Climatic conditions in Russia do not allow enjoying warmth all year round. Therefore, it becomes necessary to organize heating of your home. In apartments, this role is played by ordinary water or gas heating, which is gaining in fashion.

But in private homes, such systems do not justify themselves. This is due to large payments for utilities, which are caused by the large area of the heated room.

Solid fuel boilers for heating come to the rescue. The owner using such a unit pays only the cost of fuel and maintenance, which cost much less than if they buy ready-made heat from the housing and communal services.

Principle of operation

Many do not understand the benefits of using solid fuel boilers. By purchasing cheap solid fuel, you can provide your home with hot water and heat. Some do not use the installation rationally, limiting themselves only to heating the room. Their excess heat evaporates into the atmosphere.

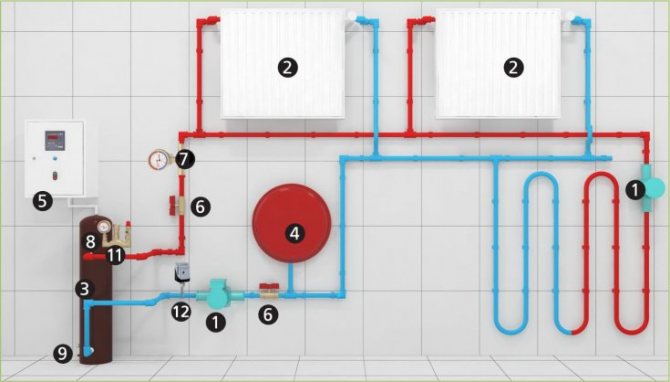

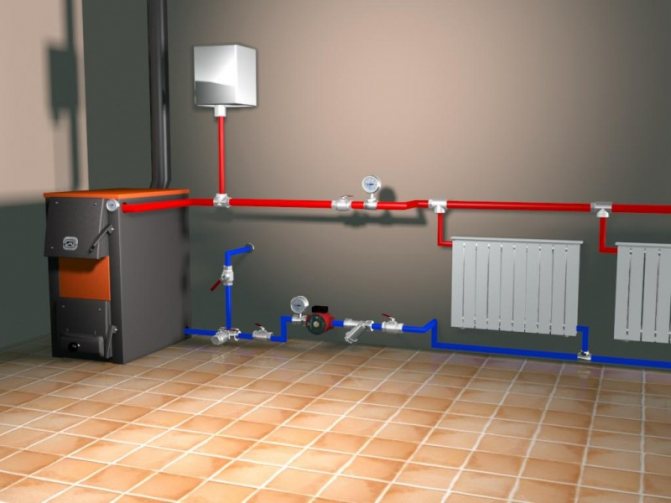

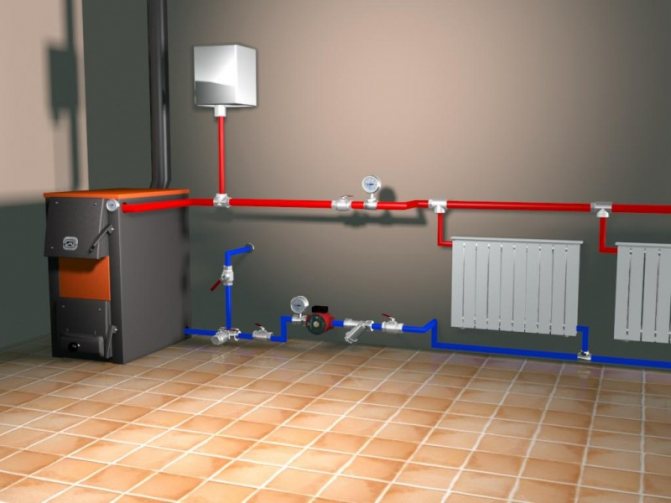

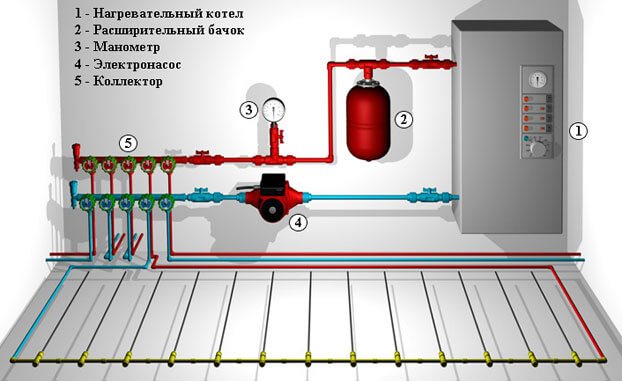

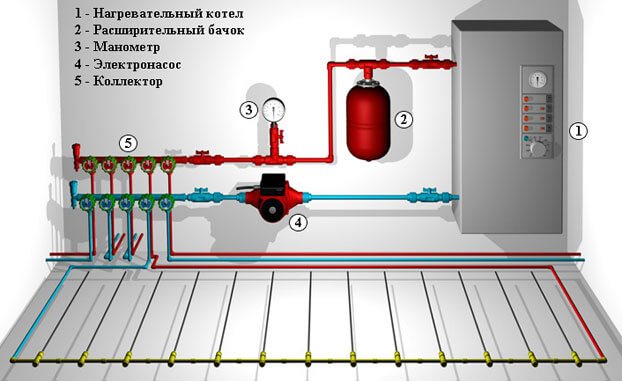

To increase the efficiency of such a boiler, you need to install a special container with a coolant, which is usually ordinary water.

A circuit of metal pipes must also be installed, through which the heated liquid will move. Thus, the whole house warms up and the owner receives additional warm water.

The following can be used as fuel in such boilers:

- Coal.

- Wood.

- Coke.

- Sawdust and wood chips.

Such a boiler is an excellent option for enterprises that generate excess combustible materials that are usually disposed of.

Electric boilers

This type of heating equipment is easy to install and operate, environmentally friendly (electric boilers do not require fuel, which generates waste during combustion).

However, electric boilers are very expensive to use - about 10 kW is required to heat a house of 100 square meters. For this reason, they are not widely used.

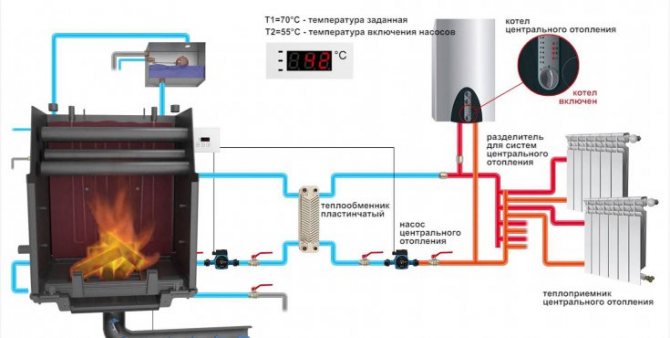

Most often, an economical electric boiler is installed as a backup heat source, for example, together with solid fuel devices. As a result, heating is carried out using a cheap energy source, and electrical appliances only come into operation when it is not available.

Economical heating boilers are gas and solid fuel devices. They are inexpensive on their own and also use cheap fuel to operate.

Advantages and disadvantages

Of course, the prices for solid fuel boilers, their ease of operation and safety have made them the most common throughout the territory of the former USSR. But it is worth noting that, having some disadvantages, such installations have a number of advantages.

Pros:

- Simplicity and low cost appears in almost all reviews of solid fuel boilers.

- Lack of a strictly defined type of fuel. If desired, any solid materials can be burned in it.

- Relatively cheap fuel.

- No additional load on the electrical network.

- Lack of complexity in use.

- Unpretentious installation.

- A lot of heat.

- No need for additional documentation in the supervisory authorities.

- No possible leakage.

- Wide range of models on the market.

- More than 80 percent of the heat is used for its intended purpose.

Minuses:

The need for cleaning the chimney.Over time, especially if the pipe is made of bricks without a sleeve, a large amount of ash and soot settles on the surface. This can render the boiler unusable, which will discharge combustion products into the living area. In addition, overheating of individual structural elements may begin.

Difficulty in installing automation in such boilers. In them, a person must regularly add fuel to the combustion chamber. But there are settings that make this process easier.

Instead of loading firewood into the stove every 3 hours, you can fill a special container with them, which, under the influence of gravity, will gradually add fuel to the fire.

The organization of additional space for fuel is required. This area must be dry and protected from fire.

Universal boilers

They are attracted by the interchangeability of fuels without affecting the thermal characteristics of the equipment.

May be:

- multi-fuel - alternately run on both electricity and solid fuel, diesel or gas;

- dual-fuel - combine only two types of fuel in combination, depending on the specified characteristics of the device.

They require competent maintenance and careful operation.

Fuel for boilers

The great advantage of solid fuel boilers is their simplicity. So, any solid materials can be used that burn well, and the soot after them does not stick to the surface of the furnace.

What can be burned:

Screen for a radiator - an overview of the best ideas and recommendations of designers for the selection of screens for a heating system- Chimneys for gas boilers - the main types and step-by-step instructions for DIY installation (video + 100 photos)

Double-circuit gas boiler: the best models, recommendations for choosing and installing a boiler with your own hands (105 photos)

- Coal. An excellent option when you need a long burning fuel boiler.

- Firewood.

- Pellets. Specially compressed fuel pellets.

- Peat fuel.

Depending on the region of residence, you can choose the cheapest fuel. You can find out about this in the same place where you can buy a solid fuel boiler. The specialists selling such equipment know the suppliers of cheap fuel.

Solid fuel boilers

This type of equipment remains as popular as gas boilers, since it is widely used in autonomous heating systems. Its advantage is the low cost of fuel, which is also readily available. As a source of energy in solid fuel boilers, peat, coal, coke, and firewood are used.

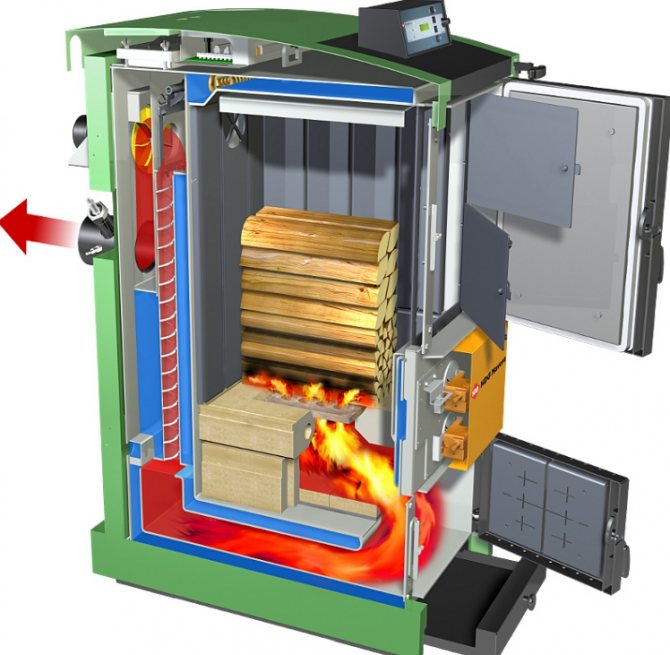

Recent technological developments have made it possible to create a new type of heating equipment - gas-generating boilers (long-burning devices). In these devices, a process called pyrolysis takes place. It is based on the fact that when wood burns, gas is formed, which later can also be used as fuel.

Compared to conventional boilers, gas generating devices have a high efficiency and a long period of operation on one batch of fuel (some models are capable of operating for two days with a full firebox filling).

Popular manufacturers and models

Solid fuel boiler, unit, rather complicated and self-made. Especially when it comes to a fluid circulation system that may simply not work due to several errors in the calculations.

Therefore, you can not worry about contacting reliable suppliers of such equipment, who will provide their products, plus they can offer a discount on installation and maintenance. The most popular are the following manufacturers:

- Zota.

- Pereko.

- Buran.

- Wiesseman.

- Stropuva.

- Hazetechnik.

Photos of solid fuel boilers from these companies can be found below.

Gas boilers rating

So, let's move on to the rating of the best gas boilers for heating a private house. And let's start with the wall ones.

Wall mounted

Which is the best wall-mounted double-circuit gas boiler is a difficult question, because a huge number of manufacturers are working in this area, who have long proven themselves on the positive side. And yet we will try.

See also: Directory of companies that specialize in autonomous gasification

Bosch Gaz 7000 W MFA

The German manufacturer offers a unique unit capable of operating on both natural and liquefied gas. There are also single-circuit models in the line. Boiler power from 24 to 33 kW.

Design features:

- ceramic monothermal heat exchanger;

- stainless steel burner;

- electronic ignition;

- two modes of water heating: "eco" - when water is needed on demand, "comfort" - maximum heating;

- you can connect a boiler through a three-way valve;

- an automatic system with which you can not worry about thermal inertia;

- The efficiency is 91%.

Gas boilers from the company BOSCH Source stroy-podskazka.ru

Baxi eco four

This is a representative of Italian production. It can also run on both LPG and natural gas. The manufacturer produces two models in terms of power: 14 and 24 kW.

Design features:

- copper heat exchanger;

- stainless steel heat exchanger for hot water supply;

- from the same material and a burner;

- there is an automation that protects the boiler from freezing and blocking;

- a sensor responsible for the movement of water;

- automatic bypass;

- weather-dependent automation;

- electronic self-diagnosis;

- flame modulation - electronic.

Gas boiler Baxi Source krayinatepla.com

Vaillant turboTEC plus VU INT

This is another German, whose power varies in the range of 12-36 kW. These are single-circuit models with a closed combustion chamber.

Design differences:

- copper heat exchanger;

- burner made of chromium-nickel steel;

- stage circulation pump;

- automatic air vent;

- protective system against freezing of equipment;

- electronic ignition;

- The efficiency is above 91%.

Boiler from the Vaillant company Source kak.znate.ru

Photo of boilers for heating

Read here - Which chandelier is better to choose: design tips for use in the living room interior and a master class for making a chandelier (125 photos and videos)