High-quality painting assumes:

- preliminary cleaning from dust, rust and dirt;

- removal of all layers of old oil;

- coating with a primer for metal, preferably heat-resistant;

- painting in 2 layers gives the best quality and even surface (one layer can be slightly diluted with a solvent to save composition).

Many actions are easy to carry out with the tools at hand, including brushes for cleaning and washing. Old paint can be removed using different methods (you can do it in a complex way):

- chemical;

- mechanical (special attachments for the grinder and a universal tool);

- thermal (building hair dryer, blowtorch);

- by hand.

Advice! Use a metal brush to scrub the surface before applying the primer to remove loose particles that can then adhere to the brush or roller.

Old radiators after painting will last for at least a decade.

Not all paint is suitable for painting cast iron radiators. Only non-toxic heat-resistant interior enamels. They are sold in different forms - cans, cans, buckets. If you paint without a primer, you can degrease it with a solvent suitable for its chemical composition. Even if the enamel is "environmentally friendly", when painting the area of a cast-iron radiator MC-140 (another model), use:

- respirator,

- work gloves;

- work clothes and footwear.

It is recommended to ventilate the room at every stage of processing, especially after the paint has set a little. All calculation data are adjusted for any modern model or old model. The area of the heated surface varies slightly for 1K60P-60x500 "Bas-relief", Standard-90, RD-90s, 2K60P-300, B-Z-140x300, MR-2KP140 "Beckard", etc. How to calculate the number of sections , on the "calculator" or through the program, decide on your own. There will be no big discrepancies.

> Painting area of cast iron radiators

The beauty of the heating device can be easily restored by painting the surface of the cast-iron battery.

Heating area of a section of a cast iron heating radiator

May 07, 2013 11:57 am

Igor_01 wrote: Calculate correctly, you can consult with your neighbors, see how they have and ask if it is good, is the girl warm to you, is it warm to you red ?!

Consulting with neighbors is entertaining, but dubious from the point of view of reliability. Someone +18 is normal, while others at +24 are ho-o-cold! The air temperature in living quarters is regulated by sanitary standards. The document is called SanPiN 2.1.2.2465-10 "Sanitary and Epidemiological Requirements for Living Conditions in Residential Buildings and Premises." Effective in the last edition from 27.03.2011.

Brief explanations of how to work with it will be given below the calculator.

Calculator for calculating paint for a cast iron heating radiator

What is the basis and how is the calculation carried out?

It is not difficult to calculate the area of, for example, flat panel radiators, since the front panel to be periodically painted has a rectangular shape. With sectional cast iron - it is more difficult, due to their complex configuration, so the calculator was made specifically for them, as they remain one of the most common.

Cast iron radiators MS - "ageless veterans"

Whatever novelties the assortment of modern heating devices pleases, cast-iron radiators will surely serve a person for a very long time.What is the secret of the longevity of these batteries, what are their technical characteristics, how to calculate the required number of sections for efficient heating of the room - read about all this in a special publication of our portal "Cast iron radiators MS-140" .

Did you like the article? Save so as not to lose!

Power of 1 section of a cast-iron radiator and room area

Replacing the heating system, in particular, radiators, is a very difficult and responsible task. The modern market offers a fairly diverse number of models from various materials. A few years ago, cast iron structures were inferior to structures made of aluminum and steel.

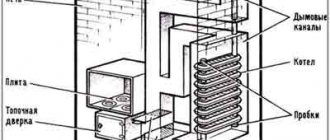

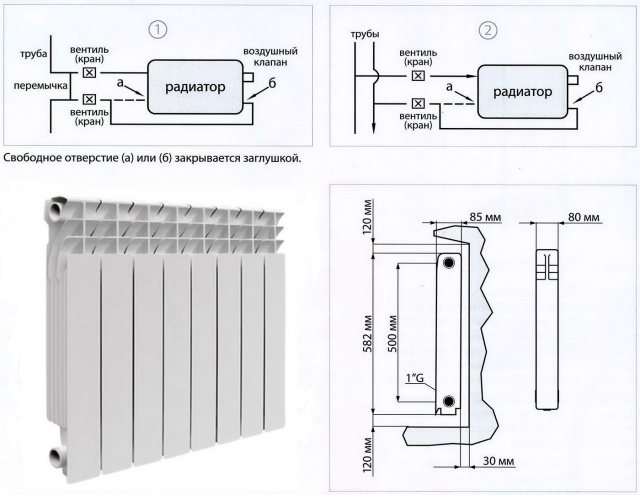

Diagram of cast iron heating radiators.

But everywhere installing modern batteries, people are faced with the fact that the reliability and durability of new radiators are not as good as those of cast-iron models.

Therefore, recently there has been a tendency for the growth of sales of cast iron heating products.

Basics of calculating the required power

In order to correctly calculate the required size of the radiator, that is, the number of its constituent sections, it is necessary to know the power, which is sufficient to maintain the given temperature.

Calculation of the required power of cast iron heating radiators.

Living room, which has one door and one window, ceiling height of about 3 meters, requires 110-120 W to heat one 1 sq. M. The power required to heat the room may vary depending on the upwind side of the condition of the window frames and the tightness of the door. The indicated power value is an average, in each room it is necessary to make certain corrections. On average, a 15 m2 room will require 1.5 kW of battery power. It is advisable to complete a corner room with two batteries, this will contribute to a more even distribution of heat. The total power of the radiators must exceed the calculated one by 30%. That is, if for an ordinary room with an area of 20 square meters, 2.5 kW of battery heating power is enough, then for a corner room, about 3 kW of power allocated by heating devices will be required. This fact is due to the fact that the corner rooms of the building are often equipped with two or more window openings and have a large contact area of the walls with cold air.

Cast iron radiator power

The power of a radiator of any type is usually expressed in the power of one section, if the battery is made up of them, or as a separate aggregate value in the case of plate radiators. Cast iron radiators are assembled from separate sections. One section has a power of about 0.15 kW (150 W). This value may vary slightly depending on the casting geometry of the section. The power of an individual section is directly proportional to its surface area. For typical cast iron products, the area value is the same. But at present, many new models of cast iron radiators are presented, which have different shapes and, accordingly, area.

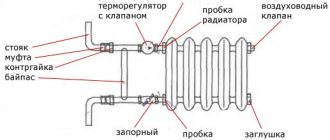

Installation diagram of cast iron heating radiators.

Classic cast iron products emit 150 watts of thermal power under the following conditions. The room temperature should differ from the heat carrier temperature by 50 degrees Celsius. For example, if the room is 20 degrees, then the temperature of the coolant is 70 degrees. If this temperature difference is observed, the section power will be equal to the declared one. Sometimes the declared power is indicated at a temperature difference of 70 degrees. This will not be a correct value, since the temperature of the coolant does not always allow this difference to be achieved. A battery with the same real power may have different values in the passport due to the conditional temperature difference. As a result, you can make a mistake when calculating the number of sections. Heat dissipation must be calculated according to the characteristics of the room.The number of windows, the number of doors, and the angular arrangement have a direct impact on what kind of heat transfer is required.

On average, 1 ordinary room, which has an area of about 15 square meters, will require 10 cast-iron sections to complete the batteries. Each additional window will require 1 or 2 additional battery sections. Specifically, it depends on the glass units used in the window construction. If the area of the premises is more than 20 square meters, then it is better to install two batteries with the required total capacity.

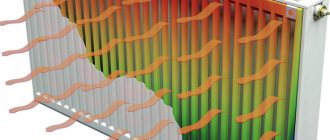

When calculating heating parameters, you should know that cast iron radiators emit about 80% of heat by convection and 20% by infrared radiation. Therefore, the location of the battery should be chosen near or under a window, as a result, the heat transfer will improve due to the increased air circulation in these places.

Wiring diagram for cast iron heating radiators.

When choosing the type of batteries, they often give preference to one or another model, starting only from the indicated power of the section. This is not always correct. Weaker heat transfer, in comparison with aluminum products, is offset by the long service life and reliability of cast iron radiators. The heat transfer of bimetallic batteries is almost the same, but they are much more susceptible to corrosion than cast iron ones.

We often hear that a cast iron radiator has a larger internal volume compared to other types and as a result, you have to consume more energy for heating in private houses. This is not true. The volume of 1 cast iron radiator is about 4 liters. Of course, this exceeds the volume value for products made from other materials. But the more the water is heated, the more heat will be given off, that is, the heating system, consisting of cast-iron radiators, has a large volume and will require more thermal energy to heat it, but it will also take a long time to give off heat to the room. 1 heated battery will release a certain number of kW as the water cools. The only drawback is that such a system is inert and it is quite difficult to accurately regulate the temperature in the room, since the heating and cooling process is lengthened. In apartments with centralized heating, this disadvantage is absent due to the deterioration of boiler rooms and heating systems, which, as a result, does not allow the preparation of a heat carrier of the required temperature. The area of the room can be successfully heated with some predetermined accuracy using a thermostatic tap.

The choice of cast iron radiators is most relevant when working in an old housing stock, which is served by obsolete boiler equipment.

Most Popular Blog Articles of the Week

Preparatory actions

They provide for cleaning the surface from dirt and old paint. Preparation takes place as follows:

Wipe off dust with a damp cloth. You need to wipe it very well. There should be no dirt in the pits. To wipe hard-to-reach places, the rag is moved between the ribs and pulled back and forth.

sandpaper and file

A layer of primer is applied. Of course, it has to withstand high temperatures and match the type of paint. It will be better if the brand of both is the same.

It can be carried out with any type of composition. but on one condition: the solution must be resistant to high temperatures. Otherwise, the updated look will not last long.

The surface of the radiator is painted with a regular or curved brush. Of course, in the beginning, gloves are put on their hands and gauze, foam rubber or rags are placed next to it. They can be used to wipe off paint that has run down the handle of the brush.

The staining process is as follows:

- With a flexible brush, they update the look of hard-to-reach places (they are located between the pipes of the sections). In some parts, the brush will not touch the cast iron. Gauze folded into a tourniquet can save you. It is placed between the sections, paint is applied to the middle, and then the ends are pulled in turn.So, the paint will somehow fall on the alloy.

- Paint the top and easily accessible places.

- Always moving from top to bottom. It is better to apply the paint in several layers than one thick one.

Painting

It can be carried out any type of composition, but on one condition: the solution must be high temperature resistant.

The staining process is as follows:

- With a flexible brush, they update the look of hard-to-reach places (they are located between the pipes of the sections). In some parts, the brush will not touch the cast iron. You can use gauze folded in a tourniquet. It is placed between the sections, paint is applied to the middle, and then the ends are pulled in turn. This will put the paint on the alloy.

- Paint the top and easily accessible places.

- Always moving from top to bottom. It is better to apply the paint in several layers.

Why calculations of paint consumption for radiators vary

Not everyone wants to get rid of old cast-iron batteries after modernizing an apartment. They are practical and reliable, and if the heating system is cleaned and rusty pipes replaced, old radiators will last at least a decade after painting.

Advice! Do not cover the yellowed, in places crumbling and cracked layers of paint with a new coating. This should be done only after removing the old paint layers and opening the metal with a primer.

Calculations for paint consumption are complicated by the variety of models of heating devices, differing in many parameters:

- mass (weight);

- aesthetics (design);

- format (dimensions of the section and the entire battery);

- power (heat output);

- the volume of the coolant (water);

- connection method (side, bottom, diagonal), etc.

Improved battery designs may require more paint than conventional batteries

New models are also produced, imitating old cast-iron "accordions". They exactly imitate the general structure of classic heating equipment. They have an improved design with artistic molding or designer soldering and comfortable feet on the bottom for floor standing. They require a little more paint and primer, materials must be taken with a margin.

Calculation of the area of \ u200b \ u200bpainting a cast iron radiator

Heating systems are available in any apartment. There are a lot of types of heating devices. They are distinguished by weight, design, dimensions, heat release and other properties.

Cast iron radiators are reliable and convenient. Houses commissioned during the Soviet era were supplied with batteries, which are perfectly controlled with their own functions and heat the apartment space during the cold season. Today's heating systems stand out from cast iron in that they are lighter and more interesting from the outside. But most people do not want to exchange their own old cast iron radiators for good and attractive today's heating devices.

Methods for calculating the area of \ u200b \ u200bcoating paint

You can find the information you need about the area covered with paint in the technical description for the model. Usually, for domestic equipment, it is indicated as "heating area" or otherwise, if it is an imported radiator.

The most popular type of heating device is MC-140. This is a classic for most old-built apartments. The length of one section is 9.3 cm, the height is 58.8 cm. The area is 0.24 m². Based on this, you can find out the total area of the battery. The area of the section is multiplied by their number. As a result, a number is obtained equal to the area of the painted surface of the cast-iron radiator. It is better to always round off the result and take into account the consumption of paint with a small margin for taps, couplings, adapters, etc.

A more modern or modified model of a heating device has a painted area of cast iron radiators of about 0.208 m 2. Accordingly, less dyeing material is needed.

Many internet sites now have dedicated online calculators. With their help, you can independently calculate the required indicator. To do this, you just need to enter the following parameters in the corresponding lines:

- radiator marking according to technical documentation;

- number of sections, their length and height.

After that, the program will make the necessary calculations of the area to be painted and give the desired result.

As you can see, it is not at all difficult to calculate the area of heating batteries for painting. After that, you can confidently proceed with the reconstruction of one of the main interior elements.

Calculator for calculating paint for a cast iron heating radiator

Modern heating radiators - steel, aluminum, bimetallic and some others, go on sale with a high-quality, multi-layer protective and decorative coating. With careful handling, they can serve for many years without requiring additional painting - it is enough to regularly wet cleaning. The good old cast-iron "accordions" are a different matter: they must be painted both during the initial installation and at regular intervals during operation.

Calculator for calculating paint for a cast iron heating radiator

The painting process can be carried out by any owner of a house or apartment - the main thing is to choose for these purposes high-quality paint that is suitable for its operational parameters for heating devices. With paint consumption, at first glance, everything is also simple, since manufacturers indicate this parameter on the packaging labels of the factory packaging of the material. But here's the catch! - consumption is indicated per unit area, and looking at the complex configuration of a cast-iron radiator, it is problematic to estimate its area. Determine the amount of paint by eye? No, not worth it, it is better to use the calculator for calculating the paint for a cast-iron heating radiator, posted in this publication.

Brief explanations of how to work with it will be given below the calculator.

What is the basis and how is the calculation carried out?

It is not difficult to calculate the area of, for example, flat panel radiators, since the front panel to be periodically painted has a rectangular shape. With sectional cast iron - it is more difficult, due to their complex configuration, so the calculator was made specifically for them, as they remain one of the most common.

If you "rummage" in the technical characteristics of cast iron batteries, you can, if desired, find the value of their surface area. In order not to send the reader to independent searches, these parameters are collected in the calculator's database for the most commonly used cast iron radiators of the MC series, as well as for more modern ones - the FM series.

Please note that some radiators have modifications - internal fins, which increase the heat exchange area. Naturally, the paint consumption for such sections will be higher. Of course, the total painting area depends on the number of sections assembled into the battery. The calculator provides the ability to immediately calculate the paint for coating the supply and return pipes connected to the radiator

Cast iron radiators MS - "ageless veterans"

Whatever novelties the assortment of modern heating devices pleases, cast-iron radiators will surely serve a person for a very long time. What is the secret of the longevity of these batteries, what are their technical characteristics, how to calculate the required number of sections for efficient heating of the room - read about all this in the special publication of our portal "Cast iron radiators MC-140".

Cast iron heating radiators: characteristics, features, basic parameters

The content of the article:

Cast iron batteries are a standard heating device adapted to the operating conditions of central heating. The characteristics of the cast iron heating radiators correspond to the requirements of the system. They are resistant to corrosion and not too demanding on the cleanliness of the coolant, insensitive to pressure drops and durable.

Design features of cast iron radiators

Cast iron radiators are the most durable

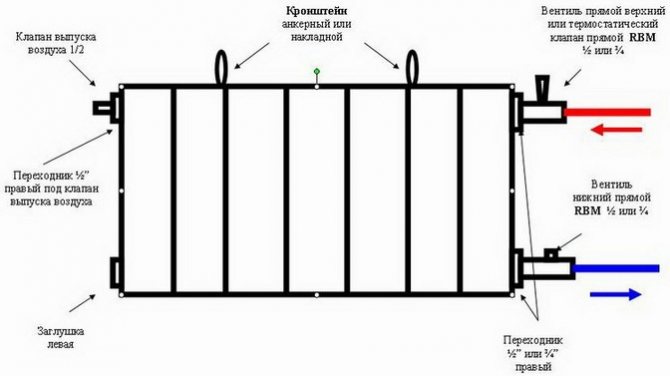

The batteries look the most traditional.The design includes several sections, interconnected by nipples. Heat-resistant rubber or paronite is used to seal the joints. The channels for the coolant inside have a circular or elliptical cross section. One-, two- and three-channel sections are produced.

The batteries are cast from gray cast iron. The material is resistant to wear and tear - radiators serve for more than 50 years. Salts are not deposited on the walls, fine debris or sand does not damage. Even after 30–40 years, the diameter of the working channels remains almost unchanged.

The size of the cast iron battery depends on the number of sections. The size is selected based on the size of the heated room. But if the width of the product is determined by the number of elements, then the height and depth depend on the device of the sections themselves.

The appearance of the product is unattractive. More modern models come with a flat front panel. Decorated with forged items.

Advantages and disadvantages

Modern design solutions

The merits of the product are due to the material rather than the design. Main pluses:

- Cast iron conducts heat well and accumulates it. The radiator heats up longer than a steel or bimetallic one, but it gives off heat after the boiler is turned off for a long time. An hour after stopping heating, the residual heat transfer for cast iron models is 30%, while for steel models it is only 15%.

- The water used for central heating is not clean. Salts, mechanical impurities, sand destroy the pipeline material. Debris is deposited on the walls: the working diameter decreases over time, the heat transfer efficiency decreases. Cast iron is not afraid of salts, abrasive particles. After 30 years, the batteries perform as efficiently as they did the first day after release.

- Cast iron batteries do not withstand constant high water pressure, however, water hammer is not afraid of it. This option is used when arranging heating with natural circulation.

- Radiators last at least 50 years. If you change the gaskets in time, even longer. Usually they are replaced not because of leaks or low efficiency, but in order to make the interior more modern.

- The price is the lowest among heaters.

Cons of radiators:

- The main drawback is its considerable size and heavy weight. The 8-section model weighs over 60 kg. They are difficult to transport, lift to the upper floor, or mount.

- If, when the heating is turned off, high thermal inertia is an advantage, then when turned on it turns into a disadvantage. The room is warmed up for at least 12 hours.

- To service the batteries, a large volume of coolant and a more powerful boiler are needed. For central heating, this is not a hindrance, since the system was originally designed to transfer a large amount of coolant. This is a significant disadvantage for an autonomous one.

- There is no need to talk about design. Rough heavy radiators hardly fit into the interior.

The advantages of a cast iron battery are well manifested in central heating systems. The disadvantages are visible when equipping autonomous heating.

Specifications

The choice of cast iron batteries is small. Most of the older models have been abandoned. In new ones, they are trying to reduce the volume of the coolant, improving heat transfer due to a larger number of channels and creating a flat surface.

The technical characteristics of the most popular models are shown below.

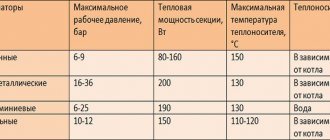

| Brand | Working pressure, atm | power, kWt | Heating area for 1 section, sq. m | Water volume in 1 segment, l | Weight of 1 segment, kg |

| MS-140 | 9 | 0,12–0,16 | 0,244 | Up to 1.45 | 5,7–7,1 |

| World Cup1 | 9 | 0,075–0,11 | Up to 0.165 | Up to 0.9 | 3,3–4,8 |

| World Cup2 | 9 | 0,1–1,14 | Up to 0.207 | Up to 0.95 | 4,5–6,3 |

| World Cup3 | 9 | 0,1–0,15 | Up to 0.246 | Up to 1.38 | 4,8–7 |

Models are selected mainly in terms of power. Comparison of the characteristics of the sections allows you to quickly calculate the required dimensions of the heater.

Height

A parameter that affects not so much the efficiency of heating, but rather aesthetics. The height of the cast iron standard battery is 59 cm. Models are available with heights from 33 to 95 cm. The working surface of each section varies according to the height.This is taken into account when calculating the required number.

Low heat sinks look more attractive even with a standard configuration.

The size

Product dimensions vary greatly:

- height - from 33 to 95 cm;

- depth - from 8.5 to 20 cm;

- width - from 4.4 to 10.8 cm;

- the center distance varies from 22 to 90 cm.

See labeling for size information. If the model is non-linear, no depth is specified.

The most important parameter - the length of the battery itself - depends on the power. The more sections, the more area the radiator can heat. However, there is also a limitation: if the length of the battery is 4 times the height, it must be connected from both sides, and this is not always possible and convenient.

Power

The indicator is calculated according to the following parameters:

- room volume;

- insulation quality;

- water temperature;

- the power of one section of a cast-iron radiator - this indicator is indicated in the product passport.

On average, at a normal level of heat loss for heating 3 cubic meters of air in a room, 1 kW is required.

The calculation is performed as follows: the area of the room is multiplied by 100 and divided by the capacity of the sections of the selected model. For example, with an area of 10 sq. m. and a segment power of 150 W receive 10 * 100/150 = 6.67. Round the result up - to heat the room, you need a radiator with 7 sections.

It is advised to increase the calculated value by at least 15%. For heating a bedroom of 10 sq. m. recommend buying batteries for 9-10 cells.

Consider the height of the room. With the same area, but with a ceiling height of not 3.5, but 4 m, at least 12 sections will be required for heating with a radiator of the same power.

Other factors are also taken into account. If there are 2 windows in the room, it is better to install 2 batteries of 5 sections in order to evenly distribute heat and neutralize cold air.

Selection rules

Flat surface radiators are more efficient

The recommendations are simple:

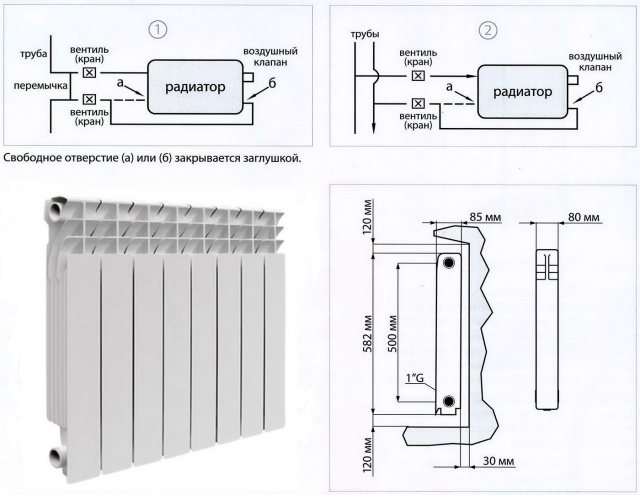

- The most important thing is the correct calculation. The section power is estimated and the efficiency of the entire heater is calculated. If the sections are not enough, an increase in the temperature of the coolant will not fix the matter, the room will be cold.

- You need to find the height. If the product is mounted under a window, at least 20–15 cm should remain between the battery and the window sill, and at least 5 cm between the floor and the lower edge of the product. For large windows, low radiators are chosen and compensate for the low height with a large number of sections. High radiators are mounted near blank walls.

- Batteries with a flat surface have a higher efficiency and a more attractive appearance. Models with art casting, with decorative coating fit perfectly into the interior in retro, classic, rustic style.

- Radiators are fixed on the wall with special brackets. However, there are outdoor models. The latter are used if the walls cannot withstand such a heavy load.

The appearance of the batteries can be radically changed by covering them with a decorative grill or screen.

Cast iron radiator manufacturers

Such products are produced not only by Russian factories and enterprises of the CIS countries. There are many foreign manufacturers offering cast iron radiators in retro or techno style. The models of domestic companies are cheaper.

Minsk plant of heating equipment

One of the most famous manufacturers. Produces two- and three-channel cast iron batteries in a variety of designs. There are classic radiators and models with a flat surface - they are more efficient, since they give off heat better, as well as options with a pattern on the surface. The number of sections is determined by the customer.

Santekhlit (Russia)

The factory offers classic models. The depths of the sections and the heights vary widely. There are models with a depth of only 11 cm. They are easy to place under a narrow modern window sill. The length of the battery is determined by the number of sections.

Viadrus (Czech Republic)

The company offers products more suitable for autonomous heating.Radiators can easily withstand a constant pressure of 12 bar and are very durable. They meet the European quality criteria.

The design of the radiators is attractive. The plant produces 8 lines in different designs and in 27 standard sizes. There are models with a flat surface, with an exquisite pattern on the sections, with sections of an unusual irregular shape.

Factors affecting the consumption of materials for painting a radiator

The amount of material for painting heating radiators is calculated based on the area of the surface to be coated. To do this, you need to know the area of one sections of the cast-iron radiator and their total number. Often, the manufacturer prescribes these parameters in the instructions for the devices. In addition, it is necessary to take into account some of the nuances of the coloring agent itself. These include:

All this is taken into account when choosing a paint. In addition, they are guided by the type of battery and recommendations from the manufacturer.

The procedure for calculating the area

A problem such as the poor look of old cast iron appliances is easy to solve, for which you need to paint their surface. First of all, you need to figure out how much primer and paint to purchase.

This can be found out by determining the area of \ u200b \ u200bpainting cast iron radiators. Then they study the recommendations that are available on the can with the coloring composition. They always contain information on the consumption of paint per square meter.

It is impossible to independently find out the area of a section of a cast-iron radiator for painting. This is not required, since the manufacturers of heating equipment provide this information in the instructions attached to the products. Rather, the documentation indicates the size of the heating area, and since every centimeter will warm up, this value is the size of its entire surface.

It is known that the rib area of the MS-140-500 product is 0.244 sq. m, and the modified section of this device, which has a center-to-center distance of 300 millimeters, has an area of 0.208 sq. m.

To calculate the entire surface of a cast iron radiator, you should:

- find out the name of the model and, if possible, its manufacturer, since the same modifications of devices made at different enterprises have different parameters - width and depth;

- determine the heating area of the rib;

- multiply this value by the number of sections.

For example, in the MS-140-500 radiator there are 10 fins, then the surface area will be 2.44 square meters. m. After that, they determine how much and what building materials will be required. When calculating the consumption of paint for heating radiators, it is necessary to take into account that it must be purchased with a margin, since each layer of the coloring composition will have a different thickness.

Radiator area calculation

At the very beginning, you need to find out how much primer and paint you need to use to paint the battery. This can be found out by calculating the area of the heating radiator. Next, they look at the recommendations indicated on the paint can. They always indicate how much paint can go for 1 sq. m... Manufacturers indicate the heating surface area of the section.

To determine the total surface area of a cast iron battery, you must:

- Find out the model name of the installed battery and the manufacturer (because the sections produced by the manufacturers of the same models have different depths and widths).

- Set the heating area for 1 rib.

- Multiply the number of sections by the area. If the MS-140-500 radiator has 10 fins, then the surface area is 2.44 sq. m.

Having made the calculation, determine the amount of composition and primer. The paint should be taken with a margin.

Preparatory activities

They involve cleaning the surface of the battery from old paint and dirt:

- Wipe the dust thoroughly with a damp cloth so that no dirt remains in the grooves. To clean hard-to-reach places, place a rag between the ribs and move it back and forth.

- Remove the old paint layer.When the chemical method is used, Dufa, SP-6, B52, ACE funds are used, but they are not able to cope with the oil formulations that were produced in the middle of the 20th century. The physical method requires the use of a drill on which a metal brush is attached. You can also use a file and sandpaper.

- A layer of primer is applied. It must not only withstand elevated temperatures, but also correspond to the type of paint, it is good if they are of the same brand.

How to independently calculate the coverage area and paint consumption

There are various ways to calculate the area of painting of cast iron radiators, but it is useless to "reinvent the wheel".

Attention! Heating equipment manufacturers reflect this information in the technical description for the model. This value is usually indicated as "heating area", other options and translations are possible if these are imported models.

Calculating the area of color of a cast-iron radiator MC-140 as a classic sample, we take into account the area of one section or "accordion ribs". It is approximately equal to 0.244 m 2. A more modern or modified section with a slightly larger center distance (300 mm) has a painting area of the order of 0.208 m 2.

The radiator can be painted in any color that suits the overall interior

The models of cast-iron batteries can differ greatly, therefore, for calculations, we take the heating area of one section from the documentation (product passport). Next, we multiply by the total area of all ribs with a small margin (adapters, taps, couplings, legs). For example, in a standard MS-140-500 there are 10 ribs, we multiply by 10 the section area of 0.244 sq. M. We get 2.44 m 2. We round up to 3 m 2 - for all adjacent parts. Next, we decide how many layers the painting will be.

Innovative methods for determining the area of painting of cast iron radiators - special computer programs and calculators. They enter the following parameters:

- radiator marking (according to technical documentation).

- number of sections, their length and height.

Only with proper pre-cleaning of the battery will the paint lay perfectly evenly

On the issue we have the real area of painting. After receiving the information, a "reset" is entered to clear the window and enter new data.

How many kW in one section of a cast iron radiator

The heat output of a cast iron radiator depends on the volume of water, wall thickness, presence of fins, height and width of the section. There are several standard models of cast iron batteries, the declared heat transfer of one section of which is:

- MS-140 - 175 W;

- MS 140-500 - 195 W;

- MS 140-300 - 120 W;

- MS 110-500 - 150 W;

- MS 100-500 - 135 W;

- MS 90-500 - 140 W.

How to hide a battery in a room - 11 solutions

In the classification, the first number denotes the width of the vertical cast-iron duct, the second - its height.

Standard 6-section cast iron radiator MS-140-500

Modern cast iron batteries differ from standard MS products. They can have other sizes and designs, there are models with air cutoffs. Manufacturers declare the performance of one section in the range from 150 to 220 watts.

If the heat output indicators are given for a temperature difference ΔТ of 60-70 degrees, they differ from the real ones.

For batteries with a water temperature of 55-60 ° C, the real performance will be 75-85%, for batteries with a water temperature of 65-70 ° C - about 85-90% of the manufacturer's specification.

Painting area of cast iron radiators: how to calculate paint consumption

Heating radiators that have served for a long period need revision. If repairs were made, then it is quite possible that the appearance of the structure needs to be slightly refreshed, that is, painted. To do this, you need to know the area of painting of cast iron radiators. High-quality heat-resistant paint is not cheap, therefore, having calculated its consumption, it is easier to save on repairs.

The restored and newly painted cast-iron heating radiator looks just as good as the new one

How many sections of a cast iron radiator do you need: how to calculate?

When installing cast iron radiators in their home or apartment, people often do not think about how many elements are needed for a particular room in order to create the required temperature regime in it. To accurately determine the number of sections, there are some calculations, the implementation of which is quite simple.

Sectional radiator diagram.

Standard settlement methods

According to all modern norms and rules that apply to heating systems designed for water, per sq. m of the room requires approximately 0.1 kW of power. This figure is typical only for residential premises; for non-residential premises, 0.05 kW, or even less, will suffice. It all depends on the specific purpose of the room.

If we take this into account, then the simplest calculations can be carried out according to the formula:

P = (S / P1) * 100, where P is the required power, that is, the number of sections; S is the area of the room; P1 is the capacity of one section.

In this simple equation, a single term is unknown, namely the heating capacity of one radiator section. It is generally accepted that it is equal to 150 watts, therefore, in all formulas, it should be taken equal to this very value.

Back to the table of contents