Gas generating boilers are a type of solid fuel, usually hot water devices. The essence of its work is that the fuel and volatile substances in it burn separately. In other words, solid fuel pyrolysis occurs, therefore boilers are also called pyrolysis boilers. This heating equipment is especially effective when working on wood, wood briquettes, drill and some fractions of coal.

Use gas-fired boilers to heat your home

Read more: long burning pyrolysis boiler.

How and with what to heat the boiler

From any solid fuel, carbon monoxide is released in a certain amount during combustion. Especially a lot of it is obtained when wood is burning.

That is why it is wiser to put firewood in a gas-generating boiler, designed to create a comfortable temperature in the house, and not any other fuel.

In order for the premises to be heated well, the gas-fired boiler must be used correctly:

- open the air damper and start a fire with a splinter;

- set the mode of regular long burning, in which the fire in the boiler will be maintained until the temperature in the furnace rises to the desired level;

- switch the damper to a mode supplying air in a limited amount.

In modern wood-burning gas-fired boilers, all of the above actions do not need to be performed, since their work is fully automated.

The fuel is ignited by means of an electric ignition, an automatic unit controls the supply of oxygen to the combustion chamber and the removal of gases resulting from the combustion of wood.

Wood-fired gas-fired boilers must be loaded with a certain type of fuel. Best suited for this are beech, oak and acacia wood.

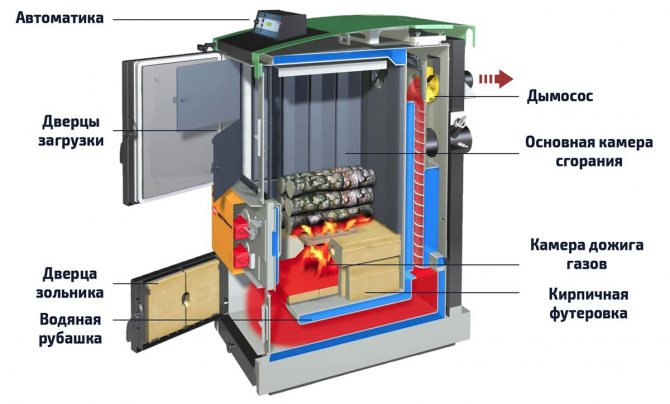

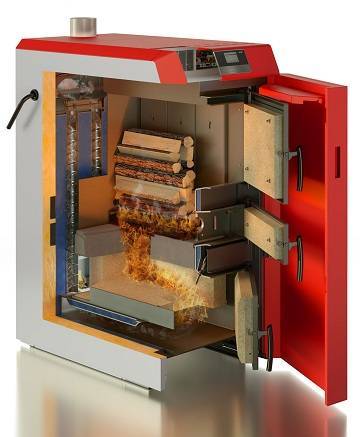

Photos and diagrams:

Coal should be abandoned altogether, since it negatively affects the performance of heating equipment.

It is wiser to use only high-quality fuel to heat the house, since more heat is produced during its long burning.

As for the moisture content of the firewood, the gas generating equipment will not function on frank raw fuel.

That is, the wood will burn as in a conventional stove, and the boiler will not work in gas generation mode.

The design of the boiler itself affects the firewood with which moisture content can be put into the gas generating equipment.

If it has a side loading, then it is allowed to load only firewood with a moisture content of not more than 20%. Such equipment is very demanding on the quality of wood.

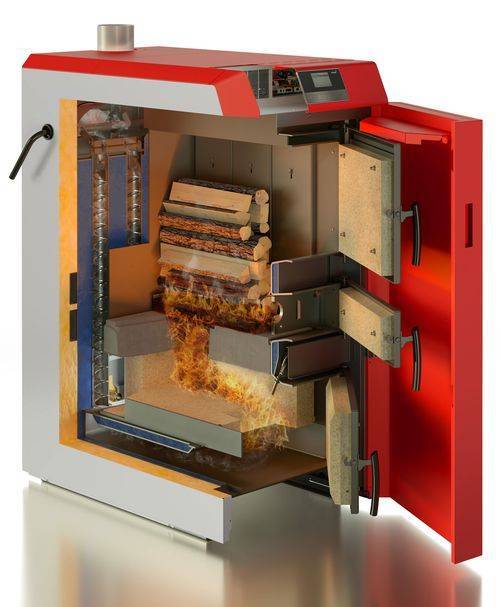

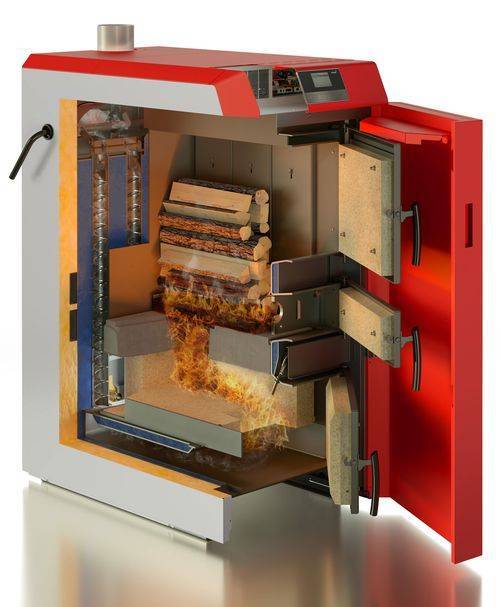

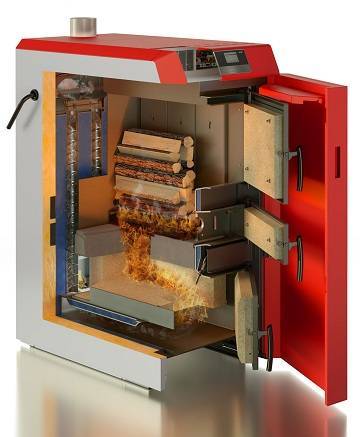

Top-loading wood-fired gas fired boilers burn fuel gradually. To do this, it is placed in a vertical firebox.

When the bottom layer of firewood burns out, they will go down, being dried by warm air. Boilers, into which fuel is loaded from the top, are transferred to gas generation mode, even if the moisture content of the wood is about 45 degrees.

Principle of operation

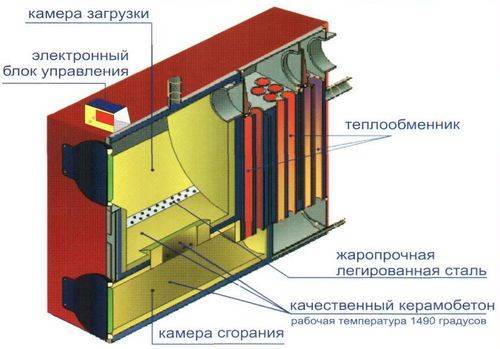

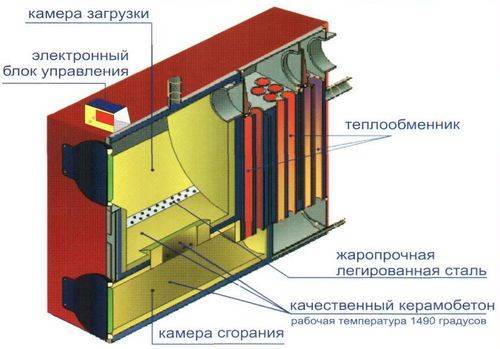

The scheme of a wood-fired gas-generating boiler has a preliminary gasification chamber in its structure. Also, a combustion chamber is installed in it, which is necessary for processing firewood into heat. The principle of operation of this chamber is aimed at moving the generated gases through the nozzles. A homemade boiler has an operating time of at least 25 hours.

The gas generator consists of two chambers, the first one burns fuel. Due to the small amount of oxygen, the substances are divided into a volatile part, forming wood gas. Then the wood is left to burn out in the second chamber.In other words, the principle of operation of the design of the device allows you to achieve maximum heat output.

The principle of operation of a gas-fired boiler is based on forced draft. Especially for this, a smoke exhauster or a fan is installed in the boilers. After the fuel reaches its highest combustion temperatures, the wood turns into a solid and volatile part. Boilers carry out the combustion process not only at maximum temperatures, but also if there is not enough air in it.

The principle of operation of the device is such that as soon as the resulting gases move through the nozzle, they are mixed with secondary oxygen, and the combustion temperature reaches 1200 degrees. Immediately after the gases release heat through the heat exchanger, they are removed from the chamber to the outside, moving through the chimney.

Connecting and starting a wood-fired gas generator

When installing a gas generator on a car, it will be more difficult to start the car - it is better to do it on gasoline

It is necessary to take into account the peculiarities of using a wood-fired gas generator when connecting it to a car. Experts do not advise to completely abandon gasoline, because starting the engine with wood is problematic. It is recommended to start the engine by supplying gasoline, and only then switch to gas. Switching to different types of fuel can be organized using a mixer made according to the scheme of I.S. Mezin.

There are other restrictions as well:

- The size of the firewood is no more than 6 cm.

- Only dried wood is used as fuel, because additional heat is spent on the evaporation of water, and less pyrolysis gases are formed in this case.

- A wood-fired gas generator engine loses 50% of its power compared to a gasoline engine.

- The ignition is carried out with the fan on, 20 minutes before departure.

Running on homemade fuel, the engine wears out faster.

Principle of operation

The gas generator boiler uses the principle of "pyrolysis" in its work. This equipment has two combustion chambers, and the fuel being put in goes through several stages of combustion:

- It is dried in a special chamber.

- In the first combustion chamber, the fuel slowly smolders at a temperature of 200-850 degrees Celsius without oxygen - pyrolysis. During pyrolysis, a large amount of "wood" gas is released from the fuel, which then enters the second chamber, where it is successfully burned using a burner and a large amount of air blowing.

- In this case, the coolant and water heating circuit (in double-circuit boilers) is designed and mounted in such a way as to take heat energy from both combustion chambers.

The gas generator boiler can work not only on trees, but also on any wood waste, as well as on briquettes and eco-granules - pellets.

Pyrolysis gas generating solid fuel boilers have the following advantages over other types of solid fuel equipment:

- High Efficiency and almost complete absence of solid combustion waste.

- Fuel availability and replenishment.

- A relatively long period of operation and the possibility of storing a large amount of fuel - the combustion chambers of pyrolysis boilers have a large capacity.

Types of boilers according to the principle of operation

Depending on the method of fuel combustion, four types of boilers are distinguished:

Classic direct fired boiler

(or natural cravings). This is the traditional and most common design. Main advantages: simple device, affordable price, ability to operate on any type of fuel, energy independence. The latter factor is very important for rural areas with poor quality power grids - as a rule, the boiler does not need electricity to operate, and thermoregulation is carried out using a damper and a mechanical drive. There is only one fundamental drawback - incomplete fuel combustion.And the rest follows from this: low efficiency in comparison with other types, a large percentage of solid residue of combustion products, labor-intensive maintenance and care. Based on this. this type is difficult to classify as "the best solid fuel boilers for home heating."

Direct combustion scheme with bottom air supply and mechanical draft "on a chain" for damper control

Classic boiler with additional draft.

There are two options for the device. In the first case, air is "blown" into the furnace, which ensures a more complete combustion of the fuel. In the second, the boiler is equipped with a smoke exhauster (an exhaust fan in front of the chimney), which creates a vacuum in the combustion chamber and increases the natural draft. The advantages are the same as those of a direct combustion boiler, except for energy independence. But the "dependence" on electricity is compensated by the increased efficiency and higher power indices with the same size of the furnace and the type of fuel.

Boiler with additional draft

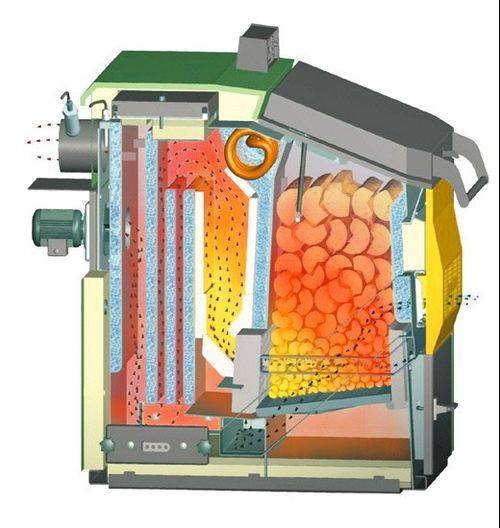

Pyrolysis (or gas generating) boiler.

To some extent, this is the next stage in the development of a boiler with additional draft, but the very principle of fuel combustion is changing. The boiler is functionally divided into two chambers. In the first, with an artificial lack of air, the wood smolders, generating not only heat, but also pyrolysis gases that enter the second chamber, where they completely burn out under conditions of additional air supply. In terms of efficiency, these boilers are the most efficient, but also "capricious". The main disadvantage is the strict requirements for stable fuel quality. If this is firewood (and most types of models of pyrolysis boilers are "tuned" to them), then the standard requirement is that the moisture content of the wood should be no higher than 20%. Otherwise, the generation of pyrolysis gases decreases, turning the boiler into a conventional discharge with forced air supply, which, given the high cost of equipment, is unprofitable. In addition to efficiency, the advantage is the burning time of one bookmark - up to 12 hours.

An example of the practical implementation of a gas-fired boiler

On our website you can find contacts of construction companies that offer a house insulation service. You can communicate directly with representatives by visiting the Low-Rise Country exhibition of houses.

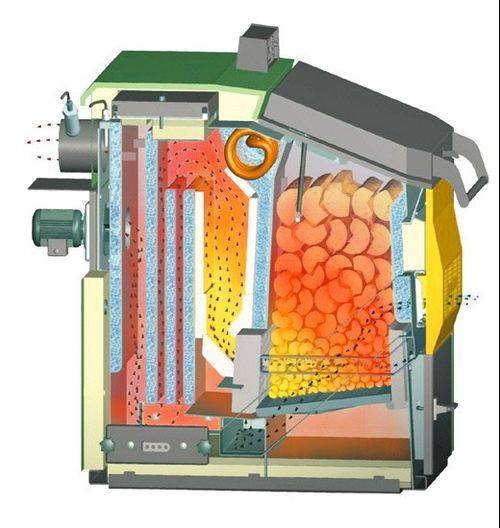

Long burning boilers.

They appeared quite recently (one might say at the beginning of this century), but have already won a solid part of the market. The combustion process of the fuel insert takes place from above due to the special design of the boiler. After the combustion of the upper layer, the process moves down, and the power regulation and maintenance of the desired mode is carried out by automation that controls the turbine for supplying air to the combustion zone. The fuel burns almost completely, with a minimum amount of solid residues. In terms of efficiency, the boiler is almost not inferior to a gas generator, but it is not so demanding on fuel, and the burning time of one bookmark can reach 24 hours and more. Such equipment tops the rating of long-burning solid fuel boilers. But such a pleasure is not cheap.

Burning time of one tab depends on the type of fuel

Separately, it must be said about boilers with automatic fuel supply to the combustion chamber. According to the principle of operation, these are traditional boilers with natural or forced draft, but thanks to a separate bunker for fuel, the operating time at one "filling" can reach from several days to several weeks (depending on the volume of the bunker and the area of the heated room).

Attention.

Sometimes sellers describe them as long burning boilers, but this is not entirely true. Although trough and retor burners provide top combustion, the principle of air supply takes place in the traditional way - blowing from the bottom.

Pellet boilers with a tray burner in fact also support "top" combustion of fuel with high heat transfer efficiency

Boilers with a hopper work either on pellets or on coal, crushed to a certain fraction (usually no larger than 25 mm). There are models with automatic ash removal, which, in combination with automation for maintaining the operating mode, makes the heating scheme of a private house with a solid fuel boiler as convenient to use as a gas one.

This might be interesting!

In the article at the following link, read about a boiler for heating a private house.

Principle of operation

And now let's take a closer look at how a gas-fired boiler works.

First, the fuel is put into the combustion chamber and ignited. The fuel ignites, after which the amount of supplied oxygen is reduced so that the fuel does not burn, but smolders.

Pyrolysis gas is released from the fuel and rises to the top. There the gas is collected and oxygen is supplied to it, heated to a certain temperature. A thermochemical oxidation reaction occurs with pyrolysis gas. Pressurized gas is fed into a tube with calibrated holes and ignites when it interacts with oxygen.

At the same time, up to 90% of the small particles contained in the gas burns, which means that harmful oxides (carbon dioxide) slightly pollute the environment. At the outlet, the gas temperature does not exceed 140-160 degrees Celsius. This means that most of the heat goes to heating the premises, and does not go out through the pipe to the street.

On average, one furnace in a solid fuel gasifier is enough for 12-13 hours, and conventional direct-burning stoves support the combustion process for no more than 4-6 hours. At the very bottom there is a sump in which all the remains of the burnt fuel are collected. If necessary, it will be very easy to throw out the remains. Below you can watch a very good video that shows the whole cycle of work.

Summing up

Thus, solid fuel gas generating boilers are very convenient and most likely this direction will develop, and old projects will become a thing of the past. The main plus is the ability to regulate the heat in the house, and not add firewood to the stove by eye. So the house will never be stuffy or cold, which is especially good for sensitive people and small children. New systems will replace old ones, as their use is more economical, environmentally friendly, efficiency becomes higher and power is greater.

Equipment manufacturers

The choice of complex technical devices is associated with certain difficulties. Therefore, it is better to trust technical documentation, while not forgetting about the reputation of the manufacturer. Based on these parameters, the most competitive in the domestic market are gas generating pyrolysis boilers of the following brands:

Buderus- Junkers (Germany)

- De Dietrich (France)

- Lamborghini (Italy)

Their choice was not accidental, except for the excellent quality of the products, all documentation was drawn up taking into account the rated power of the equipment.

Therefore, its study will allow the consumer to obtain truthful information about the duration of work on one tab and many other features of the boiler functioning.

To guide you a little in the capabilities of this equipment, we will briefly review several models. For example, consider the gas generating pyrolysis apparatus operating on solid fuel:

- Logano (Buderus)

- CF 120 CSE (De Dietrich)

German boilers are presented in a model range with power up to 45 kW for steel samples and 36 kW for cast iron. Their efficiency reaches 85%.

In this case, the duration of work on one tab is 2 hours. They are equipped with an automation system, which includes a water temperature indicator, a safety limiter.

Distinctive features include the length of firewood up to 680 mm and the presence of built-in cooling heat exchangers.

French devices are somewhat inferior in power, it is limited to 30 kW. In terms of efficiency, they are also inferior to German models, having it from 50%.But the length of the log was somewhat surpassed, with them it can reach 800 mm.

As you can see from the listed characteristics, each of them has its own advantages, and the choice depends only on your needs.

How to choose long-burning gas-fired boilers

First you need to decide what kind of fuel you have at your disposal to a greater extent - wood or coal. If coal is a more acceptable option, you should opt for boilers with upper combustion, and if heating is planned with firewood, it is more profitable to purchase a boiler with lower combustion, since its efficiency is higher than that of the previous one.

Bottom combustion boilers are the most environmentally friendly and economical. This is due to the presence of two or three combustion chambers in them, which provide additional combustion of fuel particles.

A cast iron boiler is more durable, since condensate from coal combustion causes corrosion of steel. In addition, steel heat exchangers burn out faster. Cast iron boilers consist of sections, which, in case of possible depressurization, makes it possible to simply replace the damaged part (while steel boilers require complete replacement); also, this fact ensures ease of transportation in disassembled form (however, it should be remembered that cast iron parts are fragile and sensitive to shock).

If you need a boiler that provides heating and and supply of hot water to the house, a double-circuit solid fuel boiler is suitable. The principle of its operation is as follows: the first circuit (for heating the room) turns on when the heat sensor is triggered; the second (for hot water supply) is activated when the pressure drops.

If the house has a working boiler, then it can be connected to a heating boiler. On the one hand, this will give great savings on the heat source, on the other hand, it will ensure a stable water supply.

To determine what boiler power you need, proceed from the calculation of 1 kW for every 10 sq. m (with wall heights up to 3 m). It should be remembered that the power of the boiler itself varies depending on the calorific value of the fuel and its moisture content.

Self-assembly

To independently install a solid fuel boiler, you must take into account several rules.

- It is better to place such a boiler in a separate room. This can be a room inside the house or in the basement. For this, a former children's bedroom or any other small room (the required area is 8-10 square meters) is suitable, if a special room for heating devices is not allocated during construction. In the most extreme case, you can simply partition a large room in half (it is advisable to make the partition brick, and not use drywall), making one or two exits - inside the room, on the street, or both at once.

- The floor of the room where the installation is planned must be made of fire-resistant materials. And the boiler itself should be installed directly on a concrete screed (about 10 cm thick).

- It is necessary to provide the room with forced ventilation, power supply and water supply, if they are not available.

- If the boiler is not installed in a specially designed boiler room, a chimney must be purchased and installed in advance.

Getting started installation, you need to prepare the tools and equipment that you will need for this: electrodes, welding, level, keys, screwdrivers, meter, saw for metal, screws, - as well as materials: plumbing tape, metal sheet and sealant.

- Unpack and prepare for assembly the parts that come with the boiler.

- Place a metal sheet on the floor at a distance of at least 0.5 m from the side wall (s) and 1 meter from the front and fix it securely.

- Place the boiler evenly on a metal sheet, checking that it is level.

After the preparatory work, the boiler itself is assembled directly:

- Wrap the combustion regulator with one turn of plumbing tape, fasten with a screw, set the temperature to 30 degrees.

- Install the thermostat and ten or their plugs.

- Assemble the air and safety valves, pressure gauge into a safety group.

- Install the tap and connect it to the pipes.

- Connect a security group in front of the locking device.

- Connect the boiler to the chimney using sealant.

- Push in the draft flap and the cleaning plug.

- Connect the water and check the tightness of the system.

- Light the boiler by closing the damper.

- It remains only to check the quality of the installation and operation of the boiler and to carry out pilot heating.

In order to determine the approximate cost of materials and equipment required for installation, below is their approximate price.

- Heat-resistant sealant 100-200 rubles.

- Sheet of metal (3 x 1,250 x 250) about 3,000 rubles.

- Plumbing tape about 500 rubles.

- Long-burning boilers 60,000–120,000 rubles.

- Transition steel 57-32 30 rubles.

- Steel bend Du-5016 from 100 rubles.

- Ball valve Du-15 from 100 to 1,000 rubles.

- Ball valve with squeegee Du-50 about 2,000 rubles.

- Chimney for a solid fuel boiler 20,000-50,000 rubles.

The choice of heating boilers should be based on the availability of a particular type of fuel in the region or its availability in the home. Heating with solid fuel boilers using firewood is second only to gas-powered devices in cost, electricity and diesel fuel are more expensive, and coal-dependent units round out the top five. Last but not least, this is due to the fact that solid fuel boilers have insufficiently high efficiency rates (compared to electric ones, for example). However, two-tier combustion systems can save fuel consumption by up to 9%.

The most environmentally friendly heating devices among solid fuel ones are pyrolysis gas-generating boilers, since the fuel they use burns out almost completely, which reduces the level of air pollution.

The video shows how gas-fired boilers work: