Gas-firewood

The advantage of universal gas-firewood heating boilers lies in their autonomy: a smooth transition of the system to burning firewood in the absence of gas. Also, if you wish, you can connect the "warm floor" structure, because the necessary connections and branch pipes are attached to the boilers.

Such universal boilers "gas-wood" can be single-circuit and double-circuit, so it will not be difficult to connect a boiler to heat water or heat water in a flowing way.

The disadvantages include the large dimensions of such units. Most often, they require a separate room for installation, and implies complicated service. Typically, such boilers are produced only of the floor type.

Combined gas-wood boilers for the home imply increased requirements. The operating standards and rules are described in PPB, SNiP and SP.

The combined gas-firewood boiler for a private house includes the following elements:

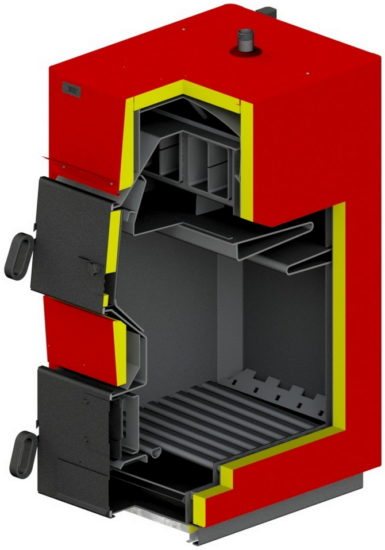

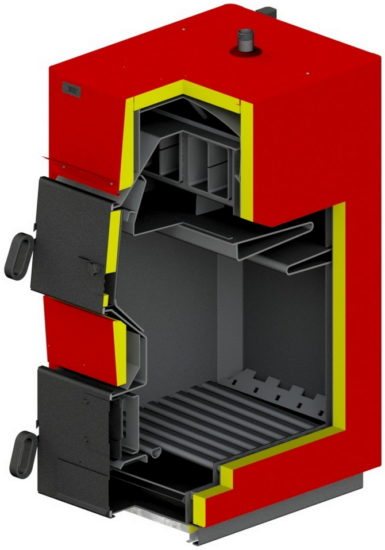

- Firebox chamber. It is made of cast iron or steel. The boiler can be with one firebox or two (more convenient). In the double version, firewood is burned in the upper section, and a gas burner is installed in the lower one.

- Hot water and heating circuits. They are produced by companies specifically for heating, or for heating to obtain hot water (double-circuit). Heating of hot water supply by the flow method.

A universal gas-firewood heating boiler assumes savings. You can verify this by looking at the following table.

| Type of fuel | Approximate cost of 1 kW of energy, $ | Approximate cost of 1 m³, $ | The approximate cost of heating a house with a volume of 450 m³, $ |

| Gas | 0,01 | 0,00047 | 0,2115 |

| Firewood | 0,02 | 0,0094 | 0,423 |

| Coal | 0,055 | 0,002585 | 1,16325 |

| Electricity | 0,03 | 0,00141 | 0,6345 |

| Diesel fuel | 0,04 | 0,00188 | 0,846 |

High-quality wood and gas-fired equipment is produced in Russia: Zota MIX, Kupper PRO (Teplodar), Karakan (STEN), PARTNЁR (KOSTER), STS (Steel Solid Fuel Systems "). And also foreign companies: Austria and Germany ("Wirbel"), the Finnish concern "Jaspi" and others.

It should be noted that in foreign counterparts, it is less common to notice flaws in the assembly and automation of the unit. They boast reliability and quality. However, the domestic manufacturer is constantly improving in accordance with the wishes of buyers.

Prices for combined heating boilers "wood-gas" depend on the country of origin, on the popularity of the brand. For example, a model ("KOSTER") will cost an average of 23 thousand rubles. Much will depend on the configuration, power and other indicators. But "Jaspi" will pull all 130 thousand rubles. The takeoff run is large, however, unlike the Finnish one, where everything is regulated by automation, in the Russian analogue, all boiler settings will have to be done independently.

Boiler installation

The device can be installed by hand. To use heating devices of this type, you do not need to obtain permission from public utilities.

However, when performing piping and installation, it is important to consider the following points:

- The boiler must not be placed on the floor; it is worth preparing a special foundation.

- Wooden and frame walls located near the device are recommended to be protected with asbestos or galvanized steel sheets.

- The chimney must be located at a distance of at least 25 cm from the ceilings.

During the installation of the device, it is important to observe all fire safety measures, because errors during installation can lead to a fire during the operation of the device.

Work order:

- Bring the device into the room, install it on the prepared foundation so that the pipes are flush with the chimney pipe.

- Fix the equipment to the foundation without distortion.

- Install the fan (if available) and connect the flue gas vent.

Chimney connection

The easiest way is to make an external attachment type chimney. In this case, the pipe is fixed to the wall in a vertical position.

In a wooden house, it can be brought out through the roof or wall using the following technology:

- Make a square opening in the roof (wall) 40 centimeters larger than the diameter of the chimney.

- Install the galvanized steel duct-shaped pass-through assembly.

- Pass a sandwich pipe through it, and fill the remaining space with basalt wool.

- Attach the outer cover of the assembly.

Coal-gas

The universal gas-coal boiler is environmentally friendly and easy to maintain. However, when choosing this type of construction, you will have to constantly monitor the presence of solid fuel, because coal ends quickly. If you suddenly come to the conclusion that "two in one" does not suit you, then you can always replace the burner - and the boiler will already run on natural gas.

More details about the features of the pellet boiler can be found here.

Most often, a coal-gas combined boiler is allowed to be heated with wood. For example, in the technical characteristics of the two-circuit model "Birch B" in the item "fuel" it is indicated "natural gas / coal" (see table). However, buyers use such a boiler for heating and firewood.

| Manufacturer and model | Characteristic |

| ATEM (Zhytomyr, Ukraine) Berezka V | The boiler is made of steel, is versatile and completely independent of electricity. It acts as a budget solution for heating summer cottages, utility rooms, outbuildings. Units of the "B" brand are created with the production of consumer hot water. Fuel - natural gas / anthracite (coal). The area of the heated room is 125 m². Rated thermal power - 12.5 kW. The maximum gas consumption is 1.5 m³ / h. Nominal gas pressure (min / max) - Pa 1274 + 100 (635/1794). Working water pressure - 0.1 MPa. The efficiency when using solid fuel is 78%. The efficiency when using natural gas is 90%. Weight - 119 kg. DHW water consumption - 280 l / h. The combustion chamber is open (chimney). The number of contours is double-circuit. |

Gas-coal-firewood

The advantage of the gas-wood-coal boiler is that it does not depend on electricity. This allows you to create autonomous heating systems. Fuel for such a unit is available in any locality and, moreover, at a low price. The firewood-coal-gas boiler from the manufacturers listed in the table below is easy to service and has an attractive design.

| Manufacturer and model | Characteristic |

| Hearth KSTG-10 (Russia) | This company has been on the market since 2003. It is a dynamically developing and reliable manufacturer. Boiler type - single-circuit. The combustion chamber is open. Installation - floor. Heating area - 200 m². Power - 20 kW. The gas is natural. Solid fuel type - wood, coal. Working temperatures - 95 ºС. Heat exchanger material - steel. The efficiency is 77%. Weight - 70 kg. |

| Outbreak KSTGV-12.5 (Russia) | This boiler model "coal-firewood-gas" is non-volatile and stable when operating at reduced gas pressure. Due to the optimal design of the combustion chamber, the boiler has a high efficiency. Built-in water heater that provides hot water. Includes a gas pressure regulator. The boiler body is resistant to temperature fluctuations. Type - double-circuit. The combustion chamber is open. Installation - floor. Heating area - 125 m². Power - 12.5 kW. The gas is natural. Solid fuel type - wood, coal. The boiler is built-in. Working temperatures - 95 ºС. Heat exchanger material - steel. The efficiency is 83%. Automatic shutdown - no. Weight - 120 kg. |

| Raton KS-T-12.5 (Belarus) | The boilers are designed for heating individual houses, buildings and structures equipped with continuous hot water heating systems with natural circulation of the coolant and an open expansion vessel. Type - single-circuit. The combustion chamber is open. Installation - floor. Heating area - 130 m². Power - 12.5 kW. Solid fuel type - wood, coal, peat. The display is not. Heat exchanger material - steel. Ignition is mechanical. The efficiency is 77%. Weight - 138 kg. The service life of the boilers is at least 15 years. |

| Brestselmash KST 12.5 kW (Belarus) | By the type of fuel, the boilers manufactured by Brestselmash OJSC belong to multi-fuel boilers designed for burning solid and gaseous fuels by means of re-equipment that does not require dismantling the boiler. Installation - floor. Heating area - 125 m². Power - 12.5 kW. The gas is natural. Solid fuel type - wood, coal, peat. The display is not. Working temperatures - up to 95 ºС. Heat exchanger material - steel. The efficiency is 90%. Weight - 180 kg. Designed for heat supply and hot water supply of residential buildings and buildings for public utilities, equipped with water heating systems with natural circulation, with a working water pressure of up to 0.1 MPa (1.0 kgf / cm²) and a maximum temperature of water at the outlet of the boiler up to 95 C °. |

| Boiler PARTNЁR 24 (Russia) | The advantages of the products of this company are in their own innovative unique design developments. The manufacturer carries out guaranteed quality components, raw materials and materials. This is a stable high-tech production. The combustion chamber is closed. Installation - floor. Power - 24 kW. Solid fuel type - wood, coal. The efficiency is 80%. Weight - 108 kg. Height - 79.5 cm. Width - 42 cm. |

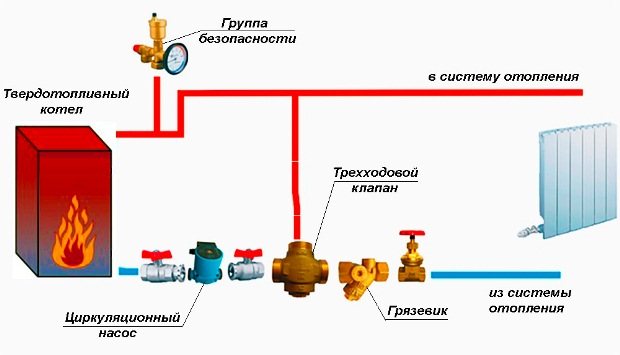

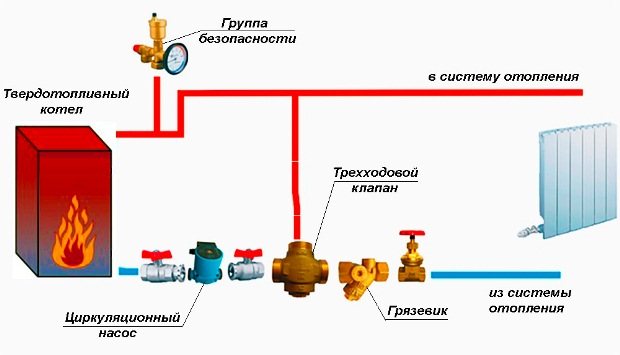

Basic scheme for piping a solid fuel boiler

For a better understanding of the processes that occur during the operation of the heat generator, we will show its piping in the figure, and then we will analyze the purpose of each element. In the event that the heating unit is the only source of heat in the house, then it is recommended to use the following basic scheme to connect it:

Note. The basic scheme, where there is a small boiler circuit and a three-way valve, shown in the figure, is mandatory for use when working together with other types of heat generators.

So, the first on the path of movement of the coolant from the boiler plant is the safety group. It consists of three parts mounted on one manifold:

- pressure gauge - to control the pressure in the network;

- automatic air relief valve;

- safety valve.

When operating a solid fuel boiler, there is always a risk of overheating of the coolant, especially at modes close to maximum power. This is due to some inertia of fuel combustion, because when the required water temperature is reached or a sudden power outage, it will not be possible to immediately stop the process. Within a few minutes after stopping the air supply, the coolant will still heat up, at this moment there is a risk of vaporization. This leads to an increase in pressure in the network and the danger of destruction of the boiler or breakthrough of pipes.

To exclude emergencies, the piping of the solid fuel boiler must necessarily include a safety valve. It is adjusted to a certain critical pressure, whose value is indicated in the heat generator's passport. As a rule, the value of this pressure in most systems is 3 bar, when it is reached, the valve opens, releasing steam and excess water.

Further, in accordance with the diagram, for the correct operation of the unit, it is necessary to organize a small circulation circuit of the coolant. Its task is to prevent the ingress of cold water from the house heating system into the heat exchanger and the boiler water jacket. This is possible in 2 cases:

- when heating starts up;

- when, due to a power outage, the pump stops, the water in the pipelines cools down, and then the voltage supply resumes.

Important! The situation with a power outage poses a particular danger to cast iron heat exchangers. Sudden pumping of cold water from the system can lead to its cracking and loss of tightness.

If the firebox and heat exchanger are made of steel, then connecting the solid fuel boiler to the heating system through a three-way valve protects them from low-temperature corrosion.The phenomenon occurs when condensation forms on the inner walls of the combustion chamber due to temperature differences. Mixing with volatile fractions and ash, moisture forms a scale layer on the steel walls, which is very difficult to clean off. This corrodes the metal and shortens the service life of the product as a whole.

The scheme works according to the following principle: while the water in the boiler jacket and in the system is cold, the three-way valve allows it to circulate along a small circuit. After reaching the temperature of 60 ºС, the unit begins to mix the coolant from the network at the unit inlet, gradually increasing its consumption. Thus, all the water in the pipes warms up gradually and evenly.

Firewood-coal-pellets-gas

Currently, these units are offered by: the manufacturer of the universal boiler "Cooper" "gas-firewood-coal-pellets", and others.

A large selection (pellets, wood, coal, gas) gives such a boiler a great advantage. In the absence of one type of fuel, you can always switch to another type and stay warm.

| Manufacturer and model | Characteristic |

| Teplodar Kupper OK15 (Russia) | Boiler type - single-circuit. The combustion chamber is closed. Installation - floor. Heating area - 150 m². Power - 15 kW. The gas is natural. Solid fuel type - wood, pellets, coal. The display is not. The efficiency is 78%. The chimney diameter is 150 mm. Weight - 98 kg. Double-turn heating, formed by a removable visor, which provides complete flame suppression in the tube sheet. In addition to the standard water jacket, there is a heat exchanger in the firebox. Power regulation from 30 to 100% (a combustion regulator can be installed on boilers). A spacious firebox that allows you to load firewood with a length of 400 mm horizontally and 500 mm vertically, or two buckets of coal. The presence of a tubular electric heater allows maintaining the heating system after the end of the fuel combustion process. |

| Raton KS-TG-35U (Belarus) | Boiler type - single-circuit. The combustion chamber is open. Installation - floor. Heating area - 340 m². Power - 35 kW. The gas is natural. Solid fuel type - wood, pellets, coal, peat. The display is not. Ignition is electric. Working temperatures - 95 ºС. Heat exchanger material - steel. The efficiency is 77%. The boiler is designed for heating residential buildings that are equipped with continuous heating systems with natural or forced circulation of the coolant. |

| Teplodar Uyut-10 (Russia) | "Uyut" is a budget heating boilers for rooms up to 100 sq. m. The firebox is in a horizontal position, which allows the boiler to be heated with wood up to 0.5 m long. The high efficiency of the boiler is ensured by the original design of the water circuit: stagnant zones are excluded, and the area of the heat-removing surface is increased to 1.1 sq.m. Possibility of installing a gas or pellet burner. Boiler type - single-circuit. The combustion chamber is closed. Installation - floor. Heating area - 100 m². Power - 10 kW. The gas is natural. Solid fuel type - wood, pellets, coal. The display is not. Ignition is mechanical. The efficiency is 72%. The chimney diameter is 115 mm. Weight - 67 kg. |

Solid fuel and gas boiler in a single-circuit system

It does not matter what kind of gas wall-mounted boiler you purchased in pair with solid fuel: single-circuit or double-circuit. Heating piping will be the same. Here is a diagram where a solid fuel and gas boiler in one system with one radiator branch:

Pay attention to the presence of check valves in the piping of each boiler: they will not allow the pump of one boiler to pump the coolant through another boiler. And at the same time, both boilers can work together at the same time or separately from each other - without any switching.

An external expansion tank for a wall-mounted boiler will most likely not be needed, its own tank will be sufficient. But just in case, count.

When supplying from a solid fuel boiler, we use only metal pipes - copper or steel - at least 1 ... 1.5 m long. Accordingly, all fittings in this section are the same!

The layout of radiators can be any, and not necessarily one-pipe, as in the diagram.

Important! Before igniting a solid fuel boiler, you need to turn on its circulation pump.

It is also important: at least a few radiators should be left without thermal heads (that is, if you even think of installing them). This will ensure a guaranteed flow of the coolant even when the circulation pump is turned off. Otherwise, the coolant in the boiler will boil, which can lead to a rupture of the system.

Gas pellets

A pellet gas boiler is equipment that easily changes its operation from heating with one type of fuel to heating with another. This usually takes about 15 minutes.

Here it is also possible to replace the burner in the event of a conversion. A tubular electric heater is available in many models.

Connection of a LPG cylinder is allowed.

The efficiency of a pellet-gas boiler reaches 90%.

The unit has several combustion chambers. The kit includes two burners and many regulating and shut-off devices. Has a high degree of security and automation. But despite this, a gas-pellet boiler, like any combined gas boiler, requires compliance with the rules of PPB, SNiP (some excerpts are described at the beginning of the article).

Do not forget to clean the boiler from time to time. During maintenance, it is necessary to remove accumulated wood dust, soot from the electric drive and moving parts.

What do you need to work with pellets?

To convert the boiler to fuel pellets, you need to install a pellet burner, which is connected to the fuel hopper. After all operations, the boiler functions as follows:

- along the conveyor from the fuel hopper, the granules are fed to the burner;

- electric ignition occurs immediately by means of a piezoelectric element;

- a built-in fan is triggered in the burner, which increases the pressure, and the pellets are burned at a high temperature, artificially raised.

Usually, gas-pellet boilers are made of cast iron, and due to their large dimensions and weight, the structure is placed on a concrete base.

What do you need to work on gas?

Pellet boilers with a gas burner are primarily connected to cylinders and gas tanks. Such units are gaining popularity in the construction of houses and plots where natural gas is planned to be installed soon.

To connect a gas burner, first, close the unused firebox with an airtight hatch. Then, a burner device must be installed in a place specially designated for gas equipment. After all, set the switch for gas consumption. Everything. The rework took no more than 15 minutes.

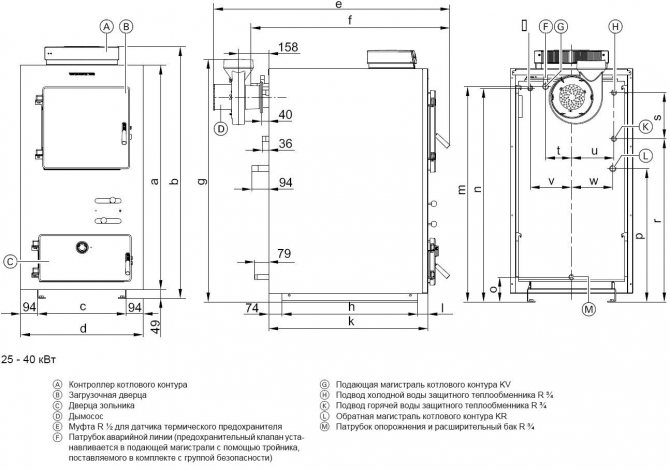

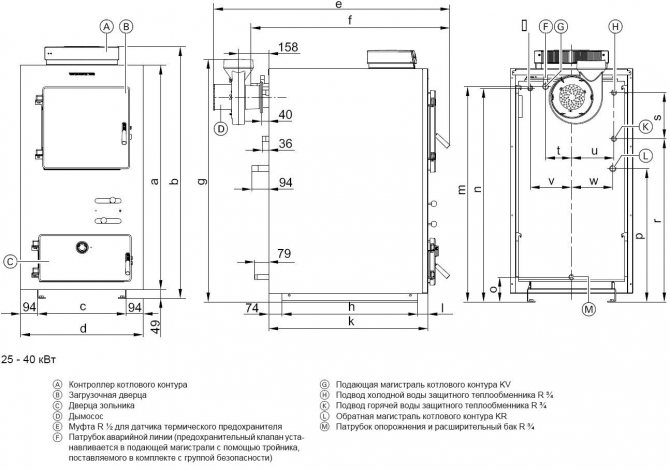

Combined boiler Wirbel ECO-CK 20

Boiler manufacturing

From all of the above, it follows that gas-generating boilers are considered the most economical and high-quality elements of the heating system.

The main problem in purchasing and using such a boiler is the cost of this product. For example, the simplest model of such a boiler, which is manufactured by domestic companies, costs about $ 1,000.

If you opt for imported manufacturers and improved models of such boilers, the price can rise 5 times. It follows from this that gas-fired boilers cannot be called generally available. But there is also a more economical option for purchasing such a boiler. This way is a wood-fired boiler made with your own hands. For the manufacture of such a boiler, it is necessary to use special drawings that are developed and posted on the Internet by the masters.

Gas-generating boilers developed by folk craftsmen have not only a low manufacturing cost, but also other positive aspects.The use of a home-made boiler, made according to ready-made drawings, provides for a significantly longer boiler operation time with one load of fuel into the combustion chamber. Due to the fact that special nozzles are installed in factory boilers under the combustion chamber, through which air supplied by forced systems enters, the combustion process of solid fuel is almost doubled. In addition, the direct dependence of such a boiler on the electrical network provides for the correct operation of the system only when the boiler is connected to the network. Homemade boilers are devoid of such elements, which allows them to work better and longer.

Some homemade boilers are equipped with two solid fuel combustion chambers. This allows fuel to be burned in the next order. When one chamber is ignited, the fire in the other chamber is automatically extinguished. This contributes to the achievement of the highest efficiency with the maximum fuel burning time in the boiler. Some design features of homemade boilers make it easy to control the combustion process in the boiler. This is achieved by correctly positioning the grates under the fuel bunker.

Almost all homemade boilers, the drawings of which can be easily found on the network, burn all contaminated particles, such as essential oils, various resins and alcohol. This became possible due to the fact that in such boilers there is a separate zone of additional combustion. Contaminated air from the combustion chamber enters this zone. It is in this air that contaminated particles are contained, which are burned in a separate order. From this it follows that a minimum amount of harmful particles enters the atmosphere, which can enter the heated room through the cracks and pores of the building material.

Solid fuel boiler drawing

A homemade wood-fired boiler is not only intended to use wood fuel. In such boilers, sawdust, peat briquettes or coal can be used as fuel.

The use of such fuel materials provides for the appearance of slag, which must be shoved. This is necessary in order for the combustion process to be carried out correctly. In order to make shurovka, boilers are equipped with a special hole under the combustion chamber. It is through this hole that you can push a poker and destroy the slag crust. This opening is closed by a small door that blocks the flow of excess air into the combustion chamber.

Drawings of homemade boilers are developed on the basis of finished factory products. The main difference is considered to be the changes made in the design and production plan. The positive side of such boilers is the ability to heat a larger amount of air heat carrier with the same volume of the combustion chamber.

As practice shows, the use of air as a heat carrier allows you to create a more comfortable microclimate in a heated room. When using such a heat carrier, it is possible to heat the air in the room in a short time. In addition, heat losses in such a heating system are minimal. Do not forget about the significant savings in money that must be spent on the purchase of a special coolant. In addition, complete tightness of an air-cooled heating system is not necessary.

The fact that the garage will not be constantly heated, but periodically, implies some problems during the winter season. Using water in the system can freeze the liquid in the pipes, which will inevitably lead to pipe rupture. Using air as a heat carrier completely eliminates such a nuisance. It follows from this that you can heat the garage several times a week, or only when you plan to carry out repair work in the garage.

Firewood-pellets-gas

If you are interested in the design of this type of heating, the table below describes the manufacturer of boilers for gas, solid fuel and pellets, its most popular model and a brief description.

| Manufacturer and model | Characteristic |

| Atmos DC 18 SP (Czech Republic) | The new series of combi boilers "ATMOS" DC 15EP (L), DC 18SP (L), DC 25SP (L), DC 32SP (L) allows ecological combustion of wood on the principle of generator gasification in combination with a burner for pellets, natural gas or extra light fuel oils (depending on which burner is built into the boiler). Boiler type - single-circuit. The combustion chamber is open. Installation - floor. Heating area - 300 m². Power - 20.5 kW. Solid fuel type - firewood, pellets. The display is not. Boiler - external (optional). Boiler volume: 78 l. Heat exchanger material - steel. Overheating protection - yes. Frost protection - yes. There is a thermostat. Ignition is mechanical. The efficiency is 92%. Weight - 429 kg. The advantages of this model are also that the boiler takes up less space than a large number of boilers. As for ecological operation, the boiler, according to CSN EN 303-5, belongs to the 3rd class. |

Thus, combined boilers for heating a house are an excellent option for obtaining not only heat, but also saving money. Since there is always a choice of fuel and its autonomous switching, in the absence of one specific type of fuel, your home will be heated at any time of the year. Combined solid fuel and gas boilers are reliability, high performance and versatility.