The American one first presented the material in 1957.Since then, the technology of its manufacture has remained practically unchanged. The versatility of expanded polystyrene foam allows it to be used in a wide variety of areas.

Currently, both the most famous brands and private entrepreneurs are engaged in the production of this type of thermal insulation. The technological capabilities of these manufacturers are very different, as well as the quality of the finished product.

What is Extruded Polystyrene Foam

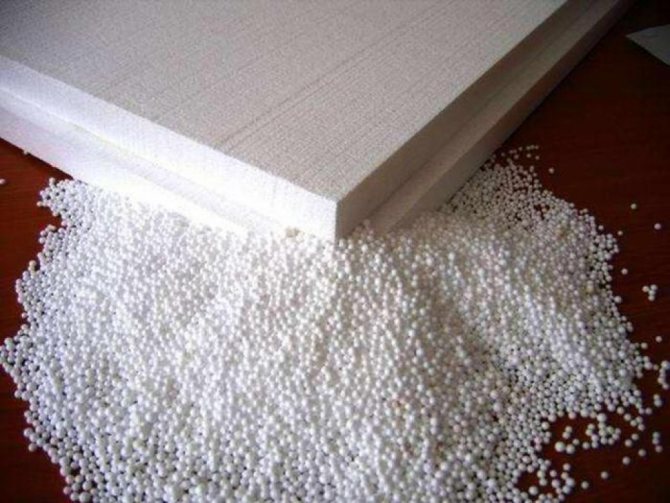

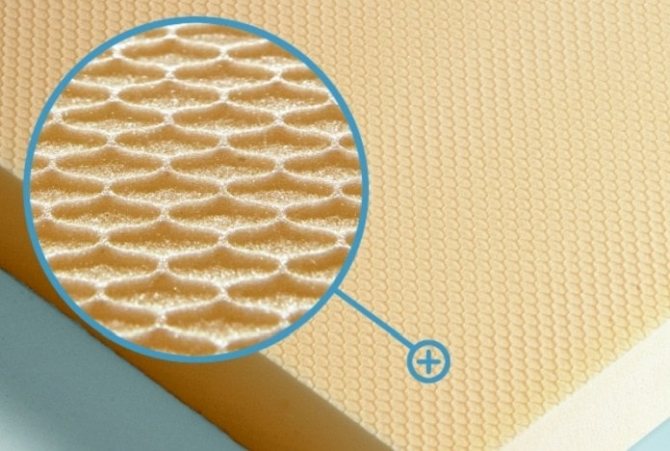

Extruded polystyrene foam is a universal high-quality heat-insulating insulation made of granular polystyrene using a special technology. At the first stage of production, the granules are mixed with special ingredients that enhance mechanical strength and fire safety. After that, the resulting mixture is melted until a homogeneous mass is obtained, and a foaming agent (most often carbon dioxide) is added.

At the next stage, the raw material is pressed under high pressure through the rectangular slot of the extruder. After the end of the calibration, the foaming agent expands, thereby providing the required porosity of the material. The received strip is cut, packed and sent to the warehouse.

Thus, extruded polystyrene foam is a mixture of polystyrene granules with special additives that has undergone extrusion processing.

More about the material

When deciding what is the best thermal insulation material, you should take a closer look at the option called extruded polystyrene foam. In addition to the arrangement of residential buildings, this type of insulation is used even during the construction of roads and railways, since it is these plates that allow you to avoid the negative effects of heaving of the soil during freezing.

Expanded polystyrene has a lot of advantages: it is the cheapest, can be easily cut with an ordinary knife, almost does not absorb moisture and keeps heat well.

Extruded polystyrene foam is produced using the extrusion method: under the influence of high pressure and temperature, polystyrene granules are mixed with a special foaming compound, and polystyrene is obtained after extrusion through an extruder. As a result, the slabs are characterized by special properties due to the dense fine-pored structure (diameter within 0.1-0.2 mm).

Overview of the properties of expanded polystyrene

Extruded polystyrene foam is distinguished by a number of features that make this kind of insulation a universal material:

- It is not hygroscopic, which means that it is not inclined to absorb moisture, which is due to the structure: expanded polystyrene plates consist of many closed cells, liquid simply does not penetrate into them;

- Provides a barrier for the outflow of heat from the room, this feature is explained by the low coefficient of thermal conductivity;

- Increased strength: this type of insulation is a slab of material compacted under the influence of high pressure and temperature;

- Extruded polystyrene foam is not subject to decay, since the insulation in this version does not absorb moisture, which means that there are no conditions for the reproduction of harmful microorganisms;

- Light weight.

If we compare polystyrene and expanded polystyrene plates, for a number of factors it is better to choose the second option.

Technical characteristics of extruded polystyrene foam

The performance and mechanical characteristics of this thermal insulation material require special consideration.

Thermal conductivity

, regardless of the brand, lies in the range from 0.03 to 0.04 W / (m · 0K). Such indicators allow the use of expanded polystyrene foam when insulating any building elements, as well as highways, runways, etc.

Density of slabs

, depending on the modification of the material, it can be from 20 to 50 kg / m3;

Moisture resistance

... Due to the closed porous structure and chemical composition, the material is not destroyed by dampness, condensation and even direct ingress of water. The only weak point is the end surfaces, the waterproofing of which should be given special attention.

Health safety

allows you to use extruded polystyrene foam even in hospitals and children's institutions. The boards do not emit harmful vapors even at high temperatures. In addition, the heat-insulating layer is usually covered with a layer of finishing materials (plaster, putty, drywall, etc.).

High strength parameters

... The permissible stress, depending on the modification, ranges from 18 to 20 t / m2.

Other characteristics of extruded polystyrene foam include:

- Frost resistance.

The material retains its insulating properties even at -700C; - Low vapor permeability

, from 0.007 to 0.008 mg / (m · h · Pa); - Antiseptic properties

the material practically excludes the occurrence of fungal colonies; - Long service life

... Regardless of the operating conditions, expanded polystyrene foam is guaranteed to last at least 45 years.

Such indicators will undoubtedly arouse increased consumer interest. In addition, it is also important that the installation is quite possible to do with your own hands, and the cost of the material is relatively low.

The main criterion for choosing insulation

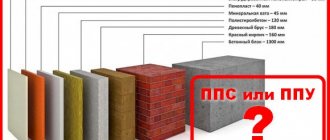

Insulation is chosen according to its heat-shielding ability. This property is quantitatively expressed in thermal conductivity, which shows how much heat energy per second will be released from the room by a one meter thick insulation with a temperature difference between the inside and outside of one degree. Extruded polystyrene foam, from which PENOPLEX boards of all brands are made, has low thermal conductivity: from 0.029 to 0.034 W / m • K. In this, the material is superior to other widespread heat insulators - mineral wool and polystyrene, in which the thermal conductivity, respectively, fluctuates in the ranges of 0.037–0.055 and 0.041–0.059 W / m • K. Thus, to create the same temperature conditions in a room, a layer of thermal insulation made of mineral wool or foam will need 30–70% thicker than PENOPLEX boards. Useful space is saved.

Scope of application of extruded polystyrene foam

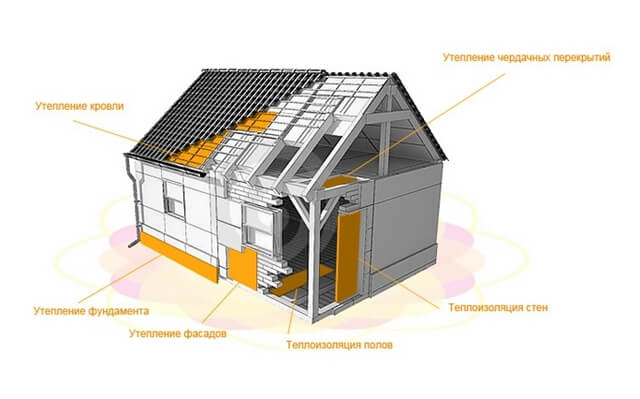

Let's consider in more detail the possible areas of use of expanded polystyrene plates. Operational and mechanical characteristics make it possible to actively use expanded polystyrene for:

- Thermal insulation of private households and CBC facilities;

- Frost protection for road cushions, main pipelines, runways;

- Thermal insulation of foundations, retaining structures and roofs;

- Manufacture of household and industrial refrigeration units, refrigerators;

- Devices of various types of hydro-barriers;

- Production of packaging and disposable tableware;

- Making household items.

Despite the fact that the scope of use of extruded panels is quite extensive, there are some limitations.

Some disadvantages of dense foam

All the pros have already been sorted out, so it remains to clarify and against. So, its mechanical strength is not as good as we would like it to be. So after warming with this material, it is necessary to carry out work to additionally protect it from possible mechanical damage. Another nuance is flammability. Of course, special additives are introduced into the composition to minimize this property, so a small spark is not dangerous. However, if a fire breaks out, the foam will flare up very quickly.

Plus, there is a widespread perception of toxicity. In this regard, one should very carefully choose such products. Be sure to ask the seller to present a quality certificate, while keeping in mind that the percentage of residual styrene should not exceed 0.1%. Otherwise, the product should be discarded. Also, in the case of a high-quality product, finishing will help a little to reduce the already small impact, without which this foam will certainly not remain in your home, for example, apply plaster.

What surfaces can not be insulated with polystyrene foam

First of all, you should not use extrusion plates for thermal insulation of surfaces, the temperature of which does not correspond to the modes declared by the manufacturers, from -50 to + 750C.

In addition, the extremely low vapor permeability of the material does not allow its use in saunas, swimming pools and other rooms with high humidity. In this case, the use of expanded polystyrene as a heat insulator will require additional measures to ensure ventilation, which will negatively affect the labor intensity and cost of work. Ignoring these measures can lead to the appearance of mold or mildew between the insulation and the enclosing structure.

Physical properties of foam

The main characteristics of porous polystyrene include:

- strength - polystyrene does not differ in outstanding strength characteristics and is capable of crumbling and breaking even with weak mechanical stress. It can be easily damaged by sharp objects or simply by hitting the surface. To reduce the likelihood of destruction, the foam is covered with layers of a harder material that evenly distributes external loads;

- flexibility - expanded polystyrene weakly lends itself to bending effects and can break under them at any time. For the same reason, foam plates are installed only permanently, avoiding any torsional loads;

- thermal conductivity - the presence of gases (natural heat insulators) in hollow capsules provides the material with a low heat transfer coefficient. This is also facilitated by the absence of convection inside the pores due to their small diameter. It will take a long time to completely warm up a piece of foam to a predetermined temperature;

- tendency to shrink - free-lying expanded polystyrene slabs give in to slight shrinkage caused by gravity. The amount of shrinkage is 1.5-3 mm within six months. At the end of this period, the natural compaction of the material stops;

- thermal expansion - as the temperature rises, the linear dimensions of the slab increase (the process is reversible). The numerical indicators of expansion correspond to approximately 1 mm per 1 m of the foam plate when the temperature changes by 15-20 ° C;

- vapor absorption - polystyrene is less resistant to diffusional penetration of moisture than to the effects of liquid water, therefore, in especially humid rooms, its surface is additionally covered with a layer of metal foil. In its absence, part of the water vapor can penetrate through the layer of material and condense when the temperature drops, which negatively affects the entire thermal insulation system.

Fire resistance class B1 which means alekstroy.ru

/ Fire protection / Resistance and hazard classes /

An important parameter of materials, especially in the field of construction, is their fire hazard. It is such a priority that the flammability groups are determined by the Federal Law. There are four of them: G1-G4. Non-combustible materials are allocated in a separate category.

It is important to understand what this classification means, this will allow specialists to choose and use building materials correctly to ensure the fire safety of facilities. It is possible to determine the degree of fire resistance only in a special laboratory that has an official profile accreditation.

The methods are regulated by GOST 30244-94

It is possible to determine the degree of fire resistance only in a special laboratory that has an official profile accreditation. The methods are regulated by GOST 30244-94.

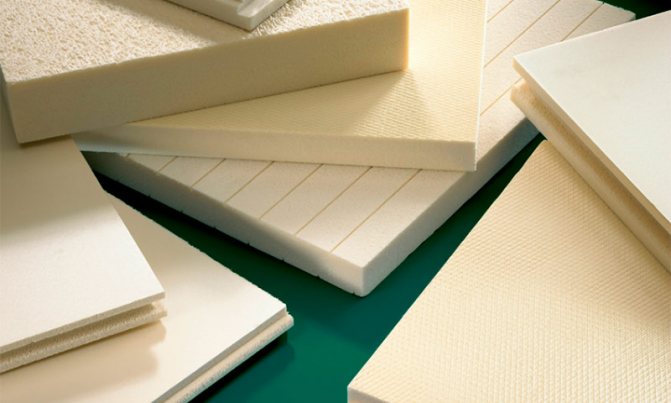

Penoplex OSNOVA

Universal lightweight insulation based on extruded polystyrene foam. Designed for insulation of ceilings, floors, walls and roofs, as well as any other structures that do not carry increased loads. Plates Penoplex Basis can also serve as effective sound insulation and wind protection. Thanks to the L-shaped edge, made on all four sides, a continuous insulating layer with tight windproof joints is obtained. This is an environmentally friendly thermal insulation and it is allowed to install it in residential premises. The material is safe, so you can work with it without protective equipment. The manufacturer produces another similar insulation - Penoplex Comfort. Its physical and mechanical characteristics are almost identical to the Base, except for one parameter - compressive strength. The material can withstand 0.18 MPa / sq. M, which corresponds to 18 t / sq. m. This indicator indicates a lower bearing capacity.

Application in thermal insulation of building structures

The versatility of use is facilitated by the low prices of Penoplex Osnova thermal insulation boards, as well as its excellent technical characteristics. The material is popular and widely used both in St. Petersburg and in all other climatic zones of Russia for thermal insulation of ceilings, floors, walls, roofs and any parts of the building that are not designed for high loads. However, most often the insulation is laid in the construction of floors, plinths, blind area.

| Thermal insulation of aerated concrete walls, well masonry system | Brick wall insulation, well masonry system | Insulation of monolithic reinforced concrete walls, well masonry system |

It is possible to appreciate the advantages of these plates made of extruded polystyrene foam when insulating the floors of the first floors above the ventilated underground. The overlap works in conditions of a sharp temperature drop and high humidity. Nevertheless, the effectiveness of the insulation is at a high level. The material will be useful when laying under a screed, for soundproofing ceilings between heated floors, as well as in constructions of "warm floors".

The technical potential of the Penoplex Base slabs is ideal for thermal protection of basement and ground floors. In these structures, there is an increase in air infiltration due to the large pressure drop between the outer and inner sides of the wall. In addition, direct contact with the soil makes such material qualities as biostability and low water absorption indispensable. That is why the area of the first floors requires increased protection, which is provided by the insulation.

| Insulation of the basement, for finishing with natural stone or clinker tiles | Insulation of the basement, for finishing with plaster with a metal mesh | Insulation of the basement from the inside |

Benefit from purchasing material

Buying these plates is beneficial for several reasons. Firstly, the convenient size and the presence of a joint edge allow you to perform an ideal installation in-house and save on labor costs.Secondly, zero moisture absorption allows you to avoid the device of a separate layer of waterproofing, that is, savings on both material and work. Thirdly, reliable heat protection and the absence of "cold bridges" significantly reduce heating costs. However, these are not all the benefits of purchasing Penoplex Osnova. A strong argument in favor of this brand is the low price both per m3 and per sheet. The plant for the production of the material is located in the Leningrad region, so that for residents of the city of St. Petersburg, delivery costs and trade margins are minimal.

Universal insulation Penoplex Basis has excellent technical characteristics. The low density provides a light weight so that the slabs do not weigh down the supporting structures. Despite the lightness, the material is quite hardy - the compressive strength is 0.12-0.22 MPa. Low thermal conductivity guarantees high energy efficiency at home and significant energy savings. The clear geometry of the slabs and the presence of an L-shaped edge help protect the house from drafts. Thanks to them, it is possible to obtain a continuous thermal insulation contour, impervious to cold.

It should also be noted such valuable qualities of the material as low vapor permeability and zero water absorption, excellent biostability and environmental safety. Thermal insulation is not subject to biodegradation, is not affected by mold and microorganisms, is completely safe for the natural environment and humans. In addition, the slabs are very durable and will last over 50 years.

Where is used

The operational qualities of the Comfort Penoplex allow it to be used not only in a city apartment, but also in a private house. If we compare the insulation with other building materials, then you can notice significant differences. Similar insulation products have a narrower specialization of application: thermal insulation of walls or roofs.

Penoplex "Comfort" is a universal insulation, which is used for thermal insulation of balconies, foundations, roofs, ceiling structures, walls and floors. Also, the insulation is perfect for thermal insulation of baths, pools, saunas. Insulation "Penoplex Comfort" is used both for internal construction works and for external ones.

Stability attribute of the class

PENOPLEX boards of all brands are durable. The service life of extruded polystyrene foam, according to the results of tests at the Research Institute of Building Physics, is at least 50 years. During all this time, the material stably retains its heat-shielding properties due to zero water absorption. Water has a higher thermal conductivity than heaters, and worsens the heat-shielding properties of non-moisture resistant materials, including fibrous mineral wool and granular foam.

Zero water absorption of PENOPLEX also deprives the source of life of bacteria, fungus, mold and other harmful microorganisms, for which this material, moreover, is not of interest as a food product. Thus, PENOPLEX is distinguished by its absolute biostability, which has been confirmed by tests in mycological centers.

Prerequisites for the development of new standards

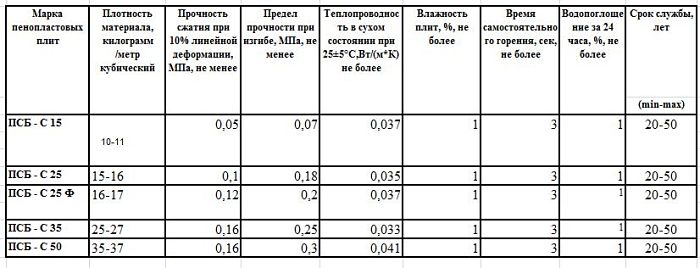

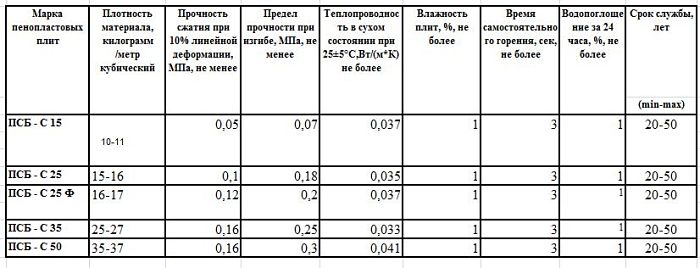

1. GOST 15588-1986 "Expanded polystyrene plates. Technical conditions "

was adopted in 1986. The need to revise it is associated with the increased requirements for the quality of building materials in the Russian market, which must be ensured, first of all, by strength, thermal insulation and other operational characteristics. When classifying and labeling expanded polystyrene boards in accordance with GOST 15588-86, these characteristics were secondary, which contributed to the penetration of low-quality products into the construction market.

Over the past 30 years, cardinal shifts have taken place in the expanded polystyrene industry, primarily in the technology of production of products from expanded polystyrene: from the autoclave method to the block method of "thermal shock".The raw material base has changed, and the main manufacturers of expanded polystyrene products have long been working on equipment supplied by world leaders in the industry. The quality and brand of products have stepped much further than GOST 15588-86, and manufacturers were forced to develop their own technical specifications.

2. GOST R 56148-2014 (EN 13163: 2009) “Products from expanded polystyrene PPS (ЕРS), heat-insulating, used in construction. Technical conditions "

designed for use in the Russian Federation. The main purpose of its development was the harmonization of national standards with European ones, the approximation of the European principles of classification and testing methods for heat-insulating materials and products to the methods used in Russian construction.

At the same time, manufacturers of extruded polystyrene foam and thermal insulation materials based on mineral fibers have prepared their own standards 13164 and 13162, corresponding to modern European standards. According to the members of the Association of Producers and Suppliers of expanded polystyrene, standard 13163 “Heat-insulating products from expanded polystyrene PPS (ЕРS) used in construction. Technical conditions ”marked the beginning of the development of a number of regulations of the Russian Federation on various special products made of expanded polystyrene, corresponding to the European level.

The Association of Producers and Suppliers of expanded polystyrene has created a comprehensive program for the development of national standards for expanded polystyrene products. The program was approved at the General Meeting and sent to TC 465 "Construction". These are the standards based on the standard 13163 “Thermal insulation products made of expanded polystyrene EPS (EPS) used in construction. Technical conditions ", such as:

- GOST R (EN 1603) “Heat-insulating products used in construction. Method for determining indicators of dimensional stability according to the results of laboratory tests at a temperature of 23 ° C and 50% humidity ";

- GOST R (EN 13793) “Heat-insulating products used in construction. Determination of properties under cyclic loading ”;

- GOST R (EN 14933) "Thermal insulation and lightweight fillers for use in civil engineering";

- GOST R (EN 14309) "Thermal insulation from expanded polystyrene PPS (ЕРS), for construction equipment and industrial installations";

- GOST R (EN 13950) "Foamed polystyrene (EPS) and gypsum board composite panels";

- GOST R (EN 14509) “Self-supporting composite metal panels with a foam polystyrene (EPS) core.

All these standards were supposed to form the basis for the creation of a national technical regulation "On the safety of buildings and structures." However, Russian technical regulation, the development of economic and political relations with the European Union, as well as within the created Customs Union, prompted us that in parallel with European codes, methods and standards, it is necessary to develop and developed Russian approaches to technical regulation and regulation, which have been successfully applied in construction. ...

3. GOST 15588-86 “Foam polystyrene heat-insulating plates. Technical conditions "

remains an interethnic standard still valid in the CIS countries. The association has started to develop an updated version of it, which describes slabs intended for thermal insulation as the middle layer of building envelope structures. The presented international standard will contribute to the development of the regulatory and technical base in construction. Its use will improve the quality of expanded polystyrene products and increase the level of energy efficiency in construction.

The purpose of developing this standard was not only to bring the regulatory framework into line with the existing reality on the market of expanded polystyrene and other thermal insulation materials, but also to maximize harmonization with European requirements for the classification and test methods of expanded polystyrene products used in construction.

|

|

|

|

|