If you decide to make a shower yourself at a summer cottage or suburban area, then you need to purchase several basic elements. One of the most important units is a shower tank, it can be found ready-made, or you can build it yourself, we will consider how to make a container from scrap materials and equip it with everything you need for comfortable and convenient use.

In the photo: almost any container of a suitable size can be suitable for our needs

general information

Why do you need water containers made of metal or any other material at all? The answer to this question is obvious, but for some it remains open. The fact is that everyone uses storage tanks in their own way. Their purpose is to collect and store water for future use. And how and in what form you will do it - it's up to you to decide.

The tank can have a different shape, depending on its purpose. A regular rectangular large accumulator can be used to collect rainwater. For a summer shower, you can use a flat, low tank, which is easily mounted on top of a metal frame. It all depends on the purpose of the application.

Often, ordinary metal drums are used as such a storage tank. This is a practical and inexpensive option, but not always convenient. Especially because of its open top, through which insects enter the water, and plants and rust form on the walls of the tank. It can also be used to collect rainwater only if you have gutters and the ability to lead the pipe directly to the barrel.

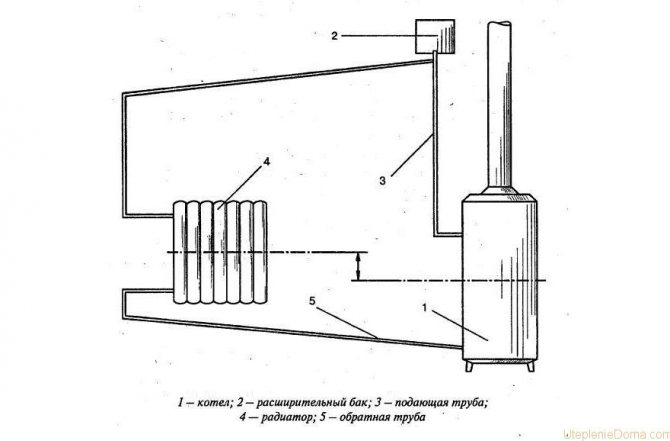

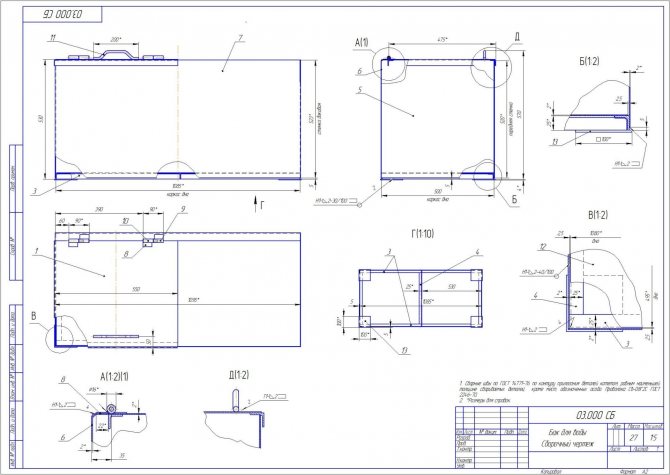

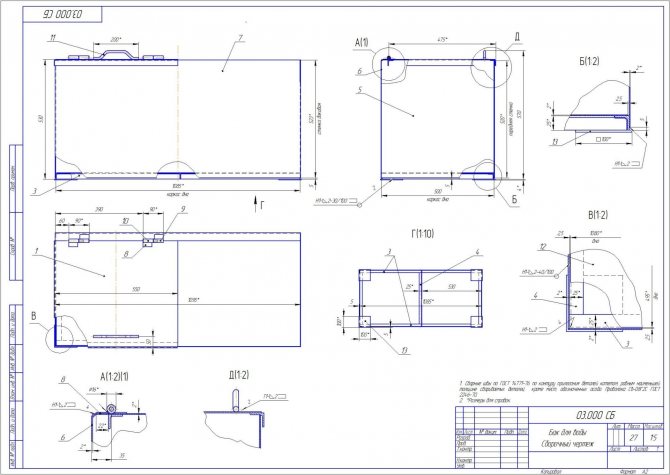

In order not to suffer with barrels, craftsmen make homemade metal tanks. They have a simple design and low cost. Below you can see one of the possible drawings of the storage tank. This container is small in size, but large enough to hold up to 200 liters of water.

Modern apparatus made of copper

A modification of such a device as a copper moonshine still has undergone some changes these days. The design is divided into separate components. She received the name "alambik". Such units are inherent in the original design. Often they are done by hand.

There are models that include a range of materials. For example, along with copper, stainless steel and glass are used. Quite often there is a device where only a tube and a dome are made of metal.

A moonshine made of copper, reviews of which are mostly positive, has the highest cost. Especially in comparison with economical options made from scrap materials with your own hands.

Homemade water tank

Preparatory stage

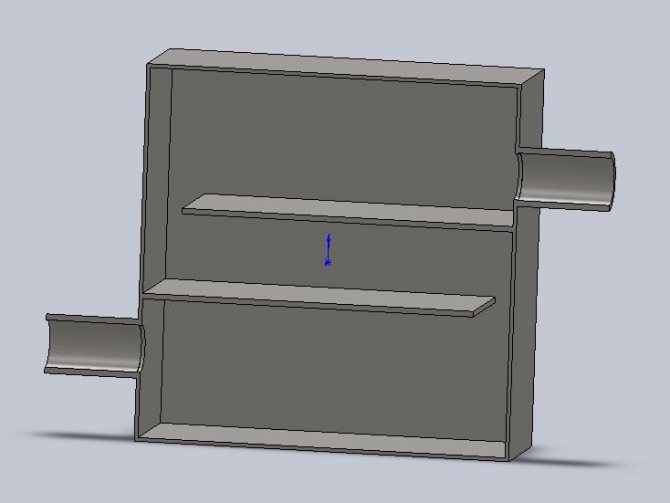

First of all, you must have a drawing according to which you need to cut out the necessary blanks from the metal in advance. The Internet is full of drawings, you can use any of them, or the one that is indicated above.

It is better to make a tank for the house and a stainless steel bath tank. Stainless steel is resistant to corrosion and the formation of plants on the walls, which is important if the container is used irregularly (for example, only in summer). As a material, you can take metal with a wall thickness of about 2 millimeters, this will be enough.

The container must have an expansion tank into which excess liquid will be drained. Otherwise, the storage tank may deform due to overpressure.The expansion tank can be made from the same materials.

If finances do not allow the use of stainless steel, you can purchase steel (technical or food). It's cheaper. But it copes with corrosion at times worse. Please bear this in mind.

Tank welding

Let's move on to the question of how to properly brew the tank.

Better to work with a partner. One will cook and the other will hold the pieces at the right angle. We also recommend placing bricks or boards under the future bottom so that the plane is even.

Cooking stainless steel is not easy, you need to have at least minimal experience. Then the work can turn out to be of more or less high quality. Use argon welding with tungsten electrodes or stainless steel wire.

Principle of operation

The spray tank starts working after being placed on a solid, perfectly flat surface and the lid is tightly closed. It is connected to the pressure line with a hose through which the coloring composition will go. In order for the structure of the paint to remain unchanged, as well as its temperature, the tank is not placed next to heat sources or under the influence of ultraviolet radiation. Otherwise, the quality of the staining may decrease.

The order of operation of the device is as follows:

- after opening the inlet valve, the paint is filtered to remove too large particles;

- the container for paintwork materials is filled, the composition is mixed using blades;

- as the paint reaches the desired level, the pressure relief valve begins to work (located inside on the body), the air supply under pressure stops;

- if the filter is clogged, or there are serious pressure drops for other reasons, the relief valve is triggered in an emergency manner;

- During normal operation of the filter and valves, paint flows into the spray gun attached to the tank.

In order for the device to work safely and smoothly, the following recommendations must be followed:

- do not allow the pressure to rise above 5 atm. (the valve will operate at 5-5.5 atm.);

- do not readjust the operation of the safety valve;

- not independently change the arrangement of elements and not make other changes to the design of the tank;

- do not pour abrasive compounds, paints with acids, gasoline, dichloroethane into the device.

Recommendations of the masters

We have collected some tips from professional welders. They will be useful for beginners and dacha craftsmen.

It is better to use stainless steel grade 8-12X18H10 or AISI 430 08X17 as a material. These brands are best suited for storing water, including long-term storage. However, it is better to drain the water before winter.

Before welding a stainless steel water tank, it is necessary to determine its volume and, based on this, make a drawing. For a bath, a tank of up to 60 liters for two or three people will be enough. On average, one person needs about 20-30 liters of water.

If you are cooking a tank for household needs, then it is better to stock up on a volume of 100 liters or more. 200 liters is just right for watering gardens and collecting rainwater.

It is better to give up the idea of welding an aluminum water tank. At home, it is not easy to make quality sealed seams. Stainless steel is also not easy to cook, then this task is quite feasible. But to work with aluminum, you need experience and a good welding machine.

Depending on the size of the tank and your experience, the entire process can take anywhere from a couple of hours to several days. If you've never cooked before, practice on unnecessary pieces of metal. After all, stainless steel is far from being a cheap material. And you are unlikely to be happy if you unknowingly weld a tank with defective seams, and it turns out to be unusable.

Self-production

Many people wonder how to make a copper moonshine still with their own hands. It is worth noting that it is better to purchase such a device ready-made.A person who is not endowed with special knowledge and experience is not able to assemble such a structure on his own. For those who still want to try to make a copper moonshine still with their own hands, there are a number of important recommendations.

Step-by-step instructions for the construction of a storage tank for water

How storage tanks are used

If your site has serious problems with regular water supply, it will be very difficult to do without a water storage tank. In such containers, both tap and rain water can be stored. Water supplies can be useful for organizing a summer shower, as well as in case of a possible fire. In addition, the water from the reservoir is used for irrigation and for "bathing needs".

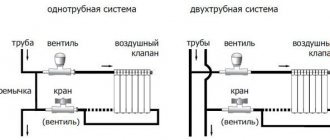

There are several common types of storage tank designs, most commonly rectangular or circular.

In order to determine the optimal size of the tank in your case, it is necessary to clearly understand the possible water requirements of the site for a certain period of time. So, if you rarely use the container, there is a high probability that various harmful organisms will multiply inside it. This probability can be several times greater if the tank is not protected from sunlight. So, it is really very important to decide in advance on the optimal volume of the tank.

Another important point: if we are dealing with a tank made of ferrous metal, then we cannot do without painting and primer, otherwise the structure will inevitably and quickly rust.

Making a dry pot

Moonshine stills made of copper with a steamer have a more complete design.

Sukhoparnik (dephlegmator or cube) is not a mandatory component. The part is connected by means of pipes to the distillation cube and the coil. It serves for the physical cleaning of alcohol from harmful impurities.

The configuration of a home-made dephlegmator can be unified.

- a three-liter jar with a metal lid, which must be tightly closed;

- two fittings with external thread;

- two nuts;

- marker;

- heat resistant glue;

- awl.

Wooden structure

To create a wooden tank, prepare:

- wooden beam;

- bricks;

- polyethylene film;

- boards;

- geotextile insulation;

- self-tapping screws.

As soon as all the materials are available, you can proceed to the construction of a wooden structure according to the following plan:

- first level the site;

- bricks are laid around the perimeter of the site;

- a timber is laid on the bricks;

- wood is attached to the frame with self-tapping screws;

- OSB boards are laid on top of the prepared structure and fixed with self-tapping screws;

- a frame is created from the boards, fixing them on the sides of the prepared wooden base;

- OSB sheets are screwed to the installed side boards;

- the inside of the wooden structure is tightened with a geotic style;

- lay the film on top (its size should be such that it goes over the edges of the wooden box);

- from the top of the container, two boards are nailed crosswise to provide additional stability of the structure;

- if the tank has a large volume, wooden spacers are fixed on the outside of the structure.

Water is poured into the prepared tank. The pressure should not be high to allow the plastic wrap to smooth out under the pressure of the water.

Plastic containers

Plastic containers and barrels are very popular because:

- their cost is much less than that of stainless counterparts;

- plastic barrels can be purchased in various sizes;

- their designs do not need additional tightness;

- they do not rust;

- barrels do not need priming and surface painting;

- the plastic case has a high level of resistance to temperature extremes.

The containers can be made of plastic. Food grade plastic has additional benefits:

- high level of strength;

- high frost resistance;

- high level of reflection of ultraviolet rays.

Thanks to these features, the water in such containers does not deteriorate for a long time.

Most food grade plastic drums have holes that can be fitted with taps.

Plastic drums can be vertical or horizontal. Eurocubes are also very popular, which are placed in a metal crate for additional strength and stability.

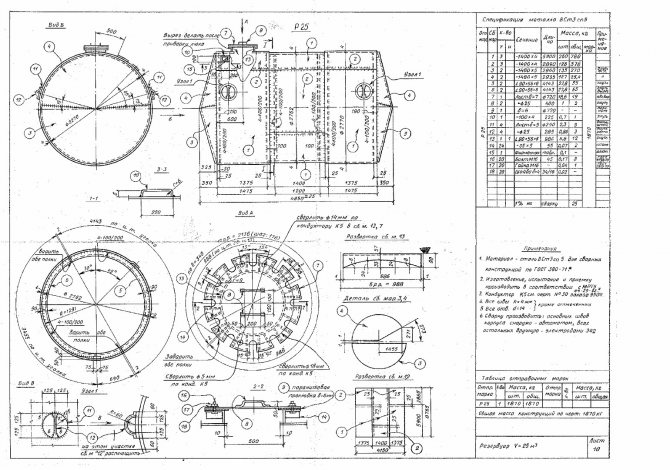

Tank drawing

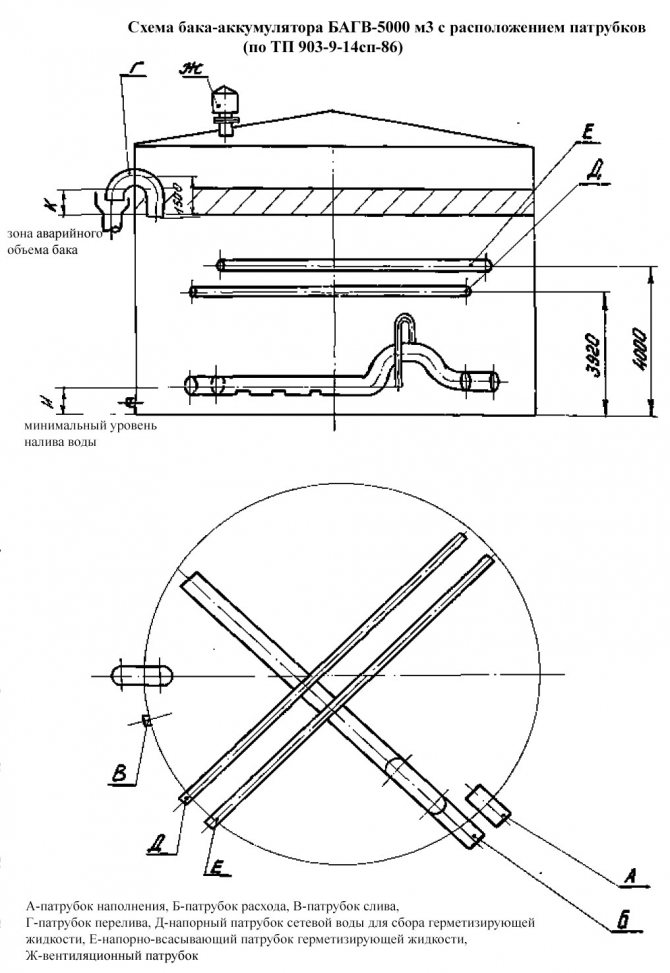

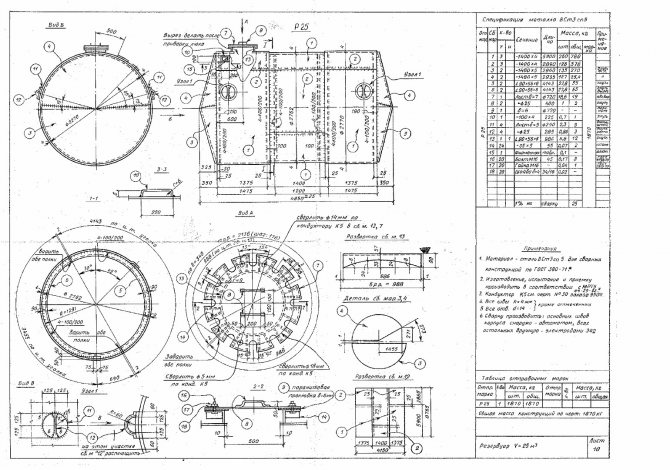

Tanks with a volume of up to 25 m3, inclusive, fit into the railway gauge, so they are completely manufactured at factories. The tank shell shown in the drawing consists of a cylindrical part and two conical bottoms. Two stiffening rings from the corners are installed inside the tank. For filling the tank and taking combustible materials from it, a hatch is arranged in its upper part. The stiffeners have holes in the lower part. The reservoir is installed slightly obliquely away from the hatch. Sediments formed in the tank flow through these holes into the lowered part, from where they are periodically removed when the tank is completely emptied.

A gas-resistant paronite gasket is installed between the hatch cover and its flange. The gasket, ensuring the tightness of the tank, reduces the loss of combustible materials, preventing their vapors from escaping into the atmosphere.

A stamped strip 15 with bent edges is welded near the tank hatch. A nameplate is screwed to it, on which the name of the manufacturer, the number of the tank, the date of its manufacture are indicated and the sign of the technical control department is put. The strip 15 does not adhere to the tank shell, so the screws attaching the name plate do not damage the tank wall. To fasten the tank to the platform, part 11 and hinges 12 are welded to it, Part 11 serves to strengthen the thin wall of the tank and prevents it from deforming from the forces applied to the loop 12.

During operation, the tank can be in very difficult stress and temperature conditions. Both filled and empty tanks can be propped up, buried in the ground, or transported on railroad cars. The tanks can be operated at different temperatures, therefore they are made of steel VSt3ps6 for welded structures in accordance with GOST 380-71 *.

Of particular interest is the technology of manufacturing large-scale tanks. Before the start of the general assembly of the tank, the bottoms and stiffening rings are made separately. The assembly of these elements is carried out at special stands. The flanging of the bottom edges for connection to the cylindrical part of the shell is performed by rollers on a rotary machine after welding the bottom seams. On the general assembly stand, the sheets of the cylindrical part are collected in the horizontal plane, grabbed to each other with intermittent seams along the longitudinal edges and welded with continuous seams along the ends. Tacks and seams are placed only on one side, in this case on the upper side. On the cylindrical part of the shell made in this way, the bottoms and stiffening rings are installed in a vertical position, and then they are rolled with the help of a cable and a winch and at the same time the shell is screwed on them. As the rings and bottoms are screwed in, they are welded to the shell. All outer seams of the shell are welded by automatic welding, and the closing seam from the inside - manually, after installing the hatch.

After welding, the tank is tested with air pressure.

Further:

What are structural steel structures drawings and why are they needed. Development of KMD in Yekaterinburg!

Ostrogradsky's theorem

Vector Field Stream Properties

The main provisions of the design of wiring diagrams

Design of welded, bolted and riveted joints

Solenoidal vector field

Metal constructions. Questions and answers

Drawing of a truss truss made of pipes

Basic rules for the design of detailed working drawings

Drawing of a tank with a volume of 25 m3

Special cases of vector fields

Special vector fields

Column drawing of an industrial building

Drawing of a truss truss from the corners

Basic regulatory documents for the design of metal structures

$ \ Rightarrow $