In many homes, the central element of the heating system is a gas boiler. However, in order to maintain the device in good condition, it is necessary to take into account the peculiarities of the functioning of the equipment.

For example, during the operation of the boiler plant inside the combustion chamber air temperature rises, therefore it is important control this parameter.

A thermocouple is specially used for this - a thermoelectric device, which is practically the only device for accurate measurement of elevated temperatures. Today, equipment is used that functions in conjunction with automatic valves.

Odnoklassniki

Features of temperature control in gas boilers with a thermocouple

The widespread use of equipment is due to the fact that this device is considered the main way to measure air temperature, as well as control the flame level.

After all, the device is not exposed to elevated temperatures and operates on a special principle that allows you to get accurate readings and quickly respond to even minor changes.

What is it for

A thermocouple is a device that is installed in heating equipment and is designed to convert thermal energy into electric current for electromagnetic coils and serves as the main component of gas control protection. The device works in conjunction with special shut-off gas valve, blocking the flow of fuel.

Principle of operation

For the manufacture of the device is used metal alloy... It can withstand exposure to high temperatures. However, if a malfunction occurs in the equipment, the operation of the gas boiler will be stopped.

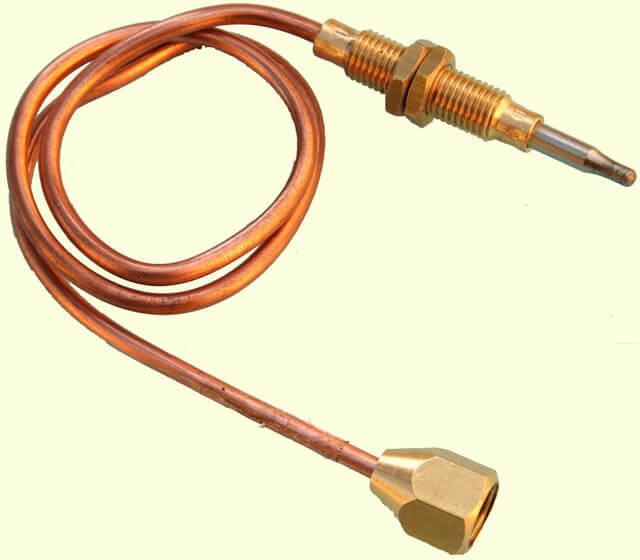

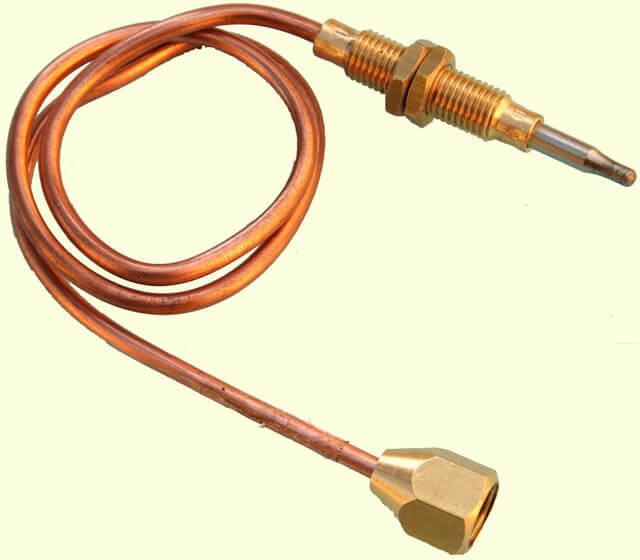

Photo 1. Thermocouple for a gas boiler with automatic equipment 345-1000 mm, Russia.

After all, this thermoelement functions in conjunction with a special electromagnetic shut-off valve that regulates the flow of gas into the fuel path, which closes immediately after the thermocouple breaks down.

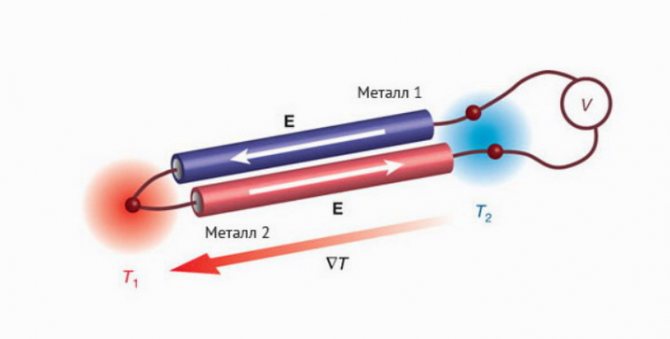

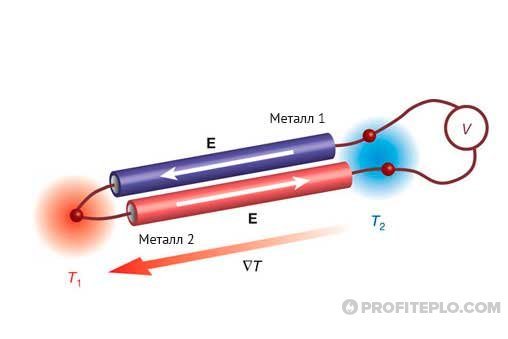

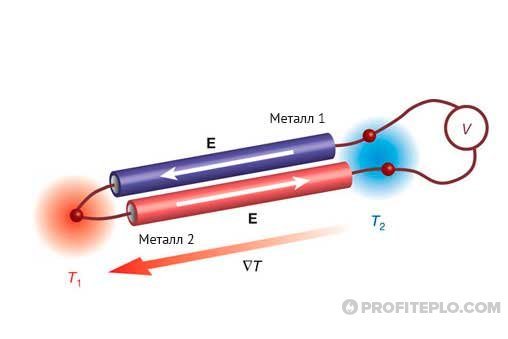

The principle of operation of the device is based on the following physical phenomenon: two metals join and when heated at the attachment points (the working area that is placed in the flame) appears at the cold ends voltage... This is called the Seebeck effect.

Attention! Many models of solenoid valves are sensitive, so they remain open until the voltage at the input will not drop to 20 mV.

Specifications

The thermocouple has the following technical parameters:

- wide range temperatures;

- high accuracy measurements;

- increased resistance to corrosion;

- electronic control mechanism.

What it consists of and how it works

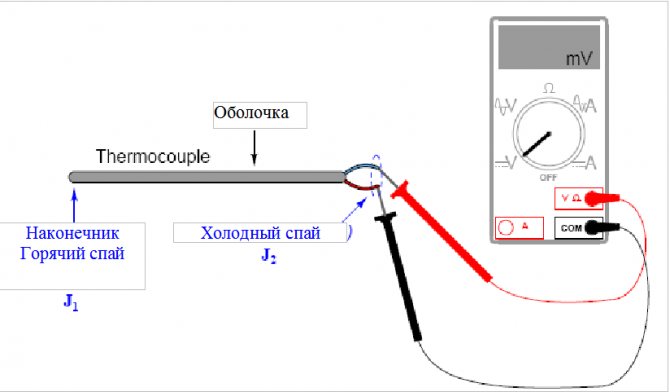

A thermoelectric converter is the simplest design that includes two conductors touching at one or more points. Dissimilar metals are the material for the manufacture of conductors. This specific composition allows the device to perform its functions, since the thermocouple works in a gas boiler due to the physical process "Seebeck effect". Provided that two bodies made of different metals are firmly connected and the connecting section is subsequently heated with an open flame, the free ends of the conductor will give a potential difference. When a voltmeter is switched to them, the circuit is closed, and the voltage is recorded on the measuring device.

Although the voltage level from the potential difference of the heated metals is not very large, even he is able to induce induction inside the coils of the cut-off valves.When the free ends begin to give tension, the valve is automatically triggered. As a result, the fuel gets free access to the igniter. It is important to remember that the latest valve models have a specific design: the increased sensitivity of the coils allows the fuel line to remain open until the voltage drops below 20 mV. A thermocouple typically produces a voltage of 40-50 mV.

Varieties

The thermocouple is characterized by a simple structure. With the appropriate skills, this device can even be made with your own hands at home. However, it is better to purchase an industrial appliance before having studied specifications, as well as features of all types of devices.

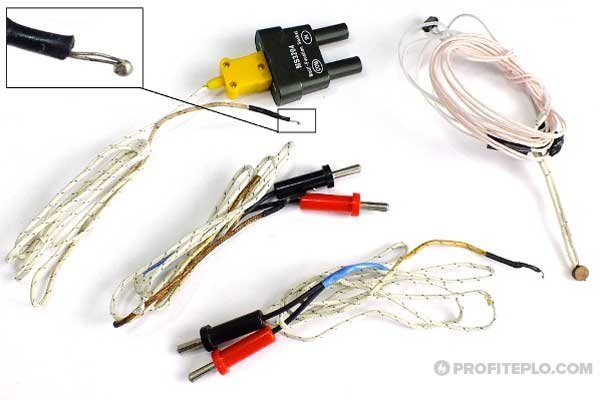

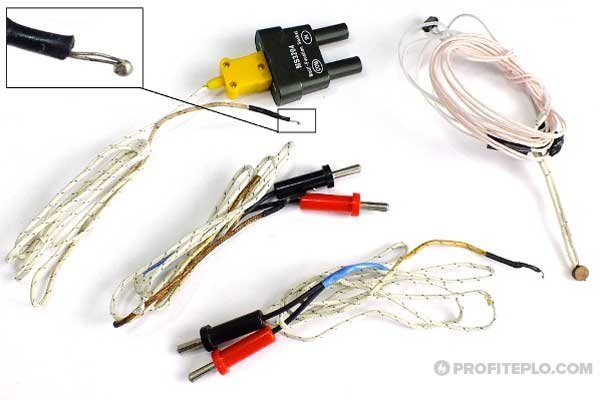

Specialized companies produce thermocouple of three types:

- Type E - two plates are used for manufacturing: constantan and chromel. This device is characterized by increased performance. In addition, it controls the process taking place in the temperature range from -5 ° С to 74 ° С.

- Type J - instead of a chromel, an iron plate is installed in the device, which does not at all impair the technical characteristics of the device. Has increased sensitivity to changes, and the temperature range - from -4 ° С to 74 ° С.

Type K - such thermocouples are the most popular. They are equipped with plates made of aluminum and chromel.

The working range varies within from -20 ° С to 135 ° С, and the manufacturers managed to increase the sensitivity itself by several positions.

The lifespan of this device is determined by environment of use: so, in carbon dioxide, a chromel plate becomes rusty in the form of green rot, the alloy quickly deteriorates and the device loses its non-magnetic properties.

There are other types of thermocouples, however, they are not suitable for use in gas boilers for reasons:

- alloys contain expensive metalstherefore they have a high cost;

- such models are nothing no better than types K, E or J.

Temperature sensors. Classification

There are several basic types of thermocouples. They are distinguished by the material of manufacture. The main materials used for temperature sensors are metals - noble and non-noble. It was their combination that became the basis of the classification. Here are the most common types of thermoelectric elements

:

- Type K: Chromel and Alumel. Temperature range (long-term): from 0 ° С to + 1100 ° С;

- Type J: Iron and constantan. Temperature range (long-term): from 0 ° С to + 700 ° С;

- Type N: Nikrosil and Nisil. Temperature range (long-term): from 0 ° С to + 1100 ° С;

- Type R: Platinum-rhodium (13% Rh) and platinum. Temperature range (long-term): from 0 ° C to + 1600 ° C;

- Type S: Platinum-rhodium (10% Rh) and platinum. Temperature range (long-term): from 0 ° С to + 1600 ° С;

- Type B: Platinum rhodium (30% Rh) and platinum rhodium (6% Rh). Temperature range (long-term): from + 200 ° С to + 1700 ° С;

- Type T: Copper and Constantan. Temperature range (long-term): from -185 ° С to + 300 ° С;

- Type E: Chromel and Constantan. Temperature range (long term): from -50 ° С to + 800 ° С;

Types of thermoelectric elements

Of course, each type of thermoelement is used for different purposes. Expensive thermocouples are used in science and industry, while simpler and cheaper thermocouples are ideal for domestic use - in gas boilers or stoves.

The device and principle of operation of the thermocouple

It is known that not every material can be permanently exposed to an open flame. As can be seen from the description of the types of thermoelectric elements, they are made of several metals that can withstand high temperatures for a long time. When the thermocouple fails, the gas boiler will require immediate repair, as the burner will fade.Why is this happening? The thermocouple works in conjunction with a shut-off solenoid valve. In the event of a malfunction of the temperature sensor, the valve closes and the gas supply is immediately interrupted.

The basic principle of a thermocouple is a thermoelectric result (or Seebeck effect). The essence of this physical phenomenon is as follows

:

- Two metals with different physical properties form a closed circuit;

- The place where the conductors are interconnected by high-quality soldering is placed in an open flame;

- At the cold ends of the junction, a voltage will appear - a potential difference.

- If you connect a measuring device to them, the circuit will close and an electric current will appear, the voltage of which will be enough for induction in the coil of the solenoid valve, which will let gas to the igniter.

The design and principle of operation of the thermocouple

In those cases when you cannot ignite the gas boiler, the igniter goes out as soon as you release the gas supply button - you can be sure that the thermocouple is out of order.

Important: the quality of the thermocouple metal junction plays a very important role. The junction is placed in an open flame, so a good junction will increase the life of the thermocouple.

For gas boilers, universal thermoelectric elements of type K (chromel-alumel), type E (chromel and constantan) and type J (iron and constantan) are most often used. Conductors in a protective sheath are welded to the cold ends of metals, and the junction is fixed with a clamping nut in the appropriate place of the boiler automation.

Other types of thermocouples in gas boilers and installations are not used due to the fact that the price increases due to the use of expensive alloys. And for gas boilers, the properties of the simplest alloys are quite good.

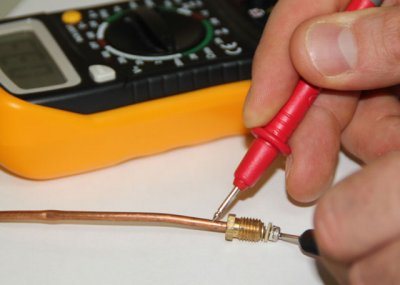

To check how a thermocouple works, you need to connect one end of it to a measuring device - a multimeter, and heat the other with a regular fire. If the device is working properly, the voltage will be about 50mV.

The principle of operation of a thermocouple is quite simple, but during the production process, each type of thermocouple is calibrated, or, in other words, corrected relative to 0 ° C. The more accurate the meter being used to calibrate, the more accurate the thermocouple will be. In addition, a conscientious manufacturer will not allow himself to make poor-quality soldering of thermocouple metals. Therefore, try to choose a product of a trusted brand when buying a thermal sensor for your gas boiler.

It is also worth considering that the measuring point should not be far from the measuring device, otherwise you will need to expand the intermediate connection wires, and this is quite expensive.

How to check if a device is working properly with a multimeter

If there is a suspicion of a breakdown, then diagnose the health of the thermostat. It is carried out in the following ways:

- One end of the appliance connects to a multimeter, and the opposite is heated by a gas burner or lighter. If the device is working properly, then the voltage below 50 mV.

- You need to check the condition carefully conductors for contamination or oxidized areas. They also indicate a breakdown.

Features of verification and replacement

As practice shows, it makes no sense to repair a thermocouple in the event of a breakdown. The main signs that a valve or thermostat is out of order is the termination of self-ignition of the gas boiler. To check the serviceability of the device, it is necessary to connect a multimeter to one of the ends. The other end is warmed up during testing using a lighter or other method. An indication of the suitability of the thermocouple is the voltage across the sensor in the region of 50 mV.

If the ends of the conductors have traces of oxidation and dirt, and the readings of the measuring device are far from normal, this is a sure sign of breakage. The best option in such a situation is to replace the old element with a new one, since it is almost impossible to repair the thermocouple of a gas boiler. As for experiments with attempts to reanimate a failed device, this is fraught with very disastrous consequences.

How to choose the right one

In order for the device to work properly and not lead to a failure of the entire system, it is necessary to carefully select the device. For this, the following features are taken into account:

- The technical parameters of the thermocouple must fully comply with to the characteristics of the gas boiler.

- The device should not have visible damage (microcracks, chips, abrasions).

- Markings should be visible.

- Preference is given to products only verified companieswho are responsible for the quality of the products.

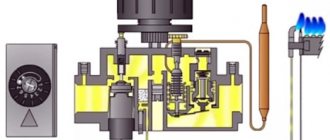

Thermocouple in the gas control system

When operating gas equipment, non-volatile automation is required, which contributes to the prompt shutdown of the gas supply in case the flame suddenly goes out. Modern boilers with a gas burner are equipped with a gas control system, which includes a solenoid valve and a thermocouple. The constituent elements of the solenoid valve include:

- core with winding;

- cap;

- returnable spring;

- anchor;

- elastic band that blocks the gas supply.

When you press the gas button, the stem goes deep into the coil and the spring is charged. According to the regulations, the supply valve should be held for about 30 seconds so that the thermocouple is warmed up, and voltage is formed at the ends to hold the valve inside the coil. The thermocouple begins to cool if the burner goes out. What happens next:

- this is accompanied by a decrease in the voltage at the ends of the thermocouple;

- the return force of the spring exceeds the electromagnetic force that holds the rod inside the coil;

- the valve returns to its original position and the gas supply is shut off.

This is how a thermocouple works in a gas boiler. The thermocouple gas control system is highly reliable, also due to the fact that it is able to function without being connected to the power grid.

Replacement if it cannot be repaired by hand

The device crashes for a variety of reasons. You can replace a broken device with a new one. on my own... To do this, you must follow the step-by-step instructions:

- First unscrews with a key special nut, which the thermocouple is attached to the nozzle.

- Unscrews compensation screwsecuring the fixture in place (located directly under the mounting bracket).

Carefully withdrawn old device.- In the vacated hole is inserted new device.

- Everything is fixed compensation screw, and then nut.

- Performed check for tightness. If necessary, a sealant is used - polymer or ceramic.

When carrying out the procedure, it should be remembered that an under-tightened, as well as an over-tightened threaded connection will be dangerous for the serviceability of the system.

Pros and cons

The use of thermocouples in the boiler automation system has its own advantages and disadvantages. The pluses include:

- the sensor has the ability to work in difficult conditions, in contact with an open flame:

- since the product has a simple device with no moving parts, it is very reliable;

- the device is capable of providing a level of measurement accuracy sufficient for use in heating units;

- replacing the thermocouple, if necessary, is fairly straightforward.

The disadvantages of the element include:

- nonlinear dependence of potential growth on temperature rise;

- potential cannot rise above a certain limit.

Advice! Since thermocouples have such properties, they can only be used for operation with a gas shut-off device. But this device is not suitable for measuring temperatures.

The disadvantage is the impossibility of carrying out repairs, in case of failure of the thermocouple, it can only be replaced. However, the cost of this element is low, so buying a new one will not be a serious test for the family budget.