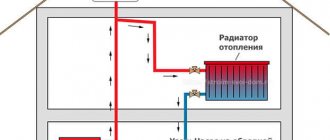

If the water heating system was assembled independently, then there is a possibility of referring to the water circuit diagram. In such a situation, it is easiest to find a leak and localize the breakage point. To identify a malfunction, improvised means are also suitable, it is only important to shut off the coolant supply in advance and completely free the heating circuits from water. This measure is especially relevant if you are not sure which area has become the source of the trouble.

Leak remediation materials

The selection of materials for repairing the damaged area is carried out depending on the location of the leak and the temperature of the coolant. All means must withstand both physical and thermal stress. The following materials are used for repairs:

- rubber elastic bandage - used to seal curved areas or locations of fittings. The bandage by itself is not able to withstand the high pressure of water in the pipes, therefore, after screwing it in, it is necessary to screw the reinforcement on top or tighten the clamp;

- repair tape - suitable for sealing pipes, withstands pressure up to 35 atmospheres, temperature range from -70 to +370 degrees. The service life of the material is 50 years;

- clamps - are metal, which brackets withstand pressure up to 70 atmospheres and temperatures over 100 degrees. Clamps are designed for standard pipe diameters, they are used only on straight sections of the pipeline;

- two-component compounds - epoxy resin or cold welding. They are good at eliminating leaks in curved areas or in hard-to-reach places. Epoxy is best used in combination with strapping materials (cloth, bandage, etc.);

- light-curing plastic - a kit that includes liquid plastic and an ultraviolet lamp. Under its radiation, the material polymerizes and hardens. Works in the temperature range -40 - +150 degrees.

All these materials are suitable for overhaul of depressurization. If there is nothing suitable at hand, then wooden chopiks, cement coating, various adhesives are suitable as temporary devices.

Where do the leaks in the heating system come from?

The most common cause of leaks in metal pipes is corrosion. Steel, even treated with special coatings, rusts. Only the speed of the process differs. It depends on the operating conditions of each specific system.

The metal is affected by temperature extremes, moisture, hydraulic shocks. Impurities in the coolant can contain aggressive chemicals, abrasives that accelerate corrosion. The places where the elements of the system rust the fastest begin to leak. As a rule, these are connections, joints, seams.

Polymer materials do not rust, but this does not mean that they do not leak. Sooner or later, metal-plastic pipes may also leak. Most often, this happens if they are incorrectly selected. Some homeowners save money and buy cold water pipes. This is a big mistake, because leads to deformations, breaks in the system.

Often homeowners suffer when they choose low-quality products for heating. Cheap polymer pipes swell, burst, and flow. If this happens, you have to change the damaged sections. Imaginary savings turn into additional costs of money, effort and nerves.

The least susceptible to the risk of leaks are metal-plastic pipes, which are specially designed for heating systems. They are designed for high temperature of the coolant, do not deform and can last for several decades.

How to find water leaks underground or in a screed

If pipes have flowed underground, in walls or in the underfloor heating circuit, it is very difficult to do without the help of specialists. To detect such breakthroughs, devices are used:

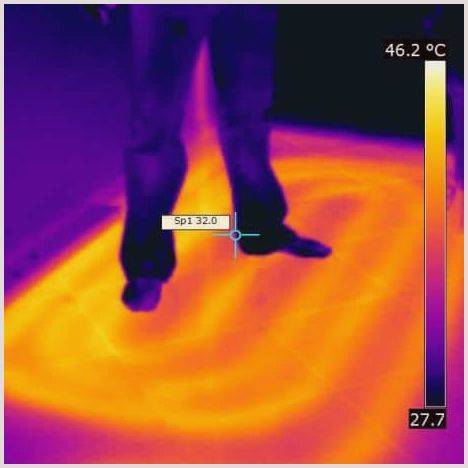

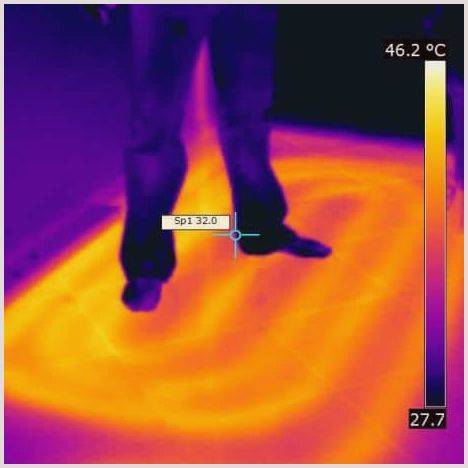

Thermal imagers. The temperature of the surface under which the heating system is hidden is high enough to use the thermal imager. If the pipes are shallow, then this device will be the easiest way to find a leak. Problems can arise only in the case of a large depth of pipes or a low temperature of the coolant.

Moisture meters. This is a less effective way to find leaks than using thermal imagers, but a moisture meter can still be useful in detecting leaking pipes in walls or in warm floors. It is not used to search for underground utilities.

Acoustic devices. Sometimes a leak can be detected using a special device that picks up sounds. By its construction, it resembles a phonendoscope. However, the benefits from it are far from always.

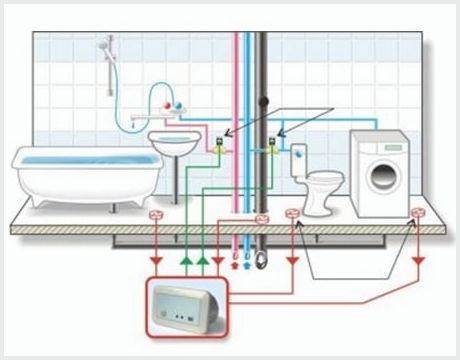

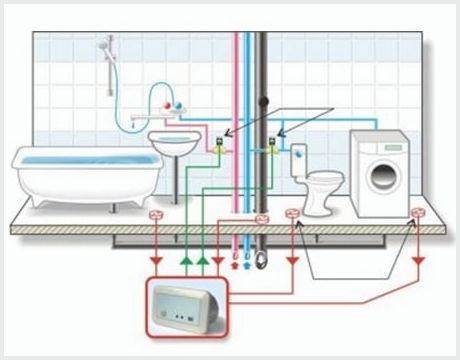

System "Neptune" - instant detection of leaks

There are special systems that instantly determine the locations of leaks in heating and water supply systems. Their installation will have to spend time and money, but the costs pay off with interest: thanks to such devices, you can avoid problems in case of serious accidents. The most popular is the domestic system "Neptune". It is cheaper than imported counterparts and has proven itself well.

"Neptune" not only instantly finds a leak, but also blocks the water supply. The system consists of a control unit, sensors and valves. It is fully automated, and once installed, the owner of the premises will no longer have to worry about breakouts. As soon as the sensor sends a signal of a leak to the main unit, the valves are activated and shut off the water. Then the owner can deal with the problem without thinking about flooding his neighbors or his own house.

How to find a leak in the underfloor heating circuit yourself

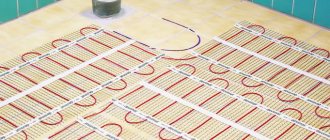

Floor leaks can be a real problem. If the cover can be easily removed, it makes it very easy to solve. Difficulties arise if the contour is located under the screed. Occasionally the breakout point will reveal a damp spot on the floor, but this only happens in cases of serious damage. When the pipe just leaks a little, it's harder to find the problem. Let's consider how to act in such a situation.

You can try to find the leak yourself, but first you have to determine where the pipes are generally located. To do this, turn on the warm floor for maximum heating, and the screed above it is abundantly moistened with water. Moisture evaporates the fastest above the loops. This will show in the lighter and drier areas of the floor.

The brightened areas are outlined with a pencil, at the same time keeping track of how fast they dry out. Where the wet spot remains the longest, look for a pipe break. This method does not always work 100%. It always shows the location of the pipes, but the faulty section is visible if the leak is strong. To find and eliminate the leak, you will have to break the screed over the warm floor.

Benefits of turning to thermal imagers

They give more accurate results. The equipment will allow you to find places with a locally high temperature, that is, zones where the coolant penetrates into the screed. Here, almost all types of modern thermal imagers can be used with equal efficiency, but with the help of models whose matrix exceeds 160x120 pixels, you can get a full-fledged high-quality image of a defect, as well as a layout of communications.

On the screen of the thermal imager, the leak will look like a blurry spot; against the background of the general picture, the warm area will stand out noticeably. The equipment allows not only to draw up a plan for the location of branches, but also to optimize their work, to find and eliminate air jams in a timely manner.

If the concrete screed is finished with glossy tiles, it will be problematic to detect a leak with a thermal imager: the cladding has a different emissivity, in which case the heat will be reflected as from a mirror. When the thickness of the screed exceeds 12 cm, it is also difficult to accurately localize the problem area: communications are reflected on the screen as a large single spot - such a floor heats up evenly.

Leakage to be done immediately

What to do immediately after detecting a leak in the heating system depends on two factors: the type of dwelling and the type of the leak itself. If the heating is leaking in a private house, then the owner can repair even a serious breakdown himself. But in the apartment you have to act more accurately and quickly. First, you can flood your neighbors from below. Secondly, you have to turn off the heating riser, which means that all apartments will cool down.

If the leak is small (the pipe or radiator only gets a little wet), you can try to eliminate it yourself with the help of improvised means. If it flows strongly, then it is necessary to immediately shut off the coolant supply and call the emergency team. Until the heating is turned off, you need to throw a blanket over the radiator or pipe so that no one gets burned from hot water.

In some apartments, special valves or taps are installed, with which you can shut off the coolant supply. However, most often such cranes are installed on the entire staircase and located in basements. It is necessary to go down there and block the riser on the main pipe. After that, you should immediately start to eliminate the leak.

Causes of leaks

Among the reasons why a coolant leak occurs (any, and not only water), there are three main ones:

1 Corrosion; 2 Violations in the technology of system installation; 3 Illiterate exploitation.

Corrosion of a metal is caused by two types of chemical reactions: oxidation under the influence of oxygen and an electrochemical reaction that occurs when metals dock with different numbers of negative and positive ions in the atomic structure of a substance.

Technological irregularities during the installation of the system, which lead to leakage of the coolant, include, for example, the use of inappropriate electrodes and the occurrence of local foci of electrochemical corrosion in the places of welding seams. The most sensitive to violations in the installation technology are metal-plastic pipes connected by threaded fittings. Such a leak is practically unavoidable and requires a complete replacement of the pipeline section together with the fitting.

Incorrect work and selection of materials

The illiterate operation of the heating system also leads to water leaks from the pipes. For example, boiling of the coolant and the accompanying hydrodynamic shock lead to damage to the gaskets and even destruction of threaded connections. If it is decided to change the type of coolant by replacing the water with antifreeze, then you need to be prepared for the threaded connections to flow. This is especially true for those devices that were mounted twenty years ago and were used to seal them with tow, oil paint, rubber and other inexpensive auxiliary materials.

An unnecessarily high pressure in the system also leads to water leakage from the pipes. It does not affect the efficiency of its operation and even harms, leading to boiling of water at temperatures below 100 ° C. Pressure is needed to pump the coolant to the upper tiers of multi-storey buildings or to activate sluggish thermal convection in single-pipe systems with lower wiring. In one-story houses, it is better to use circulation pumps with a working pressure of no more than 1.5 atmospheres.

Reinforced-plastic pipes, which have become popular recently, are very sensitive to the operating mode. They cannot withstand sudden temperature changes, overheating and water hammer. Their structure delaminates, as a result of which the pipes lose strength, cracks and fistulas appear in them.

If you pierced the warm floor

Hello dear homemade products.

What to do if you have broken through a water heat-insulated floor, and what to do if a working heat-insulated floor made of metal-plastic is broken, and below, under it, there are floors with living quarters?

The situation is extremely unpleasant, and in order not to be caught by surprise, you need to be ready for it. We will deal with this right away, and then we will find out how to eliminate this nuisance.

So, before you run a drill into the coating, under which a water-heated floor is laid, and press the punch key, you should be completely sure that there is a chunk in your pocket, exactly the diameter of the drill, with a slightly sharpened end, and a piece thin, dense matter with which this chip can be compacted.

Of course, if there is nothing to flood below, then you can not be puzzled by this, and just go and block the highway, in which case, but we will proceed from the worst-case scenario.

That is: on the floor below, a peaceful family lives, and neither in a dream nor in spirit knows that their snow-white ceiling may be flooded with streams of hot dirty water.

To prevent this from happening, the first thing to do, after you notice that the drill has started to spray with water, is to take it out, and immediately cover the hole with a piece of cloth (cover, not plug it), and drive a chick into it until it stops ...

It must enter the hole punched in the pipe, together with the sealing material, not break (be hard), and not pierce the pipe through again (be not so sharp).

This, of course, will not stop the leak, but it will knock down the pressure so much that it will be possible to go and shut off the water supply, without fear that while you are walking, so much will flow from the hole that will be enough for both you and your neighbors.

Another clarification: the warm floor is located in the screed at a depth of several centimeters, therefore, in order for the chёpik to reach the pipe, and even with the material, and not get stuck in the screed, its diameter must be carefully adjusted.

If you are working alone, then it is advisable to foresee how to fix it, for the time for which you are away, to disconnect the line. All the same, in high-rise buildings, the pressure in the system is about 4 atmospheres, it can simply knock out.

Okay, the line is blocked, you can start repairing the damage.

The first step is to clear the breakdown site. We remove the tie in this place, so that the pipe is free by 30 centimeters in each direction from the hole.

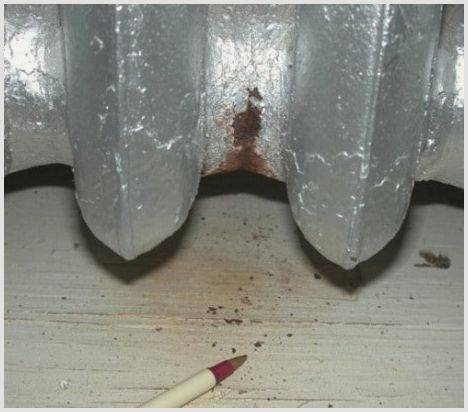

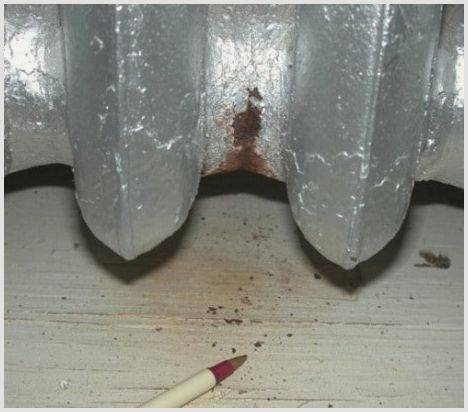

Unfortunately, I did not click the process at the very beginning, but from this picture it will be clear how much screed to remove.

It is necessary to remove the screed very carefully, with a chisel and a hammer. Never try to do this with a puncher. You won't even notice how you make them new holes.

To connect metal-plastic pipes, in places that will not be accessible later, a press fitting is used, and it is installed using press tongs. Nothing else exists.

Threaded fitting, in such places, cannot be installed categorically. The fact is that it flows, and flows are pretty petty.

At first, there is no leakage, and there is not until the heating season ends and the heating is turned off. Once the pipes have cooled down, the screw fittings will start to leak. Not all of them, of course, but one is enough for the eyes.

Press pliers, of course, are not the tool that everyone has, but you can find them. You can buy, they cost 5500 rubles, and you can rent it.

Now a few nuances of connecting the pipe (I think I forgot to say that it needs to be cut close to both sides of the hole.) With press fittings.

The first step is to check whether the pipe has enough length so that both ends to be connected are fully inserted into the fitting. To do this, you do not need to insert them into it, just bring them together and see what kind of gap is obtained between them.

If the gap is too large, then free the pipe from the tie until it tightens.

After that, we carefully unfold the ends of the pipe with a special reamer.

Now, it would seem, it is possible to insert the fitting, but it is often simply impossible to insert it dry. Imported ones are still inserted, and our RVK or RST, sometimes they fly in without effort, sometimes into any.

Therefore, you only need to insert them with soap. And apply the foam without sparing. But there are individual specimens that, even with soap, do not fit.

After some research, I found out that in such cases, all the foam is collected by the first rubber band (apparently its thickness is a little more), and the already dry pipe does not pass through the second one.

In this case, you can do the following: pull off the crimp sleeve, apply plenty of foam on both elastic bands, and insert the sleeve into place (remove and put on with effort).

Then we insert the pipe and squeeze the press with pliers. Please note that in the red clip, there are small windows. The pipe is considered fully inserted when its edge appears in this window, after which it can be squeezed with pliers.

The second end is done in the same way. The whole pipe is connected, the screed can be repaired.

I wish you success in your work.

Section Construction >>> Subsection Heating >>>

Well, what else is interesting there

Heating scheme Leningrad Welding polypropylene pipes How to wind flax How to add a radiator section How to make a water-heated floor Heating a house with warm floors How to make a floor in a bath warm Heating in walls How to make a fireplace for a sauna

How to find a water leak in a heating system

If the supply or return lines from pipes of classic traditional heating or heating devices of heat exchangers (batteries) have leaked, then it is not difficult to immediately find a water leak in the heating system and identify the place of the leak. External visual control will help you do this quickly. It is much more difficult to do this in a heating system in the form of underfloor heating or heated walls.

- Moderate prices with good quality

- Departure on the same day

- We work all over Russia

- Full working cycle from search and location of the leak to the "turnkey" restoration construction works

- Application of new technologies and equipment

- Professional skills for over 10 years

A powerful trickle of hot heat carrier that gushes out of the floor will bring quite a lot of trouble, but it is easy and quick to identify it. Much more unpleasant is a small leak in a wall or in a heated floor, covered with a concrete screed. If under the screed there is a good protection against the negative effects of moisture in the form of a "trough", then until it is filled with water, you will not know about it. "Man-made lake" with warm water in your floor will eventually overflow. The water will find the gap and start flowing out a little. As a result, the ceiling or wall under the heated floor on the lower floor will lock up, and this process will not stop until mold appears and the gradual destruction of building structures from the corrosive action of water, enhanced by heat.

There is a way to find the presence of a leak in a heating system with underfloor heating. In most cases, a pressure measurement device is installed on a boiler for heating in such a system. And if, when the floor or wall heats up, the pressure drops according to the readings of the device for determining the pressure value, then a small leak is found.

Attention! Important! If the expansion tank of the heating system is not sealed, then the pressure can drop through it.It can also fall through the air vents, i.e.

automated cranes Mayevsky

e. automated cranes Mayevsky.

It is necessary to check all open parts of pipelines and joints. But with rather hot water, a puddle of water that seeped at the junction and appeared on the floor can quickly evaporate, and you will not notice the result.

Instruments for finding leaks in floors and walls

There are a few of these devices:

- Thermal imager. Fixes a temperature rise of a couple of degrees. But:

- the water may be slightly warm;

- the leak can be hidden by a thick concrete layer;

- the place may be inaccessible to the device.

- Surface moisture meter - allows you to measure the increased humidity of the wall plane.

The method gives low accuracy, requires a lot of time. It is better to duplicate it with a thermal imager showing a large problematic area, and then look for it with a moisture meter.

A sound device, similar to a hospital phonendoscope. Allows you to hear the sounds of the "trickle" flowing in the wall and find the leak.

Our company can remove almost all the problems associated with leaks in heating systems, both in a private house and in Moscow companies.

We are engaged in the provision of the following types of services:

- search for leaks and localize these places;

- we find the location of the hidden pipelines of the water metering unit and heat supply;

- we check the condition of pipelines;

- we examine the premises and find places of heat loss using a thermal imager;

- we localize and completely eliminate leaks in pipes with hot and cold water;

- we can find places of violation of thermal insulation, and much more.

In case of problems, call our professionals at any time. Departure of professionals in Moscow is free and fast on the day of contact.

Eliminating leaks in the heating system with your own hands

If the leak is strong, shut off the heating supply in the riser. In the event of a minor malfunction (if water barely drips), you can immediately begin to eliminate it. Consider how best to fix the heating system.

Option # 1: when the pipe is leaking

If a section of a steel pipe has leaked without a thread, then the problem is a poor-quality weld. A clamp is required to repair the damage. You can buy it at a hardware store or make it yourself from a metal strip. A gasket or a piece of a bicycle tube is used as a seal.

The pipe is cleaned of paint overflows, a dense rubber gasket is applied on top, then a clamp. Bolts are provided for fastening the clamp. They are tightened as tightly as possible. Sometimes the damage is additionally treated with a sealant. This is a great way to tightly close a hole in a pipe. There will be no more leaks.

Option # 2: Leaking under the locknut

If the locknut is initially secured correctly, leaks can result from mechanical damage or corrosion. It is necessary to shut off the riser and dump the water. After that, the nut is unscrewed, sealed with flax, paint or a special compound and tightened again. Plumbing linen and other seals are wound clockwise.

When the work is finished, you need to open the riser valve again and check the tightness of the connection. If water still seeps out, repeat the procedure by adding 5-6 new threads on the pipe.

Option # 3: if the radiator is dripping

The radiator plate or the joint between the sections can leak. In the first case, it is better to immediately replace the damaged element. If this is not possible, then a small leak is dealt with using cold welding. You can buy it at any hardware store. Instructions for use should be on the packaging.

To repair the radiator, block the riser, clean it, degrease the damaged area, after which a sealing compound is applied to the hole itself and the area around it. Welding should close approximately 3-4 cm of pipe around the fistula. The composition quickly solidifies.After complete drying, you can start heating.

If it flows between the sections, then the radiator is dismantled and the nipple connection is tightly tightened. When fixing the nipple, you need to make every effort. It is almost impossible to break it, so you should not be afraid. At the end of the work, the radiator is installed in the old place and the coolant supply is turned on.

What areas and elements can leak

The most common leak is in metal pipes. The elements that can be destroyed are as follows:

- joints of pipes, adapters and seams;

- one-piece pipe;

- radiator;

- under the lock nut;

- in the underfloor heating circuit;

- space between battery sections.

Heating system leaks are often found in radiators

Most often, cheap polymer pipes are subject to violation of integrity. They break, flow, swell. Reinforced-plastic pipes are also susceptible to leaks if they were incorrectly selected. There are special products for the heating system. If pipes for cold water are installed in it, then under the influence of high temperatures they are deformed and burst.

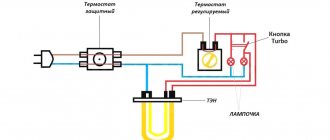

Temperature sensor problems

The sensor is mounted in a corrugation in a screed together with heating elements and transmits information about heating to the thermostat. This is the simplest element in the system. Possible malfunctions:

- The contacts on the thermostat are incorrectly connected.

- Broken cable to the sensor.

- The sensor is incorrectly mounted in the underfloor heating: it is too close to the heating element or not deep enough. In this case, the information about the screed temperature will be transmitted incorrectly. Correct sensor installation must be carried out.

So that when using underfloor heating you can quickly replace a failed temperature sensor, we advise you to lay it in a metal-plastic pipe. The corrugation will be only at the end of the pipe, directly at the very location of the sensor. How to do this, see the video below.

What elements can leak

There are several ways to eliminate leaks. The selection of the correct methods depends on the type of system element in which the leak occurs. This could be:

One-piece pipe. Here the holes are tightened with clamps, self-tapping screws, sealed with special compounds or cemented. If the pipe is plastic, it is best to replace the entire length. If this is not possible, use artisanal welding.

Places of connections. There are many different connections in the heating system - pipe attachment points, adapters, etc. Leaks appear either due to loose fasteners, or due to corrosion. Polymer parts are easier to fix, but with steel and cast iron it is more difficult: you have to apply force or use cold welding.

Between battery sections. The reason is the same - leakage. Sometimes it leaks due to mechanical damage. If water seeps between sections, remove the radiator and tighten the connections.

On the radiator plate. In this case, it is advisable to immediately change the radiator, because the most common cause of breakdowns is thin walls and low-quality material from which the heater is made. If it is not possible to replace it immediately, then cold welding will save, but this is only a temporary measure. In the next season, new troubles may arise.

How to fix the underfloor heating cable

Failure of wires is one of the main causes of malfunctions of the entire system. As a result, the electric underfloor heating does not heat. The main cause of the breakdown may be hidden behind unforeseen mechanical damage to the wires. Most often this happens during the screed or during the work of tilers. This is fraught with the failure of the entire heating of the room or a certain zone.

Diagnostics will help to cope with the problem.You can check for damage as follows: disconnect it from the temperature sensor, then measuring the electrical resistance. Here you need to walk through the sections between all the veins so as not to miss a possible malfunction. You need to check the value with the passport data of the device. An error is allowed within 5%. The most common cases are:

- The multimeter shows zero resistance. This means that a short circuit has occurred in the system. Most often, an unpleasant situation occurs after overheating or an incorrectly calculated wire cross-section.

- The meter showed infinity. This will make it clear that the cable has broken or burned out in the structure. It is worth checking the connecting elements of the system.

Do-it-yourself repair of a heated floor cable involves not only diagnostics, but also identifying the place of breakdown, eliminating a faulty unit. When the device shows the correct value, then you should go to the diagnosis of another heating element - the thermostat. The system may not work at full capacity for one simple reason: foreign developers assume that the warm floor will be powered from a 230 V network, when in reality compatriots connect the cable to a 220 V. This is where the power loss lies.

How to repair electric underfloor heating, video

Leakage reasons

It is important not only to detect a coolant leak in the heating system, but also to understand for what reasons it has arisen. The situations in which the monometer on the boiler can show low pressure are as follows:

- violation of the tightness of the joints as a result of corrosion of pipes, wear of gaskets or loosening of threaded connections;

- thermal expansion and contraction of fittings. When the coolant reaches a certain temperature, the metal parts expand, but as soon as the water cools down, the metal of the fittings narrows and begins to let the liquid through;

- change of the coolant in the pipes. If you first used water, and then decided to pour antifreeze into the system, the seals can expand, then dry out;

- overpressure in the heating system due to too small expansion vessel. This can lead to cracks in the pipes.

In addition, leakage occurs as a result of improper installation or operation. This is especially true for metal-plastic highways, which are more sensitive to any violations of the installation technology.

Repair of the thermostat of the electric underfloor heating

Among the possible reasons why the electric underfloor heating has become poorly heated, it is worth highlighting the incorrect installation of the temperature sensor. Such a breakdown manifests itself as follows: from time to time the thermostat will turn off, despite the fact that the floor has not yet warmed up.

Why doesn't the electric underfloor heating system heat up? Thermoregulator repair, video

Possible reasons for this situation may be incorrect installation of the device. Most often, an inexperienced home “specialist” places it very close to the heating cable. Often the sensor lies directly on the heating wires. What else can you expect from the device in such a situation? Of course, he will "think" that the floor has warmed up to the limit, and will turn off for the purpose of fire safety. The repair of the thermostat of the electric underfloor heating can be avoided if the device is installed correctly. Correct installation implies not only the correct placement of the sensor, but also the adjustment of the temperature regime with an accuracy of 2 ° C. A modern infrared thermometer will allow you to check the operation of the sensor.

modern infrared thermometer

If the thermostat is constantly on (this can be seen from the lit indicator), then you need to think about checking the warm floor, and then find out the cause of the breakdown.

Search and elimination of coolant leaks

Finding a place where water leaks through puddles on the floor is easy.But if you inadvertently brought the matter to this, then you can consider yourself on the verge of a communal catastrophe of a local nature.

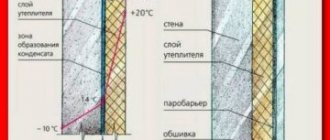

Therefore, you need to pay attention to the details - the appearance of rusty streaks in the places of threaded connections, swelling on the surface of metal-plastic pipes, their loss of shape and strength. If the heating pipes are laid in the thickness of the walls or a "warm floor" system in a concrete screed is arranged on a separate circuit, then leaks can be found only with the help of special devices

A weak (drip) leak can be eliminated without draining the water or stopping the heating of the house. Elimination of flows of different intensities is possible only on dry and cooled pipes. Therefore, it will be useful to arrange bypass lines (bypasses), dividing the system into several circuits and independent sections using installed ball valves.

Repair of metal pipes and their connections

Even heavily corroded metal pipes have a high residual strength, therefore, during repairs, significant pressing forces can be applied to them and clamps tightened with bolts can be used. For their urgent repair, you may need:

- Heat-resistant (red) silicone sealant;

- Rubber elastic bandage (sold in pharmacies);

- Two-component metal-filled epoxies (cold welded);

- Bolted metal clamps;

- Thin fiberglass or old women's tights.

In case of a slight leak in the threaded connections, it is enough to unscrew the lock nut (if any) by a quarter of a turn to form a gap of 0.5 mm. Silicone sealant is squeezed into it and evenly distributed over the entire circumference. After 30 seconds, when the sealant begins to polymerize, the nut is tightened.

If there is no lock nut, then it is necessary to clean the joint from old paint, scale, rust and degrease it. In case of a weak leak, you need to knead a piece of "cold welding", as described in the instructions for it, and evenly distribute it around the entire circumference of the joint, especially carefully smearing the edges of the joints. For a higher flow, you can apply a silicone sealant or a two-component metal-filled compound to the joint and press it with a tape of fiberglass or a piece of women's tights.

A crack or fistula in the pipe can be wrapped with a rubber elastic bandage, overlapping with each subsequent turn half of the previous one. The length of the winding should be twice as long as the damaged section. It is necessary to make 2-3 layers of winding and secure it with clamps. A good result is obtained by winding with a hemostatic tourniquet from a car first-aid kit, which can be secured with a standard latch. A crack in a pipe can also be repaired with an epoxy compound in combination with a reinforcing material - elastane or fiberglass. But at the same time, you will have to clean up to metal and degrease the entire area on which the bandage will be applied.

The underfloor heating circuit does not work

So, if the underfloor heating circuit does not work for you, you need to view in the distribution box all ball valves for each circuit that should be open, i.e. located along the pipelines.

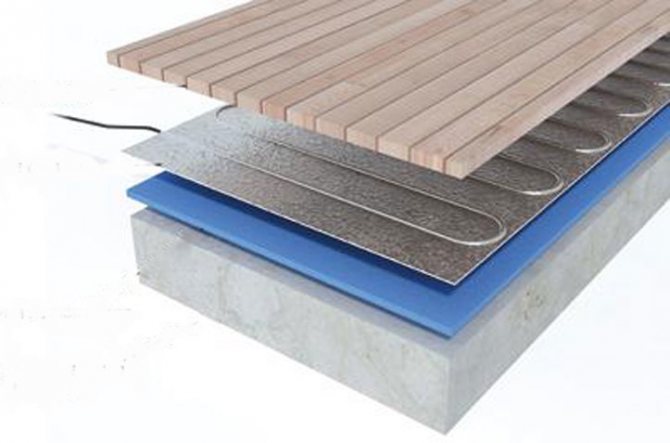

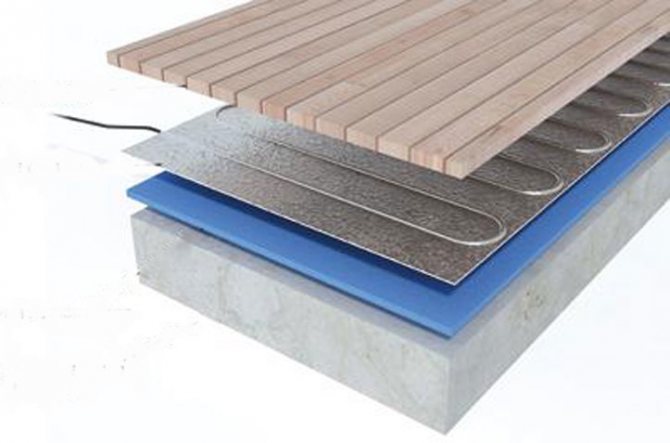

Laying a warm water floor

It is also possible that the circulation pump is out of order. Most often it is located in a switchboard near the boiler.

Listen and if you hear a little noise or feel a little vibration, then everything is in order with the circulation pump, if not, then it will need to be replaced. But, before replacing this part, check if voltage is supplied to it.

Manifold cabinet for warm water floor with pump

Perhaps, warm water floors do not heat due to burnt-out electrical wiring, so it is worth checking it first. The third reason for the lack of functioning of the circuit may be the presence of air in the system.In this case, you need the help of specialists who can pressurize the system using special equipment. By the way, you can do the crimping yourself if you have this special equipment at hand. It can usually be rented from any store that sells warm water floors.

It will also require repair of water heated floors if they have a low temperature, which is not enough to heat the space of the room. There may be several reasons for this. The first of which is the lack of the required boiler power. Here, as an option, you can try to lower the temperature in other rooms - where you are a little less often. Perhaps it's time to clean the boiler, revise the temperature sensors, or carry out preventive repairs.

The second reason may be furniture in the room. Carpets, sofas and wardrobes can have a significant effect on room temperature.

Insulation for warm water floor

Underfloor heating requires open floors, and the more, the better.

Or it may be necessary to repair the underfloor heating thermostat, often it is the thermostat that causes the low temperature in the premises.

Thermoregulator for warm water floor

It is possible that problems with a warm floor arose due to the fact that they saved on insulation. In this case, you heat either the neighbors or the soil. Here you need to decide whether to use additional sources of heating the room, or completely redo the heating system. That is why, before installing the underfloor heating system, it is necessary to carefully think over the project and carry out the installation either yourself, but as seriously as possible, or entrust this responsible matter to professionals who will install the warm water floor in the shortest possible time.