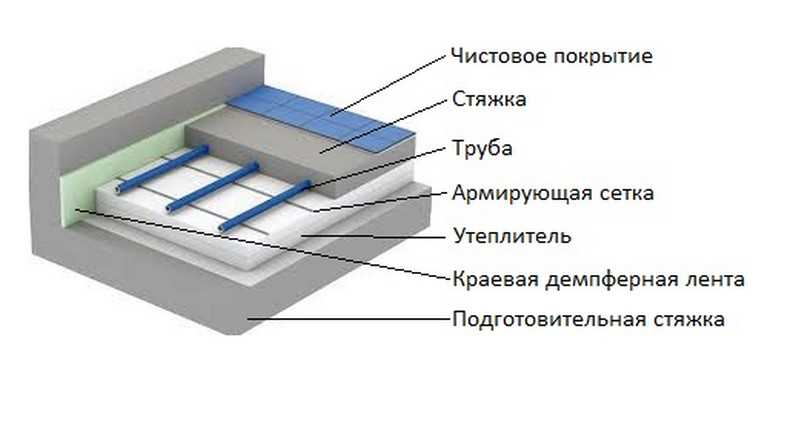

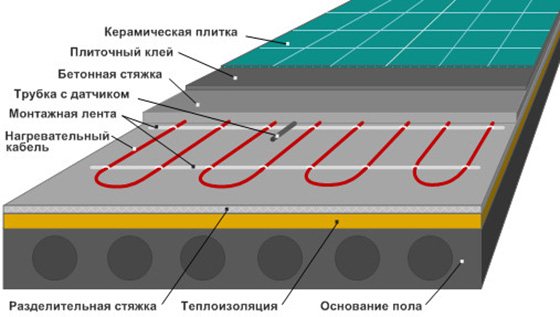

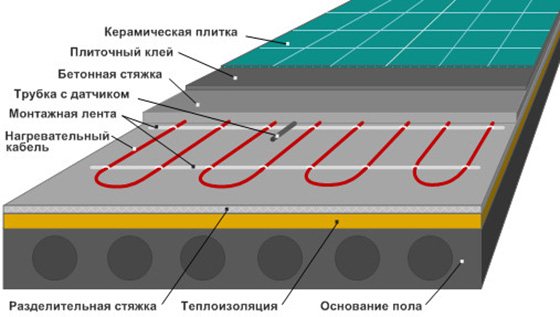

Floor Heating Pie

A private house or a typical high-rise building is equally demanding in the preparation of the base (the so-called sub-floor) for any heating system. With a slight difference, depending on the principle of operation, the multilayer structure of a warm floor looks like this:

1. Solid foundation... Cement-containing options are prioritized.

2. Waterproofing... The functional component is important here.

3. Thermal insulation... Ignoring this point significantly reduces the efficiency of energy use. After all, even a damper tape for a screed (between the wall and the screed) will significantly reduce heat loss.

4. Metal grid... The useful range includes a simplified installation of the coolant (pipes) and additional structural strength - due to the reinforcement of the screed. It is best to lay a fine mesh on the reinforcement so that it is in the depth of the screed, and not along the bottom edge.

5. Foil or other rolled metallized reflector on expanded polystyrene... The expediency of use has not been proven even in bulk (dry screed) floors. Having considered the experimental options with and without a reflector, it can be argued:

- in one case, the temperature difference on the surface of the cake does not go beyond one degree Celsius

- in the other, the floor retains heat longer if the base of the screed is effectively heated under the coolant

- the profitability of the reflector is a factor that does not stand up to scrutiny. The foil dissolves under the influence of the self-leveling solution, and the metallized polymer under the weight of the screed will flatten and lose its declared properties.

6. Pipe system... For "kulibins" suitable metal-plastic, less often copper and steel corrugated pipes. For all other citizens, calculations and selection of materials are carried out by the manufacturer of the system.

7. Screed... Mandatory minimum layer of 30 mm above the pipes.

8. Decorative finishing.

Video - which warm floor is better to lay under quartz-vinyl tiles:

Screed methods

The classic version - a composition of cement and sand is used, but other types of screed are excellent for a warm floor, where each has its own characteristics:

- Wet screed. For mixing, cement, plasticizer and sand are used.The addition of fiberglass is required, which will protect the surface from possible cracks and deformations during curing. The main advantage of the solution is that it is easy to make with your own hands, and the components have an affordable cost. But the method also has weaknesses - the floor will dry out within 28 days, cracks may appear, and the base cannot be made perfectly even;

- Semi-dry screed. During the manufacturing process, water is added to the mixture. It is best to take a ready-made composition, but if you wish, you can make it yourself. The key advantage is that when the floor dries, there are no cracks left on it and it does not need to be leveled;

- Dry screed. Each manufacturer of the composition has its own recipe, but, as a rule, the use of fine perlite or quartz sand, fine-grained slag, and so on is relevant. The method has the following positive aspects: it is quickly mounted and dries up. Subsequent work is carried out 12 hours after installation.

When equipping the tie, you should be extremely careful so as not to spoil the laid cables. If you accidentally break the protective insulation or conductive core at the time of pouring, the system simply may not work.

Electrically dependent contours

Infrared floor heating

Electric underfloor heating systems are widely known, but the assumption of their future use in a monolithic layer forces to abandon the majority of infrared. Film infrared components are simply not suitable for functioning in a screed, they do not interact well with cement mortar. Their main purpose is directly under the decorative coating (the same laminate).

In theory, it would be possible to use a film infrared system in a dry screed, with GVL flooring (paired gypsum fiber boards over the poured and compacted material) and tiles as a decorative surface. But the thermal conductivity of a thick layer of expanded clay chips is so insignificant that the option with an IR system becomes frankly expensive.

Video - which electric underfloor heating is better depending on the situation:

The most acceptable option among the newfangled wave emitters is a system of carbon rods. But this case is more like an experimental one than a proven and durable one. The reason for this is the unreliability of the connection of the heating elements with the conductive cable (the manufacturer specifies the warranty period for this part of the system in a separate paragraph). By including special plasticizers in the self-leveling mixture (a prerequisite for installing a warm floor in a solution), it is possible to somewhat reduce the load on the system, but the effect of a cement-containing solution is not difficult to predict.

Cable systems

Cable underfloor heating is certainly the most suitable option for those who do not want to face frozen pipes under the tiles, for example, in the country. The simplicity of the device and low maintenance requirements make the heating cable a good alternative to the water system.

Heating cables are widely represented in the domestic market.

- Resistive imply a constant load on the heating conductor, along the entire length of the circuit. Single and double-core, with different design features, work according to the same principle. They differ only in the way the system is connected to the power supply. What affects the footage of the cable used.

- Self-adjustingdue to their complex design, they are capable of independent change in the load on individual sections, depending on the intensity of the impact of external factors.

Heating mats - in fact, these are the same thermal cables, only already fixed on a polymer mesh.Such rolls are convenient to install, depending on the characteristics of the heat-emitting cable, they can be laid both in the screed and in the layer of tile adhesive.

If it is necessary to increase the heated area, the supporting mesh can be cut and the wire can be turned a little. True, unhealthy savings in this case can lead to insufficiently effective, partial heating (the so-called "heat zebra") of the floor surface.

Video - what kind of underfloor heating is better to mount with your own hands:

For kitchen, bathroom or living room floors, there is no restriction on the use of a cable floor. Various control units provide the desired effect.

The only thing is that, based on the general rules for organizing power supply, it is necessary to focus on the presence of a residual current device (RCD). And a separate one for each room.

Outcomes

Floor heating is good in cases where a heavy screed cannot be laid due to the low bearing capacity of the floors, in wooden or old houses, or low ceilings do not allow it. More popular are wooden warm water floors, less often polystyrene systems are used. But in any case, this method of floor heating can only be used as a means to increase comfort: heat output does not exceed 60 W / m2, which in most areas does not allow using these systems as the main heating.

teplowood.ru

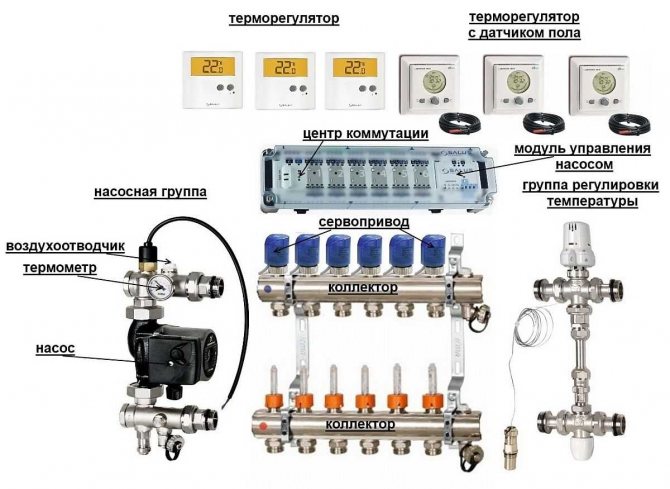

Liquid heat transfer systems

The water-heated floor in the screed enjoys well-deserved popularity, based on many factors. Among others, durability, which in turn, affects the formation of a low total cost of heating in general. Considering the performance of the system and the availability of materials, the possibility of using it in unheated loggias, this option has become widespread.

Purchased

If the planned additional heating system is installed by specialists representing the interests of the manufacturing company, then the customer's interest is obvious in terms of timing and cost.

What the pipes will be connected to, or what coolants are involved in a particular case, is absolutely not important.

The interests of normal manufacturers do not include work to restore the lost performance of the heating system. A lifetime warranty, with periodic maintenance and mandatory clarification of operating rules - this is what the customer should count on.

Homemade

When self-designing a water-heated floor, it should be remembered that the two installation options "snail" and "snake" have different technical features. For example, under the same conditions, the first option is characterized by a smaller footage of pipes than the second.

"Snail" provides uniform heating; pipes laid with a "snake" lose their temperature somewhat, as they move away from the main circuit. The design of the "snail" has less resistance, which explains the temperature difference. By the way, this feature also explains the different pressure changes in the general heating circuit.

Based on the fact that periodic maintenance of a warm floor laid under a tile is impossible, initially you should focus on durable materials. In the case of installing a home-made system, the best choice would be metal-plastic and stainless steel corrugated pipes. Polyethylene and copper pipes are used less often, since unwanted complications are possible due to contact with the cement mixture.

Given the correct calculation, for a system with its own boiler, you can avoid major troubles during operation. And by mounting the water circuit "by eye", in the conditions of an apartment building, it is quite possible to provide yourself with a number of troubles.

Of course, the bypass (a jumper between the supply and return) will serve as a kind of safety guard against problems with neighbors at the entrance, but in any case, raising the floors and redoing the circuit again is a below average pleasure.

User reviews

A warm water floor without a screed, according to reviews, is installed quickly and without any problems. At the same time, the owners of private houses claim that the simplest type of installation is the use of modular wooden or polystyrene boards. Such materials can be purchased at specialized stores.

However, if you want to save money on the family budget, you can choose the rack and pinion method for installing pipes. In this case, you need to have enough free time. This is a more complex and time consuming installation process.

If you carry out all the actions correctly, you can get a quality system. It will be reliable and durable. Heating of premises in this case will be uniform and less costly than when using batteries. It is better to entrust the connection of pipes to the boiler to a professional. The safety of the heating system depends on this.

Having considered how the installation of a warm water floor without a screed is carried out, you can mount the system yourself.

fb.ru

Dedicated to experimenters

The idea of creating a warm floor with an air heating system is being promoted solely on the enthusiasm of amateurs. In theory, this is a system of open air ducts that connect the room and the thermal chamber located below, which heats the air coming from the street.

The design, which, in principle, does not require the replacement of coolants, could become popular with the owners of suburban buildings (if you want the floors with ceramic tiles, or granite slabs). But the difficulties in designing a system for an already built room do not allow this method to gain mass acceptance.