All pipeline systems are equipped with shut-off and control valves, which include a variety of valves, taps, valves, gate valves. Their function is to regulate and shut off gas streams or liquid streams. In contrast to traditional closure assemblies in a ball valve, the closure has a spherical surface. In any of its positions, it is capable of pressing against the seat, which creates a cross-section for the flow of the medium (gas or liquid), up to its complete overlap.

The ball valve has been on the Russian market for almost twenty years and has received recognition among consumers. It has a graceful shape, as a design element, it fully meets the modern requirements of ergonomics. Ball valves are manufactured both with manual control and electromechanical drives, allowing them to be operated in automatic modes.

Design features of ball valves

The design of ball valves retains the traditional concept of using a movable spindle, which, when the handwheel or handle (item 11) or the actuator of the electric motor is turned, imparts the working movement to the locking device in the housing. But instead of the classic spool and seat of the usual conical or cylindrical configurations, the ball valve design uses a saddle with a ball valve fixed in it (key 4). Ball - the shutter is securely fixed in the saddle, but rotates freely in it. The ball has a through hole, the position of which with respect to the flow of liquid or gas changes by rotating the ball around its axis. The degree of opening of the orifice section influences the flow parameters in the same way as with traditional valves.

To maintain a stable position of the ball valve, a threaded connection of the spindle or stem (pos. 3) with a spindle nut (pos. 8), fixedly connected to the body, is used. Its self-locking ability allows you to fix the operating parameter of the flow.

The very invention of the ball locking mechanism for pipeline valves dates back to the beginning of the 20th century, but it did not receive proper application due to the lack of high-quality sealing materials in those years that could ensure the tightness of the valve. Currently, seals made of Teflon and fluoroplastic reduce the abrasion of the valve's sealing shells to almost zero, which immediately expanded the scope of these valves. In the ball valve design, all mating parts and their connections (keys 5, 6, and 7) must be properly sealed.

Control ball valves

- TPA directory

- Samaravolgomash LLC - product catalog

- Regulating Ball Valves Regulating Ball Valves

Control ball valves Control ball valves 1. PURPOSE OF THE CRANE Controlling ball valves SVM are designed to regulate the pressure or flow rate of the pumped medium in the pipeline in which the valve is installed. 2. OPERATING PRINCIPLE The principle of operation is based on the effect of flow throttling with partial blocking of the flow area of the valve. Overlapping is carried out by turning the plug around its axis by the required angle. Controlling ball valves SVM are not shut-off valves. 3. APPLICATION The cranes are designed to work with natural gas, oil, oil and gas refined products, water, and other media. 4. PRESSURE CLASSES - Crane DN 50 mm (2 ″), 80 mm (3 ″), 100 mm (4 ″), 150 mm (6 ″), 200 mm (8 ″), 250 mm (10 ″), 300 mm (12 ″) - pressure class from ANSI 150 (20.0 kgf / cm2) to ANSI 2500 (421.8 kgf / cm2) - Valve DN 350 mm (14 ″), 400 mm (16 ″) - pressure class from ANSI 150 (20.0 kgf / cm2) to ANSI 1500 (260.5 kgf / cm2) - Valve DN 450 mm (18 ″) - pressure class from ANSI 150 (20.0 kgf / cm2) to ANSI 900 (156.1 kgf / cm2) - Valve DN 500 mm (20 ″), 600 mm (24 ″), 700 mm (28 ″) - pressure class ANSI 150 (20.0 kgf / cm2) to ANSI 600 (104.1 kgf / cm2) 5. PASSAGE Full, reduced. 6. DRIVE It is completed with a gearbox and / or a power drive (electric, pneumatic, hydraulic, etc.) at the request of the customer. The actuator is the actuator in the customer control system. 7. CRANE ENDS Welded, flanged (all types), flanged with counter flanges. 8. PLACE OF INSTALLATION Ground, underground. The length of the stem extension is in accordance with the project. 9. AMBIENT TEMPERATURE Up to -60 ° C. 10. TEMPERATURE OF THE PUMPED MEDIUM Up to + 190 ° C. 11. CONSTRUCTION - The ball valve is made of forged steel to ensure uniformity and strength of the material under static and dynamic loads. - Compact all-welded spherical crane design offers maximum strength and rigidity with minimum weight. The absence of detachable connections prevents possible leakage of the pumped medium to the outside. - The spherical design and symmetrical shape of the crane make it easy to transport and install the crane on site. When installing it, no additional supports are required and there are no special installation requirements. The crane can be installed in any position. - The symmetry of the structure allows the crane to work in both directions. - The spherical element (plug) is rotated through an angle from 0º to 90º. Plug stem seals and bearings are made of low friction Teflon (PTFE). Its use eliminates the need for any lubricants. The principle of operation of the valve is based on partial blocking of the flow when the plug is turned. In this case, the flow area of the plug is set at a certain angle to the undisturbed flow at the valve inlet. This reduces the cross-section at the plug inlet and deforms the flow. Unlike conventional ball valves, this type of valve does not have locking sealing elements in the form of a saddle group, i.e. the valve does not work in the mode of shut-off valves and when it is completely closed, there are minimal leaks through the guaranteed radial clearances between the ball and the body. In the operating position, leaks through the gap between the ball and the body reduce the turbulence of the flow at the outlet of the plug bore, reduce noise and reduce the torque that tends to close the valve (Fig. 1). To prevent spontaneous closing of the valve, it is necessary to use blocking elements, for example, a gearbox.

In the control valve, in contrast to the shut-off valve, there is no blocking of the cavity between the body and the ball from the working pressure. The valve cavity is always under pressure and therefore does not drain outward. When liquid flows through the control valve in certain modes, cavitation may occur. Cavitation is accompanied by characteristic noise, the resistance of the pipeline increases significantly and, consequently, its throughput decreases. With prolonged exposure to cavitation, erosional destruction of metal walls occurs. Cavitation is normally undesirable and should not be tolerated. To calculate the possibility of cavitation, contact the SVM.

Portal of pipe fittings Armtorg.ru

Barnaul, Factory 9th passage, 5g / 8.

+7 (3852) 567-734; +7 (3852) 226-927

Share this

Previous article Next article

← Back to section Samaravolgomash OOO - product catalog ← Back to the table of contents of the directory

Latest registered companies (Register a company)

Trading House "NHI-Group"

Russia, Krasnodar Territory

NefteKhimEngineering

Russia, Moscow region

Boiler plant

Russia commodity cloud

In other ... .2038 units klapanov127 safety valves bronzovye123 stalnye932 Gates Gates Gates chugunnye571 energeticheskie145 nerzhaveyuschie368 Latches Latches Catches, steel stalnye2161 - HL369 chugunnye1101 Latches Latches Paddles energeticheskie89 stalnye292 gates chugunnye334 Test equipment for TPA119 obratnye954 Valve Valve Valve otsechnye60 predohranitelnye1108 Valve Valve reguliruyuschie557 energeticheskie128 Compensators Condensate silfonnye204 stalnye55 Condensate boiler chugunnye67 oborudovanie220 bronzovye149 Cranes Cranes Cranes nerzhaveyuschie170 stalnye620 steel cranes - cranes HL87 chugunnye149 Manometry88 Metizy433 Nasosy247 Otvody1079 Heating oborudovanie96 Switching ustroystva46 Perehody461 Fire armatura48 Radiatory33 Regulatory armatura313 repairing equipment TPA53 Counters vody146 Termometry38 Troyniki488 Truby702 Pointers urovnya71 Sealing materialy67 Filters gryazeviki380 Fitingi205 Fl antsy2399 Ball valves1197 Electric actuators249

Classification

The main criteria for the classification of ball valves are:

- Bandwidth;

- Functional purpose;

- Body shape.

Graduation of ball valves by capacity

The throughput is determined by a simple arithmetic ratio of the cross-sectional area in the valve ball-gate to the cross-sectional area Du of the pipe docked with it:

- For full bore valves, this criterion is 90-100%;

- For standard - 70-80%;

- For partial bores - maximum 50%.

Device

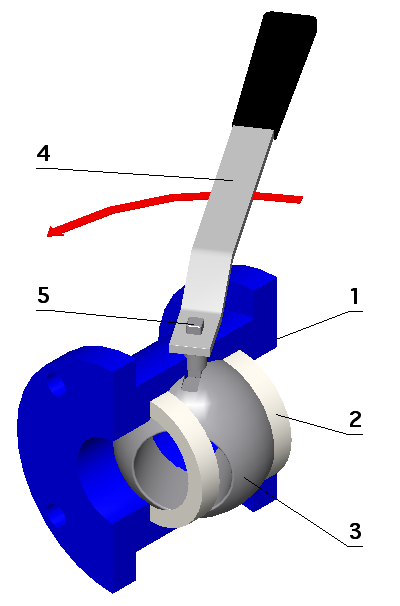

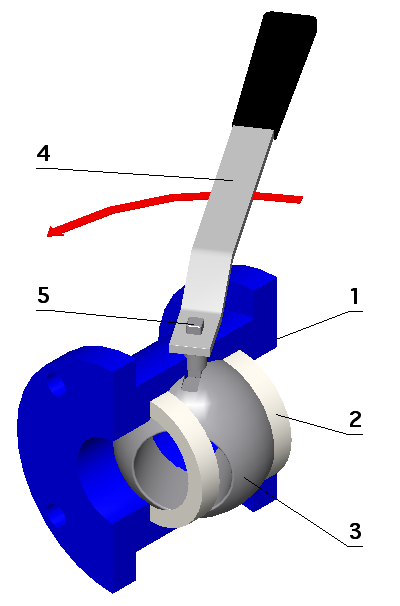

3D image of a section of a simple crane with floating ball

.

The explanatory figure shows:

- valve body (1)

; - O-ring saddles (2)

; - ball plug (3)

; - handle for manual control (4)

; - valve spindle transmitting force from the handle to the shutter (5)

.

Ball valves have a wide variety of designs, but their main differences are in the designs of the shut-off bodies: floating ball

and with

ball in supports

.

Functional purpose

Despite the abundance of functional features of the valves, there are only three main working areas:

- Shut-off ball valves used to open - close flows in pipes. The requirement for them is to ensure a tight shutdown in a closed operating state and a minimum flow resistance in an open position;

- Controlling ball valves that change the flow rate in the pipeline;

- Special valves designed for work in aggressive environments.

Manufacturing material

For the manufacture of ball valves, steel, cast iron, brass and bronze, titanium and even polyethylene are used. When choosing a ball valve, the manufacturer of which is famous for its brand, you can run into counterfeit products of Chinese or "homemade" production. Valves made in Italy have deserved recognition. They are produced by hot pressing, which ensures a homogeneous product structure and, unambiguously, high reliability. Turkish and Chinese valves are made by casting, which provides less precision and tightness than Italian products.

The most reliable and most expensive valves are made of stainless steel. Manufacturers are located in Spain, Austria, Finland, Italy, Germany and many other countries.

It is important!

The ball valve is classified as an explosion-proof product due to the fact that the spindle and stem are inserted inside the body. Even with a pressure many times exceeding the working pressure, the possibility of unauthorized stem stickout is excluded.

The ball valve is a reliable industrial device. It is actively used for the installation of water supply, in heating and gas systems, in the production of oil and gas.

The tap serves as a reliable shut-off device. Differs in convenience of design and reliability in operation.This mechanism completely replaced the cylindrical and conical cranes. The main purpose of the ball valve is to regulate and shut off the movement of gas and liquid media and create complete tightness. It is an indispensable device when working with aggressive media.

The shut-off ball valve is a ball valve with a shutter and a spherical surface. The main elements of its design include: body, ball with a cylindrical hole, movable spindle, removable handle, seals for the spindle, stem. The device has a robust design and in any position creates a flow area of the pipeline, with a hermetically sealed passage.

Shut-off, but not control valves

In the Russian market, at the moment, ball valves are presented only as shut-off valves. They are used only in the "open" or "closed" positions; it is highly discouraged to regulate the pressure with them due to their design features.

As a rule, the valve body is made of brass, like the shut-off ball. With the help of a ball, it is just possible to completely shut off the water pressure or supply it. For sealing, a PTFE sealing ring is located in the tap. When the valve is in the open or closed position, the check ball pushes the O-ring against the body to prevent leaks.

As a rule, in heating or water supply systems, most of the time, the shut-off valves are in the open position, so the O-ring practically does not wear out, because the water flow does not particularly affect it. The same situation is observed when the tap is closed, there is no water circulation in this position. But if you leave the tap in an intermediate position, then the water pressure will intensively act on the fluoroplastic ring, wearing it out. Particularly strong wear is observed in places where water contains some impurities.

If unwanted deposits appear on the locking mechanism, they make it difficult to seal and water will leak when the tap is closed. Therefore, companies that produce ball valves always indicate in the instructions that such a mechanism is not intended to regulate the flow. There are, of course, exceptions, there are models where the water flow can be regulated.

Scope of use

Valves are used at large scale and small production levels. The most popular area of use is the gas pipeline. It is very important here to eliminate the possibility of gas leakage when it moves through the pipeline. The ball valve has high tightness and is used as a reliable shut-off device on the pipeline when transporting natural gas. It is suitable for indoor networks, networks with low pressure of gas supply, for controlling gas flow with high pressure.

The valve is able to effectively regulate the flow of water and viscous liquids, aggressive chemical media and steam.

and its varieties

Depending on the engineering features, valves are classified into several types. By design, the cranes are divided into:

- straight-through;

- corner;

- mixing;

- checkpoints.

Depending on their functional features, the valves are divided into:

- shut-off;

- with the possibility of locking adjustment;

- special purpose valves.

Another feature for dividing mechanisms into subspecies is functional capacity. Here the taps are divided into:

- standard;

- full bore;

- partial bores.

To determine the bandwidth, the cross-sectional area of the hole in the ball valve is calculated to the cross-sectional area in the cylinder.

The purpose of the ball valve is also determined by the material of its manufacture: titanium, steel, polyethylene, cast iron, bronze.

Depending on the working direction, there are three types:

- Valves for opening and closing the flow in the pipe.The main requirement that they must comply with is to ensure tightness in the closed state and a minimum level of resistance in the open position.

- Ball valves with the ability to adjust - are used to change the value of the flow rate in the pipeline.

- Special purpose valves - to ensure high-quality work with aggressive media.

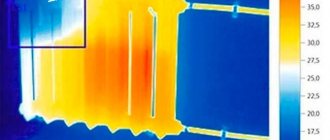

Battery regulation with thermostat

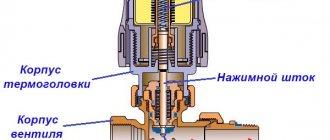

To ensure the constant maintenance of the set temperature in the room, they use thermostats for radiators (thermostats). These devices also have other names - thermostatic valve, thermostatic valve, etc. There are many names, but they all refer to one product.

The thermo-valve and thermo-valve are the lower part of the device, and the thermo-head and thermo-element are the upper part. Most of these products operate without power supplies. An exception is models with a digital display, in which batteries are placed in the thermostatic head. They often do not have to be changed, since the current consumption is insignificant.

The radiator thermostat consists of several components:

- a thermostatic valve, which is called a "body", "thermo valve", "thermal valve";

- thermostatic head or "thermostatic element", "thermoelement", "thermal head".

The body (valve) is made of metal, usually of bronze or brass. Outwardly, its design resembles a manual valve. Many manufacturers make the lower part of the radiator thermostat unified. This means that different types of heads can be mounted on one housing, regardless of their manufacturer.

Thus, it is possible to install a thermoelement with different control on the thermal valve - manual, mechanical or automatic, which is very convenient. If there is a desire to change the adjustment method, there is no need to buy the entire device, you just need to install a different thermostatic element.

Automatic regulators differ in the principle of influencing the locking mechanism. In a hand-held device, its position is changed by turning the handle. As for automatic models, they usually have a siphon that applies pressure to a spring-loaded mechanism. In electronic products, the processor controls the workflow.

The bellows is the main element of the thermoelement (thermal head). It looks like a small sealed cylinder with a liquid or gas inside. Both of these substances have a common property - their volume depends on temperature. When heated, gas and liquid begin to increase significantly in volume and thereby stretch the cylinder.

The bellows, when pressure is applied to the spring, shuts off the coolant flow. When the volume of the working medium decreases as it cools, the spring rises and thereby the fluid flow increases, and the radiator heats up again. Due to the use of such a device, depending on its calibration, the set temperature can be maintained with high accuracy - up to one degree.

Before using a radiator, everyone who decides to purchase a thermostat for it must decide what kind of temperature control it should have:

- manual;

- auto;

- with built-in or remote sensor.

Flanged valve features

Special parts are used to secure the shut-off valve to the pipeline. These include: welded joints, flanges, pins and couplings. Flanged ball valves are used to withstand special loads. The equipment is installed on pipes with a diameter of up to 50 mm. Specialized gaskets provide the valve with perfect tightness.

In most cases, a flanged ball valve serves as an optimal device for heating and boiler networks.Its connections are convenient in the field of repair, dismantling and replacement of a depressurized area. In this case, welding work is not required.

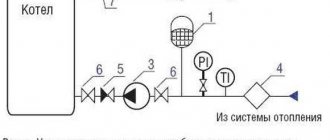

Rules for the use and installation of thermal valves for heating

For conventional heating systems, two-pipe thermostatic valves are used

When choosing the type of control valve for the heating system and the method of its installation, proceed from the following conditions:

- For conventional systems, where two pipes and circulation pumps are used, simple two-pipe thermostatic radiator valves are used.

- For gravity circuits with one pipe - one-pipe devices with an increased flow channel.

- The direction of flow of the coolant is taken into account - from the top or from the lower channel.

- The shut-off valve for the radiator is mounted at a distance of 60-40 cm from the bottom point of the room.

- The direction of connection of the shut-off valves is selected in accordance with the marking of the flow movement on the body.

To ensure the tightness of the threaded connection in hard-to-reach places where it is difficult to use FUM tape, you can use special thermostable pipe silicones.

Among the products known on the market for regulating heaters are: Italian products RBM and ICMA, devices of the German company PROFACTOR, Chinese thermo valves UNO New.

Flanged valve actuator

A mechanical, electrical and pneumatic actuator is used to regulate and control the flow of the flanged valve. The mechanical drive has handwheel equipment to manually open and close the flow. Such a drive is used when compactness is required.

Used when compressing air. This is the most unpretentious type of control of any transported substance, even the most aggressive one. The flanged ball valve is actively used on pipes with high pressure and high temperature conditions.

The electric drive is capable of fully automating the flow control from the inside of the pipe. The crane is selected according to the area of production. Barbed parts help open and close flow.

When purchasing a ball valve, it is important to know exactly the parameters of the coolant for which the valve is being selected. It will perform the function of constipating the water, not regulating it. If flow regulation is also necessary, you need to purchase a device with a servo drive. For a private house system, fittings with a coupling and a working pressure of no more than 10 Bar are sufficient. For a centralized heating system, use a ball valve with a pressure of more than 20 bar, and take into account the pressure reserve. Water hammer may be observed.

You should pay attention to the quality of the crane and not buy low-quality goods. The products of the Chinese manufacturer are not in great demand, since fragile, corrosive materials are used in the production, which significantly reduces the service life of the valve.

Automatic regulators

Man by nature is such a creature who is constantly trying to make his life easier, including everyday life. Therefore, along with manual radiator controls, there are also automatic ones.

The advantage of automatic regulators is that once you set the required temperature of the battery, you can forget about re-adjustment for a long time.

Automatic regulation is carried out using thermostats and three-way valves.

Regulation by thermostats

Thermostatic temperature controllers for heating radiators have many names, but the essence of this does not change. For yourself, you need to understand that the automatic regulator is divided into two main parts:

Thermostatic valve (thermal valve)

Thermostatic head (thermal head)

When we talked about manual control valves, there is already a thermal valve in them.Therefore, if necessary, you can turn your manual radiator valve into an automatic one at any time by purchasing an additional thermal head and screwing it onto the thermal valve without any problems.

When, like a thermal valve, it does not have wide differences in design features, thermal heads are presented with a wide selection and functionality. From simple to thermal heads with a remote room temperature sensor and electronic control. Perhaps the choice is limited only by the consumer's wallet.

Simple thermal heads do not need electrical power. They work by means of a special capsule containing liquid or gas. The content of the capsule expands or contracts with a change in temperature and presses with a certain force on the stem of the thermal valve, changing the rate of supply of the coolant to the radiator.

More expensive thermal heads equipped with a display require a battery in the form of a power supply, but usually one battery lasts for a long time.

And they can also require constant power supply from the network, for example, if there is a "smart home" system

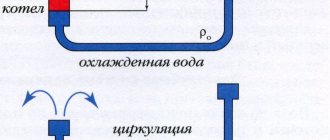

Adjustment with 3-way valves

The use of a three-way valve to regulate the temperature of radiators is rarely encountered in practice, since if we compare the price of one "three-way valve" and a conventional radiator regulator, the latter will be cheaper. But still, a few words about this method need to be written.

A three-way valve is installed on the radiator supply pipe, however, the following diagram visually shows this:

The same thermal head, which was already mentioned above, is screwed onto the three-way valve, on which the required parameters are set.

As soon as the temperature of the coolant approached the set one, the three-way valve begins to bypass water through the bypass, past the radiator.

Perhaps this is all the exhaustive material on the topic of adjusting heating batteries in an apartment and private house. We hope you find it helpful.

«>