A new type of thermal insulation materials - self-adhesive insulation - has a foil surface, which makes it possible to produce thermal insulation of small thickness with high quality insulation. The advantage of a thinner insulation is obvious - it takes up several times less space, which is especially important for internal insulation, absorbs less moisture, since it is covered with metal foil on one side, and the synthetic backing extends the service life up to hundreds of years. In addition, self-adhesive materials increase the service life of the protected elements and structures of the house.

Insulation roll with self-adhesive surface

Advantages of self-adhesive insulation

The scope of this material is extensive. It can be used to insulate walls and ceilings, pipes and roofs, doors and windows. Thermal insulation works are carried out in basements, attics and attics.

Advantages of self-adhesive material:

- versatility;

- environmental friendliness;

- fire safety;

- small thickness;

- excellent waterproofing and moisture resistant properties;

- resistance to negative environmental influences;

- a wide range of;

- low cost;

- ease of installation work.

Rolled insulation is frost-resistant. Such a self-adhesive insulation withstands temperature changes, moisture and chemical environment. Its installation leads to an improvement in the sound insulation of the surface.

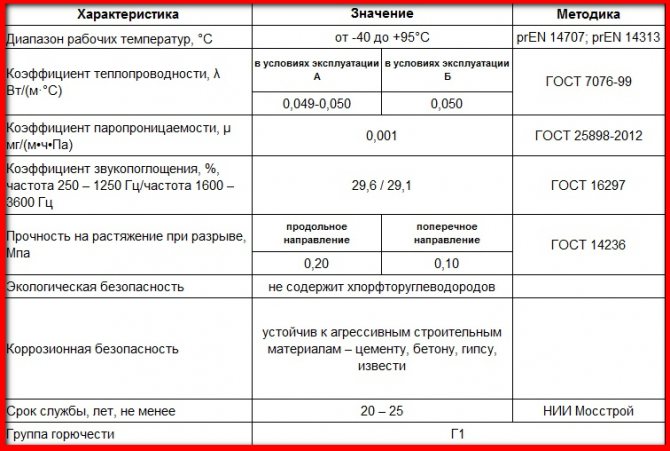

Penolen NPE MK PET

Output

Each insulation has its own characteristics, which can be called either positive or negative. This factor depends on the surrounding conditions, correct installation and timely maintenance. And if you think that self-adhesive insulation does not need "diagnostics" every few years, then you are stupidly mistaken.

Any building or finishing material can be destroyed imperceptibly and gradually. In the video presented in this article, you will find additional information on this topic.

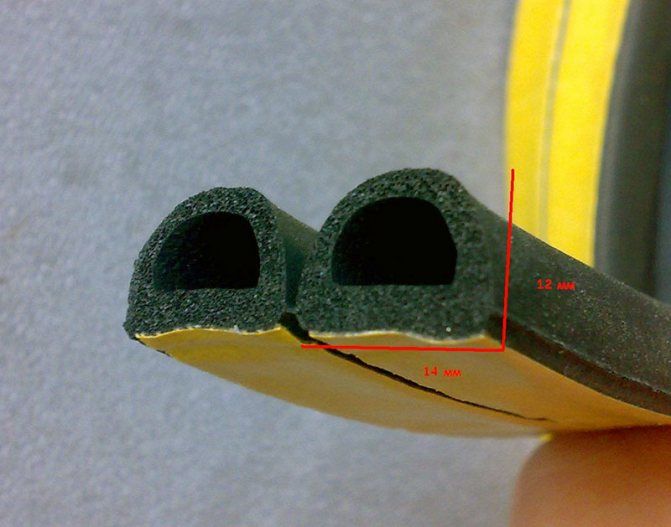

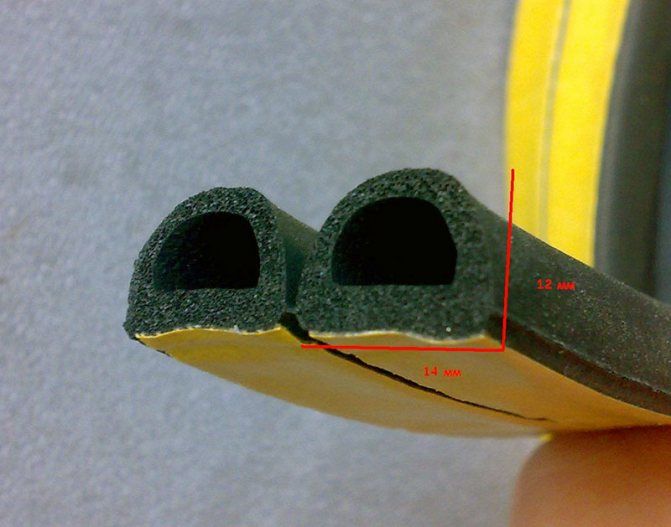

Self-adhesive tape

A common material is tape for insulating windows and doors, pipelines and tile floors. It is a strip 1-7 cm wide. For its manufacture, rubber or polypropylene is used. Thanks to this, the material has the maximum resistance to the transfer of thermal energy.

Insulation tape of rectangular shape is used for sealing even cracks up to 4 mm in size. If the gaps in the door or window openings are not too even, then it is better to use a material with a profile.

It is recommended to give preference to a soft insulation that fills all the cracks evenly. Rigid material will not compress well, as a result of which cold air currents will penetrate into the room.

The quality control of the product is carried out as follows: it must be bent and released. If the self-adhesive tape quickly returns to its original shape, then this material can be purchased.

A slow-drying adhesive is applied to the reverse side of the tape to provide greater effect when sealing gaps. It will also help in case of material changes.

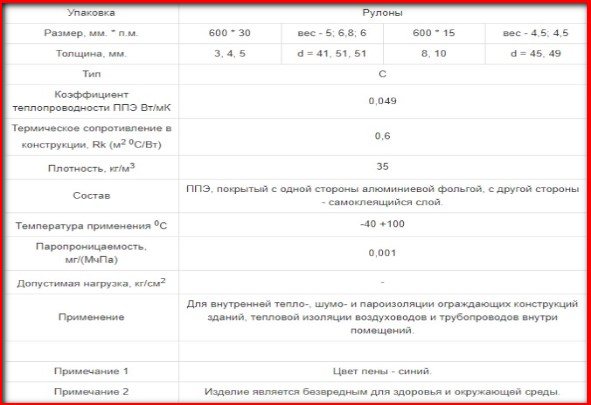

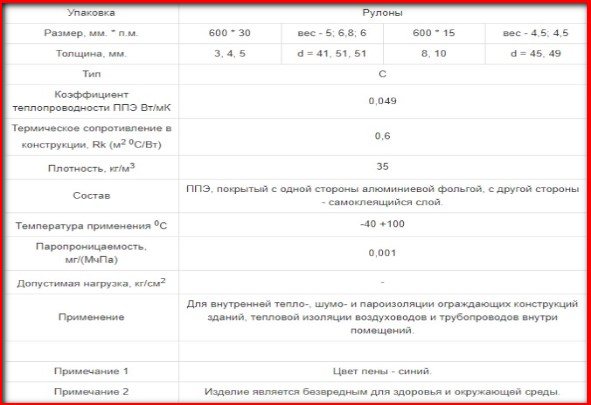

Penofol type c: self-adhesive reflective insulation

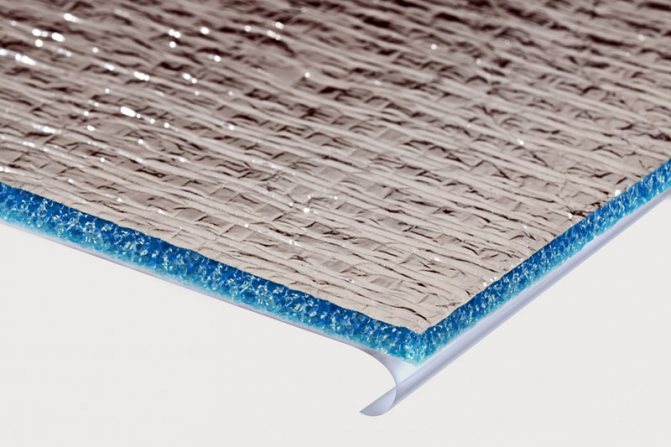

Penofol type C is polyethylene foam that has closed pores, a layer of aluminum foil and glue with a protective film. This self-adhesive insulation is lightweight, thin, flexible and environmentally friendly.

In most cases, self-adhesive penofol is used for thermal insulation of a metal surface: car vans and interiors, pipelines and air ducts, industrial drying cabinets. Thanks to the closed air bubble system, it can be used as a vapor barrier.

Definition of self-adhesive insulation

Materials with heat insulating properties are also used in the construction and renovation of buildings as hydro and noise insulation coatings. The main working layer that provides heat retention is polyethylene foam, which can be protected on one or both sides with a thin layer of aluminum foil. If the foil layer is applied on one side of the thermal insulation, then the adhesive layer is applied on the reverse side of the material, and if the thermal insulator has two layers of foil, then the adhesive is applied to one of the aluminum layers. Prior to bonding, the adhesive layer is protected with paper or polymers, which prevent damage or temporary adhesion of the adhesive layer during storage or transportation of the insulation.

[ads-pc-2] [ads-mob-2]

Insulation docking

[ads-pc-3] [ads-mob-3]

The demand for such materials is provided not only by their small thickness, but also by the fact that the self-adhesive insulation can be fixed to the surface without any tools and devices: it is enough to peel off the protective layer of paper. In addition, self-adhesive materials are often used not only as the main insulating layer, but as an addition to traditional heat insulators - mineral wool, foam, etc.

Insulation brand Penofol

Advantages of self-adhesive insulation:

- The minimum coefficient of thermal conductivity at the same minimum thickness of all known heat insulators;

- High reflectivity of light and heat energy with a foil-coated protective layer;

- Due to the foiling of the surface, the material does not pass moisture and has a 100% vapor barrier;

- Any self-adhesive insulation is very easy and quick to install - you just need to glue it to a clean protected surface;

- A variety of options for the execution of foil-clad heat insulators (rolls, tapes, strips, patches) allows you to choose the right brand for any type of work and for any surface;

- Considering all the above characteristics, we can talk about the cheapness of the material: self-adhesive materials with a foil surface are quite competitive with traditional insulation materials, but they are many times superior in their qualities and parameters.

Self-adhesive tape material

[ads-pc-2] [ads-mob-2]

This is interesting: Only self-adhesive foil insulation reflects heat energy outward in the warm season, and a feast of negative temperatures retains heat energy in the house. For comparison: traditional heaters have this effect only in 3% of the volume of foil self-adhesive. If self-adhesive materials are used for external insulation, then it is first recommended to stick a perforated film material on the surface in order to avoid wetting the battens or frame when steam is generated from moisture contained in the air.

Installation of thermal insulation

Stizol

Stizol adhesive insulation is a product of the Russian construction industry. The basis of the material is high density polyethylene (up to 40 kg / m³). Styzol is characterized by resistance to aggressive environments.

The material does not emit harmful substances, does not rot or crumble. Excellent eco-friendly properties make self-adhesive styzol a popular material for insulating living rooms. A thin layer of insulation does not increase the thickness and complexity of the structure.

Self-adhesive thermal insulation Adgilin is the best option for thermal insulation of ventilation system elements. It is a roll of insulation made of polyethylene foam.It is characterized by low vapor permeability and excellent moisture resistance.

The presence of glue in Adgilin makes installation work quick and convenient. Moreover, any surface is processed. Excellent adhesion properties and resistance to moisture prolong the operational period of the insulation, and the presence of a foil layer ensures a decrease in heat loss.

Types and types of protective construction films

All polyethylene films for construction and renovation are divided into two broad categories: conventional construction films of various thicknesses (most often from 0.2 to 0.5 mm) and specialized films. The latter are designed to create moisture resistant layers for foundations, screeds and floors. In addition, they also provide protection against water penetration, as well as acoustic and thermal insulation.

Consider briefly the types of special construction films:

- Vapor barrier films... They are used to insulate surfaces and protect against steam and moisture penetration into walls, roofs and ceilings. A vapor barrier film perfectly blocks the penetration of water vapor into thermal insulation and is a prerequisite for roof construction. They are characterized by high resistance to cracks and other mechanical damage;

- Roofing films / roofing membranes... This type of protective film is used to insulate the roof from the wind. They are usually placed in the upper parts of the walls of buildings and, of course, on the roofs;

- PE protective films... They are also called waterproof films. As you might guess, these materials are used to protect the surfaces of buildings from moisture and rain. They are installed in layers of screeds, roofs, ceilings and other structures exposed to rain;

- Foundation protective films... Or the so-called foundation films. They are used to insulate foundations and walls. Such films perfectly protect foundations, basements and basements from the ingress of water from the site. They are distinguished by their high tensile strength and high static load;

- Foil films... The presence of foil in the composition of the film improves its heat-insulating and reflective functions. Such materials are often used for insulation of ceilings, walls and vertical insulation of foundations in contact with the ground. These types of films are capable of releasing steam and condensed water to the outside.

What are the criteria for screen protectors?

The main difference between different types of films is, of course, the material from which they are made. Although most types of protective films are made from polyethylene, there are also other product models: PVC (polyvinyl chloride) films and foil films.

In addition, construction films differ in their thickness (in millimeters), width and length (in meters), coefficient of resistance to diffusion of water vapor, reaction to fire (in classes), tensile strength (in newtons) - these indicators are usually indicated along and across ... The technical parameters of the film also include elongation at break (in percent), it is still determined whether the film meets the requirements for durability and, of course, they differ in terms of service life.

Let's consider in more detail the features of the main types of protective films. And let's start with the simplest ones - for covering ponds and objects on the site.

Film for the protection of reservoirs, ponds

Not every type of construction film is suitable for covering ponds. For this, there are special films for reservoirs. Among them, you can choose polyvinyl chloride film (PVC), EPDM membrane or polyethylene foil. Each of these types is suitable not only for shelter, but also for building a pond.

Why is it important to use special pond films? The fact is that conventional building films are generally too thin and not resistant to ultraviolet (solar) radiation.This is why they are not suitable for installation in swimming pools, ponds and ponds. Even if you put the net on such a surface, you must take into account the fact that the film will last for a maximum of 1-2 seasons.

What kind of film to choose for your pond? We recommend buying protective films with the designation PE, PVC and EPDM.

The cheapest, of course, are plastic films. True, they are the most short-lived. The thing is that such products quickly become covered with cracks, they are easy to scratch (especially at low temperatures), and solar radiation and oxygen after a while lead to the fact that the film loses its elastic properties and becomes brittle. If damaged, the product cannot be repaired.

More expensive and better quality products are PVC films for ponds. Due to the presence of polyvinyl chloride in the composition, these materials are more durable and resistant to any weather conditions.

The most expensive type of film used for ponds is the EPDM membrane. They are made of synthetic rubber glued with special glue.

Protective film to protect the lawn and vegetable garden from weeds

Many people wonder what to do with the leftover construction film. Building film can protect your area from weed growth, but be sure to keep in mind that it is made of plastic that does not allow air and water to pass through properly.

In addition, construction films become very hot during construction. Protecting your crops with black sheeting will have the opposite effect of what you expected. For weed control, we recommend specialized lawn and planting films and agrotextile coverings.

Building film for insulation and insulation of foundations

Both flat films and bucket membranes are used to insulate foundations. Most often, a PVC and polyethylene film is laid for warming foundations. If you are looking to buy plastic wrap, consider products labeled PE-HD (High Density Film). Such materials are more expensive, but better and more durable.

What is the thickness of the film to choose for the basement insulation? If you choose from polyethylene films for insulating bases, its thickness should be at least 0.2 mm, and for PVC films this figure is from 0.2 mm to 0.6 mm. Although the thicker the film, the better.

How are films attached to the foundation? Ordinary flat films can be attached as you like: on glue, sealant, self-tapping screws. There are also self-adhesive and heat sealable films.

Bucket membranes are mainly polyethylene films, which are additionally reinforced with polyester, polypropylene or fiberglass mesh. The thickness of the bucket membranes is 0.5 to 0.9 mm. They are used to cover the outer layers of insulation that protect the foundation from water. Waterproof insulation, protected by bucket membranes, is more resistant to mechanical damage.

Some developers use a special construction film with the FPO marking to insulate the foundation - it consists of polyolefin elastomers, polypropylene, polyethylene, PVC polyvinyl chloride or a material based on PDM rubber.

For foundation insulation, it is recommended to choose films that will be easily bonded by welding, vulcanization, glue or solvent. The film base must be carefully smoothed out. You can apply the film to concrete, smooth masonry or ordinary plaster.

Construction film for screeds

LDPE or PE films are ideal for protecting screeds from steam and moisture. Moisture-resistant and protective insulation should be made of film with the best parameters, since the tightness of wet insulation depends to a large extent on the insulating material.The most commonly used screed film is 0.2 or 0.3 mm thick.

Roofing film

Choosing a roofing film should be guided by four factors: price, durability, quality and purpose of the film. Correctly selected material will provide high-quality insulation of the roof from water, steam and other vagaries of bad weather. The tightness of the roof and the appropriate energy balance are highly dependent on the selection of the right roofing foil.

When insulating the roof, you can apply a vapor barrier film or a low vapor roofing membrane, as well as a high vapor permeability roofing membrane or foil. The foil protects against moisture and also provides very good thermal insulation.

Construction film as vapor barrier

Construction films used as vapor barrier are usually made of polyethylene, polypropylene or foil with an aluminum screen and an additional layer of polypropylene or polyethylene.

When performing vapor barrier on the walls and roof of a house, pay attention to such parameters of the film as its thickness and vapor permeability. Remember that vapor barrier films must have low to very low vapor permeability and very high Sd.

Construction film as insulation

Most types of building films are effective moisture and vapor insulators. For insulation, insulating films, vapor barriers, horizontal films, as well as insulating membranes are most often used. The choice of material depends on the purpose and method of insulation and the location of its installation.

Building film for floors

To protect the floor from moisture, polyethylene films of suitable thickness are most often used, usually 0.2-0.3 mm. It is always better to waterproof the floor even when the floor is on the ground.

To do this, you should take care of waterproof insulation, and in rooms exposed to a large amount of steam (bathrooms, laundry rooms), it is worth using a building film under the floor, which is also an excellent vapor barrier.

Construction film - on or under expanded polystyrene?

Depending on the construction technology, the film can be installed both before and after the polystyrene. Construction protective film protects walls from moisture from the ground, and also protects expanded polystyrene from moisture penetration into expanded polystyrene.

Roof construction film

For roof insulation, vapor barrier and roofing membranes are used. Both materials perfectly protect the roof from the penetration of water vapor, and also insulate the interior space from heat loss. Films with low vapor permeability and films with high vapor permeability are the most popular solutions.

Construction film. How thick is it?

Depending on the type, construction films have slightly different technical parameters, including thickness. Construction films are made with a thickness of 0.075 to 0.1 m. For waterproofing and for floors, it is recommended to use films with a thickness of 0.15 to 0.5 mm. The thicker the material, the better.

In the case of insulating films, the horizontal thicknesses are about 0.3 mm, while the vapor barrier has a thickness of 0.15 to 0.3 mm.

Armofol

In the production of self-adhesive armofol, aluminum foil and glass mesh (or fabric) are combined. Fiberglass mesh acts as a carrier layer. Due to this, the insulation has high strength and can be used at various temperature conditions (-50 ... + 150 ° C).

The latter characteristic made it possible to use the material in refrigeration plants and saunas, outdoor pipelines and industrial premises with high temperatures.

Self-adhesive insulation Armofol is a reliable barrier against penetration of radiation and electromagnetic radiation.

Scope of use of "Isover"

We present two types of insulation "Isover":

- Industrial use.

- Household.

Mineral insulation "Isover" is used for the following works:

- insulation of roofs and walls of the house;

- insulation of apartments outside;

- soundproofing walls in the room;

- insulation of ventilation systems and pipelines;

- creating multi-layer walls;

- warming the floor of the room for the winter.

The material is also used for cladding attics and basements. Due to its environmentally friendly composition, insects and rodents do not start in it. Insulation "Isover" is also used for cladding all kinds of buildings and premises, from apartments to large enterprises.

Megaflex

Megaflex belongs to the universal heaters. For its manufacture, foamed polyethylene is used, which is able to take the form of a finished coating. For this reason, Megaflex is an effective tool for sealing rough and uneven surfaces.

Partitions between walls, interfloor floors, window frames, heating and ventilation systems are insulated with self-adhesive material. When covering ventilation ducts, the sound-insulating properties of the structure are improved, the level of noise and vibration is reduced.

Welcome to the online store of fire retardant high temperature insulation.

We are happy to accept and serve orders from Mon-Fri. from 9.00 to 18.00 Moscow time. Delivery is possible both in Moscow and in the regions (more about delivery here). Make an order through the website, and we will call you back to agree on the delivery time of the order.

"INSULATION" manufactures and supplies high-temperature silica (over 1000 degrees C) materials: KT-11-TO, KT-11-S8 / 3-TO silica fabric, polyurethane-impregnated fabric, hollow silica cord of various diameters, filled with silica thread or silica canvas , silica tapes of various lengths, needle-punched mats of the brands Supersil, Ekovul.

Production - RF. Guarantee for materials and finished products is 1 year.

Silica materials are widely used for:

- thermal insulation of heating, smelting and drying furnaces, converters, ladles and overflow trays, power turbines and reactors, incl. atomic;

- heat and electrical insulation in the production of household heating devices and appliances (electric stoves, boilers, refrigerators, irons, etc .;

- filtration of metal melts, chemical fertilizers;

- production of personal fire protection equipment and workwear;

- fire, heat and sound insulation of wall panels, interfloor ceilings, rack cassette ceilings;

- fire and electrical insulation of rooms, ventilation and cable ducts, elevator shafts and cabins;

- devices of fire protection curtains, gates, fireproof doors;

- thermal insulation of welded structures and pipelines during heat treatment of welded seams;

- noise and heat insulation of engines, cabins and cabins of aircraft and vehicles;

- fire, heat and noise insulation of railway cars;

- packing of neutralizers of exhaust gases of internal combustion engines, incl. automobile.

The materials have high heat, sound, electrical and fire insulating properties, the material can withstand temperatures up to 1700 ° C, various types of acids, high pressure and electricity. Silica materials have excellent flexibility characteristics, but unlike most similar materials, they do not contain any adhesive binders, which means that during prolonged exposure to high temperatures, for example, in a fire, they do not emit smoke and toxic gaseous elements.

It is an environmentally friendly heat-shielding and heat-insulating material that does not contain asbestos. The materials comply with all existing sanitary and hygienic, environmental and fire safety requirements, which are valid not only in the Russian Federation, but also in the USA and Europe.

Tilith Black Star Duck

Foamed polyethylene is used for the production of this roll insulation. The main field of application is the thermal insulation protection of the ventilation system. TILIT Black Star Duct is safe for human health.

The insulation has a long service life (up to 25 years) and is resistant to a humid environment. Condensation will not appear on the surface finished with self-adhesive TILIT Black Star Duct.

The lineup is represented by two products. Self-adhesive material with AL marking indicates that it contains polished aluminum foil.

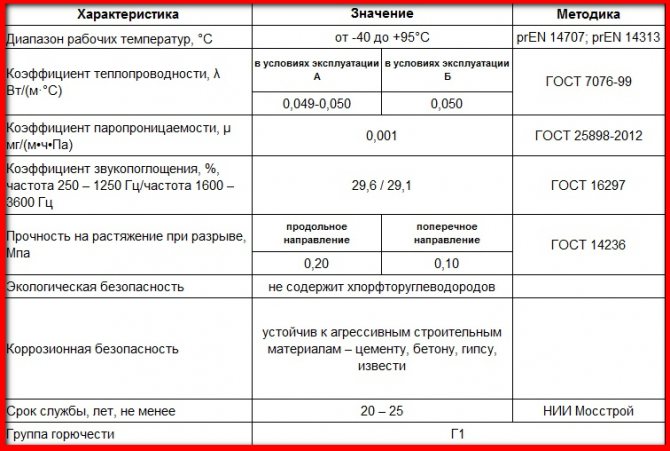

Foam insulation NPE MK PET with an adhesive layer

NPE MK PET foam has the same characteristics as Penofol C. Insulation is a reflective insulation consisting of two parts: a duplicated metallized film and an adhesive layer.

In addition to thermal insulation, NPE MK PET foam acts as a vapor barrier and sound-absorbing product, is resistant to negative environmental influences and is easily attached to the surface.

The scope of application is extensive. It can be used both for underfloor heating and for bath insulation.

Installation of self-adhesive insulation

At the initial stage of thermal insulation work, the surface to be treated is checked. The old insulation is removed. If necessary, alignment of the walls is carried out. Windows, pipes, air ducts are washed, degreased and dried.

When insulating windows and doors, measurements of structures are made. Self-adhesive material must be glued in a single piece without cutting in the corners. When gluing, the protective film is removed gradually.

The quality of the work is checked with a candle. The flame from a lighted candle near a window or door should not fluctuate.

If the walls are covered with foil insulation, it is recommended to fix it to the crate. This will create an air gap for ventilation. The material is laid with the foil side inside the room. The joints are glued with tape or tape.

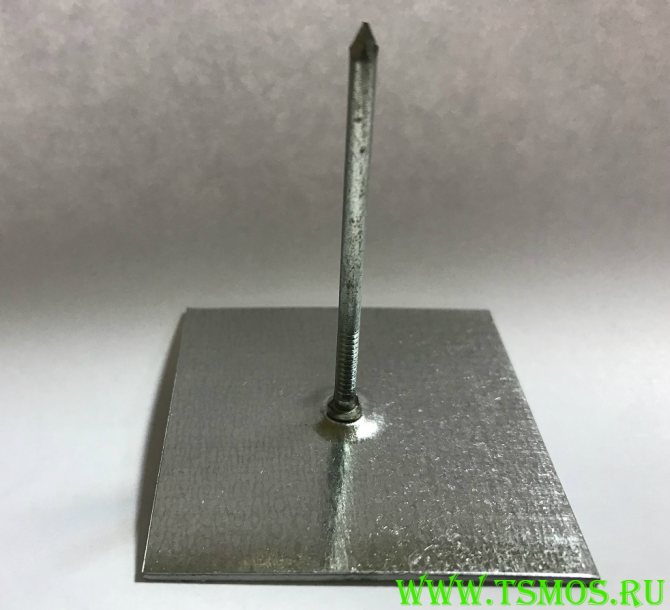

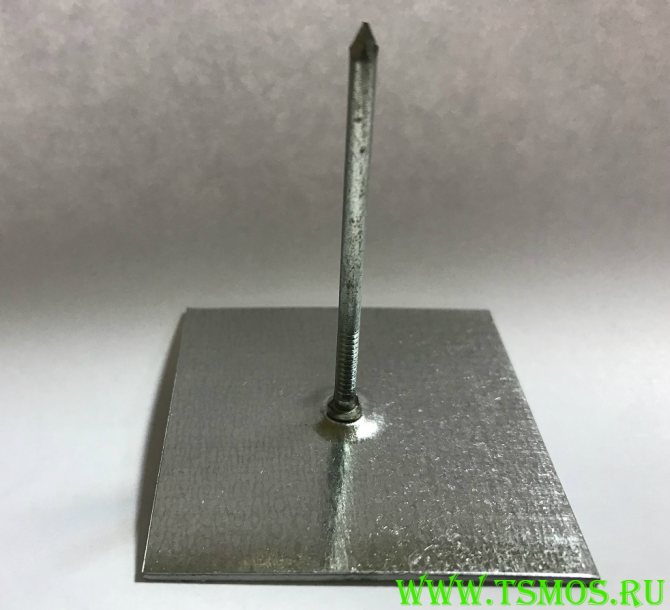

Self-adhesive spikes

Self-adhesive spikes for fastening insulation For air conditioning systems, fire retardant or thermal insulation mats are required. In different situations, there are different tasks to ensure a normal and complete ventilation system. When fixing the thermal insulation material or fire protection on the air duct body, there is a specialized solution that the manufacturer prescribes in the technological regulations. So, Rockwool LLC recommends the use of welded pins for fastening insulating and fire retardant materials. This is due to the testing of all structural elements, which allow the manufacturer to be calm about its main products. So why do you need self-adhesive spikes for fastening the insulation? In our country, this fastener is used to permanently fix the insulation, but everyone forgets that at subzero temperatures the spikes simply come off. Their need exists for temporary fixation with the subsequent removal of fasteners from the air duct body. Self-adhesive spikes include: √ heel with double-sided tape (50 * 50 mm) √ length of the spike from 19 to 114 mm √ locking washer 30 mm √ protective plastic cap

Installation errors Many editors go for little tricks. Self-tapping screws are fixed in the heel (heel), on which the adhesive composition (double-sided tape) is fixed, which facilitates the task of fixing the thermal insulation. How to understand that there are self-adhesive spikes on the mounted air duct under the insulation? Self-adhesive spikes can be easily identified by their steel color, where their ends will be visible even through the protective caps. The right solution for fixing insulation and fire protection For ventilation systems, fixing of insulating materials is provided only with welded copper-plated pins. For their fastening, specialized welded equipment is required. Installation of self-adhesive spikes A spike with a self-adhesive base is glued to the cleaned surface of the air duct. For 1 m2, it is recommended to use at least 12 pieces. Insulation is punctured on the sharp ends of the self-adhesive spikes and pressed against the air duct body with locking washers, which are included in the purchase package. The protruding parts of the spikes are closed with protective plastic caps.

It might be interesting:

| |

| |

| |

| |

|

LLC GK "TEPLOSILA" - together with you since 2005!