Swagelok offers a variety of needle shutoff and control valves to control flow in general and severe service systems.

Features:

- Provide reliable and constant flow control;

- They are made of various materials, have various sizes and types of end connections;

- Designed for use in aggressive environments and harsh conditions.

General Purpose Needle Valves (GU Series)

BUY catalog

General purpose GU series needle valves are designed to shut off or bleed media. The hardened stainless steel non-rotating needle ensures a seal and long system life. Low emission certification available in accordance with API 624.

Characteristics:

| Operating pressure | up to 413 bar |

| Temperature | 0 to 650 ° F (343 ° C) |

| Flow rate | Up to 2.25 |

| Material | |

| Body material | 316 stainless steel, carbon steel |

| Seal material | Carbon / glass filled PTFE, graphite |

| End connections | |

| A type | NPT, socket weld connections |

| The size | 1/4 to 1 inch; from 6 to 25 mm |

How air appears in the heating system

The first condition for the reliable functioning of an automatic air plunger is to keep it under constant water pressure. The pressure value should not fall below 0.030 bar. This condition is provided by plunging the expansion tank into the system. It has a pressurized rubber bulb.

In order not to clog and jam the air vent valve, the mechanism is periodically disassembled and cleaned. Also, you cannot operate the system without coarse filters. They also need to be inspected periodically.

When water seeps through the air valve for heating, and this cannot be eliminated by cleaning, it is more expedient to replace the device.

Needle valve with integral bonnet (series 0,1, 18, 20 and 26)

BUY catalog

We offer injection-molded needle valves in various sizes, configurations, materials, and applications. Low emission certification available in accordance with API 624.

Characteristics:

| Operating pressure | up to 413 bar |

| Temperature | -53 to 315 ° C |

| Flow rate | Up to 1.80 |

| Material | |

| Body material | 316 SST, Brass, Steel, Alloy 400 |

| Seal material | Polyurethane foam |

| End connections | |

| A type | Swagelok® Tube Fittings, ISO Female NPT |

| The size | 1/8 to 3/4 inches; from 3 to 18 mm |

The main task

The main task of the valve is clear from its full name: automatic discharge of air and other gases from pipelines and vessels filled with a liquid medium.

How do these same gases get there? Here are the main paths:

- Dissolved in the coolant:

this applies specifically to air. Ordinary cold water contains a considerable amount of this gas in dissolved form - about 30 g per 1 cubic meter. m. Often it is poured as a coolant without preliminary preparation, as a result of which all the dissolved air is inside the system. It is known that with increasing heating, the solubility of gases in liquids decreases. In accordance with this law, when the water is heated, air begins to escape from it. To prevent such a phenomenon, the water must be subjected to a special preparatory procedure before pouring - deaeration. It contributes to a significant reduction in the amount of dissolved air - up to 1 g per 1 cubic meter. m. In the same way, you need to prepare the water used for make-up. If ordinary tap water is used for this, which happens quite often, air will still accumulate in the system little by little. - When the system fills up quickly:

Experienced plumbers know to fill the heating circuit gradually, thus allowing air to escape naturally. It usually takes several hours to refuel a branched system within one floor, while the coolant must be poured from below. If you neglect this rule and fill in the coolant faster than it should be, a fair amount of air will remain inside. - Through the walls of polymer pipes:

some brands of polymer pipes, for example, cross-linked polyethylene, do not have an anti-diffusion coating. As a result, their walls allow air to pass through. It is clear that it will gradually accumulate if such pipes are mistakenly used in the heating system. - When performing repair work

, especially related to the dismantling of equipment. - When the system is depressurized.

- Due to corrosion.

In this case, we are not talking about air, but about hydrogen. It is released from a water molecule when the oxygen present in it reacts with iron (recall that corrosion is the oxidation of iron and other metals). The volumes of hydrogen evolution are quite noticeable: with rusting 1 cu. cm of iron from water 1 liter of this explosive gas is formed.

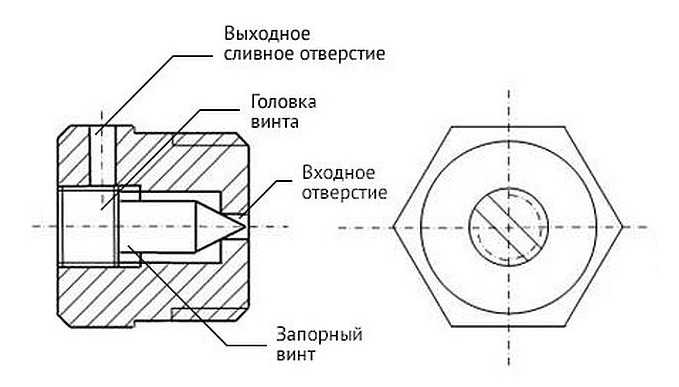

Disassembled air vent for heating system

Hydrogen and oxygen are emitted especially actively in aluminum radiators. The fact is that aluminum plays the role of a catalyst that promotes the decomposition of a water molecule into gas components.

For this reason, it is forbidden to smoke and use open flames near the air vents installed on such devices. In bimetallic radiators, this phenomenon is also observed, although to a much lesser extent.

Screw Bonnet Stainless Steel Needle Valves (JB Series)

BUY catalog

Threaded bonnet needle valves can be supplied with a regulating stem or check-tip stem, straight and angle configuration, and adjustable packing.

Characteristics:

| Operating pressure | up to 206 bar |

| Temperature | -40 to 315 ° C |

| Flow rate | Up to 0.58 |

| Material | |

| Body material | 316 stainless steel |

| Seal material | PTFE or Grafoil® |

| End connections | |

| A type | Swagelok Tube Fittings, NPT, ISO Male |

| The size | 1/8 to 3/8 inches; 6 and 8 mm |

Operating principle

An automatic air valve for a heating system has a cylindrical or cone-shaped body, inside which a float is placed.

The body is provided with a thread for connection to the system elements. It can be made of brass, cast iron or plastic. The float is made of plastic.

By means of a thrust, it is connected to a needle valve that closes the discharge hole.

How the heating air valve works:

- Air accumulating in the upper part of the housing gradually displaces water. This lowers the float.

- Moving down, the float carries with it the rod and the needle of the bolt mechanism attached to it. In this case, air squeezed out by the coolant is discharged through the opened hole.

- After removing the air, the coolant again forces the float to rise and close the vent hole. Until the next cycle, the device goes into standby mode.

In addition to the main function, the air valve can perform one more: it allows air to pass inside when draining the system, providing a faster drain of the coolant.

So that the vent hole can be quickly closed in the event of a breakdown of the air vent, a plug in the form of a cap is installed on it. At the factory, this cap is screwed down completely, thus preventing dirt from getting inside. After installing the product, the cap must be slightly opened by turning it counterclockwise several times. If this is not done, the air valve will not work.

Some auto air vent models are supplied with an adapter that has a spring-loaded valve inside. It closes automatically as soon as the vent is removed.

Air vent on the radiator

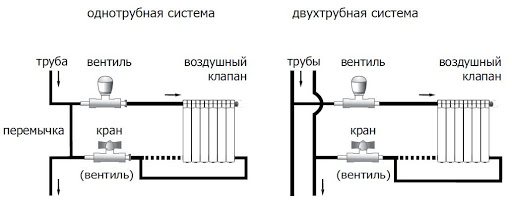

Automatic air vents are produced in 3 versions:

- Pipe straight lines:

are screwed onto a vertical pipe, the end of which is facing up. The body of such an airplane has the form of a straight cylindrical or conical sleeve. This option is used most often. - Pipe angular:

the vertical part of the device is identical to the one just described, but at the bottom it rotates at an angle of 90 degrees. This design allows the air vent to be installed on a horizontal pipe, which is sometimes necessary (for example, due to lack of space, it is not possible to install a vertical pipe section for connecting a direct air vent). - Radiator:

designed for installation on radiators, for which they have a corresponding thread. As noted earlier, it is aluminum and bimetallic radiators that need automatic air vents. On cast iron, manual air valves can be installed - the so-called Mayevsky taps. Air from such batteries has to be vented only occasionally, most often when the system is started up after a summer shutdown.

Since air and other gases are much lighter than water, the Archimedean force causes them to rush upward. Therefore, air vents must be installed at the highest point of the serviced circuit.

Ideally, air vents should be on each device, including steel radiators. They are also mandatory placed after the boiler, usually as part of a security group.

At this point, the valve is needed to vent air when filling the boiler heat exchanger.

In addition, if the boiler piping is correctly designed, using an air vent, it can be emptied separately from the entire system (the valve will let air in), and after repair, it can be refilled with coolant.

It should be borne in mind that automatic valves are demanding on the quality of the coolant. If it contains a large amount of contaminants, the waste hole quickly becomes clogged and the needle valve can no longer close it tightly. The device has to be disassembled and cleaned.

It is used to prevent an accident in the heating system. We will consider the principle of operation of the device and recommendations for installation in the article.

See the instructions for making a heater with your own hands.

Brass Screw Bonnet Needle Valves (JN Series)

BUY catalog

Characteristics:

| Operating pressure | up to 41.3 bar |

| Temperature | -40 to 148 ° C |

| Flow rate | Up to 0.43 |

| Material | |

| Body material | Brass |

| Seal material | Primary PTFE |

| End connections | |

| A type | Swagelok Tube Fittings ISO NPT |

| The size | 1/8 to 3/8 inches; 6 mm |

Lever valves (OG, 1G, and 92 series)

BUY catalog

Easy and fast on / off regulation.

Characteristics:

| Operating pressure | Up to 20.6 bar |

| Temperature | -28 to 93 ° C |

| Flow rate | Up to 0.70 |

| Material | |

| Body material | 316 stainless steel, brass |

| O-ring stem seal material | Fluorocarbon FKM |

| End connections | |

| A type | Normal pipe thread |

| The size | 1/2 inch |

| Configuration | Straight, oblique, oval |

Instrumentation Purge Valves (6DB Series)

BUY catalog

Characteristics:

| Operating pressure | Up to 413 bar |

| Temperature | -53 to 648 ° C |

| Flow rate | Up to 0.86 |

| Material | |

| Body material | 316 stainless steel |

| Seal material | Grafoil |

| End connections | |

| A type | Swagelok tube fittings, NPT, socket weld ends, VCR male fittings, VCO male fittings |

| The size | 1/4, 3/8, and 1/2 inches; 10 and 12 mm |

Views

Currently, more than a hundred types of such shut-off and control valves are produced. The price of equipment depends on the size, as well as the material of manufacture.

Stop valves are allocated depending on the type of connection to the pipe:

- The valve is needle coupling.

- Flanged.

- For welding.

- Nipple.

- With ferrules.

- Fitting.

- Combined.

- Angle type (angle needle valve turns the flow at right angles, but once, which allows to reduce hydraulic resistance).

There is a three-way valve (tee valve) that has one medium inlet and two outlet ports.

Compact gauge valves

BUY catalog

Compact gauge valves with a purge function are easy to install and provide easy gauge maintenance: lighter and smaller than conventional gauge assemblies.

Characteristics:

| Operating pressure | Up to 275 bar |

| Temperature | -53 to 315 ° C |

| Material | |

| Body material | 316 stainless steel |

| O-ring material | Polyurethane foam |

| End connections | |

| A type | Swagelok Tube Fittings |

| The size | 1/2 inch; 12 mm |

How can you replace the valve on an inflatable mattress. How to repair a valve for an air mattress?

Inflatable mattresses "Intex" are in great demand due to the variety of shapes, sizes and affordable cost. However, such products blow off rather quickly, because the valves installed on them cannot be called a model of reliability. What to do if the valve of the air mattress does not hold?

We offer you to familiarize yourself with the Air ionizer: benefits and harms to human health

How to determine how tight a valve is for an air mattress? To do this, you need to prepare a soapy solution. You will also need a soft-bristled brush or a regular piece of cloth to check.

First, it is recommended to clean the valve for an inflatable mattress from dust, small debris and rinse under a pressure of water. In some cases, even such actions can improve the tightness of the device. After all, the valve of the mattress, in a sense, acts like a vacuum cleaner, pulling in blockages from the outside. Thus, between its membranes there may be layers of dust, hair, threads, etc. It is the debris that most often causes the air mattress valve to leak.

After cleaning, it is worth dipping the product, previously filled with air, in a soapy solution. If fluid starts to bubble in the area of the valve, then the blockage is not the cause of the poor tightness. In this case, it will have to be repaired or changed.

High pressure needle valves

BUY catalog

Cold-machined 316 stainless steel body and high-pressure end connections allow these valves to be used in systems up to 45,000 psi. inch (3102 bar).

Characteristics:

| Operating pressure | Up to 3102 bar |

| Temperature | -53 to 454 ° C |

| Flow rate | Up to 0.19 |

| Material | |

| Body material | 316 stainless steel |

| Seal material | Glass-filled PTFE |

| End connections | |

| A type | Straight male thread, high pressure, NPT female |

| The size | 9 / 16-18, 3 / 4-16, 1 1 / 8-12; 1/4 inch |

Automatic air vent

There are mainly Italian and German models of automatic air vents on the market. These are Caleffi, Pettinaroli, Valtec, Watts, Oventrop and Flamco. Mostly there are air valves of the so-called float valve type.

Design

There is a float in a brass or stainless steel body. To it one of the edges is attached the simplest hinge mechanism, which has the name "rocker". A needle (rod) is attached to the other end of the mechanism. When the body is filled with water, the needle is at rest and the valve remains closed.But as soon as air accumulates in the air vent housing, the water level, and with it the float, drops. The needle, together with the "yoke", starts to move. When the needle enters the spring-loaded spool, it pushes on the stem, which, while moving, opens the holes for air release. This is how an automatic air vent works.

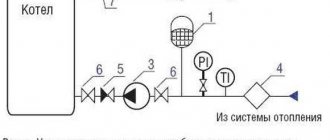

Installation

In addition to the air valve, which is part of the boiler safety group, an automatic air vent must be installed at the highest point of the circuit. Installation can be carried out both in vertical and horizontal pipelines. To do this, the manufacturer makes the supply of the coolant into the air vent as lower end and lower radial. The working position of the automatic air vent is always vertical.

To be able to remove the automatic air vent without emptying the entire system, its threaded part (G1 / 2 ″, G1 / 4 ″) is connected to the heating pipe through a shut-off valve.

This simple device is a lug with a plastic shutter. When screwing in the air vent, the damper automatically opens, when unscrewing it closes.

When installing the air vent, a conventional open-end wrench is used, the lower part of the air vent body is made in the form of a hexagon. During installation, the air nipple cap must be closed.

Valve malfunctions and remedies

Due to the high salinity of the coolant, the needle can become scaled up and the air vent begins to leak. To clean the air vent from scale and rust, unscrew it, having previously insulated and drained the water from part of the pipeline. If there is a cut-off device on the fitting, then the water is not drained. The valve is disassembled, washed, and the needle is carefully cleaned. During the assembly process, the body parts are sealed together.

To prevent the automatic air vent from clogging, it makes sense to put a mechanical filter directly in front of it.

Very often the air vent is made collapsible. The body and cover are connected through a special ring. If it breaks down, it leads to a leak. It is unlikely that you can buy such a ring at retail. It is easier to use fum tape or silicone sealant.

If the air vent is mounted with a deviation from the vertical, then it will leak. Here one salvation is to dismantle, plug the fitting and install it strictly vertically in a new place.

A skewed float may be the cause of the leak. It is easy to fix it yourself when disassembling.

Non-Rotating Stem Needle Valves (D Series)

BUY catalog

Characteristics:

| Operating pressure | Up to 206 bar |

| Temperature | -28 to 232 ° C |

| Flow rate | Up to 0.53 |

| Material | |

| Body material | 316 SST, Brass, Alloy 400 |

| O-ring material | Fluorocarbon FKM |

| End connections | |

| A type | Swagelok Tube Fittings NPT |

| The size | 1/8 to 3/8 inches; 6 mm |

Gauge Valves (6P Series)

BUY catalog

These gauge valves have an easily accessible through hole and gauge connection ports. They are available in a variety of materials and provide system versatility.

Characteristics:

| Operating pressure | Up to 413 bar |

| Temperature | -28 to 204 ° C |

| Flow rate | Up to 1.80 |

| Material | |

| Body material | 316 SST, Alloy 400 |

| Saddle material | Acetal |

| End connections | |

| A type | Normal pipe thread |

| The size | 1/4 to 3/4 inch |

Method without glue

The hole in the mattress can be sealed with thick paper:

- unscrew the valve mechanism;

- turn out the damaged area;

- offset torn edges on a heat-resistant base;

- cover the punctured area with a thick sheet of paper;

- iron the surface.

After cooling, the paper is removed, the fabric is tucked in and the valve is installed in place.

- Make sure there are no sharp objects on the mattress before dropping it on the floor.

- Do not place on the ground, use a thick cloth.

- Do not drag inflated on the ground, do not roll children, this leads to the rupture of the internal partitions and the divergence of the seams.

- If the mattress is not for bathing, do not use in water.

- Do not jump abruptly onto an inflated mattress.

- Keep pets away from the mattress, which can damage the surface with claws or teeth.

- Do not pump with air as the mattress wears out faster and may burst.

There are a number of reasons why one or more holes will form in your favorite soft bed. As a result, the mattress squeaks, lets air in and deflates (lowers). It may be that one of its edges suddenly swelled up. This indicates a rupture of the internal partitions.

Manufacturers recommend using several techniques in order to identify damage.

- The velor bed must first be inflated and immersed in water. Bubbles will begin to appear at the location of the hole. This method is convenient if your house has a large water tank, for example, a swimming pool, or you are outdoors next to a river or lake. Placing the mattress in the bath is unlikely to work.

- The second method can be applied both indoors and outdoors. You should also inflate the mattress and apply pressure with your hands over its entire area. A slight whistle will be heard at the location of the gap. If you bring your palm closer to this area, you can feel a faint jet of air coming out of the hole.

- The third check option is used extremely rarely, but it is very effective. For control, you need to press a little on the inflated mattress, take a lighter and, at a distance of 3-5 cm from its surface, move it lit along the canvas. In the place of damage formation, fire vibrations will surely begin. You need to work very carefully, because any careless movement will contribute to the fact that you simply waste the inflatable bed.

- The mattress can be evenly covered with powder or any other powder. A cloud of dust where the hole is formed will be evidence of air leaking from the mattress.

- Soapy water is often poured inside the mattress. As a result of pressure on certain areas of the outer velor surface at the site of damage, water seeps from the inside out with a characteristic whistle. He will be evidence of the formation of a crack.

- The most effective and commonly practiced method is to use lather or shaving foam. It covers the entire surface of the inflated mattress. Bubbles appear at the site of damage to the bed. Thus, you can accurately detect the area where air leaks are occurring.

We suggest that you familiarize yourself with How to deal with cobwebs in the house

When purchasing an Intex inflatable mattress, you should initially understand that you will not be able to use such a thing as a sofa. Only with careful storage and operation will there be no need to repair certain units of the product. Observing a number of rules, you will be able to use an inflatable bed for a long time.

- The inflated mattress must not be thrown on the floor or the ground without first making sure that there are no cutting or stabbing objects on which it could be damaged.

- It is recommended to additionally underlay a dense, non-slip fabric under the mattress. A thin blanket is best for this.

- Children should not be allowed to jump and run on the inflatable bed.

- Try to isolate pets from where you plan to place the mattress.

- To avoid cracking at the seams, it is not recommended to inflate the bed too much.

- Store the inflatable product deflated in a dark, dry place.

- In case of contamination, wash the mattress with standard detergents, without resorting to any strong powders or mixtures.

For repairing a burst partition on an air mattress, see the next video.

To avoid problems during the operation of the product, it is recommended to pay attention to the following points:

- Do not over pump the mattress. It is enough to fill it by 80-85%. Otherwise, excessive pressure will be exerted on the valve. Over time, this can lead to rupture of the seams at the point of its connection with the rubber part of the product.

- In no case should you jump on an inflatable mattress. This is fraught not only with the divergence of the seams, but also with the popping out of the valve elements.

- It is only necessary to inflate the mattress using the factory pump designed for this purpose.

- To avoid damaging the valve, it is not recommended to sleep on a swimming mattress.

Polyurethane foam needle valves

BUY catalog

These needle valves are made of high purity polyurethane foam for chemical resistance, with polyurethane foam tube fittings end connections for system reliability, full flow through bore, and a plug-on stem for flow control.

Characteristics:

| Operating pressure | Up to 12.4 bar |

| Temperature | -17 to 148 ° C |

| Flow rate | Up to 1.39 |

| Body material | Primary PTFE |

| End connections | |

| A type | Swagelok Polyurethane Foam Tube Fittings |

| The size | 1/4, 3/8, and 1/2 inches |

| Safety-related product selection: In order for the system designer and user to be assured of safety-related product selection, the system design and the complete product catalog must be taken into account. When choosing products, the entire system should be taken into account in order to ensure safe and trouble-free operation. Compliance with the intended use of the devices, material compatibility, proper operating parameters, correct installation, operation and maintenance are the responsibility of the system designer and user. Caution: Do not replace or mix Swagelok two-ring tube fitting components (or other non-industry standard products) with components from other manufacturers. |

Location and installation

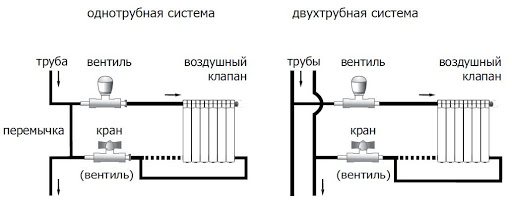

Installation diagram

When installing the air release valve, the following factors must be taken into account:

- Air in the water supply system and in the heating system accumulates at the highest points of the equipment. This feature is present in radiators, floor heating collectors and heating boilers.

- If the installation location is incorrectly selected, the thermal balance will be disturbed. Because of this, the efficiency of heating the room will be significantly reduced. When it comes to underfloor heating systems, if installed incorrectly, whole cold zones are formed.

To avoid the consequences of incorrect installation, it is recommended to follow the advice of specialists. The air vent must be installed in the following places:

- in the area where the pump-mixing unit of the heating boiler is located;

- for underfloor heating - on equipment collectors;

- on the additional equipment of the heating boiler, while it is necessary to select the highest point near the expansion tank;

- on standard radiators.

The insulated valve can be installed on the hydraulic arm.