General information

Today, collectors, which are popularly called combs, are used for the aggregate connection of a number of heating and plumbing fixtures. Outwardly, this device is a cylindrical part with one input and many branches. Each branch is supplied with shut-off valves.

The principle of operation of this device is as follows - water or other liquid is supplied to the inlet under pressure. Further, it is distributed to the taps, which allow you to connect in parallel several plumbing fixtures or, for example, several circuits of the underfloor heating system.

The collector connection allows you to ensure a uniform water pressure in all plumbing fixtures when they are turned on at the same time. In the case of using combs in heating systems, uniform heating of all heating devices (radiators or underfloor heating circuits) is ensured.

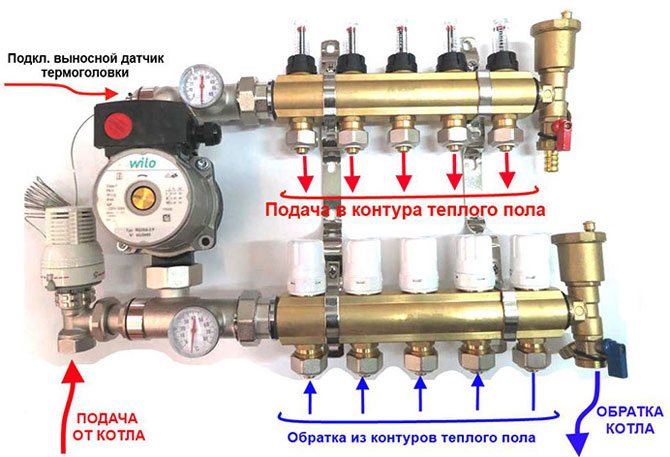

Diagram of the use of collectors in the floor heating system

It is quite simple to assemble a polypropylene comb with your own hands, and for this you only need a set of tees and ball valves.

In this case, the device will have a number of advantages, such as:

Corrosion resistant. Tightness, as the fittings weld together reliably. Durability - virtually no scale settles on the polypropylene walls of the fittings. Cheapness, due to the fact that the price of polypropylene pipes and fittings is not high. Reliability, since polypropylene is a fairly strong material. The ability to make exactly as many bends as required. The ability to use the product both for the water supply system and for heating.

For these reasons, many specialists prefer self-assembled devices from polypropylene parts to metal collectors.

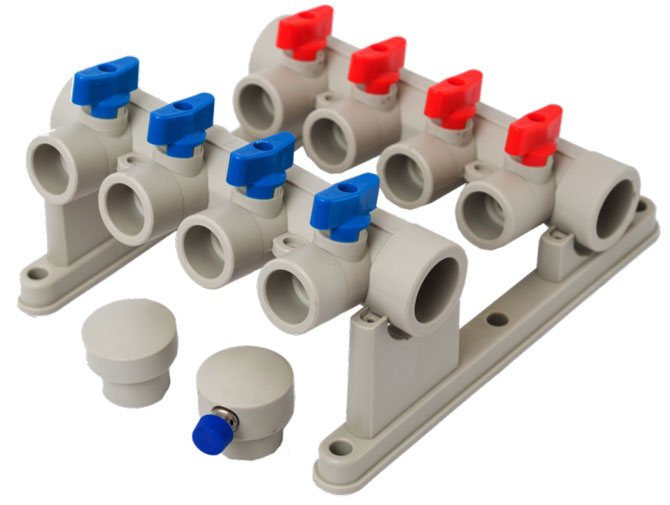

Homemade collector

It is important to follow the direction

Making a homemade distribution manifold must begin with planning. You need to determine for yourself some of the components of the heating network at home.

The number of circuits where the coolant will be directed. The number of heating equipment. Do not forget to decide on its power, water temperature, and so on. That is, you need its technical specifications. If in the future you plan to integrate additional heating elements into the heating system, for example, a heat pump or solar panels, then it is best to take them into account in advance. The number of additional equipment (pumps, valves, fittings, storage tanks, thermometers, pressure gauges, etc.).

Now the design of the device is being determined, especially it is necessary to take into account how each circuit will fit and from which side (bottom, top, side)

We draw your attention to some of the nuances of connection

Gas or electric boilers are connected to the manifold either from the bottom or from the top. If a circulation pump is installed in the heating system, then the connection is made only from the end of the comb. Indirect heating boilers and solid fuel units cut into the collector only from the end. The supply circuits of heating systems cut in either from the top or from the bottom.

It is good if a small drawing of the collector structure is transferred to paper. This will give a visual image that will make it easier to manufacture the device. In addition, you can accurately indicate the dimensional characteristics that will have to be maintained during the manufacturing process.For example, the distance between the nozzles of the supply and return circuits should be within 10-20 cm. Do not do more or less, it will simply be inconvenient in terms of maintenance. The distance between the two compartments (supply and return) should be in the same range.

Make your device compact and beautiful. We recommend that you indicate in the figure all threaded connections with an indication of the thread sizes, do not forget to sign all the necessary contours. This will allow you not to make a mistake when connecting. Now from the sketch it becomes clear how much and what materials you will need to make a homemade distribution manifold.

Manufacturing process

Please note that the supply and return compartments can be made of round or square pipes. Many craftsmen prefer the latter option.

They claim that it is easier to work with.

So, here is the manufacturing sequence:

For all the dimensions that were indicated in the sketch, it is necessary to prepare the appropriate materials. These are practically all pipes. They are connected according to the design of the drawing in accordance with the purpose of each. The connection is made using a welding machine. Welding points must be cleaned with an iron brush, if necessary, degreased. The finished device must be tested for leaks. Therefore, all the pipes will have to be closed tightly, leaving only one. Hot water is poured into it. If none of the joints is dripping, then the work has been done at a high level. The collector must be painted and dried. It is possible to carry out installation and connection of all pipe systems with the installation of valves.

A simpler option

Now to the question, isn't it better to buy a ready-made version? There is one "BUT" here. The finished distribution manifold may not exactly fit your heating system; you will have to align the heat engineering indicators in other ways. For example, by installing an additional comb. And this is extra costs and extra volume of installation work. And a homemade comb, in which you took into account all the design features of heating your home, will definitely fit it and will work efficiently and rationally.

So it is worth thinking about the question that was posed at the beginning of the article, how to make a distribution manifold with your own hands? Let's just say it's a simple process that will take you one day. But you simply must have the skills to work with a welding machine and other locksmith tools. Without this, it will be impossible to guarantee the quality of the device.

gidotopleniya.ru

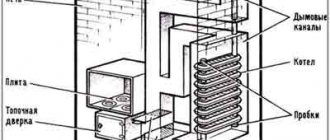

Arrangement of the heating system

To heat the building, an indirect heating boiler is used, which is connected to the collector. In addition, a boiler must be used as an additional heat source. It can be both gas and solid fuel. In autumn and spring, when the required temperature in the circuit can be achieved exclusively through solar energy, the boiler can be left out.

If the winters in your area are cold enough, you will not be able to achieve normal heating of the coolant with only one collector. Nevertheless, using the equipment in question will allow you to save quite a lot. Since a little warmed up water will flow into the boiler. Accordingly, less fuel must be consumed to fully heat it.

The collector size should be as large as possible. This will allow you to use it in the most optimal way. The collector size should be equal to 0.4-0.45 of the area of the heated building.

Views

Collector groups for heating systems are sold ready-made, while they can have different configurations and the number of outlets.You can choose a suitable collector assembly and install it yourself or with the help of specialists.

However, most industrial models are versatile and do not always suit the needs of a particular house. Converting or reworking them can significantly increase costs. Therefore, in most cases, it is easier to assemble it from separate blocks with your own hands, taking into account the peculiarities of a particular heating system.

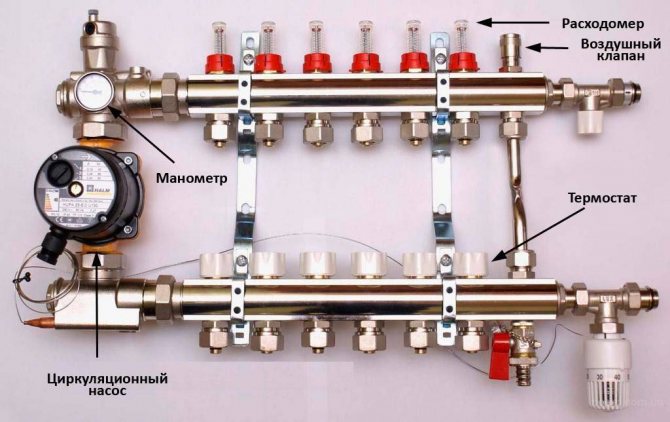

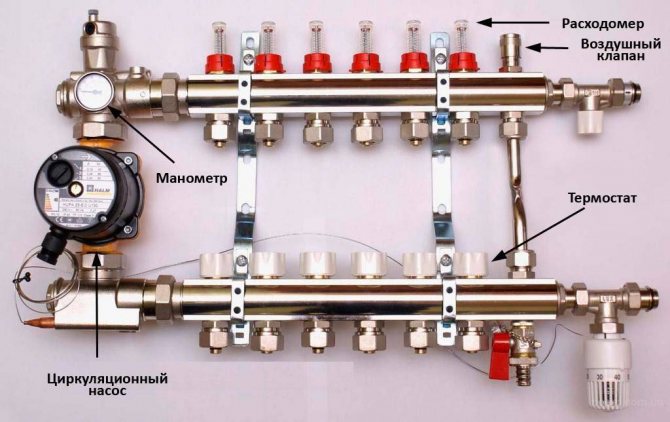

Collector group for heating system, complete

The design of the universal collector group is shown in the figure. It consists of two blocks for forward and reverse flow of the heating medium, equipped with the required number of outlets. Flow meters are installed on the supply (direct) collector, thermal heads are located on the return collector to regulate the return water temperature in each circuit. With their help, you can set the required flow rate of the coolant, which will determine the temperature in the heating radiators.

The manifold distribution unit is equipped with a pressure gauge, circulation pump and air valves. The supply and return manifolds are combined into one unit with brackets, which also serve to fix the unit to a wall or cabinet. The price of such a block is from 15 to 20 thousand rubles, and if some of the taps are not used, its installation will be clearly inappropriate.

The installation rules for the finished block are shown in the video.

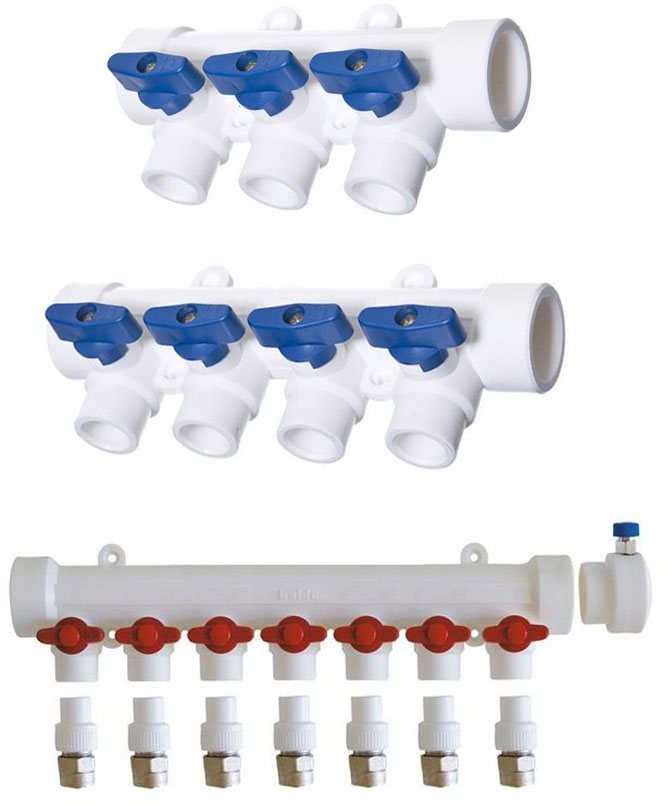

Comb - manifold unit

The most expensive items in a manifold block are flow meters and thermal heads. To avoid overpaying for unnecessary elements, you can buy a collector unit, the so-called "comb", and install the necessary control devices with your own hands only where it is necessary.

The comb consists of brass pipes with a diameter of 1 or ¾ "with a certain number of branches with a diameter for heating pipes ½". They are also connected to each other by a bracket. The branches on the return manifold are equipped with plugs that allow installing thermal heads on all or part of the circuits.

Some models can be equipped with taps, with their help, you can adjust the flow manually. Such combs have a cast body and are equipped with a union / nut thread at the ends, which allows you to quickly and easily assemble a manifold from the required number of branches.

In order to save money, the manifold for heating systems can be assembled from individual elements independently or completely made by hand.

Flexible tube construction

Only high-quality materials are used to create a reliable solar collector. For this purpose, metal-plastic pipes or ordinary hoses used for irrigation are suitable. The collector can be made up of several modules. Pipes must be laid in them and tightly fastened.

This design is the simplest. Its key disadvantage is the need to use a pump. Since natural circulation is impossible in such a design. If the length of the pipes is too long, the indicator of the hydraulic resistance will be greater than the head force created due to the temperature difference.

Note that installing the pump does not present any problem. Moreover, such a system will quickly pay off.

Pool installation

The collector option under consideration can also be used to heat pool water. It must be connected to a filtration system with pumping equipment. The liquid circulating inside will be heated before it enters the pool container.

There are options for which it is permissible to abandon the installation of the storage tank. This approach can be implemented if the heated water is intended exclusively for use in the daytime in a small volume. For example, the length of the contour is one hundred and fifty meters.In this case, the indicator of the inner diameter is sixteen millimeters. This design holds thirty liters of liquid. If the structure consists of several compartments connected into one system, there will be much more heated water.

Tips for installing a collector for underfloor heating

Types of collectors.

Installation of such a structure for a warm floor can be done independently. The manifold for distribution is in most cases located in a manifold cabinet or in a separate room that is hidden in the wall. When installing the structure, you should take into account the nuances:

- Try to place the distribution manifold at the highest point of the heating system in relation to the level of the hinges placed. This is necessary so that, if necessary, it is possible to remove air from the installed pipes.

- The manifold for distribution should be located in the central part of the premises that are heated.

- You will need to connect circuits of the same length to one structure. If such contours are not available, the length should be as close as possible to the length of the element that is located nearby.

Functional purpose

To begin with, there is one very important rule, and if you do not strictly adhere to it, then the heating system of the house will work poorly. This rule states that the diameter of the outlet pipe of the heating boiler must always be equal to or slightly less than the total indicator of the diameters of all circuits consuming the coolant

The best option if it is larger.

For comparison, here is an example of a wall-mounted unit in which the diameter of the outlet pipe is ¾ inch. Imagine that this boiler will heat up three separate circuits:

- The main heating is the radiator system.

- Warm floor.

- Indirect heating boiler, which will use water intended for domestic needs.

Now imagine that the diameter of each circuit is at least ¾ inch, like the boiler. But the total figure will be three times more. That is, no matter how you want, it will be simply impossible to deliver the required amount of coolant through the diameter of the heating boiler nozzle so that it is enough for all three circuits. So much for a decrease in heat transfer over the entire area of the house.

Of course, individually, all circuits will work fine. For example, the main circuit (radiator) without the inclusion of warm floors will completely master the heated space. But as soon as you turn on the underfloor heating system, everything, neither here nor here, will not have enough coolant. The coolant has enough temperature, its volume is not enough.

This rather serious problem is solved by installing a distribution manifold in the heating system. In fact, this is a structure made of stainless metal pipes, in the device of which the devices for the input and output of the coolant distributed along the circuits are installed. To regulate temperature, pressure, flow volume and its speed, shut-off valves are installed along the outputs, which performs all the necessary functions.

The most important thing is that with the help of the distribution manifold, you can control the temperature regime in a single room. And this will not affect the neighboring rooms and the temperature of the house as a whole.

Collector device

The collector consists of two pipes:

- Connects the flow line from the boiler to the flow circuits of the heating systems. This compartment helps the distribution of hot water. His device especially helps in the case when the question arises of repairing one or another branch. In this case, on a certain circuit, where it is necessary to carry out repair work, the shut-off valve closes. It simply shuts off the coolant supply.

- The return compartment regulates the pressure inside each circuit, which ensures the quality of the movement of the coolant.And, hence, the quality of heat transfer from heating systems.

Anyone who does not understand what is the essence of installing a distribution manifold begins to build various additional installations into the heating system: a circulation pump, valves for various purposes, and so on. Let's face it, this will not help; they cannot be used to increase the volume of the coolant. You will simply make unnecessary expenses that will turn out to be in vain.

Attention! If you are the owner of a large multi-storey building, it is recommended to install a separate distribution manifold for each floor.

"Winter" scheme

To equip a solar collector that works all year round, you need to use a different coolant. Antifreeze is used instead of water. We'll have to use a completely different scheme. To do this, you need to use a boiler that works on the basis of indirect heating. The bottom line is that the heat carrier heated by solar energy passes through the serpentine heat exchanger into the boiler, and heats the water inside the tank.

To ensure the normal operation of the circuit under consideration, it is necessary to use a safety valve, an automatic air vent and a pressure gauge.

What is it needed for

When installing water-pressure systems, there is a rule: the total diameter of all branches should not exceed the diameter of the supply pipe. With regard to heating equipment, this rule looks like this: if the diameter of the outlet of the boiler is 1 inch, then two circuits with a pipe diameter of ½ inch are allowed in the system. For a small home heated only by radiators, such a system will work efficiently.

In fact, there are more heating circuits in a private house or cottage: underfloor heating, heating of several floors, utility rooms, and a garage. When they are connected through a branch system, the pressure in each circuit will be insufficient to effectively heat the radiators, and the temperature in the house will not be comfortable.

Therefore, branched heating systems are performed with collector systems, this technique allows you to adjust each circuit separately and set the desired temperature in each room. So, for a garage, plus 10-15 ° C is enough, and for a nursery, a temperature of about plus 23-25 ° C is needed. In addition, warm floors should not heat up more than 35-37 degrees, otherwise it will be unpleasant to walk on them, and the floor covering may deform. The manifold and the shut-off temperature can solve this problem as well.

Video: the use of a collector system for home heating.

Collector groups for heating systems are sold ready-made, while they can have different configurations and the number of outlets. You can choose a suitable collector assembly and install it yourself or with the help of specialists.

However, most industrial models are versatile and do not always suit the needs of a particular house. Converting or reworking them can significantly increase costs. Therefore, in most cases, it is easier to assemble it from separate blocks with your own hands, taking into account the peculiarities of a particular heating system.

Collector group for heating system, complete

The design of the universal collector group is shown in the figure. It consists of two blocks for forward and reverse flow of the heating medium, equipped with the required number of outlets. Flow meters are installed on the supply (direct) collector, thermal heads are located on the return collector to regulate the return water temperature in each circuit. With their help, you can set the required flow rate of the coolant, which will determine the temperature in the heating radiators.

The manifold distribution unit is equipped with a pressure gauge, circulation pump and air valves.The supply and return manifolds are combined into one unit with brackets, which also serve to fix the unit to a wall or cabinet. The price of such a block is from 15 to 20 thousand rubles, and if some of the taps are not used, its installation will be clearly inappropriate.

The installation rules for the finished block are shown in the video.

Comb - manifold unit

The most expensive items in a manifold block are flow meters and thermal heads. To avoid overpaying for unnecessary elements, you can buy a collector unit, the so-called "comb", and install the necessary control devices with your own hands only where it is necessary.

The comb consists of brass pipes with a diameter of 1 or ¾ "with a certain number of branches with a diameter for heating pipes ½". They are also connected to each other by a bracket. The branches on the return manifold are equipped with plugs that allow installing thermal heads on all or part of the circuits.

Some models can be equipped with taps, with their help, you can adjust the flow manually. Such combs have a cast body and are equipped with a union / nut thread at the ends, which allows you to quickly and easily assemble a manifold from the required number of branches.

In order to save money, the manifold for heating systems can be assembled from individual elements independently or completely made by hand.