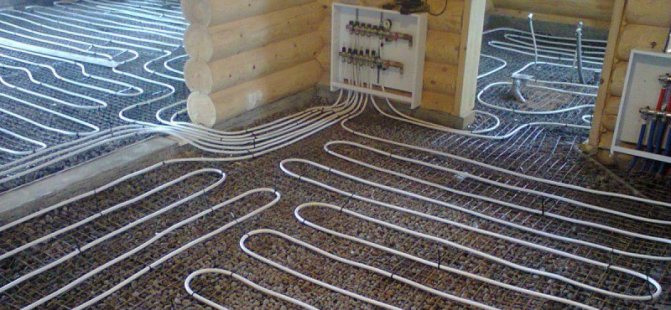

- Laying pipes for underfloor heating (for example, a metal-plastic pipe)

- PEX pipe laying: features of XLPE pipe installation

- Installation of the Rehau underfloor heating pipe on mats with lugs

Here we will see how laying pipes for underfloor heating on the example of metal-plastic and PEX pipes.

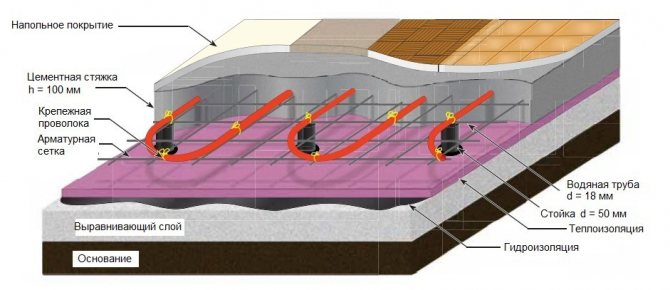

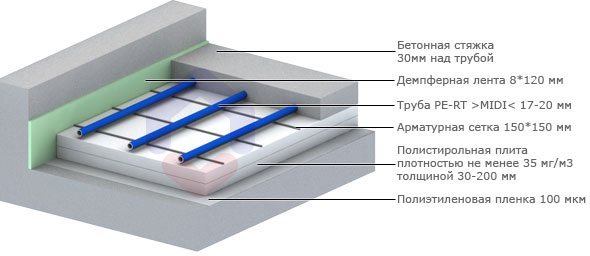

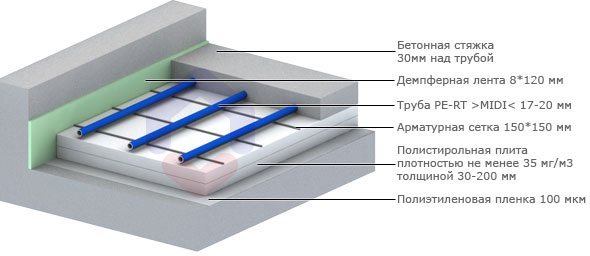

Attention! Underfloor heating pipes with a concrete screed are laid after all other layers of the underfloor heating "pie" have been made: rough screed, insulation, plastic wrap, reinforcing mesh (or mats with lugs / grooves), and a damper tape is fixed around the perimeter of the room. If you do not know what this is about, because you immediately got to this page from a search engine, then first read the articles from the sections Arrangement of a warm water floor and Installation of a warm water floor. In a decking or wooden underfloor heating systems, the layout of pipes is also preceded by different actions, so everything said above is also true for such systems.

Which pipes are better to use

For floor lines, only those circuits are suitable that can withstand high temperatures.

Today on the market there is a variety of products made of the following materials: copper, metal-plastic, cross-linked polyethylene. Separately, we will talk about galvanized pipe-rolling materials.

Each type has its own characteristics, and is intended for use in specific conditions.

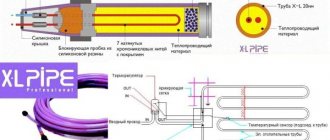

XLPE PEX pipes

Pipes made of cross-linked polyethylene have excellent performance characteristics due to which they receive an indisputable advantage over other materials, therefore they are popular both for cold water supply and for laying in a warm floor structure.

The material for their manufacture is polyethylene with a certain density. Stitching of products is carried out according to several methods.

Depending on the production process, the pipeline is of different classes:

- PEX-a - high-density polyethylene is used in the manufacture. The method of production is peroxide, it consists in melting polyethylene under the influence of high temperature. After that, the resulting amorphous mixture is squeezed out through a special forming hole, this method is called extrusion.

PEX-a is a multi-layer construction with an aluminum insert between the layers, which helps to maintain the shape of the product. A special glue is used to connect the layers; it does not change its properties under the influence of temperature.

For your information! The product is capable of passing oxygen to the coolant. To eliminate penetration, manufacturers began to equip it from the outside with a protective EVOH coating - a layer of thin plastic (polyvinylethylene).

- PEX-b - for its manufacture, medium density polyethylene is taken, which softens to a solid consistency. With this method, crosslinking is done after extrusion.

- PEX-c - the raw material in this case is also polyethylene of medium density. Stitching is carried out at a temperature equal to the environment, while the state of the material is solid.

Cross-linked polyethylene hoses are widely used in the installation of underfloor heating, but PEX-a is more often used, since they have good elasticity, and allow you to lay a line with a bend of up to 5 diameters.

PEX-b are harder and therefore break easily. And PEX-c does not tolerate high temperatures, therefore it is more often used for cold water. In addition, products made from this material are durable and lightweight, which is a plus for DIY installation.

PEX-a pipes have memory - when deformed, they are able to completely restore their shape, for this they need to be heated. PEX-b do not have such properties, while PEX-c has this property downgraded.

Polyethylene PE-RT

Pipe rolling PE-RT is modified, it differs from PEX in the absence of seams. The system made of such tubes is practically noiseless, withstands subzero temperatures, but high positive temperatures, although it tolerates well, but not for a long time.

In addition, this material is susceptible to aggressive substances, and there is no structural memory. But, despite this, heat-resistant polyethylene is widely used in underfloor heating, as it has an affordable price.

Reinforced plastic

A metal-plastic pipe for a warm floor is an excellent option. It is flexible and pliable, and lends itself to bending even without heating. In addition, the material is durable, tolerates temperature changes well and is environmentally friendly.

The reinforced-plastic pipeline consists of several layers - cross-linked polyethylene inside, then metallized foil, and a polymer coating on the outside, it protects against mechanical damage. In such a design, corrosion does not form and scale build-up does not occur. With proper installation, the pipeline will last more than 50 years.

If we compare which is better - metal-plastic or cross-linked polyethylene for underfloor heating, then we can note the high thermal conductivity of plastic. But at the same time, there is a great risk of the coil breaking, and since such a product does not have the ability to restore its shape, this area will have to be removed.

Metallic

Metal pipes for warm water floors are produced in the following types:

- Copper - have a high cost, so they are not very popular when installing hydraulic floors. In addition, it is not easy to lay such a pipeline, special equipment is required, and it is unlikely that it will be possible to install it yourself.

However, it should be noted that a copper pipe is ideal for a warm floor, as it has excellent characteristics:

- high thermal conductivity;

- durability;

- not susceptible to corrosion;

- plasticity and strength.

- Steel corrugated stainless steel is a relatively new type that is well suited for underfloor heating, but due to the high price, they are not often used. The product has a protective polymer coating, and the stainless steel does not corrode, it perfectly tolerates mechanical, chemical and temperature influences.

In addition, such a model has increased flexibility, laying according to the most complex scheme is possible, without the risk of creases.

Summing up, we can saythat the most popular models that are used for underfloor heating are reinforced plastic pipe or XLPE loop.

They have good performance and are affordable. But if financial resources allow, then it is better to use a metal (copper) pipeline, it has high thermal conductivity and durability.

How is the installation of the line carried out?

For water-based underfloor heating, a flat surface of the rough base is required. It is recommended to perform a screed, self-leveling floor or use a self-leveling mixture. Plumbing is laid on a dry surface. It is recommended to use insulating materials so that all the heat from the water circuit is directed to the floor.

- The base is covered with a thin plastic wrap.

- I install thermal insulation. It is recommended to use Rehau polystyrene contour covering. The PEX underfloor heating pipe fits well to the contour of the coating. The line is laid with a "snake" or "snail", outlining the protruding bosses. They squeeze the pipe from the sides, fixing it securely in a certain place.

- The line is fed to a manifold that has an outlet for hot and chilled water. Connect the entire system to the heating boiler.Testing the heating system.

- Pour underfloor heating with PEX pipes with a concrete screed up to 8 cm deep.

We recommend: How to install the underfloor heating film?

Foam plates are used as insulation for the base of the floor. Foil material is placed on the plates. It is a reflective screen that directs heat upward. Reinforced mesh and mounting brackets are used to strengthen the line.

The staples are installed on the mesh with a certain pitch. They are made of plastic and have downward prongs. The teeth will not allow the water circuit to change position, to get out of the groove.

PEX pipes are used not only for floor heating, but also for cold and hot water supply. Corrosion and salt deposits do not form on the inner surface of the product, which prolongs the service life of the water circuit.

When heated, PEX-a cross-linked polyethylene does not emit toxic substances. The products are used in pharmacological enterprises. Cross-linked polyethylene for PEX-a and PEX-c are classified as environmentally friendly products.

YouTube responded with an error: Access Not Configured. YouTube Data API has not been used in project 268921522881 before or it is disabled. Enable it by visiting https://console.developers.google.com/apis/api/youtube.googleapis.com/overview?project=268921522881 then retry. If you enabled this API recently, wait a few minutes for the action to propagate to our systems and retry.

- Similar posts

- How to choose a plasticizer for a warm floor?

- How to install underfloor heating on a concrete floor under a laminate?

- How is the underfloor mesh laid?

- How to set up a programmable thermostat for a warm floor?

- How is the length of the underfloor heating pipe calculated?

- How to install a warm floor with a snail?

Is it possible to connect underfloor heating pipes or not?

When laying a pipeline for a warm floor, it is not uncommon that the length of the circuit is not enough to make a one-piece loop. In this case, the question arises - is it possible to connect the pipes together, and how to do it? There are several methods for connecting contours, which depend on the type of material.

Important! When choosing a method to join the floor pipes, the operating pressure should be taken into account, since each joint is designed to withstand a certain load.

Let us consider in more detail the methods - how to connect the pipes of the warm floor.

Connection of pipes made of cross-linked polyethylene and metal-plastic

Contours made of polyethylene or metal-plastic can be sewn using fittings (brass, bronze and plastic), they are able to withstand high temperatures. Fittings are:

- Electric welding ones are effective, but special equipment is required for their installation, therefore they are rarely used. The process looks like this:

- an electric welding fitting is put on the pipe cut;

- welding equipment is connected to the terminals, it will supply voltage to the element, which will lead to heating and fusion of the joints;

- the device turns off, the resulting connection is able to withstand pressure up to 12 Amp.

- Pressing - the main plus is that during pressing, the entire space is filled with polymer, thereby obtaining a high-strength connection.

Sequencing:

- a nut is put on the edge of the crimp tube, with the thread towards the connection;

- the split ring is put on with an indent from the cut by 1 cm, and is fixed;

- the hose is stretched with a fitting for the fitting;

- the crimp nut is tightly tightened with two wrenches.

- Crimp fittings are the easiest to install at home:

- a clamping sleeve is put on the polymer hose;

- the end of the contour is stretched in diameter using an expander;

- the stretched edge of the tube is pulled up to the stop on the fitting of the fitting;

- the joint is fixed in this position for several minutes, this is enough for a tight splicing of the fitting.

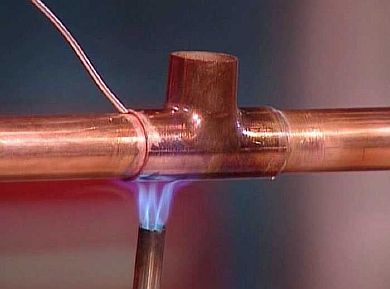

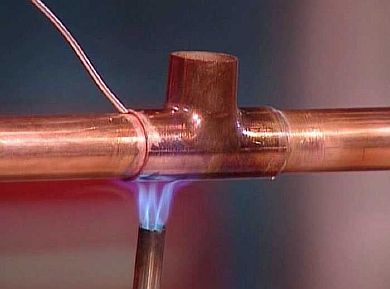

Stitching copper pipes

As well as when installing a plastic circuit, copper can be joined using press or push fittings. This method is recommended in open areas, so that in case of a leak, you can easily change the part.

But, the most reliable and practical is to solder copper pipes. This is a more time-consuming process, but the connection is durable and reliable. Sequencing:

- contour cuts are cleaned from the outside and from the inside;

- with a special connector for soldering pipes of a warm floor made of copper, the edges of the parts are lubricated - only from the top;

- the products are joined, and the excess mixture is removed;

- the joint is heated with a gas torch and the solder fills the gaps.

How to connect underfloor heating pipes (press fitting)

As mentioned above, the pipeline can be connected using press fittings. This part consists of:

- body - it can be of different shapes (angle, tee, coupling);

- sleeves - the basis of the fitting, stainless steel is the raw material for its manufacture;

- clips - an elastic ring (gasket) that connects the body and the sleeve.

For your information! The body of the fitting is equipped with a "window" to control the correct insertion of the tubular product. Only when the tube is visible in this hole can you start pressing.

Pressing is carried out using special pressing tongs. The essence of the procedure is to squeeze the handles of the instrument. The process is quick and easy, and no special skills are required to carry out these works.

The advantage of using such a connection is strength, long service life and the structure does not need maintenance.

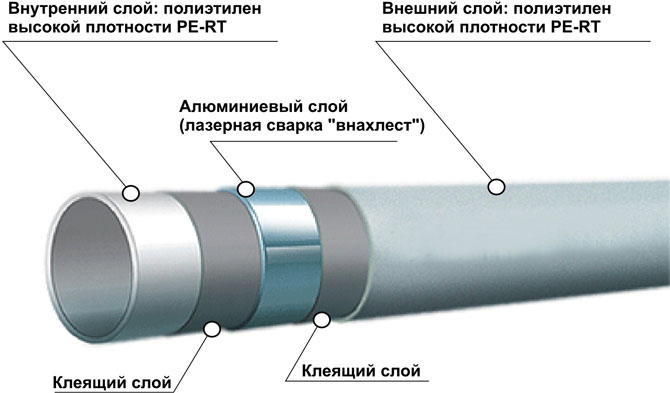

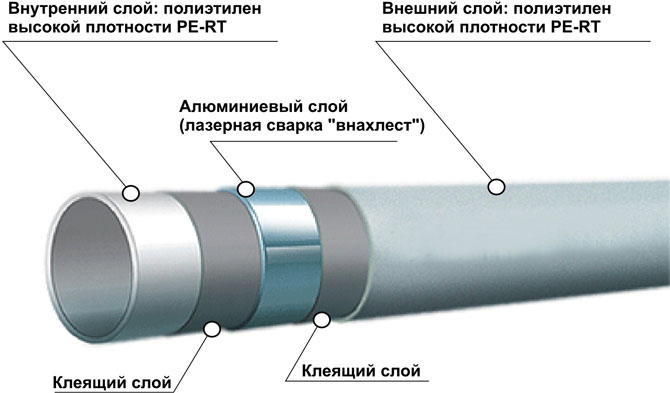

Characteristics of metal-plastic pipe products

A metal-plastic pipe is a combination of layers of polyethylene, metal and special glue.

Each layer has its own function of withstanding loads and contributes to the strength of the reinforced-plastic pipe.

Its structure can be schematically described as follows:

- The inner layer is cross-linked polyethylene. A material that is characterized as chemically inert, resistant to mechanical stress, environmentally friendly. The structure of the polyethylene ensures a flawless smoothness of the inner wall, which prevents the build-up of salts or dirt.

- First layer of glue. The difference between high-quality metal-plastic and inexpensive analogs lies in the glue used, which increases the cost of the production process.

- Aluminum layer. Metal thickness varies from 0.2 mm to 2.5 mm. For underfloor heating, pipe material with a diameter of 16 mm is used with a minimum foil thickness.

- Second layer of glue.

- Outer layer. Depending on the material chosen, it can be sewn or regular polyethylene. Crosslinked polymer makes pipes stronger, but also more expensive.

Note! You can check the quality of the gluing of the layers by heating the pipe on the cut. At the boiling point of water, a cheap pipe delaminates, which becomes noticeable visually.

Connecting underfloor heating pipes in a screed

Although experts advise laying a water-heated floor under a screed without joints, it is not forbidden to do them.

But it is worth noting that it is impossible to connect the floor contours by a threaded method: "American" or PRH. It is better if the pipes will be connected using a press fitting or coupling.

Important! When filling such areas with screed, fittings or couplings should be insulated from the concrete solution. This can be done by wrapping them in plastic wrap.

How can you bend plastic pipes?

Reinforced-plastic pipes for underfloor heating can be turned and bent with a special device - a pipe bender. It is designed for manual processing of pipes, light and maneuverable, the pipe bender accurately and quickly forms any structure.

As a rule, the average man in the street does not have a pipe bender in stock, and its purchase is completely optional. With a limited estimate, you can bend the pipe manually using a spring conductor.

The device will cost about 150 rubles, and will reliably save you from marriage and mistakes. Without such a safety net, the radius is often exceeded, the pipe breaks or flattens too much.

Thanks to the conductor spring, bending from three radii is performed accurately and efficiently. The device is either internal or external, which easily moves along a bent pipe.

How to solder a floor heating pipe

Soldering is a common method of connecting plastic pipes for underfloor heating. The technology is simple and does not require large financial investments. There are two soldering techniques:

- Coupling - for this, a shaped part is used (a coupling or a contour with a large diameter). This method is suitable for 63 mm tubing. The welding process consists in melting the edge of the product from the outside and part of the sleeve inside. After that, the parts are joined, forming a tight connection.

- Straight line - consists in melting small sections of two plastic pipes, which are then joined by their ends. This rather simple method reliably combines two parts into a single contour.

For your information! Along with hot technologies, the method of "cold" soldering is practiced. A special solvent is used that softens the plastic.

Selection of pipe by diameter

The laying of metal-plastic in the "warm floor" system is carried out strictly in compliance with the installation rules. The pipes themselves hold their shape well when turning. The main thing is to observe the correctness of the bends.

The diameter of the pipe affects the convenience of working with the MP pipeline of the "warm floors" system. The 16 mm section is considered the most convenient. It is recommended to start working with it for a novice master. Such material carries a minimum amount of water or heat carrier. For example, in 1 meter of a pipe with a cross section of 16 mm, 110 milliliters of water comes in; with a section of 20 mm - 180 milliliters of liquid. It is more difficult to bend the "twenty" into a snake. When laying, a step of 0.5 m is observed. In addition, the 16-mm section is cheaper in price.

How to connect a pipe underfloor heating with a metal-plastic pipe

Although experts recommend using a pipeline from one material when installing a warm floor, sometimes it becomes necessary to connect a metal-plastic circuit with products from other raw materials.

For example, when connecting this circuit to steel (copper) parts of the water supply or heating. This requires a compression fitting and a calibrator. When joining products from different materials, the thread should be selected according to the size of the steel pipe, and the collars and washers - along the metal-plastic pipeline.

Tow is wound around the copper pipe, and then the fitting is screwed on. The edge of the product is pushed onto the cone and the nut is tightened.

If it is necessary to dock the reinforced-plastic circuit with polyethylene products, special threaded fittings can be used as a connector for underfloor heating pipes. Such a joint is more often done when connecting a warm floor to a boiler.

How is the installation of metal-plastic pipes carried out?

First of all, it is necessary to calculate the maximum length of the circuit, while laying is carried out in increments of 0.3-0.35 m. If you calculate the area of the room, you can calculate the total length of the heating circuit for a warm floor.

Saving on length without losing the performance of the system is possible if you do not heat the contour of the areas under furniture or massive objects. This reduces the length of the piping and prevents overheating of the system. A project is being drawn up for laying a contour for a warm floor in a spiral or a snake.

It is easier to make a snake, but it is characterized by uneven heating. The back room, for example, will be heated with hotter water than the doorway at the entrance to the room.

This property can be used to heat different areas of the room - in places of frequent visits, a hotter coolant is needed, and in places of rare use, the air can be cooler.

Spiral laying will give an even distribution of water, but installation is more difficult due to the need for a double step for the return.

Using fittings

Fittings can be collapsible (compression or crimp), as well as press. Pressing devices are easier to install, but buying special equipment for them is not always advisable.

Fittings for metal-plastic pipes

Collapsible fittings are simpler and cheaper for installation work, but their use makes sense with a small footage of the object. The installation time for crimp or compression devices is usually quite long.

How are compression fittings used:

- The pipe is processed on both sides by the calibrator to a perfectly even circle. Sandpaper are passed over the surface and remove burrs;

- The nut from the fitting is twisted together with the union ring. The quality of the seal must be checked especially carefully - there should be no protrusions from the groove;

- The compression ring (cracker) is put on over the union nut in the first section of the pipe;

- The fitting of the fitting is inserted all the way to the stop;

- The ring and nut are screwed close to the fitting;

- The nut is screwed in with an open-end wrench until it stops.

Press fitting installation:

- The pipe is processed along the edges with a calibrator;

- The compression fitting is pushed as deeply as possible;

- The nozzle in the press is selected of the appropriate diameter, the equipment works with the rotation of the base, which makes it easier to work with it;

- A pipe is inserted into the mouth of the press, crimped and sent to the installation of the circuit.

When pipe joints are inside the same room, it is necessary to avoid placing the fittings in a concrete screed, it is better to bring it into the wall and cover it with baseboards.

What to do if the underfloor heating pipe has been punctured?

In the presence of warm water floors in a house or apartment, there are times when the floor pipeline can be broken. First of all, if the floor is functioning, it should be disconnected from the water supply. But more often, such damage occurs during the installation or repair of the system, when the topcoat is not laid and the screed is not poured - this is a huge plus.

If there is a concrete screed, you will need a hammer drill, chisel, and hammer to find the damage site to break the concrete. This should be done carefully so as not to damage the whole circuit.

When punching pipes made of metal-plastic or polyethylene, they are repaired with press couplings, using a special press.

For your information! If the heating element after repair will be filled with a screed, then the use of threaded fittings is not possible.

Having calculated the place of breakdown, the damaged area should be removed, and a whole circuit should be installed in its place. The connection is carried out using press sleeves, which should be wrapped in plastic wrap to protect against cement mortar.

Advantages of metal-plastic for underfloor heating

Acceptable expansion ratio. That is, when heated, the pipes do not grow too much. The aluminum layer makes the pipe both strong and elastic.

Excellent quality, considering that the pipe is simply poured into a concrete slab. The pipes can be bent, while they retain their shape - this is very convenient for a warm floor. The snake can be bent from a single piece without resorting to joints, which are the weak point of the system. The temperature at which the pipe can work stably is + 95 ° C, which may not be enough for conventional heating, but quite enough for a warm floor system. It is usually heated to 28 - 36 ° C. The working pressure is 10 bar, while in an average household system, it is 1.5 - 5 bar.

Laying of pipes made of metal-plastic

The glue is used heat-resistant, it provides reliable adhesion of dissimilar materials, they do not delaminate.

It is convenient to connect the pipe - you can do without special equipment. You just need to pick up adapters, fittings and couplings in stores for all docking points.

Can the pipes be lengthened if there is not enough length?

As you know, making a loop of a warm water floor is better than a solid one, this gives the system reliability, and the connections are made at the attachment points with the collector. With a large size of the heated room, it is recommended to divide the area into several branches.

In order not to make a mistake in the size of the loop, you should make the correct calculation. To do this, you can use an online calculator.

However, it is still possible to lengthen the underfloor heating circuit, if necessary, by connecting the missing pipe section to it, which, by the way, is allowed according to GOST. It is possible to build up floor loops with heating using various methods; for this, butt joints are used - more often press fittings.

For your information! It is recommended to use piping and fittings from the same manufacturer in such cases.

Summing up, we can say that the connection of underfloor heating pipes is permissible, and there are various ways. But it is more practical and more reliable to lay a solid loop, especially under the screed, so that in case of a leak, you do not have to destroy the concrete layer.

In addition, you should give preference to high-quality tubular products and fittings from trusted manufacturers. In such cases, the heating floor will serve you for a long time and will create a comfortable atmosphere in the house.

Calculation of pipe length

In order to correctly calculate the required footage of the pipe, you must first draw a diagram of its laying. Underfloor heating can be installed with a snake, spiral and double spiral. Each of the methods has its own pros and cons, its own area of application. In large rooms, several circuits have to be laid, since the maximum length of one circuit should not be more than 60 meters (120 meters of pipe). It is recommended to place the circuits so that they are approximately the same length - this will ensure uniform pressure and the absence of stagnation in the system when supplying the coolant and, therefore, more uniform heating of the premises. The maximum allowable variation in the length of the contours is 15 meters.

When planning the layout of the contours, the distance between the turns is 30 cm, the indents from the walls are 15-20 cm. The contours are not placed under household appliances and furniture. According to the finished scheme, the length of the turns is calculated, summed up and multiplied by 2, since there will be two pipes - supply and return. It is recommended to add 10-15% to the obtained length. You can calculate the amount of material yourself, use an on-line calculator (you will need to specify the material, diameter, thickness of the screed and floor covering) or consult with specialists.

Heating elements of a water-heated floor and their calculation

gas heating

Water underfloor heating is a popular heating system in which the heat carrier is water, which is taken from the heating system or.

Also, electrical and are used to heat the coolant. Before entering the heating elements, the heat carrier is supplied to the collector, which is the main distribution center for this type of heating.

In the central heating system and plumbing, the water has a sufficiently high temperature (60-80 0 С), and the warm floor itself must be heated to 30-40 0 С.

For this, flow meters are installed on the manifold, which control the supply of the coolant to each circuit.

A separate pipeline is called a circuit in a water underfloor heating system. Since the collector is installed alone for the entire apartment or house, many pipes are connected to it when installing this type of heating throughout the apartment. Pipes, being a heating element, must have a flexible structure and are made of reliable materials, without deforming when temperatures change.

There are several types of heating elements that have certain characteristics:

- polypropylene pipes;

- copper pipes;

- corrugated metal pipes;

- metal-plastic heating elements.

Copper and steel elements of the system have the best thermal conductivity, but they are not as often used as metal-plastic and polypropylene ones because of their cost.

waterproofing, reinforcing mesh to which the heating elements are attached, the pipes themselves, cement-concrete screed and topcoat.

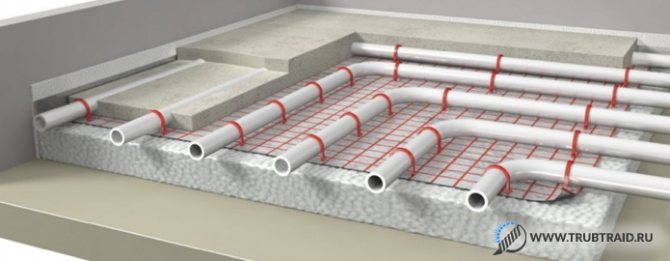

Pipe laying methods

Today, two methods of laying heating elements are widely used:

- zigzag;

- spiral.

Pipe laying with a spiral or snail (2nd name) is carried out in large rooms, places with long-term frosts and in the northern regions of the country. Since this laying system implies high costs of the heat carrier, intensive heating of the rooms is obtained accordingly.

A warm water floor with a spiral pipe laying method is often used to organize the main source of heating. This new type of heating is able to evenly warm up the finishing flooring and the entire room as a whole, creating an excellent microclimate.

Zigzag heating elements can be installed in any room. This method requires less (than with a spiral) amount of coolant to create a comfortable indoor environment. But there is one drawback of this pipe system - the uneven heating. Since water is supplied at the beginning of the circuit, and taken at its end, a smooth temperature drop of the flooring is felt, having the same direction.

To avoid such a phenomenon, a double zigzag pipe system is used, with water supply from different heating circuits. This allows for uniform heating. When laying pipes in a zigzag, a warm floor is often used as an additional type of heating for small rooms (bathrooms, balconies).

It should be remembered that depending on the atmospheric characteristics of the installation site of the warm floor and the climatic zone, as well as taking into account the owner's requirements for room temperature, the distance between the pipes of the warm floor for both methods of installation may be different.

Causes of leaks in the underfloor heating system

A warm floor mounted from metal-plastic into a single whole system can leak for three reasons:

- The installation technology has been violated.

- From the influence of an external force.

- Leaky connection at the joints.

Most often, the third reason pops up when water droplets appear at the junctions.

- The first thing that is recommended is to tighten the nut of the connecting element more tightly.

- If the problem persists, then the rubber gaskets on the fitting are revised.

After the leak is eliminated, all threaded connections are lubricated with silicone grease, wrapped in addition with a seal.

- Repair of the junction of the pipe with the press fitting begins with its dismantling. Then the ring on the metal-plastic material is changed.

- A piece of the pipeline changes if a leak is observed on its surface or a bandage is applied to a problem area.

For more than 15 years, the "warm floor" system has been in demand. It is mounted to evenly warm the room. Over the years, the question of the correct choice of metal-plastic pipes, their quantity remains relevant. The main conclusion on this issue remains unchanged: the performance and durability of the entire system as a whole depends on the quality of the material.