Quite often, a situation occurs when the ball valve for water breaks down. It makes no difference which manufacturer he has: Roca or Kaiser, or some other. People often don’t know what action to take due to the difference in design with such devices. It is important to understand what device a ball valve for water has, what features does the repair have? To understand how to repair this device, you need to know the design of the ball valve for water and the method of supplying water.

At first glance, a ball water tap is a complicated device and repair. In a conventional valve, it is enough to replace the rubber gasket for repair, but with a ball valve, the procedure will be different.

Features of the

So, recently, special ball valves have been used in gas pipelines. These devices are designed to completely shut off or open the gas flow. The peculiarity of these devices is contained in the locking mechanism, which is made in the form of a ball with a through hole. Moreover, the hole in diameter converges with the diameter of the pipeline (see also the article "Where and how a high pressure valve is used").

To shut off the flow, the ball is rotated so that the hole is perpendicular to the pipeline, i.e. it must be rotated 90 degrees. The locking mechanism is controlled by a lever. Tightness is provided by rings made of soft and durable materials.

Differences from plumbing fittings

It must be stated that the external difference between a gas tap and a water tap is that the lever is yellow, not red.

There are much more structural differences:

- They have a more durable body, which is made of special grades of steel or brass with a high copper content.

- They have a longer connecting thread.

- The locking mechanism is made of very durable chrome or nickel-plated material.

- The stem is made of extra strong polymer material.

- These taps are capable of withstanding more pressure than water taps.

- O-rings are more durable and provide better sealing.

Note! Regardless of the fact that the price of gas taps is higher, they cannot be replaced with plumbing fixtures, since the savings can be very expensive. But it is not allowed to use gas valves instead of water valves.

In general, all that differs a gas faucet from a water stop valve is an increased level of tightness. The rest of the points are not so serious in domestic gas pipelines. Proceeding from this, in principle, any valve corresponding to the tightness class "A" can be used for a gas pipeline.

Application features

In most cases, shut-off valves for gas pipelines are installed in the kitchen, i.e. where gas equipment is used. Moreover, a separate valve is installed for each source of consumption.

For example, in buildings and apartments where gas stoves and water heaters or boilers are installed, I install separate gas taps for stoves and for other devices. In addition, usually one non-specialized valve is installed at the inlet, which allows you to completely shut off the gas supply.

It must be stated that stop valves are used not only to shut off the flow, but also to control it, for example, a three-way gas valve allows the flow to be redirected from one pipeline to another. Indeed, such devices are not used in everyday life.

Advice! When implementing gas supply to a house with bottled gas, it is possible not to install non-specialized shut-off valves, since a valve is constantly mounted on the cylinder, which allows the gas to be shut off.

Technical description

The first thing to consider is the ball valve arrangement.

Structure

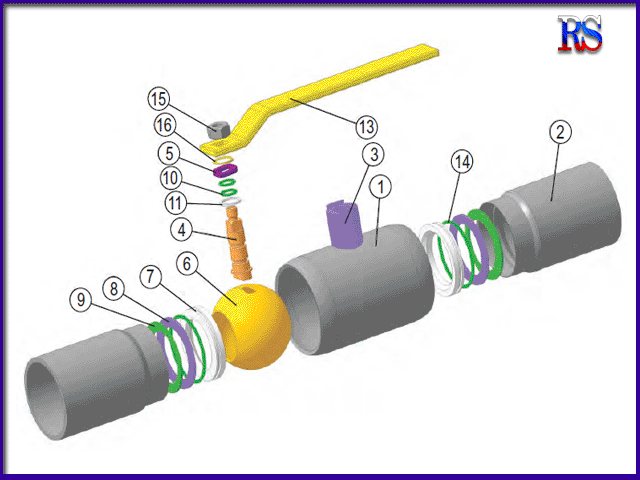

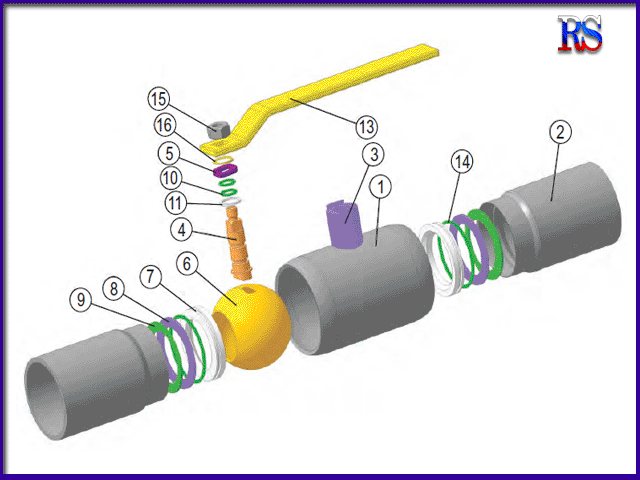

Gas ball valve design

| Designation in the figure | Name |

| 1 | Body part. Most often found in brass or steel. |

| 2 | Connection branch pipe. Can be threaded or welded. |

| 3 | Throat part. Passes the stem through itself. |

| 4 | Connecting rod. Connects the handle and the ball. |

| 5 | Restraint washer. |

| 6 | Shut-off ball. Directly performs the closing and opening of the passage. |

| 7 | Saddle. Positions the ball in the desired location. |

| 8 | Annular support. Holds the saddle. |

| 9 | Spring. |

| 10 | O-ring seal. |

| 11 | Ring. |

| 12 | Flange. |

| 13 | Lever. |

| 14 | Seat seal. |

| 15 | Locking nut. Holds the handle. |

| 16 | Stopper. |

Principle of operation

Steel hollow ball

The most important and basic part of the gas valve under consideration is the shut-off ball, which has a through hole equal to the diameter of the connecting pipe and is connected to the switching handle by a stem.

The instruction for the functioning of such a mechanism is elementary:

- A person with a slight movement of his hand turns the handle 90 degrees.

- The stem transfers this movement to the ball.

- The wall changes to a hole, creating a free passage.

Advice: it is not recommended to set the handle in a half-open position, as this significantly increases the wear of the structure.

Dignity

Ball gas valve KSHG made of steel

Ball valves for a gas pipeline have a whole set of positive aspects:

- Relatively low price... Achieved due to the simplicity of the design, which excludes the use of expensive components.

- Light weight... Does not weigh down the pipeline, allowing it to be limited to standard pipe fittings.

Conventional gas pipeline mount

- High reliability... Only high strength materials are used in the manufacture.

Tip: It is recommended to select the material of the valve depending on the conditions of the environment in which you plan to use it. So, for example, brass models will perfectly cope with corrosive processes, and steel ones will withstand more powerful mechanical loads.

Robust brass gas ball valve body resistant to corrosive processes

- High speed and ease of use with your own hands... A short turn of the knob is enough to change the position from “open” to “closed” and vice versa.

- Maintenance free... Such shut-off valves can be safely installed in hard-to-reach places.

- High tightness of flow shut-off... The closed position of the valve guarantees complete sealing of the gas pipeline.

- Mounting even underwater... At the same time, the penetration of liquid into the system is absolutely excluded.

- Small size... They allow the product not to stand out against the background of the pipe itself and simplify its installation, which is easily performed by 1-2 people.

Ball valve on gas pipe

- Attractive appearance... The only detail that stands out is the handle, which can be a butterfly or an extended arm. In any case, the technical unit looks quite aesthetically pleasing.

- Easy to install... Both threaded and welded connections are possible.

Technical data

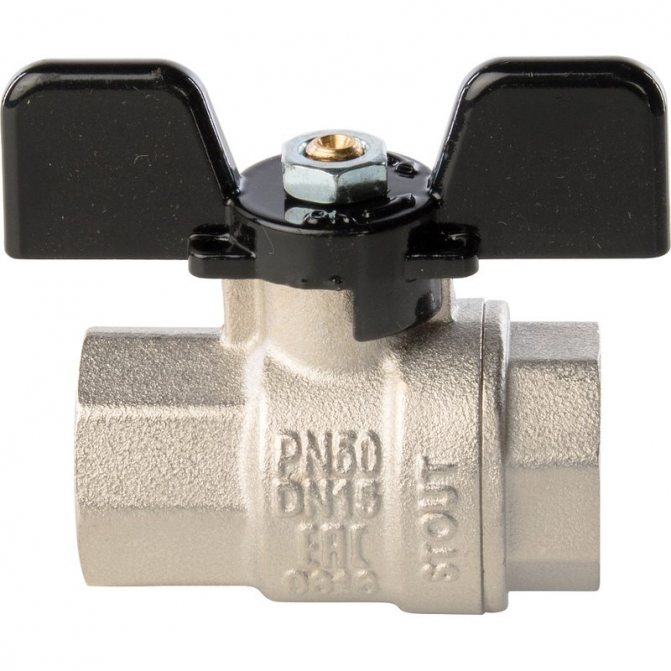

Butterfly valve with 15 mm nominal bore

Let's analyze the parameters of the classic model for installation on a home gas pipeline:

| Parameter | Value |

| Cross section | 1.5 cm or ½ inch |

| Number of threads on a threaded connection | 6-7 |

| Tightness index | Class A |

| Withstanding pressure | Not less than 6 MPa |

| Allowable temperature | -20 to +130 degrees Celsius |

| Body material | Brass grade LS-59-2 |

| Stick type | Butterfly |

| Handle color | Yellow in accordance with the rules of gas pipeline designation |

| Gasket material | Fluoroplastic |

| Threaded connection for pressure gauge | G ½ / G ½ |

| Types of threaded connections | Internal-external and internal-internal |

| Item Height | 5.8 cm |

| Length including handle | 6.7 cm |

| Body length | 6.7 cm |

| External diameter | 3.3 cm |

Possible varieties

It should also be noted that ball gas valves may differ in some features, namely:

- If possible, make repairs... There are collapsible and all-welded samples.

Tip: if you are installing a crane in a hard-to-reach place, then it is better to opt for an all-welded product with a welded connection pipe. This way you will achieve maximum tightness, which is necessary with the condition of difficult maintenance in the future.

- Down the aisle... Ball valves can be full bore and partial bore.

In addition, there are models that have an electric drive that allows you to automate the process of closing and opening.

Types of ball gas valves

In addition to the fact that the observed shut-off valves differ in diameter, the differences lie in the installation method. The following types of devices are used much more often in gas pipelines:

| Threaded (coupling) | They have a small diameter. In most cases, these products are used in household gas pipelines. The connection to the pipeline, as it is not difficult to guess from the name, is carried out using a threaded connection. |

| Flanged | They are used in external gas pipelines of huge diameter. The connection is carried out by the flange method using bolts. Like threaded, these devices are collapsible, i.e. they can be dismantled and then reinstalled. |

| Welded | Like flanged ones, they are used for external gas pipelines. Their diameter can range from 10 to 70 millimeters. The connection to the pipeline is carried out by welding. Accordingly, this installation option is non-separable. The advantages of such products include complete tightness and high reliability. In addition, the welded shut-off valves are maintenance-free, i.e. tightening of flange connections. |

Advice! In addition to ball valves, there are also plug valves. But, they have less reliability and durability, therefore, they are very rarely used recently.

Features and purpose of ball valves

The oil, chemical or gas industry cannot be imagined without valves. The shut-off pipeline fittings produced on modern high-tech equipment will ensure the safety of the entire system.

Gas pipeline shut-off valves are an indispensable structural element. These devices are used for both external gas pipelines and internal systems.

The purpose of gas ball valves is quite large:

- equipping complex systems through which aggressive and non-aggressive environments pass;

- use in pipelines located in hard-to-reach places;

- efficient operation in case of nominal pressure up to 16 MPa, etc.

When using gas ball valves, there is no need to create a manhole and enclosing structure.

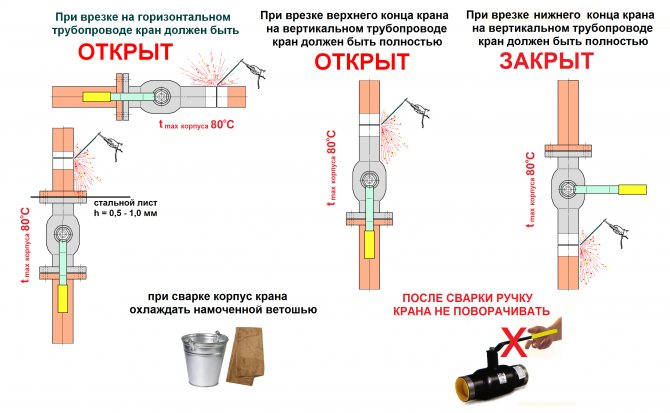

If you need to dismantle any product, part of the pipes is simply cut off. In this case, the valve must be in the open position so as not to damage the shut-off ball. The design of the valve is not intended to regulate the flow of the pumped medium.

For any repair work on gas pipelines, the shutter of the ball valve must be open so that the structure does not break completely

If it is required to install a restricting device on buried highways, then most often they use ball gas valves driven by an electric motor, reducer or pneumatic cylinders. If the design contains hydraulic or pneumatic actuators, they can be controlled by external sources or the conveyed medium.

For this, holes are made in the body of the gas valve through which the drive is piped. To prevent the structure from breaking, the spindle extension is protected by a shell in the form of a vertical tube.

Moreover, this tube is attached to the upper part of the valve body in a flanged manner. Most often, stopcocks are installed directly where the gas equipment is located.

A gas ball valve can be installed on a section of a gas pipeline only after preliminary cleaning of the inside of the pipe and adjacent sections.

At the same time, for each source of gas consumption, an individual valve is mounted, which ensures the sealing of a certain pipe. It is also possible to install one additional valve with a ball valve at the inlet, which is responsible for completely stopping the gas supply. Such an installation meets all the necessary safety requirements.

Gas ball valves provide two-way gas movement in the pipeline. Such devices can be mounted on gas pipes of any diameter. They can be used on trunk networks, used in the operation of storage facilities and in the transportation of natural gas over long distances, etc.

Manufacturers

Gas pipelines are one of the most important housing supply systems. Proceeding from this, the choice of all its elements, as well as shut-off valves, should be given special attention.

You need to buy products only from well-known, well-proven manufacturers.

In particular, it is possible to give preference to cranes from such Italian companies as:

- Bugatti;

- FIV;

- Valtec;

In addition, the products of the following companies are of good quality:

- Dungs - Germany;

- Profactor - Germany;

- Broen Ballomax - Poland;

- Efar - Poland;

- LD - Russia.

Advice! You should not take the most inexpensive gas valve, since there are many low-quality valves from China on the market, which do not always meet all the requirements for gas valves.

Causes of malfunction of a single lever mixer

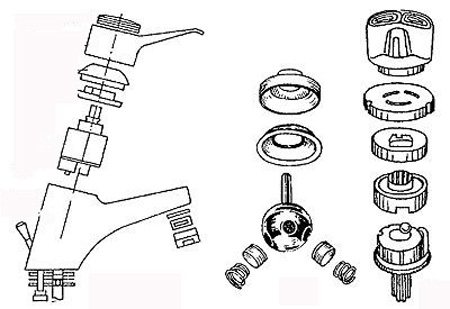

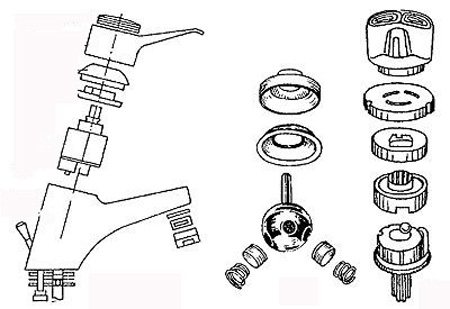

Disassembly diagram of a ball valve.

Housewives are in demand for single-lever kitchen faucets. Such a single-lever mixer has a handle that turns smoothly without passing or jamming. If grains of sand have penetrated into the head of a single-lever mixer, its tightness is impaired. The kitchen faucet begins to leak if the grains of sand that have got into the parts of the head have created small grooves. In this case, the head of the kitchen faucet is changed. And for this you need to disassemble the crane. Another reason for repairing a faucet is the deformation of the locking mechanism under the influence of hard water.

In this case, it is necessary to change the lever and head on the crane, which is called a swivel head.

Features of replacing the gas valve

Certainly, each stop valve may fail, for example, gas taps are not insured against breakdowns. If this unit is found to be defective, it must be replaced immediately.

Immediately go to declare that you are not allowed to do this work with your own hands! But, some actions still need to be performed independently.

So, the instructions for replacing this shut-off valve are as follows:

- First of all, it is necessary to tell about the problem to experts from gas work or a personal organization that owns a license to perform similar work.

- After that, you need to purchase a new crane from a specialized store.First, you need to measure the diameter of the pipeline, so as not to make a mistake when choosing a product.

- For the arrival of experts, go to prepare a technical passport and a contract for gas supply. A technical passport is needed to make a note about the work performed.

- After that, you need to light the gas on the stove and turn off the central valve. Leave the burner until it is completely extinguished, so that the whole gas escapes from the pipeline.

- Upon the arrival of experts, it is necessary to open a couple of windows in order to create a draft in the room. This is necessary in case of a gas leak.

- At the end of the work, go together with experts to diagnose the installed valves for leaks.

- At the end of the work, it is necessary to give the workers of the work a technical passport and ask them to make a note in that direction.

Advice! It is possible to find out gas leaks with soap foam. It must be applied to the joints of the device with the pipeline, and to the valve itself. If a soap ball forms in some place, it means that the shut-off valves are allowing gas to pass through.

At the end of the work, leave the windows open for another 15-30 minutes, which will allow for full ventilation of the room.

Ball valve repair

A ball valve is a device that may require repair. There are many tips, some of them:

- Be sure to shut off hot and cold water before repairing.

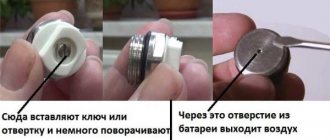

- Next, unscrew the screw that holds the pivoting arm in the mixer. Next, the lever itself is removed. To do this, you need to shake it from side to side with a certain effort.

- Next, we take the pliers and remove the dome in the mixer and the plastic element.

- If the tap is leaking, check the seal for damage and also look for obstructions. If so, they must be removed with extreme care. Otherwise, you risk damaging the seal, which will lead to even more leakage.

- Next Yes Then you need to check if there is any damage in the mixer ball. If they are, then you will have to change it.

- Next, we remove the seals of the rotary element. This is easy to do with a flat screwdriver.

- We replace the deformed gaskets.

- If the springs have lost their elasticity, they should also be replaced.

Reassemble the valve in reverse order. In this case, all gaskets must be lubricated, regardless of the degree of their novelty. Moreover, the question of choosing a lubricant must be taken responsibly, because the effectiveness of the repair depends on it. In some cases, you can make things even worse.

Single lever mixer device

The device is a single-lever mixer with a ball mechanism.

When it comes to repairing a kitchen faucet, it turns out that you just need to know the basics of plumbing and that disassembling a single-lever mixer is different from disassembling a two-lever mixer. The device of a two-valve mixer makes it possible to use two handles that allow you to control cold and hot water and regulate its temperature.

Modern two-valve faucets have tapered handles and an arched spout in the center that changes the direction of the water. The design of a single-lever mixer is much simpler and more elegant. The insides of these mixers may vary. They are divided into ball mixers and devices with ceramic cartridges. The ball mechanism has advantages over the ceramic cartridge.

Single lever mixer diagram.

It is cheaper, made of metal, easy to maintain, and easy to disassemble. Having a single-lever mixer with a ball regulator, you do not need to purchase a coarse water filter. Ball mixers are mortise, wall-mounted and combined. A ball with a diameter of 20 mm is the basis of such a mixer. The mixer function depends on the correct shape of the ball.

Two drilled holes for hot and cold water are connected to one outlet. Their diameter is 4 mm. When the handle is lowered, water cannot enter the holes.When the handle is raised, the holes in the ball coincide with the water supply pipes. The water mixes in the ball and enters the spout through the outlet. The mixer handle can be raised higher or lower to adjust the water flow, and can be turned to the right or left to adjust the water temperature. Cold water will appear at the far right, hot at the far left.

Possible problems when using the ball valve

High pressure ball valve device diagram.

A crane cannot be repaired if it has visible damage in the form of cracks on its body. This defect is often found in cheap faucets made of poor material. When the water pressure decreases, it is necessary to disassemble the device and look for problems inside. First, you should check if the pressure has decreased due to the fact that the water pressure has dropped in the system. To do this, you need to open other taps in the house and see what kind of pressure they have. Another cause is a clogged aerator in the outlet duct. It just needs to be removed and cleaned. If rusty water flows from the tap, the cause should be looked for in the water supply system, and not in the device itself.

Related article: Do-it-yourself bathroom screen

The most common failures of ball valves are: water leakage from the mixer, low water pressure and improper water temperature control. Water can leak due to clogging in the space between the rubber gaskets in the cartridge and the rotating element. Even a small grain of sand can lead to a violation of the tightness of the structure and leakage. Therefore, you should disassemble the mixer and clean it, otherwise the leakage will increase due to the deformation of the rubber gasket, which will require replacing the latter.

The reason for the weak water pressure may be a clogged valve. In order to avoid this malfunction, it is necessary to install a coarse filter in front of the mixer and at the entrance to the house. Changes in water temperature will clog one of the holes in the ball with grains of sand or pieces of rubber gasket.

If the causes of the malfunction were not found, it is necessary to replace the valve on the riser with water. The reason for this is the desire to save money on the purchase of high-quality taps and mixers. Such devices are usually made from silumin, a cheap material with low strength and often crumbling under any mechanical stress. Therefore, it is better to purchase a high-quality device than to repair a cheap mixer later.