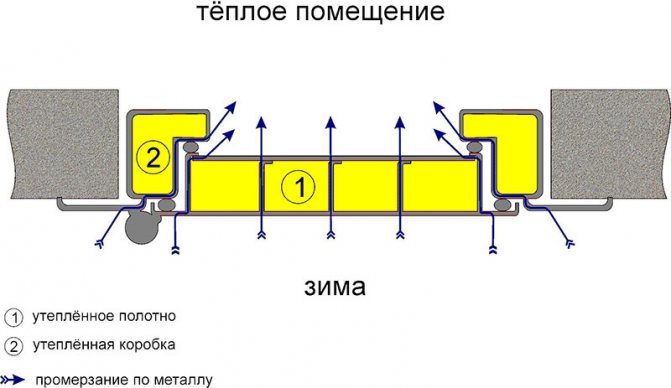

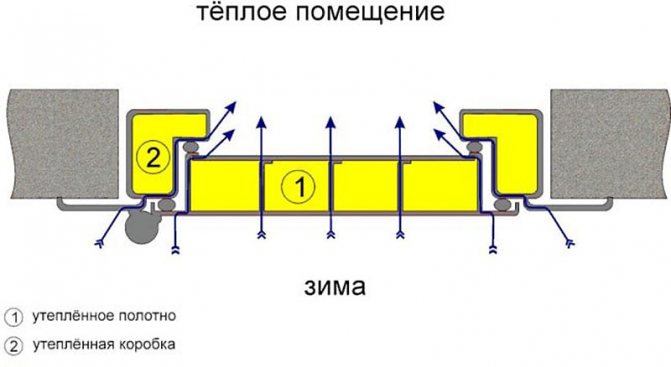

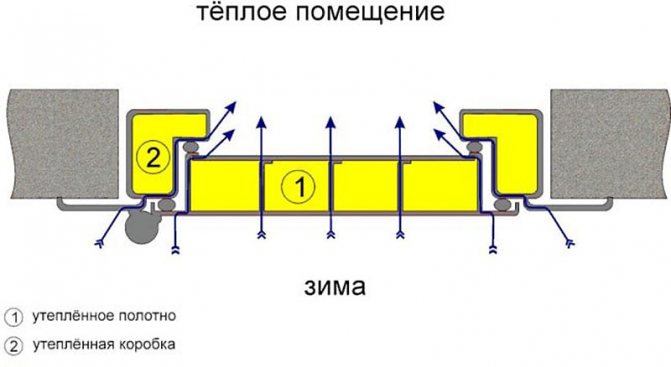

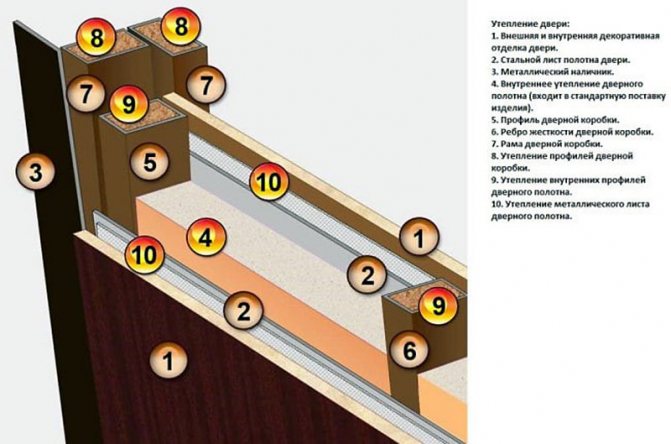

The main disadvantage of iron entrance doors in private houses is the high thermal conductivity of the metal, which is why condensation forms inside the box during frost, flows down and accumulates in a confined space, making it possible to develop metal corrosion. In high-rise buildings with entrances, this problem is not so acute, since the air at the entrance in winter is always warmer than the outside temperature. But for an open entrance to a house, the problem of how to insulate an entrance metal door is indicated quite specifically, and it has an effective inexpensive solution - read about this in the article below.

This is what a non-insulated steel door looks like in winter

The choice of materials for door insulation

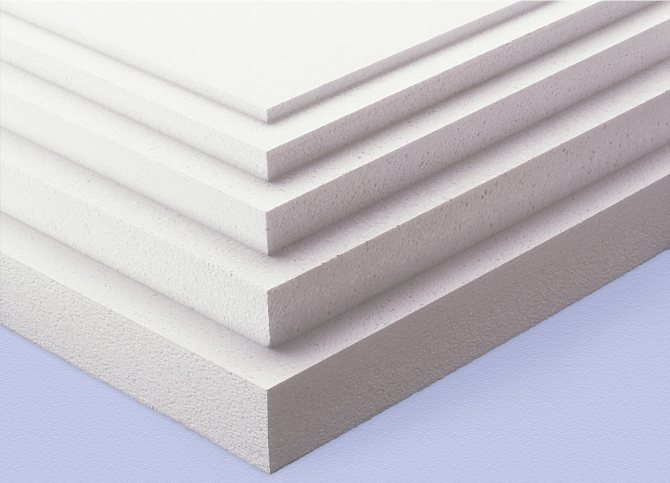

The best solution is to buy an insulated steel door, but this is not always possible for many reasons. To insulate a door with your own hands made of metal, fibrous materials are used, and most often - polystyrene or extruded polystyrene foam, and before insulating an iron entrance door, you need to decide on this item.

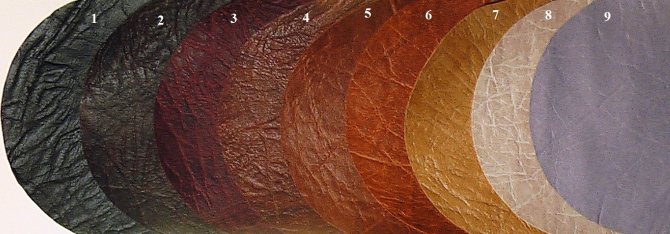

To the question of how to insulate doors: fibrous materials are mineral wool slabs or rolls. Mineral wool is a good insulator for the front door, non-flammable and non-toxic, but it is not suitable for your private home - too much temperature difference outside and inside the room creates ideal conditions for the occurrence of humidity, and when humidified, mineral wool noticeably loses its thermal conductivity. Therefore, foam or polystyrene remains - it does not absorb moisture, it is not afraid of temperature changes, so it will work for a long time and efficiently in the terminator zone.

The choice of foam with different sheet thicknesses

How can you insulate the door at the entrance?

When planning to insulate and sheathe the door block with your own hands, you should correctly approach the choice of insulating material. According to the location of the entrance to the housing, a reliable insulation is selected. Do not forget about the properties of the materials used, which allows you to make the right choice and get a durable result:

Foam rubber

Suitable for interior structures (vestibule, entrance). Does not tolerate external influences and quickly collapses from precipitation and wind.

Minvata

Differs in high moisture absorption. If mineral wool is used to insulate street doors, additional insulation will be required to protect against moisture.

Polyurethane foam

It is resistant to external influences, does not deform from thermal drops, and serves for a long time. It is used as an internal insulation.

Izolon

A type of roll material, on one surface of which an adhesive composition is applied, which simplifies the installation process. Suitable for structures that need to be insulated from the outside / from the inside.

Styrofoam

Resistantly tolerates the influence of moisture, does not deform, but has a low fire resistance.

Polystyrene

A cellular material similar to polystyrene, but with greater fire resistance and durability. Suitable for all types of insulation.

Ready-made kits

In order not to rack your brains over the choice of thermal insulation, you can use ready-made kits. These are standard sets, which already include everything you need: insulation, rubber contour of the seal, upholstery, decorative nails.

An equally effective ready-made solution for Moscow and other cities is a door model with a thermal break. It consists of two heat-insulating materials with a layer of polyamide fabric with low thermal conductivity.

- Entrance door laminated VLD 003

- Laminated entrance door VinL 1

- Entrance door with powder coating PN-8

- Warm entrance door VFD 007

- Entrance door elite VFD 013

- Entrance door with thermal break VMDT001

Foam insulation technology

There are only two ways to insulate a metal door: outside and inside. Of course, you don't want to cover a beautiful, for example, forged or corrugated surface with a layer of insulation, so the most popular way is to install thermal insulation on the inner surface of the doors. This technology uses materials for insulating large surfaces and seals for gaps and crevices.

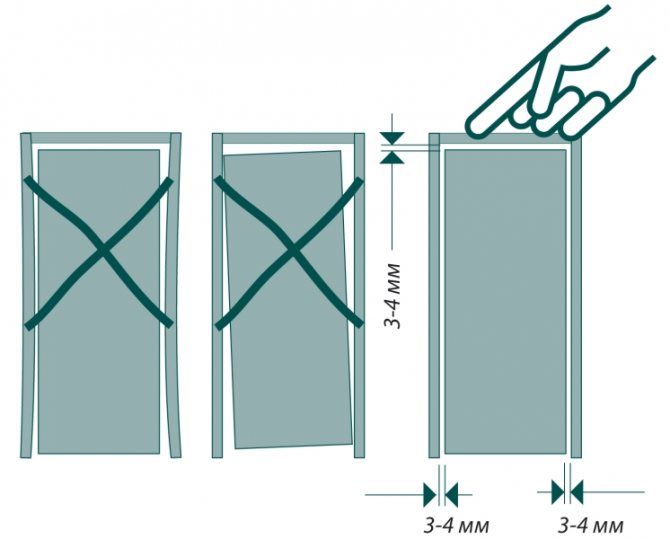

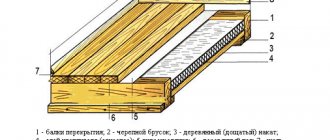

Before insulating an iron door in a private house, it must be prepared:

- Measure the depth of the enclosed space that formed from the stiffeners, as well as the length and width of these cells;

- Prepare foam sheets of the same thickness;

- Cut PPU blanks according to the specified dimensions with a positive allowance of 2-3 mm so that the foam fits tightly into each cell;

- Number all the blanks.

Weaknesses in the insulation of steel doors

The table shows the results of comparing the properties of thermal insulation in conventional units:

| Comparison characteristics | PPP | Minvata |

| Price | 1 | ≥ 1,15 |

| Weight | 1 | ≥ 3,0 |

| Coefficient of thermal conductivity | 1 | ≤ 0,75 |

| Lateral bending resistance | 1 | ≤ 0,8 |

| Noise absorption coefficient | 1 | ≤ 0,8 |

| Resistance to chemically and biologically aggressive influences | 1 | ≤ 0,67 |

| Environmental friendliness | 1 | |

| Fire safety | 1 | ≤ 4,6 |

| Allowable operating temperature range: For external surfaces For internal surfaces | - ꝏ, + 700С - ꝏ, -350C | -600C, + 6500C -350C, + 6500C |

| Installation Requirements | Not | Forbidden in wet weather |

| Installation restrictions | Not | When working in the food and medical industry |

Nuances of outdoor insulation

A factory or home-made metal door is insulated along a sash located from the inside of the room. The same heaters are used. Heat loss protection is carried out in two ways:

- Thermal protection using a frame on rails. After dismantling the fittings, the slats are fixed on the canvas by means of self-tapping screws, or a metal profile is mounted by welding. The resulting frame is filled from the inside with a thermal insulator attached to glue. On top of the resulting structure, fiberboard is fixed, pre-cut to the desired dimensions.

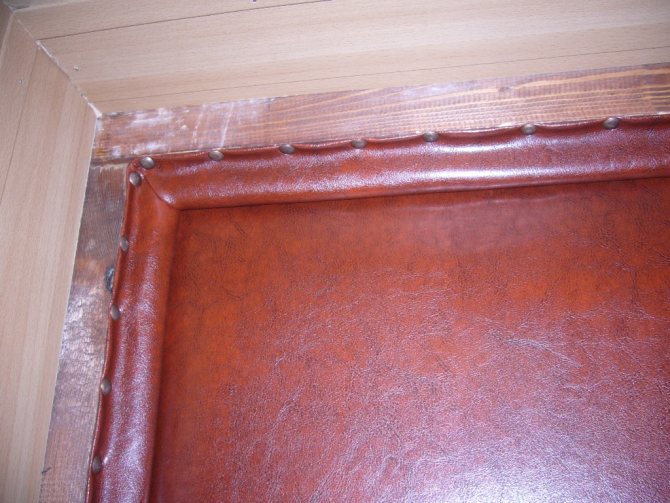

- A less laborious option is sheathing with thermal insulation material. To carry out the work, the canvas is removed, its surface is cleaned and coated with glue and a layer of insulation is laid. Thermal masking is done with an upholstery fabric secured around the outer perimeter.

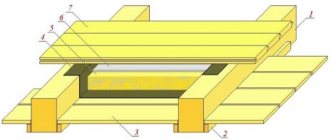

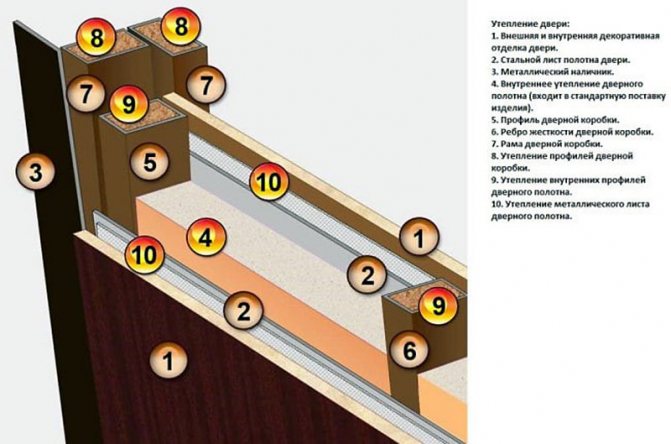

The location of the foam in the door

In the cells, the polystyrene is fixed using construction polyurethane foam:

Foam installation with foam

- Before insulating the iron door with your own hands with the help of polystyrene foam, shake the foam cylinder fixed in the assembly gun;

- You need to apply foam with an inverted bottle. They do this first on all sides of each cell, and then make several lines of foam inside the cells (see the figure above);

- Insert the trimmed and numbered sheet of insulating foam into the cell under the same number, press it against the foam;

- Repeat operations with all cells;

- After filling all the cells, the gaps between the foam and the metal are poured with foam. The main insulation of the entrance metal door with your own hands can be considered complete - it remains to decorate the canvas.

Placement of workpieces in cells

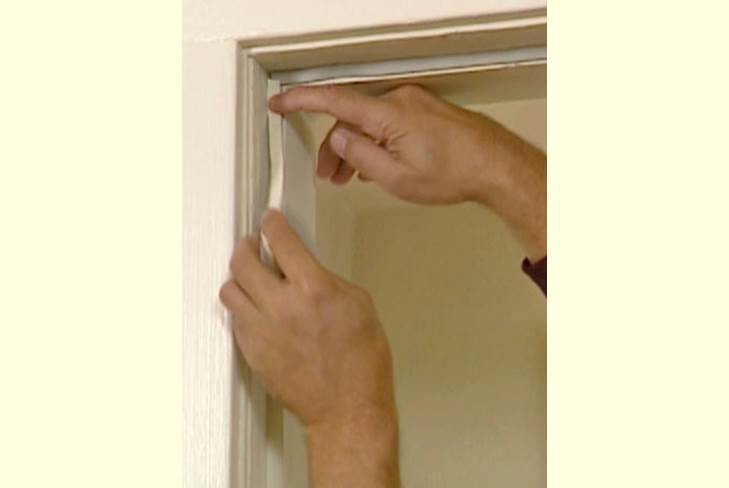

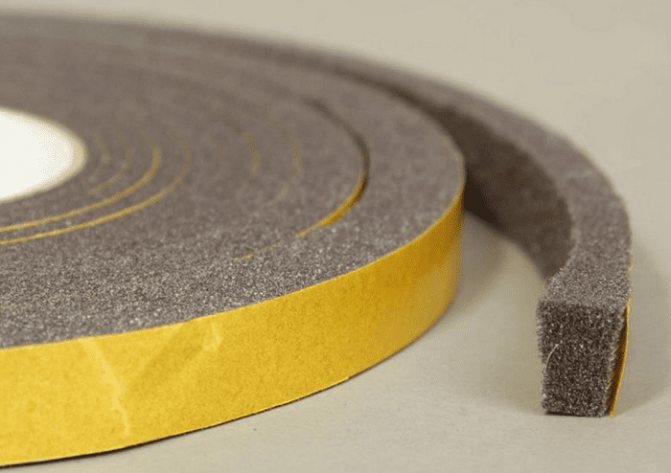

We insulate technological gaps.

Heat loss can occur even with an insulated door. This may be due to technological gaps between the wall and the door frame. As a rule, they are from 20 to 25 mm and they are sealed with polyurethane foam. To do this, you need to adhere to the following steps:

- Remove the platbands from the inside of the door;

- At the junction of the box and the wall, use adhesive tape to attach a plastic wrap;

- Remove the platbands from the outside;

- In order to speed up the hardening process of the polyurethane foam, pre-technological gaps can be moistened;

- First, gently apply the first layer of foam;

- After its expansion, after 20 minutes, proceed with the application of the second layer so that when expanding, the foam does not go beyond the perimeter of the box (if it does, then cut off the excess with a construction knife);

- When the foam has completely hardened, you can remove the protective film from the inside of the door and reinstall the platbands.

How to install and fix the inner door panel

- The metal door is insulated from the inside as follows: the sheet with foam and foam is covered with waterproof laminated plywood. To do this, it is advisable to remove the door from the awnings and lay it on the floor on supports;

- A U-shaped bar with a groove is attached to the metal frame of the door on the sides and bottom with bolts, along which plywood and MDF must be inserted. The height of the pocket should correspond to the thickness of the plywood sheet plus the thickness of the MDF panel and the height of the screw heads;

- The cut plywood and MDF sheet are inserted into the U-shaped strips on the sides of the frame, pushed all the way;

- The upper bar must be collapsible so that you can repair the MDF by replacing it, so it is attached to the silicone using a construction gun.

Important: it is recommended to select the MDF panel to match the interior decoration of the corridor so that the inner surface of the entrance door is similar to the surface of the interior doors in the apartment. It is also advisable to choose fittings similar to the one installed on the interior doors.

Door insulation scheme

https://youtu.be/cHAhTXyNd9A

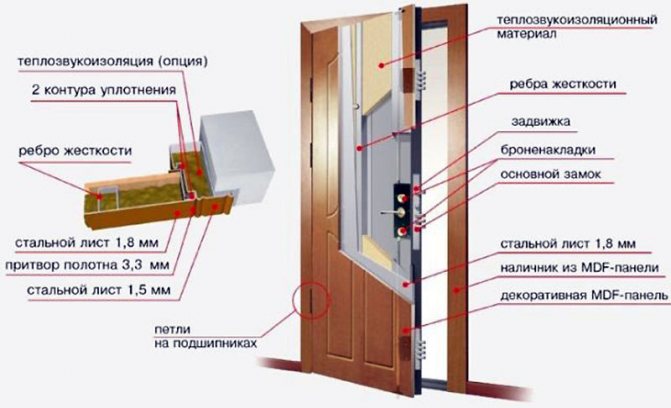

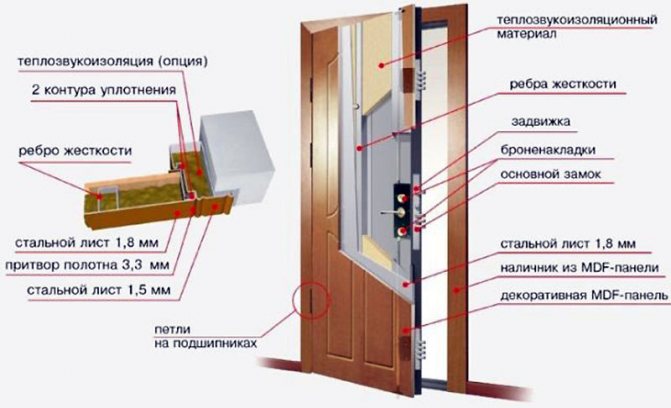

Features of door block insulation indoors

Before starting the internal insulation, you should study the design of the installed door block. In traditional split designs, the thermal insulation layer is located between the decorative panel and the steel sheet. With non-collapsible models, the insulation procedure will be more complicated.

Insulation of collapsible structures involves the sequential performance of a number of actions:

- Dismantling of all hardware elements in order to simplify disassembly.

- Gaining access to the interior space by removing the decorative panel, removing the old insulation (if any).

- Filling the interior with the selected thermal insulation. When using sheet materials, a small margin should be made to densely fill the voids.

- The heat insulator is fixed on glue, liquid nails.

- Elimination of voids left after work with polyurethane foam.

- Installation of the decorative panel after checking the free space for mounting the peephole, as well as the locking mechanism.

Do you want to disassemble a metal entrance door for insulation? Use the external option to maintain the integrity of the block. This method is also perfect for non-separable models.

In this case, the internal space is filled with thermal insulation in the form of granular materials. The cut of the card at the end allows you to fill in the insulation inside. However, if there are blocking anti-burglary crossbars in the design, this option will not work, since the use of bulk materials can block their mechanism.

Recommendations for masters

If the insulation of the iron door is done correctly, then the thickness of the door will increase noticeably, and this may affect the convenience of opening - the length of the key may not be enough, and you will have to order new keys. This does not apply to lever locks - they have long keys.

Also, the insulation of the doors will lead to the fact that you will need to make the supporting square on which the handles are put on longer. These squares are sold separately from locks and can be chosen in any length.

Standard insulation scheme

Door frame insulation options

For the manufacture of a box of metal doors, a steel corner is used, fixed with anchor bolts. After dismantling the old structure, large gaps often arise between the load-bearing wall and the new frame. Subsequently, they are filled with polyurethane foam, although this material has one significant drawback: it collapses under the influence of sunlight. Protection of insulation from ultraviolet radiation helps to exclude destruction. This requires:

- Remove excess polyurethane foam from the wall. Remove the layer of plaster up to the brickwork or concrete, remove the resulting dust.

- Moisten the surface with water, which will improve the adhesion properties of the foam, foam the voids.

- Remove excess material after solidification.

To give the opening an attractive look at the end of the work, plaster, whitewash or paint is applied.

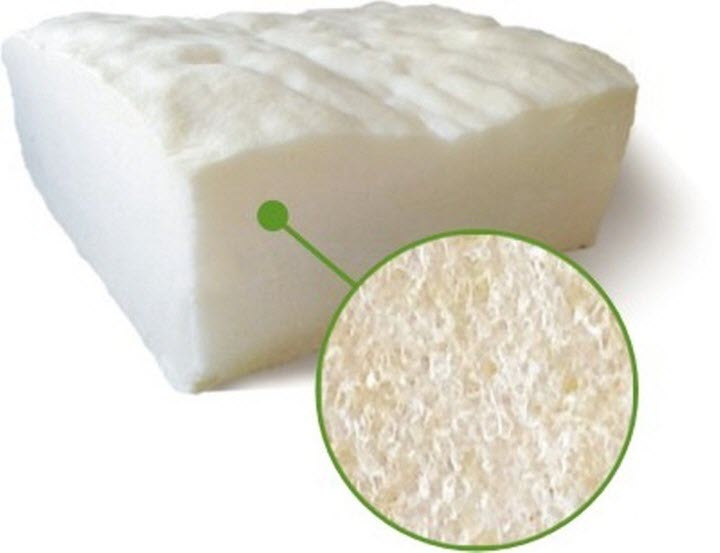

Mineral wool

Minvata is made from silicate rocks. High noise and heat insulation characteristics of the product are determined by the fibrous structure. Minvata is environmentally friendly, non-flammable, resistant to moisture penetration, the influence of temperature fluctuations, is not afraid of the effects of chemicals, and besides, it is characterized by a moderate cost.

The main disadvantages of the material are subsidence under its own weight, as a result of which voids are formed. The installation of additional stiffeners that can keep the insulation from slipping helps to avoid this.

Mineral wool

Cotton wool is applied to the entire surface of the door leaf, avoiding gaps, using glue or fasteners, paying attention to insulation around the perimeter. From above it is covered with a decorative coating (leatherette).

Today, this method of door insulation is rarely used in practice due to moral and technological obsolescence.

The cost of the material is from 385 rubles. per package and above. Mineral wool without a binder costs from 35 rubles. for 1 kg.

The main types of thermal insulation products

There are different types of door seals. Which one is the best for them is up to the consumer to decide. The following types of heat-insulating material are used to insulate external door structures:

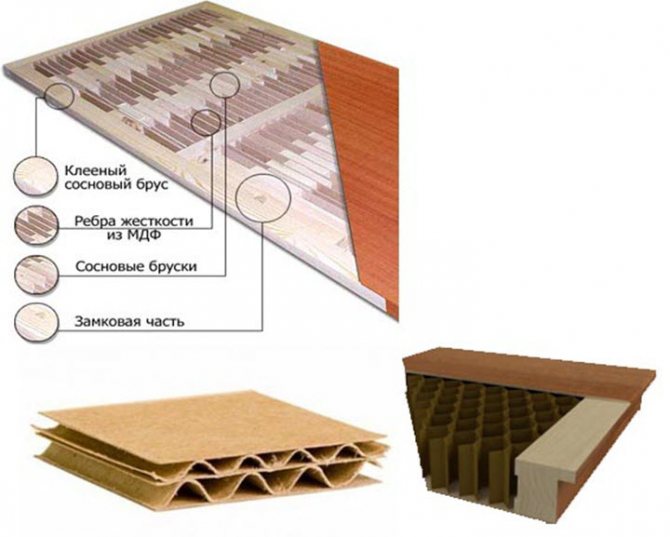

- Corrugated cardboard

Insulation of the door with corrugated cardboard

The product is a compressed cardboard with a high degree of thermal conductivity. Sound insulation performance is poor. Its main function is to use it as a filler for voids in the door. It is better not to use cardboard as a heat-insulating sealant in regions with cold climates, it is suitable for use in places with warm climates.

- Mineral wool

Mineral wool is distinguished by its non-combustible properties

The product has been used as a heater for a long time, an environmentally friendly seal with a fairly low price. The main disadvantages are exposure to moisture, cotton wool settling after a certain period of time, as a result of which voids are formed in the canvas. Cotton wool, absorbing moisture or its vapors, loses its thermal insulation characteristics, freezes at low temperatures. When using insulation for metal doors, it is necessary to install a vapor barrier to prevent moisture penetration. You can use plastic wrap instead.

- Styrofoam

Polyfoam has excellent heat-saving properties

The gasket is in great demand among heat-insulating materials for door insulation, is easy to use, has high thermal and sound insulation properties. Polyfoam has a moderate, affordable price. In addition to its advantages, the product also has disadvantages, which include the flammability of the product, a large amount of toxic substances are released during combustion.

- Polyurethane foam

Insulation with polyurethane foam is one of the most popular

A synthetic product can be used both in the form of foam and in bulk. When used, the foam fills the entire space of the doors, as well as all hard-to-reach places. When cured, it has low thermal conductivity properties, the product does not burn and is easy to install. The sealant has two types of cell structure, which are formed as a result of foaming. They are divided into types: rigid structure, closed cells and completely filled with gas; elastic structure, cells of this type are open.

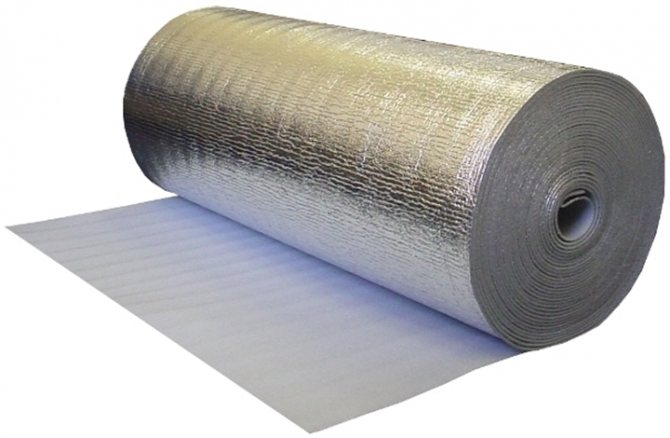

- Reflective insulation

Reflective insulation works like a thermos

Products of this type are used for metal and wooden structures. It is made from polyethylene by foaming with a surface coated with thermal reflective foil. The insulation has a thin appearance, at the same time it is able to retain almost 70% of the warm air. This is achieved by a reflector that returns heat back, and the rest of the heat is retained by polyethylene. The material can be with a reflector on one side or on both sides of the product. A self-adhesive seal with a one-way reflector is often used, it has a reflector on one side and glue on the other. Its installation is quite simple. Self-adhesive insulation is glued on both sides of the door leaf and sheathed with a decorative product. For example, it can be genuine leather or its substitute.

In addition, for the insulation of the exterior doors of the house, such types of seals as synthetic winterizer, sealing tapes and similar products can be used. When using them, a mandatory surface cladding of the door leaf is required.

Which heat-insulating seal is best used depends on the type of door leaf and climatic conditions.

How to insulate a split steel door?

The process of protecting an iron split door from cold penetration is similar to the thermal insulation of a conventional metal model. Design features are of prime importance here.

The sash is removed from the hinges and is positioned horizontally on the stops. All elements (handles, locks, etc.) are dismantled, after which the inner lining is removed. For non-monolithic models, the fastening of the trim is usually performed with self-tapping screws. After disassembly, cardboard is removed from the inner space of the canvas, the surface is cleaned of dust and debris.

If there are stiffeners inside, holes are drilled in them through a small gap, after which the voids are filled with foam.

After that, they move on to creating a hydro-barrier, cutting and fixing the insulation (a number of materials do not need protection from moisture). The insulation procedure itself does not cause difficulties and is carried out by analogy with an integral structure.

A pad is located on top of the fixed insulation. If it is damaged during dismantling, the inner panel is replaced. After that, the peephole, handles and locking elements are installed in place, the sash is hung on the hinges.

Expanded propylene

The main advantages of this insulation are environmental friendliness, light weight, insulation characteristics, resistance to fire, moisture, chemicals and atmospheric agents. Polypropylene foam withstands loads, does not absorb water.

Available in the form of air plates, which can be easily cut to the required dimensions and easily attached to the door using special glue or liquid nails.

The material costs starting at 1100 r and above for 1 package, which differ in size or number of sheets.

Expanded propylene