How to fix a leak in a new dryer

A heated towel rail in the bathroom performs two functions at once: it heats the room and dries the bath towels laid out on it (hence its name).

In fact, it is a serpentine curved radiator pipe connected to the riser of a heating or hot water supply system.

It often happens that, due to thermal expansion during operation, under the influence of increased pressure and corrosion, a heated towel rail is leaking. What to do in this case? How to fix a leak? Everything in order.

This plumbing fixture is also called a coil. Today, in specialized stores, you can buy coils of any configuration, size, and from various materials.

Available in stainless steel, copper, chrome-plated brass, aluminum and enamelled steel. The thickness and quality of the metal is also different.

Copper is considered the best, but stainless steel coils also have a long service life.

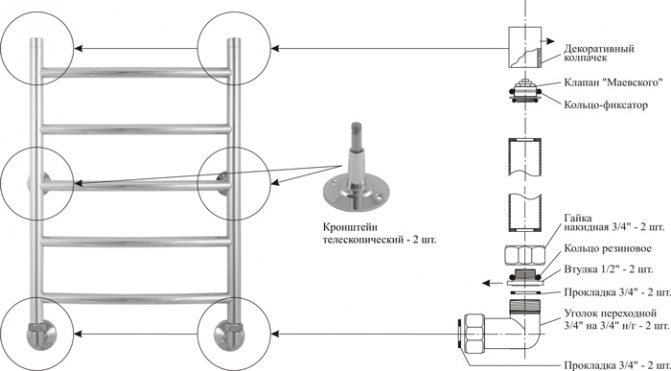

Parts of the heated towel rail, improper installation of which may cause leakage

Depending on the device and principle of operation, heated towel rails are of the following types.

- Water-based: the most common devices of this type, but their operation depends on the availability of hot water in the heating or water supply systems. This limits the location of the coil and makes it difficult to transport. The advantage of such devices is the relatively low cost and simplicity of the device. They fail less often than others.

- Electric: these heated towel rails differ from conventional electric heaters only in appearance and do not depend on heating and water supply systems. Installation of such a device is possible anywhere with an electrical outlet.

- Combined: the most expensive and versatile devices. In summer, their operation is ensured by a built-in electric heater, and in winter they use water heated by the central heating system.

The form of heated towel rails is: M-shaped, U-shaped, serpentine, in the form of a ladder and combined (for example, in the form of a lattice).

When choosing, it is worth considering whether a heated towel rail is made from a seamless or from a seam pipe. The first option is more reliable: its leak is likely only at the points of connection to the riser.

Suture options are cheaper and therefore more common. But leakage is possible anywhere in the device.

Most popular design options

Trouble can occur with both an old device and a new, recently installed one. There are several reasons and they do not depend on the type of devices.

- Violation of the tightness of the connection of the device with the riser pipe due to wear of the gasket (or inept installation) or metal corrosion. It manifests itself by constant digging and traces of drips with rust.

At the junction of the device with the pipes of the riser, a leak is likely due to wear of the gasket

- Leakage due to water hammer: most often occurs at the seam site of coils made of seam pipes. This is the most dangerous type of damage: it can occur instantly and is accompanied by copious flows of water.

- Mechanical damage unnoticed earlier, caused by accident during repair. The reason may be a hammer that has fallen from above or a perforator drill that has jumped off to the side.

- Manufacturing defects: cheap thin-walled heated towel rails made in China are “sinned” by this.In the event that a “sink” is hidden in the “body” of the pipe (a place not filled with metal), with an increased pressure of the coolant or as a result of corrosion, such a defect will manifest itself in the form of a leak.

Water hammer can destroy the heated towel rail pipe

The way to eliminate the leak depends on the cause of its occurrence. Let's consider them in accordance with the above information.

- In some cases, a leak at the connection point can be eliminated with a wrench of a suitable size: it is necessary to tighten the clamping nut tightly. To avoid damaging the nickel coating of the nut, wrap it with a rag.

- If it is established that the cause of the leak is the failure of the gasket, it is necessary to seek help from the housing maintenance company. It is required to shut off the coolant supply, drain the water from the riser and then replace the gasket. The system is then carefully filled to prevent water hammer.

- If a leak is detected in the coil section due to the appearance of a crack in the seam pipe or a fistula due to a "sink", the damaged section can be tried to weld or solder. To do this, it is also necessary to shut off the coolant supply. Another way to stop the leak is with a suitably sized “clamp” with a rubber gasket. It can be purchased ready-made or made by yourself.

- If a leak occurs due to metal corrosion, then the device is worn out and must be replaced. Repair by welding will not be possible, and the use of a "clamp" can only be a temporary solution to the problem.

You need to know that a manufacturer's and seller's warranty must be provided for a new heated towel rail. If after installation a fatal defect was found, such a device must be replaced.

A device with a manufacturing defect must be replaced

In order to avoid problems associated with improper installation, experienced specialists of enterprises with certificates confirming their competence should be invited to perform the work.

When a person buys a heated towel rail, it may not always be of high quality. On the outside, they are all attractive and, at first glance, good. But there are manufacturers who sell defective towels. As a result, unpleasant situations happen.

Some time after being installed in the bathroom, the towel starts to leak. When the water starts, high pressure is created, which finds a weak point, a thin wall of the towel, and squeezes out a small hole in this place through which water oozes.

You can eliminate any leak with a clamp, but for this you first need to turn off the water supply to the towel.

Usually, air accumulates in the hot water system before starting water. Accordingly, it enters the water supply systems of multi-storey buildings.

Air in the system appears as a result of centralized repair of highways, replacement of valves, pipeline ruptures at home and other troubleshooting of the pipeline system.

Heated towel rails are usually connected to hot water supply. The reason for a cold towel, if there is hot water in the taps, is an air lock in the system or in the heated towel rail. To solve this problem, you need to bleed air from it.

The swivel mechanism is made of plastic. It has an opening that serves to direct the air bleed flow. It is necessary to bleed air until water without air begins to flow steadily.

If the heated towel rail remains cold after that. Then you need to ask the neighbors from the upper floors to do the same at home.

If a brass heated towel rail is installed in the bathroom, and it cracks or a small hole appears, you need to replace it with a new one.Of course, there is a way to fix it by soldering.

Ordinary tin soldering is not suitable for repairing brass pipes, since a wide seam remains behind the tin, and besides, it is not strong.

To solder the pipes of a brass heated towel rail, you need to prepare:

- Gas burner;

- Graphite crucible;

- Boric acid;

- Borax and asbestos base;

- Silver and copper.

It is necessary to prepare the brass pipe solder. It is manufactured using a gas burner and a graphite crucible. It contains one proportion of copper and two particles of silver and is thoroughly mixed before they are fused.

Then the crucible must be lowered into chilled water, and ready-made solder is taken out of it for repairing brass pipes. The resulting consistency is cut into strips and the powdery mass is planed using files of different roughness.

We suggest that you familiarize yourself with How to unclog a toilet bowl yourself at home

Making flux for soldering: 20 gr. borax powder, 20 gr. boric acid, 250 ml. water. You need to mix.

- The towel must be placed on an asbestos base and lubricated with the flux that was originally made;

- Sprinkle the fabricated solder shavings over the damaged area.

Then we gradually heat it up with a gas burner; - The soldering temperature should not exceed 700 ° C, you need to carefully monitor the temperature of the burner (brass must not be overheated, especially thin brass).

Stainless steel is a material that is made by an alloy of iron, chromium, molybdenum, nickel. There are notions of food and non food stainless steel. Food grade stainless steel is used for the manufacture of cutlery and tableware.

Non-food stainless steel is used for the manufacture of various products, including heated towel rails.

Heated towel rails made of stainless steel are the most common and are in great demand among customers. Next to this, they are very reliable and give off heat well.

There are situations when such a towel needs repair. It doesn't happen often. The situation when a stainless steel heated towel rail is leaking can occur due to defects in production. The damage can be repaired by soldering.

- Soldering with low-temperature solder, which contains no lead;

- Soldering with high-temperature solders;

- Manual arc welding using argon. This is the most common and reliable way to solder stainless steel, which can be done even at home.

Photo of the correct diagram for connecting a heated towel rail to the water supply

It sometimes happens that a heated towel rail is leaking, although it was just purchased and installed in a plumbing unit. There are logical explanations for this, as well as recommendations for troubleshooting.

- Mismatch of technical characteristics. Some people buy dryers based solely on external aspects or some other point than the most important. The point is that the coil must correspond to the characteristics of the heating system specifically for your case. For example, the device is simply not designed for the pressure that you have. There is only one solution - to change the heated towel rail to another.

- Installation errors. Or simply unscrupulous work. This is also the fault of the masters who provide installation services from the store where you purchased the device. Even if you installed it yourself, be sure to check in the first few days for moisture at the joints. If you see drops and traces of smudges, be sure to secure the elements more securely, use an additional layer of sealant.

- Defect from the manufacturer. This is not a rare situation. Especially when heated towel rails are purchased from unknown companies.That is why it is better to study the current manufacturers right away, to determine the most tested and received positive reviews from buyers. You can find the information you need on the Internet. Just distinguish advertising materials from real, objective reviews about certain dryers. In addition, be sure to present documents, receipts to the store, demanding from them a new, serviceable dryer without marriage. This is your legal right as a consumer.

- Violation of the output of pipes. Crooked removal of the ends of the pipes is fraught with leaks, or the need to redo all the work. First, remove the dryers, make the ends of the pipes even so that they are in the same axis with the pipes of the heated towel rail. Then mount the system, do not forget about the sealing layer at the joints, and start the already non-leaking dryer into operation.

- Loose hexagon inside or using a silicone gasket. If the leak comes from the junction, here it is enough to use tow and red lead. If the device is "planted" on silicone gaskets, it is recommended to immediately replace them with thicker ones made of rubber. Someone advises to do the insulation from above, that is, without disassembling the connecting elements. This method will work, but it will only have a temporary effect. It is better to immediately eliminate the problem at the very beginning of its development, so that further operation of the heated towel rail does not lead to more serious consequences and heavy repairs.

- Swivel assembly leaking. Unfortunately, the swivel knot on the coils is one of the weakest points. But if you install new seal materials, then the problem can be solved quite quickly. Alas, some situations develop in such a way that you have to change the entire swivel unit.

- Joints are leaking on polypropylene pipes. Probably, during the installation process, the joint was not sufficiently tightened, and leaks began due to the high water pressure. Here you can go in two ways. The first, more economical, is to use a building hair dryer and a clamp of the right size. You need to properly heat the joint, which will make the joint soft, and you can deform it slightly by putting on the clamp. Tighten it properly and the leak can be repaired. The second method is cardinal, since it requires cutting off the connection and installing a new one in its place.

Varieties of heated towel rails

Dryers are divided into types according to the type of heating:

- The water type model is connected to the heating system if it is an imported device. It is also connected to a water supply pipe with hot water supply or to a boiler with two circuits. The choice of the installation site depends on the location of the riser and the wiring of the communication. The model is popular due to its low price.

- The electrical appliance does not depend on the functioning of the heating system, hot water supply in the general water supply system. It continues to function even in summer. The principle of operation is similar to oil-type heaters. The power source is the electrical network. Most models are equipped with protection. They are disconnected from the network if the heating reaches the desired temperature or a program malfunction occurs.

- In multi-storey buildings in the summer, when the hot water and the heating system are turned off, the combined model of the heated towel rail will be a lifesaver. For this period, she works on electricity. There will be no work stoppages, which is important for a family with small children.

Any of the three dryers can break. But it is not recommended to repair an electric one with a dielectric liquid inside. She needs to be taken to the workshop. You can find out the cause of the leak, fix the breakdown yourself, with a water and combined heated towel rail.

Water leakage under the union nut

Water leak

The heated towel rail can be connected to a common DHW system with pipes using a union nut coupling.If a stream of water flows from under the nut, then the reason may be either an insufficiently stretched nut, or a worn gasket under the nut.

Due to the temperature difference, even a tightly tightened nut can loosen over time, therefore, so that it does not flow anymore, it is enough just to tighten it again with a wrench. For the same reason, water flows from under the nut if there is a fluoroplastic gasket under it. When cooled, fluoroplastic tends to shrink slightly.

What if the rivulets are still flowing when tightening the nut? Unscrew the joint and go over all surfaces with automotive or silicone sealant. Give it time to dry. After that, the flow should stop.

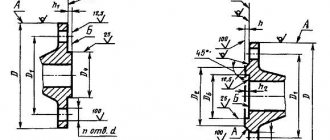

Another option is to replace the gasket. You can buy new pads from the store or make your own. To do this, take a suitable sheet of rubber or paronite and cut new gaskets out of it, using the old one as a sample. If you pick up a piece of pipe of the required diameter, sharpen the edges on emery and, placing a wooden lining under the sheet, simply knock out the gasket with a hammer blow.

Paronite gaskets can be held in hot water for a while before installation. Sometimes it helps to install an additional gasket to the existing one.

Leak elimination methods

If a leak occurs, you can use several methods of elimination.

When a leak occurs in the connection area where the nut is located, a wrench can be used. Here you need to correctly calculate the strength and not overdo it. It is necessary to tighten the nut a little, but do not try to turn it. To avoid damaging the surface of the nut, cover it with a rag.

A situation is possible when the gasket fails, here you should not take action on your own, as it is quite dangerous. The first thing to do is to shut off the water supply, if you cannot do this on your own, then you need to contact the housing office.

We offer you to familiarize yourself with Bathroom decor (76 photos): self-adhesive film and other decorative coatings on the wall, ideas for doing it yourself in a small area

A situation arises when a leak appears in the place of the coil, due to cracks that appear on the seam pipes:

- you can try to solder or weld the damage, but this requires equipment;

- when using this method, the water supply should be shut off;

- you can use a clamp that has a rubber gasket. It is sold in stores or it is made independently.

When the pipes have suffered from corrosion, then the repair work will not be useful, they need to be replaced. When using a clamp, you can achieve only a temporary result, so you should solve the problem immediately.

Most often, breakdowns are formed due to improper installation, a specialist must work here. If a leak has already happened, you can solve the problem yourself for a while, but you still have to invite a master to avoid aggravating the problem.

The most correct decision is to inform the housing office and turn off the water, and then carry out repair work. Such a leak is dangerous because no one can foresee when the situation will get complicated. And in high-rise buildings there is also the fear that neighbors can be flooded.

You can repair a coil leak yourself, but this will require a number of tools and materials, including:

- adjustable wrench;

- sealant;

- tow;

- fit gaskets;

- scissors;

- set of open-end wrenches.

If the problem lies in damage to the heated towel rail by corrosion or in a factory defect, then a welding machine should be used when carrying out repair work. It is necessary to prepare a bucket or basin in advance for draining water from the device. You will need another rag or towel.

Owners of heated towel rails from time to time are faced with a problem such as leakage. Very often, this problem occurs precisely at the junctions.

If you notice that the joint is constantly wet and dripping from it - you definitely need to shut off the water! In the case when a bypass is installed on your heated towel rail, it will be enough just to turn the tap handle.

This should be done as soon as possible, since the pressure drop inside the pipes can further worsen the situation and the towel dryer can simply break off. It is not always possible to immediately deal with a leak and eliminate it. Therefore, if you do not have time to do repairs, remove the dryer and put special plugs on the pipes.

Bathroom towel radiator

Such a nuisance as a leak can occur at any time. And not only with an old and long-used heated towel rail, but also with a new, recently installed one. The reasons for this can be very diverse:

- Towel dryers that have been in use for a long time can corrode. It should immediately be noted here that not only the metal pipes themselves are subject to corrosion, but also the places in which they are connected.

- Mechanical damage. In this case, a leakage problem may arise if the heated towel rail is accidentally damaged by some foreign object. Very often, mechanical damage occurs during repairs in the bathroom, as well as with a careless attitude to the dryer.

- Wear of parts. This is the main problem. Due to the wear of the rubber bands and gaskets, the dryer begins to flow precisely at the joints.

- Incorrect operating conditions. Often there are cases when a heated towel rail is completely different from the functioning of the system in the bathroom. So, for example, it can be noted that the coil may not be designed at all for the pressure from the system.

- Poor installation. A negligent attitude towards the installation of plumbing products, as well as non-compliance with simple rules during installation, can lead to a dryer leak.

- Defective equipment. Exceptions are quite rare, and mostly defective models very soon remind the owners of their shortcomings.

- Incorrectly routed pipes. During installation, the ends of the pipes may be pulled out crooked. In this case, you should not be surprised that after a while your heated towel rail began to leak.

As you can see for yourself, there are a lot of reasons for this. Even an insufficiently tightened internal hex can cause you a lot of trouble, including leakage too. That is why it is important to know not only the cause of the leak, but also a good enough way to quickly stop this leak.

It is important to know what material your heated towel rail is made of.

There are not one or two good ways to help you get rid of the leakage problem once and for all, or at least for a long time. So, first of all, it should be noted that the way to deal with a leak depends on the very reason for the leak.

Therefore, if a heated towel rail is leaking due to corrosive damage, you need to shut off the water, remove the dryer and replace the equipment. Moreover, the replacement should be made without fail! Otherwise, increased pressure in the system and water hammer can lead not only to a leak, but also to a whole flood.

In this case, it is very easy to avoid breakage and leakage of the dryer. All you have to do is check the general health of the device from time to time.

It is also recommended to check the joints for moisture after installing a new dryer. If the heated towel rail leaks - try to fix the problem as soon as possible and completely eliminate it.

Once again, we remind you that the condition of the heated towel rail largely depends on the quality of the work performed.If you are installing yourself, try to take this assignment as responsibly as possible.

Follow all instructions correctly, and if in doubt, seek help from specialists. So, in the case when the ends of the pipes are brought out incorrectly (unevenly), you need to eliminate this. First you need to remove the dryer, then align the ends of the pipes.

After that, you can reinstall the equipment, be sure to pay attention to the sealing of the joints. The weak point in the dryer is not only the gasket, but also the swivel unit. In this case, the installation of new sealing materials will help you to eliminate the problem.

Often, drips occur at threaded joints. In order to eliminate the leak in this case, you can use not tow, but a special gel sealant. After the gel is applied to the thread, it hardens quickly enough to turn into a dense and durable plastic. Such a gel is able not only to protect you from leakage, but also to save threads from corrosion.

Corrosion is the main cause of towel warmer breakage.

It is very important to understand that the formation of a leak is influenced not only by the material from which the heated towel rail is made, but also by the water in it. The quality of water, which is now used in all plumbing systems, leaves much to be desired. Only models made of stainless steel can resist its corrosive effect and corrosion.

However, when choosing a steel heated towel rail you need to be extremely careful. Stainless steel models are quite popular nowadays and this leads to the fact that they are more often than others counterfeited. In order not to buy a fake, or a defective dryer, you need to carefully examine the future purchase, and also ask for a quality certificate.

People who have country houses very often buy heated towel rails made of ferrous metals. Such products look pretty nice.

We suggest that you familiarize yourself with the device of a toilet in the country with your own hands

They will serve you faithfully for many years only if your bathroom has good ventilation and a well-equipped heating system. In an ordinary apartment of a multi-storey building, heated towel rails made of ferrous metal do not take root for a long time.

They corrode, become clogged with fine particles of sand, salt, as well as other micro-objects and impurities that are found in the coolant.

That is why it is very important to know what material your heated towel rail is made of and how long this material will be able to serve you under similar conditions and irritants.

No matter how sad it may be, when a heated towel rail is leaking, in some cases it must be completely changed.

Of course, replacing bathroom equipment requires money, and every time they buy a new dryer, people give their money in the hope that this one will certainly not leak. But the problem repeats itself again.

And then the question arises: "Is there a heated towel rail that does not flow?" Of course there is!

Corrosion on the heated towel rail

A heated towel rail in which there is no water will never flow. So, if you are tired of water appliances, you can easily replace the water heated towel rail with an electric one, and it certainly will never flow. Electric models have many advantages:

- The very first and most important of these is that the electric heated towel rail never leaks!

- It is also independent of system pressure and hot water supply.

- Installing and maintaining an electric model is easy enough.

- You can adjust the heating temperature of the dryer yourself.

- If you have nothing to dry, you simply turn off the heated towel rail and it does not consume electricity.

It is safe to say that electric models will be able to replace water heated towel rails and will successfully fit into bathrooms.But electric models also have some drawbacks.

The most important of these is considered to be the use of electrical equipment in high humidity conditions.

What to do in this case? Is it really the only drier that doesn’t flow in the bathroom? Sure you may! But this must be done by a professional! Professional work will help you avoid electric shock.

Water seeps through the threads

When the water sockets are located in the wall, in the immediate vicinity of the place where the heated towel rail is installed, for example, a "ladder" with a bottom connection, it is convenient to use an assembly of metal threaded fittings, brass or stainless steel for connection. A "nipple" is connected to the water outlet, after which, if necessary, an extension cord, an angle with an internal or external thread, then an American and a transition sleeve can be installed.

Water seeps through the threads

It is quite possible that the drip of some of the elements of this connection was not twisted securely enough during installation, somewhere there is not enough winding. As a result, the entire structure flows. What to do in such a situation?

First of all, you need to carefully inspect all connections from this assembly and make sure that it flows precisely along the thread. There may be a problem elsewhere: for example, the American has an unimportant gasket and leaks from under the union nut. Then try tightening the nut with a wrench first.

If, upon inspection, you are convinced that the flow is really in the threaded connection, unscrew the fittings and take flax and plumbing paste. Many people prefer to use Unipak paste, it is designed to work at temperatures up to 140 ° C and does not affect water quality. In addition, together with flax fibers, it provides good tightness and makes it possible to adjust when assembling the joint.

You can use other similar pastes, silicone sealant. Previously, they used drying oil, red lead, but after applying paint, it is almost impossible to disassemble such a connection. For reeling it is better to use old reliable linen. Fum tape does not give such quality, it is more suitable for tapered connections.

Before winding flax, thoroughly clean the threads from dirt. Winding is performed evenly along the entire length of the thread, in the direction of its pitch. An even layer of paste is applied on top. After a while, you can assemble and stretch the fittings and reconnect the condenser.

Reasons for leaks of an old heated towel rail

If a heated towel rail installed many years ago is leaking, you need to act quickly so that the problem does not become global, because the operating time leaves an imprint on the state of the structure.

- If, after inspection, it is found that the heated towel rail at the junction or on the surface of the pipes is covered with rust, then it is recommended to replace the entire structure or its individual parts. It is impossible to simply ignore the appearance of corrosion. Otherwise, the slightest fluctuation in pressure in the system will provoke a breakthrough and, as a result, then a bathroom. For the safety of the old model, a hydraulic protection is installed at its entrance.

- When dents are found on the heated towel rail, it is recommended that you consider replacing the structure or partial repairs. In most cases, mechanical damage to the old model is the cause of the leak in this place. Moreover, the crack grows rapidly due to structural wear. If the problem arose after the work of the repair team, then the team should dismantle the old one and install the new heated towel rail.

- At the joints, gaskets are installed and lubricated with sealant. Over time, they deform, dry out. It is for this reason that the heated towel rail is leaking.The water supply in the riser is shut off, the gaskets are changed and re-lubricated with silicone sealant.

Most of the problem areas arise from the fact that the model has already worn out and has lost its strength. Small cracks quickly develop into large leaking holes. Therefore, repairs in this case are sometimes more expensive than replacing with a new model.

An example of a heated towel rail corrosion that causes water seepage

To begin with, let's consider the main causes of leaks that the owners of old heated towel rails face and who have been working for the benefit of the plumbing unit and its inhabitants for quite a long time.

- Corrosion effect. Rust formation. Corrosion can appear on both pipes and joints. Leaks for this reason can be prevented by periodically checking the device for rust. If a problem is found, the hardware must be replaced. Otherwise, subsequent water hammer or increased pressure in the water supply system can provoke a full-fledged breakthrough. Replacing corroded elements, as well as installing hydraulic protection at the inlet to the coil, will additionally secure the device.

- Accidental mechanical damage. Sometimes a heavy object can hit the dryer. For example, during the renovation of the premises. You may not have noticed this, but over time, it begins to flow exactly at the site of the recent impact. Therefore, after the repair, check if everything is normal, if there are any dents or damage. If you were repaired by specialists of a company, and after them a leak began, you have the right to contact them and demand repair, or a full replacement of the device.

- The seal is worn out. Sealants are not eternal, and therefore over time they can dry out and lose their effectiveness. Sealing occurs at the joints, so you simply need to turn off the water supply and replace the sealant layer with a new one.

As you can see, with old heated towel rails, everything is quite clear and obvious. Troubleshooting is also straightforward. But remember, if the device has been serving you for more than a year, and its "age" is approaching a good ten years, it can be much more expensive to fix problems than to buy a new one.

In addition, the centralized hot water supply is gradually discontinued in many cities, heating is becoming too expensive to be spent on round-the-clock heating of a bathroom. That is, you should think not just about replacing the old dryer, but about installing an electrical analogue in its place.

Why does the heated towel rail rust and leak | Protection against electrocorrosion

In April of this year, FOR THE FIRST TIME IN BELARUS, the mass production of heated towel rails of the "Lesenka" type with protection against electrocorrosion will begin !!!

Why is this topic so acute and relevant? In fact, consumers often ask questions about what is the protection of a heated towel rail from electrocorrosion., they are also concerned with topics such as:

- What is this "heated towel rail electrocorrosion", "stray currents", or the more general term "electrochemical corrosion"?

- Why is a stainless steel heated towel rail still leaking?

- Why does almost none of the manufacturers give a guarantee if a heated towel rail is leaking due to electrochemical corrosion?

- Is it possible to protect a heated towel rail from stray currents at all?

Later in the article we will try to answer these questions in more detail.

Stainless steel towel warmers

One of the popular materials from which heated towel rails are made is stainless steel, or "stainless steel". The name suggests that this material does not rust.

The presence of oxygen in our tap water has always been the main cause of corrosive black or galvanized steel heated towel rails.Indeed, a stainless steel heated towel rail is not subject to this kind of corrosion for at least 10 years, provided that high-quality stainless steel is used, for example, the AISI 304 brand.

However, one circumstance is an exception - these are stray currents in a heated towel rail. They are the reason for the question "why is the heated towel rail leaking?".

What are stray currents in a heated towel rail?

The nature of the occurrence of currents in tap water is still not fully understood. Therefore, it is difficult to find methods to combat this phenomenon. At the moment, all manufacturers of heated towel rails recommend grounding as a way to solve this problem.

For example, there may be such a case: a neighbor on a riser grounds a faulty household appliance (most often it is an old "washing machine") to the water supply pipes. Thus, the currents propagate through the pipes, and since the supply of polymer pipes is made to the heated towel rail (i.e., the pipe material is dielectric), the current passes into the water, and a process begins, which leads to the inside of the heated towel rail rusting.

As a result, points with signs of corrosion appear on the heated towel rail. The number of these points increases over time, and the initial points increase in diameter, and you can already notice a slight leakage of water through them. The electrochemical corrosion process has begun. Here is the answer to the question why the heated towel rail is flowing.

In the case described above, grounding will help save your heated towel rail.

For this you need:

- Make potential equalization: connect the metal parts of the riser together with a copper wire. The places where the wires are attached to the pipes must first be cleaned of paint.

- For reliability, ground the metal riser itself. It is necessary to bring the copper wire from the riser to the PE-bus of the nearest storey electrical panel. First, you need to make sure that the grounding on the electrical panel is operational.

However, the case described with an old washing machine is not often the case in practice. It is much more common for products to deteriorate due to other causes that cause electrical corrosion of stainless steel. And the installation of grounding is no longer able to provide full protection for the heated towel rail.

Currents can even occur in the device itself. For example, in hard water, simply due to the contact of incompatible materials: for example, a brass sleeve with a steel towel warmer body.

The reasons for the corrosion of the heated towel rail may be different. However, the consumer is interested not so much in the reasons that cause rusting of the device, as in the protection of the heated towel rail from electrocorrosion.

In Belarus, the question is often asked: a heated towel rail is leaking, what to do with this problem? The problem is especially urgent in cities with hard tap water with a large presence of salts and chloride compounds.

These cities include Soligorsk and Mikashevichi. In part, this problem is relevant for Baranovichi, Luninets, Vitebsk, Gomel and Minsk.

Protection against electrocorrosion

To solve the problem, our engineer and technologist have developed a special protection for the heated towel rail. Thanks to it, the service life of the product in cities with hard water is extended three times when compared to a stainless steel product without this protection. And provided that grounding is installed, and brass fittings are not used when connecting a heated towel rail, the service life will further increase significantly.

I must say that this protection is installed only in products of the "Ladder" type, and M- and MP-shaped heated towel rails are produced without protection against electrochemical corrosion.

We offer reliable heated towel rails of the "Ladder" type with protection against electrocorrosion. They will be relevant both for residents of Belarus and for other countries where the same problem exists:

- Kazakhstan (Astana and most cities in central and northern Kazakhstan).

- Russia (Moscow, Chelyabinsk region, Kaliningrad region, Primorsky region and a number of other regions and cities), etc.

We are ready to provide these cities and regions with our heated towel rails with protection against electrochemical corrosion. For the convenience of settlements, companies in Russia do not need to work directly with Belarus.

Signing contracts, issuing documents and all settlements will be carried out through a Russian company. In this case, transport costs, as a rule, do not exceed 5% of the product cost.

The shipment of heated towel rails is carried out to the Russian Federation by means of transport and fuel and energy complex "Transaviatur" ...

We are waiting for your orders!

What will help avoid leakage

Many breakdowns on a heated towel rail are eliminated by hand, without calling the master.

- It is possible to reduce the number of breakdowns and manifestations of leaks if you approach the purchase of a model thoroughly, with a study of the technical parameters of the hot water supply system, heating, pressure inside the system. After that, the model of the dryer is selected.

- The choice of the model manufacturer plays an important role. A well-known name in the plumbing market is a guarantee of the quality and reliability of a plumbing fixture, which serves both for drying clothes and as an element for heating a room.

- In addition, a preventive measure to prevent leaks will be the installation of water purification filters at the inlet to the water supply system. It is known that poor water quality affects the performance of the appliance.

- The choice of material is important. For example, models made of ferrous metal look respectable, but in apartments without ventilation they are covered with rust.

The towel warmer is dripping (leaking), what should I do?

Have you noticed that heated towel rail leaking... Something needs to be done, as women say.

Do I need to shut off the water?

Situation 1. Definitely necessary if water flows out in significant volumes and there is a serious risk of flooding your bathroom, apartment and neighbors below. We are looking for a couple of containers and organize a watch for the timely drainage of water, while we ourselves run (call) to the housing office and insist on shutting off the water. To be convincing, you can promise a mogorych - you don't have to choose, repairing a neighbor's apartment will be more expensive.