Mora branded boilers from the Czechoslovak manufacturer of heat and power and plumbing equipment have a high level of comfort and are adapted to the operating conditions of the housing and communal services system in Russia, characterized by low gas pressure and voltage drops in the power grid. The gas unit efficiently controls the water heating process to provide heating and hot water services. It is equipped with a set of Mertik control devices, consisting of water and gas fittings.

Features of boilers Mora TOP

The device starts operation by turning on the main burner, which is ignited by the piezo igniter, depending on the speed of the circulating water, starting from 5.5 l / min. This indicator corresponds to the minimum power of the unit, the nominal is achieved at a flow rate of 8 l / min. The unit is supplied without the By-pass function, therefore, when starting the system, leave the valve open on at least one radiator. The regulation by the technological process takes place in several modes, but it always starts in the same way - from turning on the pump.

The main regulation is carried out with a capillary thermostat in the range of heating water from 7–77 ° C. A more efficient regulation will be carried out by a 220 V room thermostat, depending on the user-set indoor temperature. In this case, this thermostat is connected in series with the capillary.

For DHW preparation, the Mora TOP boiler can be connected to an indirect heating boiler using additional equipment. In this case, regulation is based on the demand from the DHW boiler thermostat (ON / OFF). The capillary and room thermostats remain unconnected, the water temperature is regulated at 85 ° C. If the capillary is set to the “snowflake” position, the unit is in the frost protection mode, and as soon as the temperature of the supply water drops below, the water circulation in the internal heating circuit will begin.

Questions to specialists on malfunctions of Mora boilers

___________________________________________________________________________

Question: Mora 20 boiler is non-volatile, the wick stopped burning in standby mode. Lights up normally without problems when the temperature is set, the thermostat turns off the boiler and then the wick goes out and everything turns off. This happened after purging the external gas lines. Answer: Most likely, the gas block of the boiler has been contaminated. You need to clean it up. Either the electrode for monitoring the presence of a flame is faulty. It either needs to be changed or cleaned out. Try to clean up first - maybe it will help. Question: the gas wall-mounted boiler MORA TOP PROXIMA 20 KT burned out the coil on the gas block (the solenoid closes the gas) the operation indicator blinks red or blue. When operating in heating mode, hot water drips from an open DHW tap (cold water is shut off) and the pressure in the boiler drops, recommend what to replace. Answer: Judging by the description of the problem, the burned-out coil has nothing to do with it. It is very likely that you have a leaky DHW heat exchanger and water from the heating circuit enters the DHW circuit, but this should not be so. From this, you and the pressure drop in the system. So, most likely the reason is this.

Or (as an option, but unlikely) the three-way valve wedges and you see that the boiler is in heating mode, but since the valve is not fully closed (three-way), part of the boiler's power goes to the heat exchanger for DHW heating. But in this case, the pressure in the heating system should not drop. Question: Please tell me. Boiler wall-mounted mora tor titanium.when the thermostat is turned on, the burner does not light up immediately, when the desired temperature is reached, it does not go out at all, it boils, you have to turn off the gas! Please tell me what could be the reason? Answer: It is not entirely clear from your question about inclusion. The boiler should work like this: first ignite its ignition wick with a piezoelectric element. Next, ignite the main burner (it will not light up if the flame sensor is in the boiler - it capillary will not open the gas valve completely).

At the same time, the pump turns on and water circulation begins. Also, according to the indications of the capillary sensor, the gas block is blocked. Most likely, you have it in him. This is how the boiler firing up process is described in the instructions for it: Always before starting the boiler or after a long break it is necessary to perform the following steps - Check the water pressure on the boiler pressure gauge. Open the gas valve.

Turn the control knob to the ignition position and, by pressing it, turn it to the “asterisk” position. An ignition spark will appear - the pilot burner will ignite. From the moment of the ignition burner, hold the control knob for 10 seconds. After releasing the handle, the pilot burner should burn. If the pilot burner does not light, repeat the steps again. Question: I have a mora boiler top meteor plus 24 kt. Gives an error E1. What to do? Answer: Error E1 indicates several types of malfunctions, namely:

Ignition error - Burner ignited after ignition finished - manual restart required.

Loss of flame - Loss of flame during heating - the boiler will automatically restart.

Program error - Boiler electronic board processor error - manual restart required.

How do we understand the third option for you? If the restart does not help, then most likely yes, you need to replace the electronic board of the boiler. Question: I have already asked a question about the Mora Top Meteor Plus 24 KT boiler malfunction code, the display read E1. I was advised to replace the control board. After the replacement, the boiler worked for 2 hours, turned off and issued an error code E6. Can you tell me what this means? Answer: This error indicates an error in the flue gas outlet. Since you have a boiler with a closed combustion chamber, then, in principle, this error should not be. Check the electronic board, namely, whether the jumper on the board is installed correctly, which determines what type of boiler you have. Question: boiler mora top proxima 20st, please tell me what pressure should be in the heating system and the expansion tank when the volume of water in the system is 150 liters. Answer: For almost any domestic boiler, regardless of the volume of the system, the norm is a pressure of 1 to 2 bar. Anything over 3 Bars is already an accident. The pressure in the expansion vessel is exactly the same as in the entire system. The tank is part of the system. Question: The MORA METEOR PLUS 18.24 boiler is new. 1. pops of gas during ignition. 2-3 seconds piezo ignition crackle. E1 jumped out and all attempts by the rheostat to remove E1 are UNSUCCESSFUL. What is the reason? Answer: Does the boiler work for you? If it does not work, then it is very likely that the electronic board of the boiler is faulty. We need to change it. Question: Such a question - the cauldron of mora proxima has been in operation for 6 years. the relief valve was triggered during heating operation. she turned off the heating, but the pressure rose to 2.5 atm overnight. I closed the cold water tap on the boiler. the pressure did not rise above 2.0 atm. Answer: The question is - do you have cold water from the water supply system or do you have your own pump? And what is the pressure in the cold water supply system? What you describe is very similar to the fact that the DHW heat exchanger has leaked and since the pressure in the heating circuit is less than in the DHW circuit, water from the DHW circuit gradually enters the heating circuit. Therefore, the relief valve worked. Question: My sea top boiler is working fine, there are pumps for each circuit, the water heating is turned off (there is a separate column), the warm floors are hot, the second floor is warming up, the first is practically cold.bleed air from each battery, restarted the result 0 system. Please tell me how to fix the problem. Answer: a lot of things have been done wrong or maybe done with a margin, but it doesn't matter. In your case, it is important how the layout goes. If the main flow of the coolant first goes to the warm floors, then to the second floor, and then only to the first, then the reason is the lack of heat.

Why not enough? But here you need to figure out how you made warm floors. Why we have a feeling that you have the same temperature in all circuits, but it should not be so. In warm floors, no more than 40-45 degrees, and in the main system 80-85 (possibly more and a little less, but this is not so common).

Do you know how you have done it? If everything is done correctly, you still need to watch the system. The water flows where it is easier for it to flow - then the reason for not warming up is that something on the radiators of the first floor interferes with the flow of the coolant. Another option is possible - but this does not happen often - the heating system is more powerful than the boiler produces and there is simply not enough power. Question: the mora top 15 kw boiler began to shut down the pump and the heating system at random, please tell me the reason. Answer: Most likely, the reason is a malfunction of the electronic board of the More boiler. You need to check the master. The board is the "heart" of the boiler and, as a rule, it is precisely because of its breakdown that the boiler begins to "freak" like that. Make a visual inspection of the board yourself, you may see for yourself that something is burnt or melted. Question: my mora top 24kt meteor boiler today issued an error e2, I know that this is a monostat error, as usual, I tried to restart the boiler, but it issued e1 and nothing happens what can be done thanks in advance Answer: The only thing that can be advised is a manual restart of the boiler. If the problem persists, the electronic board of the boiler may be faulty. Question: I have a single-circuit boiler Sea Top TITAN 14SK. After turning on the main burner, within 5-10 minutes, the flame gradually decreases and goes out, the pump is running, the igniter is on. What is the reason? Answer: This is how the boiler should work. It heats up the system in 5-10 minutes and "understands" by the sensor that it is necessary to turn off the burner. In this case, the igniter in your boiler does not go out completely until you turn off the boiler completely. The pump must be running - otherwise the system will overheat. Then the cycle of switching on - switching off is repeated.

___________________________________________________________________________

___________________________________________________________________________

- Malfunctions of the AOGV-23 ZhMZ boiler

- Parameters and device of gas boilers AOGV and AKGV

- Boiler automation Baxi Luna-3 Comfort

- Installation and assembly of the Baksi Slim boiler

- Adjustments and maintenance of the boiler Beretta Chao

- Determination of error codes and malfunctions of Rinnai boilers

- Errors and malfunctions of the gas boiler Termet

- The meaning of the error code and malfunctions of Vilant boilers

- Determination of faults and errors of Wisman boilers

- Questions about the maintenance of boilers Navien

- Questions on malfunctions of Kiturami diesel boilers

- Junkers boilers - Masters answer user questions

- Experts answer questions about Electrolux boilers

- Expert answers for the repair of Nova boilers

- Questions about the service of Hermann boilers

- Answers from Daewoo boiler maintenance masters

- Questions about the maintenance of boilers Ferroli

- User questions on the repair of electric boilers Evan

- Because of what the gas boiler AKGV lights up and immediately goes out

- What is the malfunction of the Alpha Color boiler, if it shows the error code E01

- Because of what the AOGV boiler ignites and quickly goes out

- How to eliminate error E01 on the Baltgaz boiler

- What is the breakdown if Dani's boiler ignites, but immediately goes out

- Why does the Danko boiler light up, but quickly goes out?

- The Demrad boiler stopped holding pressure, what is the problem

- Because of what the Gazlux boiler began to warm up and make noise

- What is the reason if the Keber gas boiler lights up, but quickly goes out

- How to fix error code 01 on the Kiturami boiler

- Because of what the Conord boiler ignites, but immediately goes out

- What is the reason if the Lemax boiler ignites and quickly goes out

- Why does the Mimax boiler ignite, but it goes out sharply?

- Why the boiler The hearth ignites, but immediately goes out

- Why the Ross gas boiler lights up, but goes out quickly

- What is the malfunction if the Siberia boiler lights up and goes out sharply

- Why does the boiler Signal light up and go out sharply?

- Because of what the Termet boiler can make noise and heat

- Why does the gas boiler Thermotechnician ignite, but suddenly goes out?

- How can I fix the E01 error on the Thermon boiler

- For this reason, the Electrolux double-circuit boiler began to hum and heat up

- For what reasons the Ferroli gas boiler gives an error with the A01 code

- For some reason, the Immergaz boiler does not function on hot water supply

- Why does the Navien gas boiler constantly turn off and turn on immediately when heated

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

- Heating boilers piping

- STS boilers

- Solid fuel boilers KBT

- Pellet boiler Peresvet

- Steel floor boiler Raton

- Solid fuel boiler Thermology

- Errors and malfunctions of the gas boiler Termet

- Repair of Thermon boilers

- Repair of boilers Nova

- Boiler service Hermann

- Comparison of gas boilers Lemax Premium-20 and Danko-20s

___________________________________________________________________________

- Maintenance of Daewoo boilers

- Boiler malfunctions Demrad

- Mora boiler malfunctions

- Boiler repair Westen

- Immergaz boilers malfunctions

- Types of solid fuel boilers

- Combined boiler models and designs

- Oil and double-circuit boilers

- Cast iron boilers for coal

- Boilers with simulating burners

- Imported boilers for heating systems

The main types of gas boilers Mora TOP

The main modifications of gas units are divided according to the principle of installation - wall and floor, according to the design of the furnace - open and closed, according to the method of exhausting flue gases, there are three options.

Varieties of MORA-TOP TITAN:

- Device with atmospheric burner and flue gas discharge into the chimney, version B11BS. The boiler will not start up without the working pressure of the network water. This is the basic version, supplied with a temperature limiter in the boiler, which prevents the water from overheating and cuts off the gas supply.

- The atmospheric gas boiler "Mora" is equipped with a thermocouple, an expansion tank in the heating system and a reverse draft fuse that prevents gas leaks in the room.

- The unit with the "Comfort" burner reduces the temperature of flue gases in the chimney by installing an additional boiler to generate heat for the needs of hot water supply.

Important! The boiler has a function to prevent water freezing in the heating circuit. When the water temperature in the network circuit drops below +5 ° C, it will begin to heat it in order to protect the system from freezing.

Mora Top gas boiler malfunctions

In case of any malfunctions in the operation of the heating structure of this brand, the display will show the so-called "error code" and notify the owner.

The error can be knocked out due to a pump malfunction, a switch closed, a gas supply to the burner, a malfunction in the safety module, etc. However, the display may not appear, but you will understand that there is a malfunction. In this case, analyze what exactly the problem is, find a description of it in the article (above link), read a possible solution to this problem and fix it.

Gas boilers of the Czech manufacturer Mora Top are adapted to domestic working conditions, which many boilers from other manufacturers with similar technical characteristics cannot boast of. The buyer has the opportunity to choose a suitable heating model. The product range is huge: from 15 to 750 kW. You can choose a fully automatic installation and a classic boiler without built-in complex automation. Elementary rules of use are also at the heart of the popularity of Mora models.

teplofan.ru

The company boasts a very significant product line of gas water heating equipment, as well as various boilers for heating systems.Today, on the Russian market, we can find mounted gas boilers, gas flow water heaters, electric mounted boilers, as well as stationary cast iron floor boilers. MORA-TOP equipment brings unforgettable comfort and warmth to the home of its buyer.

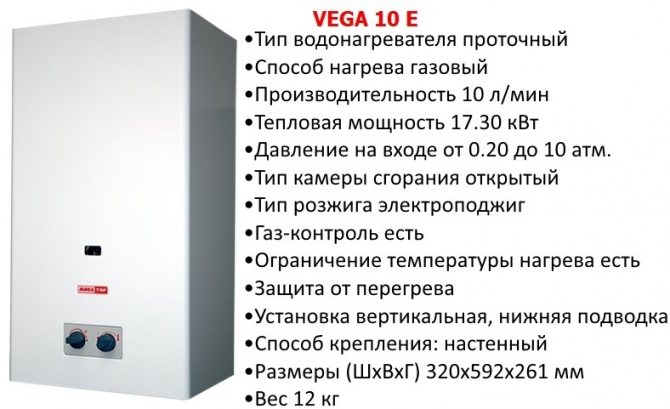

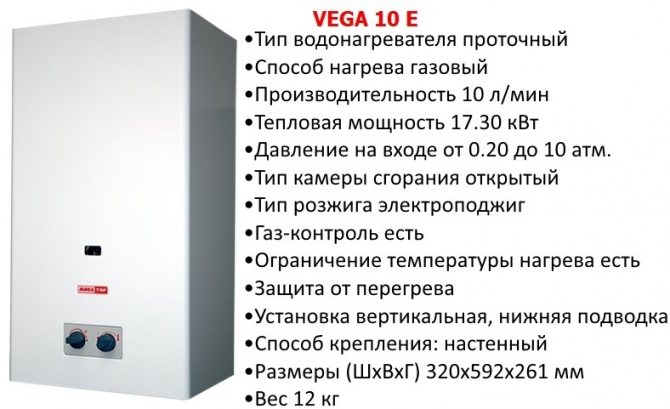

Geyser MORA-TOP model 10 MAX and VEGA 10 E MAX

The presented Geyser MORA-TOP has a thermal power of 17.3 kW, with a water flow of 10 liters per minute. Distinction VEGA 10 MAX from VEGA 10 E MAX

is as you can see the index

E

, which indicates the equipment of the model

electric ignition. The column is perfect for heating water in homes and offices. Model characteristics:

Advantages:

- The operation of a water heater is very simple.

- The model has an average water flow of 10 liters / min.

- Thermal power 17.30 kW

- Equipped with an electric ignition system.

- Equipped with an open combustion chamber

- Wall mounting with bottom gas and water supply

- Safety systems are standard: overheating and gas control

- The control is simple, two knobs regulate the limitation of the water heating temperature and the magnitude of the burner flame.

Geyser MORA-TOP VEGA model VEGA 10 and VEGA 10 E

Geysers VEGA E - presented by the manufacturer, as an absolutely "star" sample of the column of the Czech company MORA-TOP. The column is perfect for heating household water in consumer homes as well as in enterprises. the column, as in the previous model, has electric ignition in the presence of an index E.

Due to its small size, laconic design and remarkable technical characteristics, Vega gas water heaters, according to the manufacturer, surpass all similar products on the market of water heating equipment. The characteristics of the model completely coincide with VEGA 10 MAX and VEGA 10 E MAX

respectively.

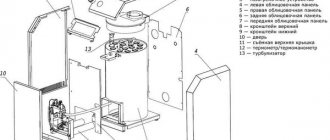

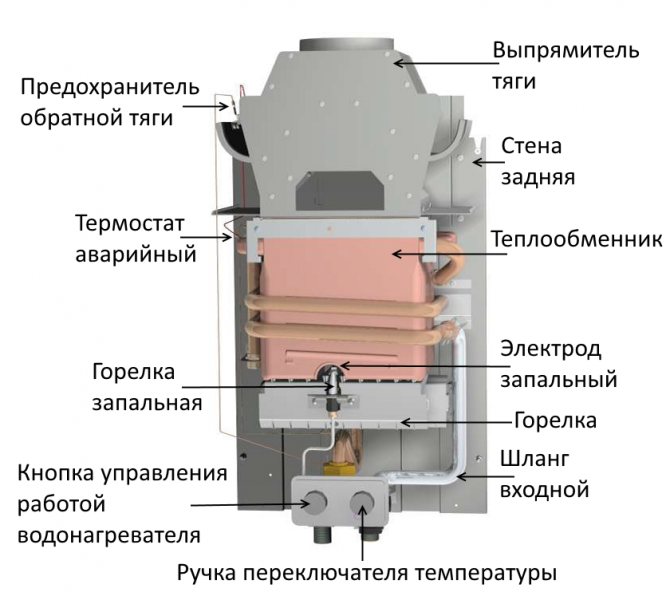

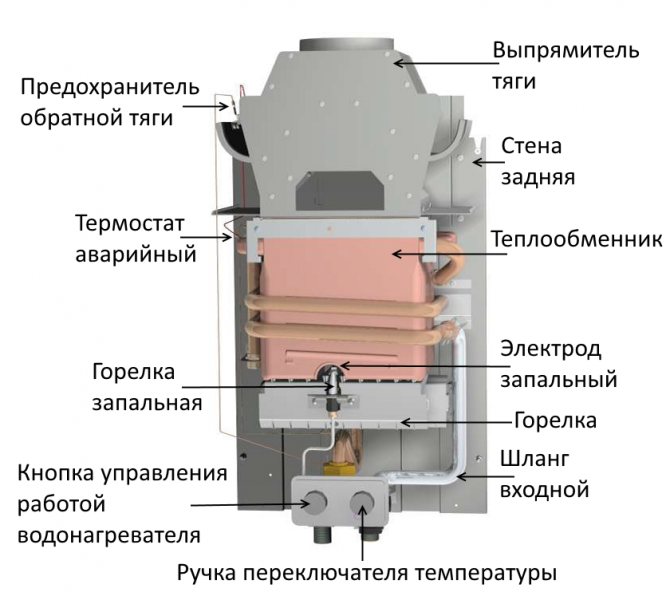

Device diagram VEGA 10, VEGA 13, VEGA 16

Geyser MORA-TOP model VEGA 13 and VEGA 13 E

Column VEGA 13 - one of the representatives of the bright family from the company MORA-TOP.

A distinctive feature of the model is the increased power up to 22.6 kW. This power allows you to work with a productivity from 6.5 to 13 liters per minute. At the same time, the column is equipped with reinforcement made of combined materials of the German company Mertik. The manufacturer guarantees the inclusion of the column even with a water flow of 3.25 liters per minute. Model characteristics:

Dignity

:

- The model is not large in size

- Simple operation and maintenance of the device

- The column is fully automated.

- The manufacturer guarantees gas savings up to 10%

- Quite high efficiency in the segment of water heaters: 92%

- Heat exchanger with tubes ⌀ 18 mm

- Convenient, simple stepless power control using knobs on the front panel

- Automatic retention of the set temperature regime.

Thanks to the design innovations, the combined reinforcement Mertik is used, as a result of which the moving parts are excluded from work in the aquatic environment. Thus, one of the main reasons for the breakdown of most columns was solved - namely, water leakage. As you know, the weak point is precisely the junction point of the water and gas fittings.

As we know, leaks of this kind require the replacement of the entire structural unit. The heat exchanger with tubes is equipped with turbulators, which prevent the formation of scale on the walls of the heat exchanger. Additionally, turbulators provide instant water heating.

teplogalaxy.ru

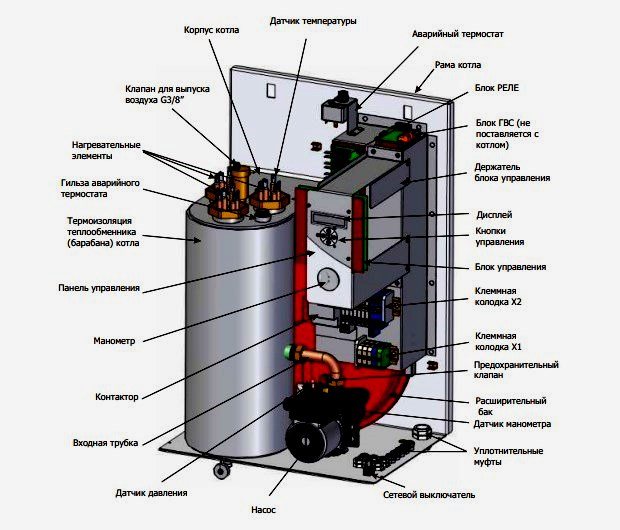

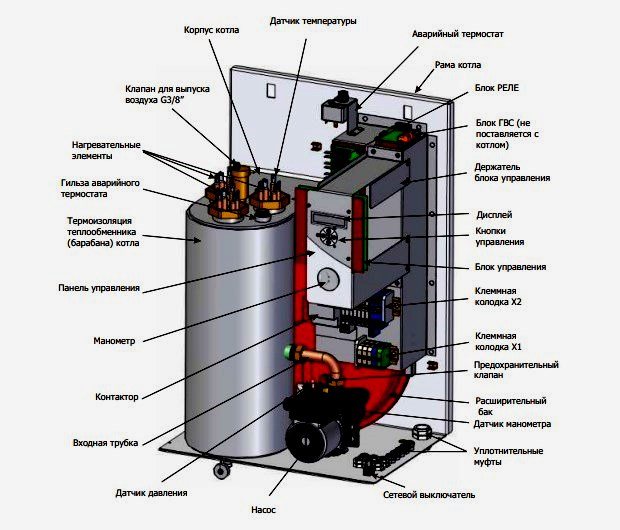

Floor standing

Atmospheric floor standing boilers MORA SA 40 G are recommended for heating objects located in areas with unstable power supply. Models of the Classic series are equipped with a stainless burner device that works stably even with low gas parameters. They belong to the class of cast iron boilers and have proven to be reliable, inexpensive and fairly economical heat generators.

Note! According to buyers, today in Russia they are the most common among similar devices.

The burner device is characterized by simplicity and operational reliability. Its advantages are quiet operation and low power consumption. The developers have provided the Mora boiler with maximum resistance to frequent pressure drops in the gas main, including modes with low gas inlet pressure.

The durability of the device is provided by a complete set with a cast-iron heat exchanger, which does not suffer from low-temperature corrosion, like a steel one, and does not burn out like a copper one. The unit has the function of monitoring the flame of the burner using a thermocouple to prevent gas leakage. The backdraft fuse works in the protection system and prevents flue gases from entering the room. Electronic regulation with a temperature limiter in the boiler controls the heating level of the circulating water, and in case of overheating in an emergency, it will give a signal to the shut-off valve to shut off the gas supply to the boiler and take it out of operation.

Built-in reliability features

The reliability of units of this design is ensured by the following functions of the boilers:

- Protection of the secondary boiler against scale formation by applying a special agent to the heating surface.

- Prevention of freezing of water in the internal heating circuit.

- Guaranteed operation of the pump and three-way valve without jamming.

- Boiler overheating protection. After stopping the gas supply, the pump will continue to circulate until the permissible cooling of the medium.

- Stable operation of the unit with parameters in the electrical network 160-250 V.

Note! When the circulation circuit is clogged, it is possible to provide movement in the primary boiler with a bypass line.

How to troubleshoot Mora's boiler

_______________________________________________________________________________

_______________________________________________________________________________

Gas boiler Mora Top Meteor PK24KT does not start. While holding the on / off button, the burner is in operation. But as soon as you release the key, the device immediately goes out. Explain the cause of the breakdown? It looks like a defect in the thermocouple or a broken gas valve. There is also a decrease in gas pressure on the intake manifold. Sometimes the control board voltage is too low. There is a problem. The start-up is very difficult. The igniter is on, but there is no flame on the main burner. Can anyone please explain what is the reason? Apparently, damage to parts of the ignition mechanism. The boiler must be serviced and the ignition mechanism cleaned. What is the problem if the Mora Titan boiler does not turn off after the heating reaches the required temperature? Heating goes up to 85C, followed by a malfunction. When restarting, the problem persists. It looks like the board is out of order, the thermal sensor is damaged, the sensor is broken for overheating. It is possible that an automatic settings error has occurred. Tell me why the boiler does not heat the water more than 70 C? I try to set more, but the display says it is the highest value. How should the heating be set? If the appliance does not manage to increase the temperature of the heating circuit, the following causes are likely. In the adjustments, there is a limitation on the maximum heating temperature to 70 C. A decrease in the draft speed in the chimney duct is noted. The Mora Top Proxima double-circuit boiler does not work correctly in the heating mode of the DHW system. From the tap can alternate between hot water and cold. Explain what is the problem? The factors for the appearance of a functional failure are most likely the following. There is a mixing of cold water due to the fact that the 3-way valve is inoperative. The heat exchanger is heavily soiled. You need to clean it up. Water leaks regularly from the tap under the boiler. The unit itself does not turn on. What do you need to do? Perhaps there is a discharge of the heat carrier from the safety valve. This symptom indicates high pressure in the system. In addition, the system filling valve can be open, or it is recommended to pump the expander tank.Tell me, what is the reason that the pressure increases rapidly, and the water discharge valve is also triggered? The heating symbol lights up indefinitely on the display in unit heating mode. What happened? There is a breakdown of the heating circuit temperature sensor. There is no normal circulation in the heating system. Why does the gas wall-mounted boiler Mora Meteor constantly turn off? Let's say that today the ignition did not work in any way. Service maintenance of the device was carried out at the beginning of the month. What is the malfunction? There is a suspicion that functional disturbances have appeared in the smoke extraction system. You must perform a chimney inspection. Inoperability of the electric ignition will mean a malfunction of any component due to a voltage drop or water has entered it. Can you help me fix my chimney problem? For two days now, reverse thrust has been observed, due to which the smoke enters the room immediately. I made the chimney myself. It looks like a pipe made of metal. There are probably omissions in the calculations. The unit produces hot water well, but if you start heating, the water quickly boils, and the device goes into failure. What is the problem and how to fix it? Most likely, the circulation pump is damaged, the control board is damaged, the temperature sensor is faulty. The filter mesh may also become clogged with debris. In the process of supplying hot water, the unit starts to dispense hot and cold water in turn. I don't understand what is the reason. How to set up the heating of the coolant yourself? Obviously, the heating system is clogged or the heat exchanger needs to be cleaned. There may also be a defect in the sensor that monitors the pressure, or the circulation pump could fail. The main factor may be an incorrectly made structure of the chimney duct. Soot deposits often occur on the pipe walls, which drastically reduce pipe performance. In addition, it is desirable to control the ventilation in the room. Installed a Mora Top Sirius boiler a week ago. The unit instantly picks up temperature over 96C, but then it locks up with overheating. Later, when it cools down, it can turn on on its own. What is the reason for this? Failure of overheating functions indicates a violation of the circulation process. First of all, you should inspect the faucets on the radiators. They must be left open. Then a check is carried out for contamination of the dirt filter, and it is also recommended to make sure that the heat exchanger is not clogged. We installed this boiler in 2020. After about three months, the device began to emit a noise. Explain why there is noise in the boiler? The presence of scale in the heat exchanger is likely. When the water is hard, limescale will subsequently be deposited in the wall of the radiator pipes. I plan to connect the Mora 5106 gas boiler to the heating system. Interested in how to correctly put such a unit into operation? For the correct commissioning of this apparatus, we recommend the following procedures. Connect the power supply to the device. We put the gas valve open. Then we start up the gas burner equipment. At the end, we set up the required theme. We need repairs. Please advise how to drain the water from the device? According to the instructions, this operation is implemented in this way. We disconnect the unit from electricity. Close the gas valve. We open the automatic air vent. We open the drain valve. Then remove any spilled water. If required, it is allowed to drain the liquid using the safety valve. This component is located at the bottom of the device. Can you tell me how to check the 3-way valve? I think that this part is not fully open. The last batteries are not pumped for heating, and in the hot water supply mode, the heating pipe under the boiler heats up. Of course, we recommend checking the 3-way valve for poor stem travel in an intermediate position.In turn, we recommend checking the heating system itself. I installed and connected a wall-mounted boiler Meteor Plus PK18ST in the apartment. Has acted well until now. At the moment, 3 seconds after switching on, the device goes out. There is an assumption that he is unable to drive the liquid into the system. Help, please, what is the problem? A possible cause of this damage may be an ionizing electrode that does not detect a flame, or there is no circulation. There is a problem with this unit recently. During the heating cycle, it whistles. I tried to reboot - the attempt was successful, but no changes occurred. Perhaps someone will tell you why this is happening? Very often, a strong whistle appears if the pressure on the nozzles of the gas burner device is not adjusted according to the instructions. It is necessary to check the established indicator and correct it, if appropriate. The gas boiler has recently been filled with water and malfunctions. For example, if you set some temperature, and the heating mode occurs exclusively up to 22 degrees, and then the device stops. Explain what went wrong? If water gets into the electronic board, it is most likely damaged. We recommend that you carry out its zeroing using a direct disconnection of the unit from the mains. Then re-launch and check its performance. I have a Mora Proxima gas by-pass boiler installed. Now, at the start, the wick lights up for 10 seconds, the main burner does not catch the fire, and because of this, the unit goes out. How best to get out of the situation? Probably, the automatic ignition is damaged or there is a problem with the burner. Just in case, you need to check if the phasing is correct when connecting to the power supply. Completed the commissioning of the same device in early August. After about 3 months, a malfunction occurs in the DHW circuit, although the heating circuit operates without interruption. I tried to open a hot water tap, but it only displays the temperature, and does not want to heat at all. What is the problem? There may be a broken three-way valve. It needs to be replaced. Explain why a safety temperature sensor is installed in the boiler system? The temperature sensor stops the gas supply to the burner when the liquid in the primary heat exchanger overheats. It is required to wash and clean the main water heat exchanger. Tell me how to detach this component without error? This element can be easily disconnected from the boiler unit using a conventional screwdriver. Here is the dismantling process. We drain the water from the apparatus using the drain cock. The next step is to free the hot water supply system from water. Unfasten the fixing screws of the primary heat exchanger and pull it out of the frame. I performed independently commissioning of the Mora Top Meteor Plus PK24SK boiler. Approximately three months later, the water pressure in the apparatus decreased. Often he slows it down and turns off. More precisely, it does not hold pressure at all. Why doesn't he hold up the pressure? When the machine does not hold the water pressure, the make-up tap is likely to leak. When shutdown occurs and the water pressure has dropped to zero, the three-way valve is damaged. Tell me how to clean the cold water filter? First, you need to drain the hot water system. Second, unscrew the flow sensor nut. Next, we take out the sensor together with the filter from the recess. After removal, we clean from debris and dirt. The device, when launched, made a buzz before, and at this time it rumbles even more loudly. Initially, the sound appeared for a short time, but now it lasts much longer. Has anyone observed this issue? The formation of an extraneous unpleasant sound indicates the presence of mineral deposits inside the heat exchanger, which does not heat up equally due to the unequal wall thickness. The more dirty the heat exchanger, the louder the rumble, and, accordingly, the lower the heat transfer.The device seems to be working, although water, apparently, does not circulate in the system. Very hot return pump. What is the reason? Apparently, the filter is clogged or the tap is closed in some place, which interferes with the passage of the coolant. The circulation pump could still be faulty. Why did the hot water stop heating? The tap water is barely warm. Help me understand what happened? Clarification of problems leads along several paths. If the DHW temperature sensor is damaged, it should be replaced. Perhaps the power settings of the device for heating the hot water supply are out of order. From time to time it is possible to observe the breakdown of the flame during the ignition. The burner is clean, the chimney is in order, the draft is excellent. Where to watch the breakdown? The unit does not detect a flame due to insufficient signal from the combustion mechanism. It is required to diagnose the wires from the ionization sensor to the electrode. You should probably tighten it up. There may also be damage to the sensor insulation, which must be replaced.

_______________________________________________________________________________

_______________________________________________________________________________

- Gas boilers

- Electric boilers

- Boiler error codes

- Elimination of malfunctions in boilers

- Gas water heaters

- Malfunctions and repair of gas water heaters

- Water heaters

- Troubleshooting water heaters

- Repair of indirect heating boilers

- Elimination of malfunctions in electric convectors

_______________________________________________________________________________

- BAXI ECO FOUR

Heating system control. Installation. Connection. Transfer to another type of gas. Adjustment devices and protection devices.

- BAXI LUNA

Features. Installation and assembly. Automation components.

- BAXI MAIN FOUR

Technical specifications. Installation. Adjustment and check. Maintenance.

- BAXI SLIM

Regulation and protection. Installation and assembly. Pressure setting. Maintenance.

_______________________________________________________________________________

_______________________________________________________________________________

- BAXI - REPAIR

After starting, a malfunction appeared. He does not want to turn on, he worked for two years, now the entire display is on fire as if the boiler is turned on, when the self-diagnosis mode is on, then it clicks, turns off for miles and then turns on the entire display again. It turned on once, but gives an error E10 water pressure, although the pressure in the system is 1.5 atm. Tell me what could be?

- BAXI - OPERATION

In operation, the Baxi main four 240 boiler is turned off with an E35 error (parasitic flame). Tell me what to do? The first season is in operation.

- BAXI - SETTINGS

We installed and connected a Baxi Fourtech 24 F boiler. What cold water pressure is allowed at the inlet to the DHW unit?

- BOSCH - REPAIR

Bosch 6000 boiler 24 kW, single-circuit with a built-in three-way valve. Does not see the boiler sensor, gives an error. Tell me how to make sure that it does not give an error and work normally both for heating and for a boiler?

- BOSCH - ADJUSTMENTS

If you disable the DHW flow sensor, can it be possible to reprogram it into a single-circuit device through the L3 menu?

- ARDERIA - REPAIR

Installed the Arderia esr 2.13 ffcd boiler. If my coolant pressure drops a little in 2-3 days for a couple of divisions, can there be a reason for the malfunction of the three-way valve (there are no leaks from the radiators)?

- ARDERIA - ADJUSTMENTS

The gas boiler Arderia is in operation 2.35. Tell me about the power reduction. I heard something about modulation, fan speed and so on. Is it possible to really reduce the power?

_______________________________________________________________________________

- BUDERUS FLOOR

We installed and connected a Buderus Logano G234-WS-44 kW boiler, Logomatic 4211 automatic equipment. Heating on cylinders without hot water supply, nozzles for reduced gas were also replaced. We survived the winter, the cylinders were replaced, all without problems. Then in the spring, when the temperature outside is + 16 + 18, the boiler began to turn off for a long time and when turned on, it began to display a burner error on the screen and a red button light on the front wall lit up. We pressed the button, turned on the power again and everything worked. It happened several times, then for the summer they turned off the boiler completely, what could be the malfunction?

- BUDERUS WALL

In a single-circuit Buderus 072, is the BKN coil circuit heated by the same heat exchanger as for heating or the same as on the 2-circuit one that is on the DHW?

- VAILLANT - REPAIR

Tell me, for Vaillant wall-mounted gas boilers, are there real / actual differences for the better in the new generation turboTEC plus VU / 5-5 compared to / 3-5?

- VAILLANT - ADJUSTMENTS

Malfunction in the operation of the boiler, the green LED (power supply) flashes, the instructions say that the thermal protection has worked, the green indicator flashes, even if nothing is connected to the board. How to fix? I checked all SMD resistors and transistors, everything is in order.

- DAEWOO

A double-circuit gas boiler Daewoo Gasboiler with an electronic panel is in operation. When the DHW is turned on, the heating is heated, the operating mode is summer. I took off the three-way valve, there is no dirt and production. It seems that the board does not control the three-way valve. How to check?

- ELECTROLUX

The wall-mounted boiler Electrolux Basic Xi is installed and connected. A malfunction began that the boiler stopped seeing the flame and turned off the gas supply after 7-8 seconds. And after 3 attempts, it gave an E1 error. How can you fix it?

- KOREA STAR

Malfunction of the Koreastar boiler. The heating works perfectly, hot water is intermittent, when the hot water tap is turned on, cold water comes first, then boiling water. After a few seconds, cool, then boiling water again. What could be the problem?

- FERROLI

Malfunction of the ferroli domiproject 24 boiler - I adjust 60-70 degrees, it goes to minimum combustion, does not turn on, does not turn off. Restarting is unstable. No pattern is revealed. What to do?

- JUNKERS

In operation, the gas boiler Junkers euroline, when hot water is turned on, ignites the gas, then goes out and so on several times. If you turn it on while the heating is running, then the water heating turns on immediately. Can you please tell me what could be the problem?

- NAVIEN

Tell me about the adjustments of the gas boiler Navien Ace 16 turbo remote control v1.3. The fan run-out cannot be set. I bet 30 seconds, but still 2 minutes. twists.

- OASIS

Malfunction of the boiler Oasis ZRT18. The unit starts up, the gas is ignited, then it goes out. It lights up again, goes out (three times it happens). Then it flares up and works fine. It does not give any error. What is the reason?

- SAUNIER DUVAL

Malfunction of the gas boiler Senor Duval - the water pressure sensor shows 0.0, the indicator flashes red, hot water does not heat up, but the water pressure in the apartment is good. How do I fix the problem?

- VIESSMANN

Where should a condensate drain be installed in the coaxial flue? Boiler wh1d with a closed combustion chamber, located at a distance of 1m from the wall.

- WESTEN

The problem of starting the Westen Pulsar D boiler. Piezo ignition works, but there is no flame, after a crackling error E01. Rearranged the fork in places.

- BERETTA

The Novella floor-standing gas boiler has blocked - the green lights on the panel are on, and nothing else happens. How to fix?

- ARISTON

An Ariston gas wall-mounted boiler was installed and connected, which does not hold pressure at all: during the cooling of heated water, the pressure drops to zero, although water is regularly drawn. What's with the pressure?

- SIME

Malfunction of the metropolis dgt 25 bf boiler. The hot water supply stopped working, the heating is working, it does not give an error. What do you advise?

- SOLLY

Please tell me how to solve the problem. The Solly Standard boiler, with any attempt to turn it on or hot water, gives a GS error.

- WOLF

The Wolf boiler is in operation. Recently, he began to behave strangely: in the pause between starts, he turns on the burner for one second five times, and 70 degrees jumps out on the display. Where to look for a fault

- ACV

ACV Wester Line works very unstable: it often goes into an accident, at startup it emits a characteristic knock and stalls, and sometimes everything is fine. The unit is almost new, what's wrong with it?

- DEMRAD

In the gas boiler Demrad, gas is no longer supplied to the burner. The piezo element clicks, but there is no ignition. Everything is in order with the gas stove, there is gas. What is the reason?

- KITURAMI

Malfunction of the Kiturami world boiler, stops periodically. I wipe the flame sensor and the apparatus works well for a while, but soon everything repeats itself. He also began to smoke heavily. Maybe it's a short chimney, and you need to lengthen it?

_____________________________________________________________

- IMMERGAS - ERRORS

Errors of boilers Nike Star, Eolo Star / Mini, Mythos.Boiler malfunctions with the possibility of automatic unlocking.

- IMMERGAZ - REPAIR

My boiler in winter mode systematically raises the temperature to 80 degrees. I summoned the master three times. He said that this is for many imergaz models, and offered to install a programmer, but not the fact that it would help. Tell me how to solve this problem and will this programmer help?

- AOGV

Model 11.6; 17.4; 23.2; 29.3 kW. Specifications. Control elements of the automation unit. Installation and maintenance. Malfunctions and their elimination.

- AOGV - REPAIR

The gas boiler AOGV was installed and put into operation. Hot water dispensing problem. The heat exchanger has been flushed. Less than a month has passed, and the water does not flow again. We put the filter on the water, but time has passed, and again hot water does not flow. What could be the breakdown?

- AGV

Assembly and installation. Start-up and adjustment. Malfunctions and ways to eliminate them.

- AKGV

Technical specifications. Installation and connections. Startup and work order. Automation adjustments.

- NEVA LUX

Malfunction of the boiler Neva lux 7023. With a frequency of 2 times a month, it gives an error E7. But after a reboot it still works. Now it gives an error E6. It will work for 15 minutes, and then it turns off. What could it be?

- ROSS

Construction and automation unit. Firing up procedure. Malfunctions and repairs.

- ATEM ZHITOMIR

Tell me if the Atem Zhitomir boiler goes out because of the weak gas pressure, it clicks and goes out. What is the problem? Is it possible to turn off the automation for a while and how?

- LEMAX

A gas boiler Lemax KSG-12.5 Premium was installed. After turning off the main burner, a click occurs after a couple of minutes, what is the reason, tell me?

- KEBER

A gas boiler KS-G was installed and connected, for 250 sq. m. When firing up, it does not turn off, the temperature rises, if I am not mistaken, the automatic Arbat 1. The flame is not regulated - too large. What to do?

- LIGHTHOUSE

I installed a gas boiler Mayak and connected it. It works fine. But the reason is this. When he works on a unit, he beeps strongly, if the regulator is turned 2-7, the squeak disappears. Tell me what could be?

- DANKO

We installed and connected the Danko gas boiler with the Kare automatics, it works fine on the igniter, but it is worth adding the power on the burner, it completely fades, yesterday it faded out for 5 minutes, today it works for 20 minutes and completely goes out. Who faced this problem?

- GAZLUX

The boiler gazeko 18 is in operation. When hot water is turned on, the pressure in the system drops after make-up, the pressure reaches 3 bar. Have to dump. What's the matter, how to fix it?

- NOVA FLORIDA

Water often boils in the boiler, while it goes into an overheating accident. The heat exchanger was recently washed, the system is not clogged. What's the matter?

- RINNAI

Malfunction of the Rinnai 167 RMF boiler. Recently I started showing error 14. How can you fix the breakdown?

- CELTIC

The Celtic ds boiler heats up to 45 degrees and costs the whole day it does not turn off and does not heat up the batteries, sometimes it shows an a3 error. How can this problem be resolved?

- MORA

The hot water pressure in the Mora Top boiler has dropped. What is the reason?

- MASTER GAS SEOUL

Seoul wall mounted gas boiler stopped turning on due to no ignition error. How can it be eliminated? What exactly is out of order?

Wall mounted

Wall-hung boilers "Turbo" with a heating capacity of up to 24 kW are produced with a closed combustion chamber, and "Combi" for joint heating and hot water supply. The device meets all the latest requirements of domestic and European standards in matters of safe and economical operation of heating units.

Note! The main innovation is the control unit.

- protection of the health of residents and the safety of property;

- custom function - for setting comfort modes in heated rooms;

- function of ensuring the technological process of the unit.

The unit has a wide range of heat load adjustment - from 30% to 100%. Initially, the Mora gas boiler heats the coolant in the circuit at maximum mode and then switches to economy mode.

Note! The boiler is protected against frequent switching on / off of the burner at low operating parameters, when the required heating load is below the lower limit, for example, a sharp increase in the outdoor temperature at the beginning or end of the heating season.

Structural advantages of wall modifications:

- thermostat for automatic regulation of the system according to the internal air temperature;

- quiet operation of the burner during start-up and operation;

- high-quality preparation of hot water supply with a minimum flow rate of 3 l / min;

- ultra-fine temperature control of the DHW circuit, regardless of the volume and pressure of the source water;

- easy accessibility of the internal elements of the boiler for maintenance and repair;

- LCD display of the control unit for setting;

- automatic diagnostics of malfunctions.

- built-in processor with software for diagnostic control of all units of the unit;

- protection against starting gas to the burner at low pressure or lack of water in the circulation circuit;

- protection against low DHW flow rates;

- ionization fuse for gas leakage control;

- flame separation control.

Mora TOP boilers maintenance cost

| Type of work | Price, rub |

| Diagnostics of malfunction of gas equipment | RUB 500 |

| Repair of equipment with replacement of one or more parts, setting gas control parameters, gas pressure, etc. or elimination of another malfunction, regardless of its complexity and + MOT | 1000 rub |

Do you have any questions? Do you want to place an order? Contact us by phone +7 (495) 627-67-66 or leave a request on the website.

Request a call

Technical characteristics of gas boilers "Mora TOP"

| The name of indicators | Unit measurements | Indicator, value | ||

| Model | METEOR PLUS 2 KT | TITAN 14SK | MORA SA 40 G | |

| Installation type | wall | wall | Floor standing / open hearth | |

| Burned fuel | main gas G20 | main gas G20 | main gas G20 | |

| Thermal power | KW | 23.0 | 14.8 | 35 |

| Gas pressure in front of the burner | mbar | 13.0 | 13.0 | 13.0 |

| Gas pressure in front of the nozzle | mbar | 10.5 | 6.0 | 3.0 |

| Maximum gas consumption | m³ / hour | 2.67 | 1.78 | 3.90 |

| Maximum DHW flow rate at Δ 25 ° C | l / min | 13.1 | 10.0 | without DHW |

| Minimum water velocity | l / min | 3.0 | 3.0 | without pump |

| Flue gas temperature | ° C | 111.0 | 140 | 150 |

| Permissible pump head | m | 6.0 | 6.0 | without pump |

| Flue gas outlet | a type | Turbo | without fan | |

| Gas outlet pipe diameter | mm | 60/100 | 110 | 145 |

| Voltage | IN | 220-230 | 220-230 | 220-230 |

| Current frequency | Hz | 50.0 | 50.0 | 50.0 |

| Power consumption for unit maintenance | W | 127.0 | 140 | 100 |

| Noisy when working | dB | less than 50 | not | |

| Temperature of emergency shutdown of the coolant | ° C | 95 | 95 | |

| Dimensions: width / height / depth | mm | 400x750x380 | 380x740x241 | 845x540x151 |

| Boiler weight | Kg | 33.5 | 17 | 151 |

| Price as of June 1, 2019 | rub. | 29900 | 21200 | 81989 |

Installation of gas boilers Mora Top

Experts have thought over the design of the boiler and made it as simple as possible for installation and maintenance. All electricity-dependent models have a built-in self-diagnosis option. Any malfunctions are displayed on the LCD. The boilers are equipped with Mohr equipment. Therefore, automation, burner and other components work for a long time and stably.

Boiler start-up and adjustment works:

- Models dependent on electricity are connected to the network. The self-diagnosis function is automatically started immediately. The sensor analyzes the presence of pressure in the heating system and in the gas pipeline. When a malfunction is detected, a signal in the form of an "error code" is issued on the display. After adjusting the work, the boiler starts up.

- In boilers independent of energy, there is no option for self-diagnosis, auto ignition of a flame, etc. Therefore, before starting the equipment, a company specialist must check that all recommendations regarding installation work have been complied with.It is necessary to install a water treatment system and a security group, it may be necessary to connect an expansion tank and a circulation pump.

Mora gas boilers, as a rule, start without difficulty, however, there are still exceptions, and they are usually associated with improper installation or transportation.

A common malfunction of a 2-circuit boiler is a breakdown of a thermocouple. After its replacement, the functionality of the equipment is fully restored.

Instructions for connecting and operating gas boilers Mora TOP

Before starting to operate the boiler, the manufacturer urges the maintenance personnel to study the document "Mora top" - gas boiler, instructions.

Installation and adjustment are carried out by representatives of the service organization, which is certified by the manufacturer. After completing the entire complex of work on commissioning, they must make an entry in the warranty card, without this the warranty will be invalid. Start-up measures must be carried out in accordance with the requirements of regulatory documents on safety in the gas industry of the Russian Federation.

During commissioning, the specialist must carry out the following steps:

- checking the tightness of the water and gas connections, the reliability of the wiring and the ground loop;

- adjustment measures for the boiler;

- diagnostics of the operability of all functions of the unit;

- checking the operation of the automation and protection unit;

- training of users on the rules of maintenance and control of the operation of the heating unit.

User reviews of gas boilers Mora TOP

According to the owners, as well as by the number of boilers sold in recent years, Mora TOP are recognized as the best in the rating of units of similar power. It is noteworthy that the opinions of users relate to the long-term period of operation of the boilers, that is, the devices show their positive qualities not only in the first years of operation, but over the course of decades.

Aleksnadr V., 47 years old:

“The single-circuit wall-mounted unit MORA TOP is a budget option, although it is not inferior in design to more expensive ones. Installation is lightweight, lightweight, which is good for thin walls, which are common in houses in rural areas. In case of any external gas failure, the unit stops and does not start itself into operation, which is not very convenient, but safe. The flame is regulated very simply - through a piezo ignition. Economy mode, heating of the house proceeds quickly, and another very important advantage - the torch is not blown out by strong winds. "

Mikhail K., 54 years old:

“The wall-mounted version for heating and hot water supply has been operating for 10 years without failures, even with low gas parameters in the network, the antiCa system protects the device from hard water. Good protection against overheating, accurate operation of the sensor, the boiler in emergency situations turns off instantly, there was only one error in the control unit for the whole time, nothing was fixed, they just made a reset. "

Innokenty S., 61 years old:

“We purchased the boiler in 2006 in Kaliningrad. The first 7 years I worked without problems. Then the control board failed, they consulted with specialists, tested the board and found a breakdown. They offered a spare part and replaced the burnt-out smd-component, the repair cost 300 rubles, it has been working without problems to this day. In the 12th year, a leak appeared from under the three-way valve due to the gasket, the gasket was replaced independently, the unit worked for another three years. Now the gas valve has begun to fail - the solenoid is malfunctioning, the repair is not cheap, but they decided to replace the boiler with a new one, because the term of 13 years of operation deserves it. "

Note! Thus, gas boilers of the Czech brand MORA TOP for heating and hot water supply have been creating warmth and comfort in consumers' homes for two centuries.

Today it is a state-of-the-art production with a microprocessor control system capable of adjusting the precise regulation of technological processes in the temperature range from 7 to 77 ° C in two circuits - heating and hot water supply.

The MORA-TOP geyser is presented on the Russian market in three models, each of which has two modifications. MORA-TOP is a Czech manufacturer's brand. The brand of the company has been known to the consumer in the market of heating and water-heating equipment for more than two hundred years.

The company tirelessly delivers warmth, comfort and coziness to people's homes. The symbiosis of modern technologies with more than two centuries of experience and allows us to speak with confidence about the quality and reliability of MORA-TOP products.

The company boasts a very significant product line of gas water heating equipment, as well as various boilers for heating systems. Today, on the Russian market, we can find mounted gas boilers, gas flow water heaters, electric mounted boilers, as well as stationary cast iron floor boilers. MORA-TOP equipment brings unforgettable comfort and warmth to the home of its buyer.

Geyser MORA-TOP model 10 MAX and VEGA 10 E MAX

The presented Geyser MORA-TOP has a thermal power of 17.3 kW, with a water flow of 10 liters per minute. Distinction VEGA 10 MAX from VEGA 10 E MAX

is as you can see the index

E

, which indicates the equipment of the model

electric ignition.

The column is perfect for heating water in homes and offices. Model characteristics:

- The operation of a water heater is very simple.

- The model has an average water flow of 10 liters / min.

- Thermal power 17.30 kW

- Equipped with an electric ignition system.

- Equipped with an open combustion chamber

- Wall mounting with bottom gas and water supply

- Safety systems are standard: overheating and gas control

- The control is simple, two knobs regulate the limitation of the water heating temperature and the magnitude of the burner flame.

Geyser MORA-TOP VEGA model VEGA 10 and VEGA 10 E

Geysers VEGA E - presented by the manufacturer, as an absolutely "star" sample of the column of the Czech company MORA-TOP. The column is perfect for heating household water in consumer homes as well as in enterprises. the column, as in the previous model, has electric ignition in the presence of an index E

.

Due to its small size, laconic design and remarkable technical characteristics, Vega gas water heaters, according to the manufacturer, surpass all similar products on the market of water heating equipment. The characteristics of the model completely coincide with VEGA 10 MAX and VEGA 10 E MAX

respectively.

Gas boilers MORA TOP "Sirius"

Modern technology, practicality, reliability!

The wall-mounted flow-through gas boiler SIRIUS MORA-TOP can be used to heat private houses, apartments and other premises with heat losses of up to 20, 25 or 35 kW.

Czech company MORA-TOP s.r.o. started its activity in 2000 as a subsidiary of the joint stock company Mora Moravia with the production of equipment for heating and hot water systems. In 2003 MORA-TOP s.r.o. gained financial and legal independence and began promoting products in the markets of Russia, Romania, Poland, Bulgaria and Slovakia. In 2004, the management of MORA-TOP began full-scale work on the construction of a new modern plant in Unicov. In six months, a high-tech plant was erected with a modern conveyor and a staff of more than 100 employees.

offers you a profitable purchase of the MORA TOP SIRIUS boiler. When developing SIRIUS, special attention was paid to the use of modern and high-quality components, comments and suggestions from specialists, customers and consumers were taken into account. The characteristics of the boiler are ideal for work in Russian conditions.

To find the necessary boiler for heating your home, we recommend reading the following articles:

- How to choose a coolant

- Choosing a gas heating boiler

- Cast iron or steel gas boiler heat exchanger?

- Safety precautions when operating a gas boiler

- How to conduct gas to a private house?

- Boiler room design: how does it happen?

Or contact our specialists of the gas equipment department, who will promptly answer all your questions, competently select a heating device and additional equipment. We are always ready to help you purchase boiler and auxiliary equipment at a profit. To get a discount you just need to call.

Technical description:

Safety

- The burner will not turn on with or without water flow in the heating system;

- The burner will not start without sufficient pressure in the heating system and sufficient DHW flow;

- Ionisation fuse for burner flame supervision protects against gas leakage;

- Heat exchanger overheating protection system.

- Control system for the removal of the emission of flame and combustion products;

- Frost protection system.

Profitability

- Power regulation in DHW and heating systems from 25% to 100%.

- High efficiency - 92.5%

- Protection against too frequent switching on and off of the burner is triggered if the power consumption when heating heating water is lower than the minimum boiler power.

- The control unit regulates the gas flow, electronic sensors measure with high accuracy the temperature at the outlet of the utility and heating water;

- When the boiler is operating at low power, the "anti-cyclic" function prevents frequent switching on and off of the boiler.

Reliability

- Uninterrupted operation at mains voltage in the range of 155–255 V;

- Protective system against deposits with a secondary heat exchanger with an inner surface treated with a special solution;

- High reliability of adjusting elements;

- Bypass;

- Anti-blocking function of three-way valve and pump.

Comfort

- Connecting a room thermostat provides the most comfortable space heating;

- Connecting an external sensor provides equithermal regulation;

- DHW preparation with a flow rate of 1.6 l / min;

- Modern control programs for DHW preparation and heating with the connection of the OPEN THERM unit;

- Silent start and work;

- The DHW temperature is regulated regardless of the pressure change in the water supply network and the amount of flowing water;

- A DHW cylinder can be connected to any type of boiler;

Functionality, ease of management and maintenance

- Control panel with a wide range of custom functions, all information is displayed on a digital display;

- Easy access to the internal components of the boiler for service;

- Possibility of installing a cascade control unit.

Environmental friendliness

- Low content of CO2 emissions into the environment.

Buy with this product:

- Household gas meter

- Bellows liner

- Thermal shut-off valve

- Gas alarm

Instantaneous water heater

Mora Top geysers are assembled at their own production in the Czech Republic. These are reliable and high-tech units for the installation of a hot water supply system for an apartment or cottage.

Water heaters are characterized by high efficiency, the efficiency is 92%.

Their operation is practically silent, which allows them to be installed anywhere. The fuel for them can be both natural and liquefied gas.

The mora speaker line consists of the following models:

- VEGA 10 (versions 10 E, 10 MAX, 10E MAX) - power 17.3 kW, water consumption 5 - 10 l / min. The series is produced as a more modern replacement for models 370, 371, 5502, 5505.

- VEGA 13 (variant 13 E) - power 22.6 kW, water consumption 6 - 13 l / min.

- VEGA 16 (version 16 E) - power 26.4 kW, water consumption 8 - 15.2 l / min.

It's important to know:

electric ignited speakers require periodic battery replacement!

The capacity of these water heaters is sufficient for the simultaneous operation of 1 - 3 water-folding devices. All models are available in compact wall-mounted enclosures. The difference in the variants of the models lies in the presence of electric ignition from the built-in batteries, letter "E" in the marking.

Gas water heater Mora Top: installation and operating instructions

The line of wall-mounted Czech speakers Mora Top consists of several models, different in performance. In the floor-standing series, the Mora 100 NTR boiler stands out for quality and efficiency. The most powerful wall-mounted model is considered the Vega 16, capable of passing up to 15.2 liters of water through itself per minute. The most affordable of the Top line is the Vega 10 gas boiler. All models are available in a compact body and differ only in the type of ignition (models marked “E” have electric ignition).

Features of the

Instantaneous water heaters of the Vega series have a number of unique properties that have won the sympathy of buyers for these devices:

- All water heaters of the Vega series use fittings from the German company Mertik, which include a column at a flow rate of 2.5 l / min.

- Automatic maintenance of temperature when changing water consumption.

- The design of the heat exchanger provides a heating rate 15% higher than analogs.

- The diameter of the tubes is 18mm and special turbulators on their inner surfaces prevent scale settling.

- Diameter of the gas duct neck from 115 mm.

- The heat exchanger is protected by a water temperature limiter that prevents overheating.

- Backdraft fuse, prevents combustion products from entering the building. This allows you to install the water heater in any room.

- The flame fuse monitors the burners.

- Dry-start fuse - the burner will not ignite without water.

The price of Mora top gas water heaters does not exceed analogues, the same Hayes. Market value from 16 thousand rubles. Compared to analogs of Mora, they have higher consumer properties.

Czech gas water heater Mora: device, advantages and disadvantages

Mora's gas water heater is a flow-through device that allows you to provide an apartment, a private house and a summer cottage with hot water. The column consists of an igniter, a gas burner, a heat exchanger, a gas-water valve block.

The principle of operation of the column is quite simple: when the tap is opened, the igniter ignites the burner, which heats the water in the heat exchanger.

Passing through the tubes of the heat exchanger, the water heats up and enters the heating and hot water supply system. When the tap is closed, the ignition goes out, the column turns off. Different Mora speakers can have different types of ignition: from a piezoelectric element and from rechargeable batteries (electric). The equipment runs on natural gas, but, if necessary, it can be switched to the mode of using liquefied fuel. Such multifunctionality of the columns is extremely important for the implementation of continuous heating and hot water supply in country houses and dachas not connected to the gas main.

Among the advantages of the Mora gas water heater, it is worth noting compactness and economy.

In addition, the advantages of Mohr's columns include:

- Multi-stage safety system: the dispensers are equipped with overheating protection, backdraft valves, burner flame and dry start fuses;

- High efficiency (about 94%);

- High efficiency even at water pressure from 0.2 atm;

- Thick copper heat exchanger, which, over time, will not leak;

- Sophisticated burner design and ignition protection system from contamination;

- Quiet operation.

The disadvantages of the equipment include complaints from users about the lack of parts in the modern market for Mohr's old equipment, the rather high cost of speakers. Although, the price of the equipment does not exceed well-known analogues (such as, for example, Hayes). So, both Heis and Mora will cost the buyer 16 thousand rubles.

Installation of instantaneous water heater

Before installing the column, you need to decide on the room and place of installation. The room must have ventilation, and the wall must be made of non-combustible material.

... Installing a column is usually straightforward and consists of the following steps:

- fixing the device to the wall. Standard brackets from the delivery set are used. Pay attention to the strength of the wall and its flammability;

- supply of pipes for cold and hot water.It is advisable to install shut-off valves before the inlet pipes;

Expert advice:

a non-combustible gasket must be laid between the wall and the speaker case!

- chimney connection. The chimney is connected with pipes with a diameter not less than the outlet of the device. The chimney material should be resistant to combustion products and high temperatures, its length should be minimal;

- connection of main gas. It is better to entrust this procedure to the professionals involved in the installation and operation of gas equipment.

Maintenance and repair

The operation of the water heater consists in turning it on and setting the required temperature. For this, two knobs are provided on the front panel of the device. The operation control handle has four positions:

- off, the column is off;

- ignition, ignition of the pilot burner;

- readiness, combustion of the pilot burner;

- operation, regular operation of the device in automatic mode.

The water temperature knob allows you to adjust the water heating from the minimum - by 25 degrees, to the maximum - by 55 degrees values.

Good to know:

the higher the heating temperature, the lower the water flow through the water heater.

The columns have high reliability and a service life of at least 12 years. Customer reviews indicate that they rarely fail.

If the operating instructions are followed, then the main reason for the failure is the formation of scale and salt deposits. In this case, the repair consists in flushing the water path and the heat exchanger.

Over time, heating efficiency may decrease, traction may deteriorate.

A possible cause is soot and soot deposits. The elimination of this malfunction consists in disassembling and cleaning the gas path of the column.

In the event of more complex malfunctions, especially in the part of the gas path, it is necessary to contact a service center with qualified specialists and the necessary spare parts.

For an overview of the Mora Top Vega 10 E geyser, see the following video:

2017-03-09 Sergey Dyachenko

Consider the typical breakdowns of Mohr's gas column and the necessary DIY repairs. Before starting troubleshooting, close the valve on the pipe through which the gas is introduced into the water heater. Even if a non-gas part is broken, there is a chance that it will catch on.

Gas water heater mora do it yourself repair (video)

The Mora water heater is a reliable flow-through equipment that can operate on both natural and liquefied fuel. Breakdowns associated with wear of equipment parts, quality of tap water and ventilation draft can disrupt the operation of the gas water heater. Most of the possible malfunctions can be easily eliminated on your own. Use the above recommendations, and you can easily and quickly restore the operation of the water heater!

This instruction in Russian is intended for heating boiler Mora-Top Meteor, describes the principle of operation and the main points of operation of the device.

The manufacturer strongly recommends that you carefully study this manual before turning on the boiler.

The MORA-TOP geyser is presented on the Russian market in three models, each of which has two modifications. MORA-TOP is a Czech manufacturer's brand. The brand of the company has been known to the consumer in the market of heating and water-heating equipment for more than two hundred years.

The company tirelessly delivers warmth, comfort and coziness to people's homes. The symbiosis of modern technologies with more than two centuries of experience and allows us to speak with confidence about the quality and reliability of MORA-TOP products.

The company boasts a very significant product line of gas water heating equipment, as well as various boilers for heating systems. Today, on the Russian market, we can find mounted gas boilers, gas flow water heaters, electric mounted boilers, as well as stationary cast iron floor boilers.MORA-TOP equipment brings unforgettable comfort and warmth to the home of its buyer.

Geyser MORA-TOP model 10 MAX and VEGA 10 E MAX

The presented Geyser MORA-TOP has a thermal power of 17.3 kW, with a water flow of 10 liters per minute. Distinction VEGA 10 MAX from VEGA 10 E MAX

is as you can see the index

E

, which indicates the equipment of the model

electric ignition. The column is perfect for heating water in homes and offices. Model characteristics:

- The operation of a water heater is very simple.

- The model has an average water flow of 10 liters / min.

- Thermal power 17.30 kW

- Equipped with an electric ignition system.

- Equipped with an open combustion chamber

- Wall mounting with bottom gas and water supply

- Safety systems are standard: overheating and gas control

- The control is simple, two knobs regulate the limitation of the water heating temperature and the magnitude of the burner flame.

Geyser MORA-TOP VEGA model VEGA 10 and VEGA 10 E

Geysers VEGA E - presented by the manufacturer, as an absolutely "star" sample of the column of the Czech company MORA-TOP. The column is perfect for heating household water in consumer homes as well as in enterprises. the column, as in the previous model, has electric ignition in the presence of an index E.

Due to its small size, laconic design and remarkable technical characteristics, Vega gas water heaters, according to the manufacturer, surpass all similar products on the market of water heating equipment. The characteristics of the model completely coincide with VEGA 10 MAX and VEGA 10 E MAX

respectively.

Device diagram VEGA 10, VEGA 13, VEGA 16

Geyser MORA-TOP model VEGA 13 and VEGA 13 E

Column VEGA 13 - one of the representatives of the bright family from the company MORA-TOP.

A distinctive feature of the model is the increased power up to 22.6 kW. This power allows you to work with a productivity from 6.5 to 13 liters per minute. At the same time, the column is equipped with reinforcement made of combined materials of the German company Mertik. The manufacturer guarantees the inclusion of the column even with a water flow of 3.25 liters per minute. Model characteristics:

Scale build-up in the heat exchanger

Mora heat exchangers are made of high quality copper, 1 mm thick. Water heats up inside the tubes and scale accumulates on their walls. This leads to an increase in the heating time and a decrease in the head. The main sign of clogging of the heat exchanger pipes will be that water flows out of the tap actively, and the pressure through the column is weaker.

To clean the scale with your own hands, you should remove the casing from the water heater, drain the water and unscrew the union nuts from the outlets of the heat exchanger. After that, a special liquid for dissolving salts, which is sold in a hardware store, is poured into the tubes using a hose. Alternatively, you can use a solution with citric acid or vinegar. It is necessary to wait a few hours for complete cleaning.

For prophylaxis, the heating temperature should be set to no more than 50 degrees. If the temperature is higher, scale settles especially actively.

Mora boilers - Faults and repairs

___________________________________________________________________________________________

- Mora boiler error codes

- Thermon boiler error codes

- Thermona Boilers - Troubleshooting

- Sime boilers - Repair recommendations

- Solly boiler malfunctions