Why is there noise in the boiler?

Extraneous noise in the boiler is most often not as dangerous as it might seem to an ordinary person. The threat consists only in the appearance of malfunctions when the boiler needs major repairs or replacement. Do not postpone checking the heating system indefinitely when extraneous sounds appear in the gas burner. You need to immediately contact a specialist who can determine the cause of the noise and eliminate it. It is not recommended to disassemble the boiler yourself if there is no firm confidence in how it functions and what parts it consists of.

The most common causes of humming, tapping, hissing and other noise accompanying the operation of a gas boiler are:

- operation of anti-freeze media

- decrease in gas pressure

- limescale on boiler parts

- malfunction of circulation pumps

- incorrect installation of the burner

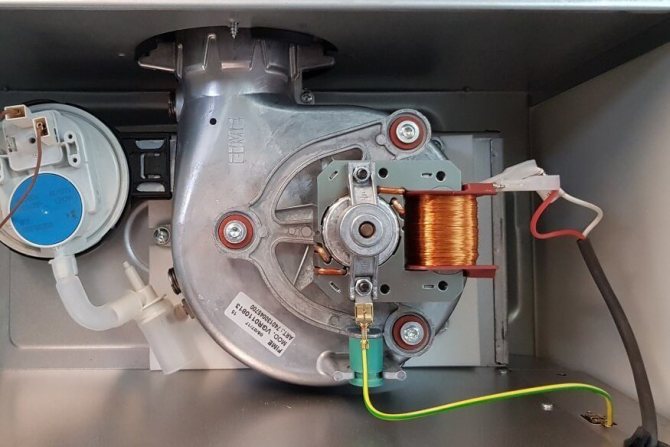

- fan failure

Reasons for the formation of sounds and claps

Harsh noises and popping have the following causes:

Semi-automatic boiler wick

Scale on boiler parts

Due to the fact that water is not filtered before it enters the heating elements (read about the choice of a filter for heating in a separate material), therefore, sediment often remains on the inner surfaces of the gas boiler. Parts are gradually losing their functionality. The problems start with the heat transfer elements. Further, sediment forms on the walls of radiators, pipes, this reduces the space through which water must flow. It is quite simple to get rid of scale, just open the gas boiler and clean it using special means. In this case, only the wear resistance of the equipment itself suffers. To avoid similar problems in the future, it is enough to carry out periodic preventive cleaning.

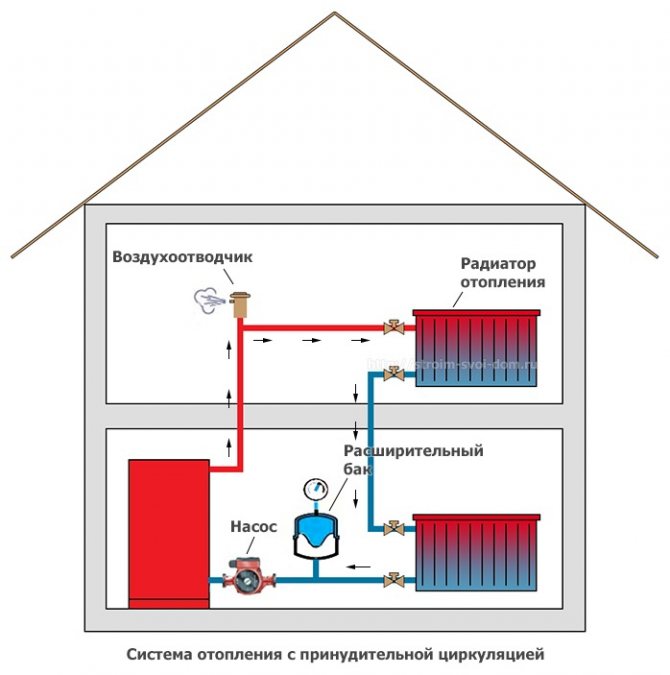

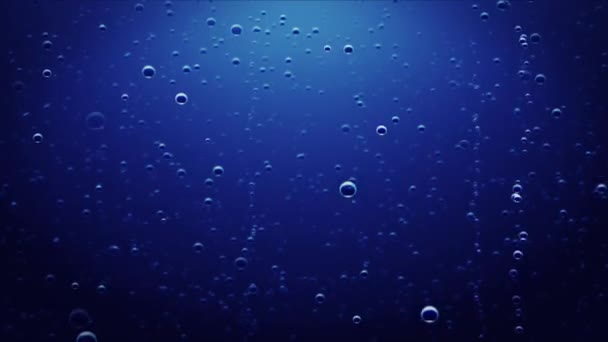

System water saturation

The problem with a high concentration of dissolved gases in water most often occurs in open heating systems. Due to the large area of contact of water with the atmosphere inside the expansion tank, gases are allowed to freely dissolve in the coolant and get into the heating system. In addition, oxygen is able to penetrate through the walls of polypropylene pipes and air vents, as well as enter together with water and make-up of the system.

IMPORTANT! During normal operation of the boiler, a little noise is inevitable. This phenomenon should not cause concern. It makes sense to worry if these sounds have dramatically changed the key or volume level.

When water is heated, the gas dissolved in it begins to evolve in the form of bubbles, which become a source of extraneous sounds. Noise can occur for the following reasons:

due to gas accumulation in the upper part of the boiler or radiators. Gas bubbles violate the free flow of the coolant and create vibration both in the boiler itself and in the entire system;- if the gas bubble has increased to such an extent that it began to create serious resistance to the movement of water, then it is carried away by the stream and it begins to move throughout the system. This phenomenon is periodic.

To get rid of the problem with the gas content of the coolant, either switching to a closed heating system or checking the operability of the gas outlet helps. Another way is to install Mayevsky taps on radiators, which allow you to bleed air from the system as needed.

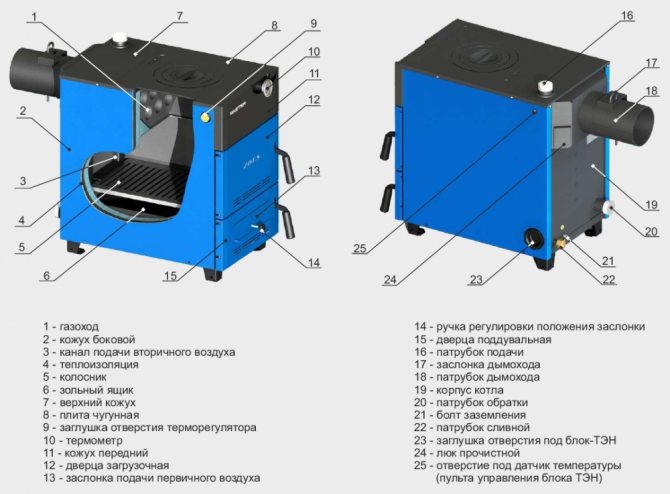

Incorrect burner installation

Quite often, a noise resembling tapping or whistling can be caused by the fact that the gas burner in the boiler was initially incorrectly configured and installed. To check, you will need to compare the level of gas pressure leaving the burner and the recommended indicators in the technical passport of the equipment. Entrust this task to the specialist who installed the gas boiler.

Other causes of the humming of the gas unit

There are other reasons why the gas boiler hums or makes noise:

- Incorrectly set bypass or gas valve, resulting in howling sounds.

- If the power of the gas appliance is exceeded, this often leads to vibration and a rattling sound.

- With a lack of coolant in the system, the gas boiler will also emit vibration noise.

- If there are sounds of rattling metal, then this may be due to errors in the installation of the unit.

To avoid malfunctions with the gas unit, you should follow the rules for caring for it specified in the instructions.

Extraneous sounds in the heating boiler

Sometimes boiler lighting is also accompanied by some sounds. When cold equipment heats up and begins to crack, then the characteristic clicks should not cause panic - the metal makes such sounds when it warms up.

Gurgling and gurgling are also possible - this is also a normal phenomenon: the coolant began to heat up and set the system in motion. However, the same sounds can occur when there is not enough coolant in the pipes. In this situation, it is enough to add water to heat evenly.

How to avoid noise

It is important to shut off the gas before doing any repair work. If you suddenly feel that you stink of gas, immediately close the tap at the entrance to the house, turn off electrical appliances, ventilate and call the gas service.

During installation, it is possible to install an elastic vibration absorbing layer under the body in all places where the boiler is in contact with the wall.

Boiler cleaning

First of all, it is important to carry out regular maintenance of heating equipment, which includes cleaning the units, removing dust and lubricating some elements. This will extend the life of your boiler and eliminate noise even before it occurs.

In a closed system, water should be added from time to time while monitoring the pressure gauge. In some devices, for example, Visman Vitopend, it is displayed on the control panel at the bottom of the case.

Let's figure out what to do when the device already emits extraneous sounds:

- If oxygen saturation in the water is the cause, the problem can be solved by converting an open system to a closed one. For this, air vents are mounted on the water heating boiler and the expansion tank is replaced with a membrane one.

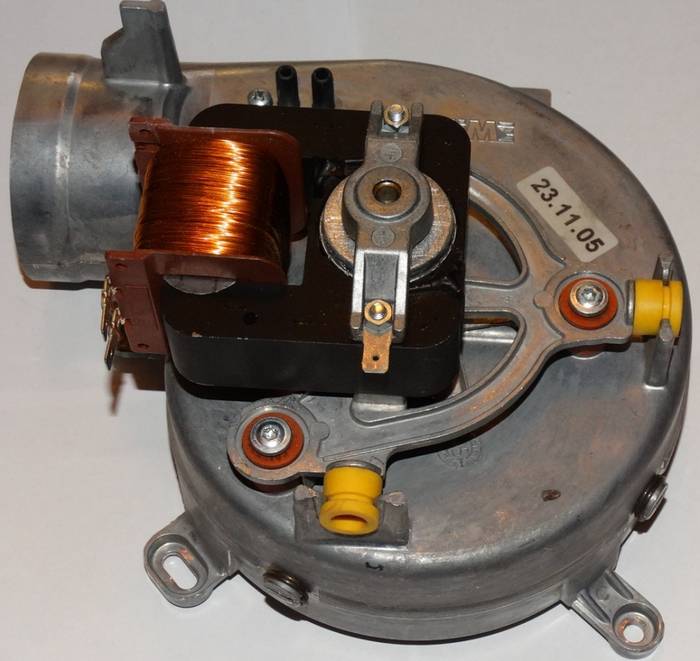

- The fan should be inspected and cleaned. It is important to consider that the main blades are located inside the housing under the casing. After cleaning dust and dirt, additionally lubricate its bearings. If this does not help, the cooler needs to be replaced.

- When the heat exchanger howls, you need to clean the scale inside it. In order to remove it, the casing is removed and the pipes connected to it are unscrewed. It is best to pour inside a special chemical descaler, which is sold at hardware stores, and leave it on for a few hours. If it is too difficult to remove the heat exchanger, the agent is poured inside using a flexible hose.

- If the gas valve whistles, check its settings. The correct configuration is written in the instruction manual.

Automatic gas valve - When the power of the pump exceeds the demand of the system, it is necessary to reduce the speed of its operation by changing the position of the white switch under the cover on the terminal block.

- The air from the heating system is discharged through a brass air vent on the front of the device.

- If a popping occurs during ignition on semi-automatic models with piezo ignition, such as the Bosch W, clean the nozzle and pipe of the ignition burner that the starter ignites from dust and debris.

- When an automatic boiler, for example Ariston Genius, turns on with the strongest clap, the ignition electrodes should be cleaned and, if necessary, their position should be corrected. The ignition will then be quiet.

- Noise from the valves can be prevented by replacing them with ball valves or adding an extra rubber gasket.

- To get rid of the fact that the gas meter clicks, you need to call the gas service for a check, as on it. Most likely, you will have to replace the device.

- In order to remove the metal knock when the temperature of the radiators changes, the wall mounts should be rearranged to the places that coincide with their support points. It also solves the problem of putting rubber pads on the brackets.

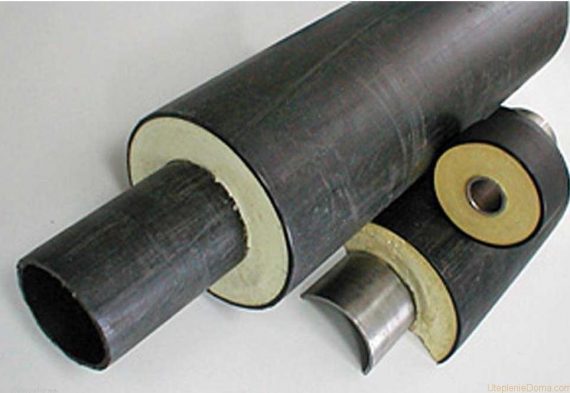

- When the heating pipes installed in the wall ring, you need to lay a special insulating material merelon around them. It is advisable to think it over at the time of installation, so as not to spoil the repair later.

Causes of noise

There are actually not so many reasons for the appearance of knocking in heating pipes during heating. Some of the noises can be ignored - they do not harm the system and heating devices. But such noises as buzzing, crackling, knocking, gurgling, howling should give reason to think and take urgent measures.

- air locks in the system;

- clogging or overgrowing of pipes due to poor-quality coolant;

- pipeline leaks;

- violation of installation work during the installation of cranes, valves and pipe laying;

- failure or wear of working equipment;

- cavitation, pressure increase in places of increase (decrease) in pipe diameter;

- incorrect calculation or non-compliance with design recommendations when installing the heating system.

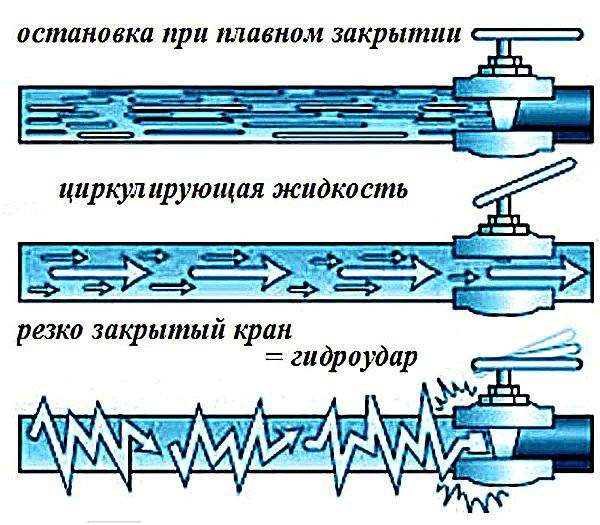

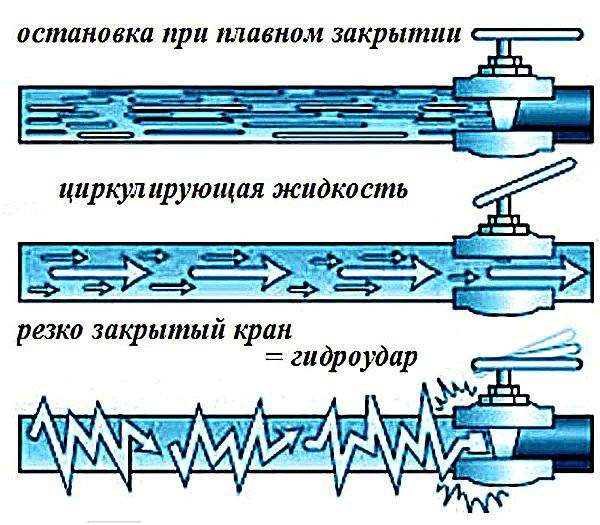

Buzzing pipes due to water hammer

Clicks or knocks can also be caused by such a phenomenon as water hammer. The reason for this is that the water, under the action of inertial forces, cannot instantly stop in the pipe. If the circulation of water in the system temporarily stops (for various reasons), then the water, suddenly bumping into an obstacle, strikes the inside of the pipe. This is called a water hammer.You can control the flow of water depending on the temperature using special regulators.

Note! Water hammer and water noises in the heating pipe occur at the moment when the water is completely shut off. After all, liquids are practically incompressible, therefore, inertia cannot be instantly extinguished. At the point where the water flow stops, the pressure can reach tens of atmospheres. In turn, this can be fraught not only with unpleasant noises, but also with the destruction of system connections, tearing out valves and even rupture of batteries.

Water hammer can occur anywhere in the system. Including even the underfloor heating system. Accordingly, in this case, the knocking will be heard under the floor. The strength of the water hammer can be affected by the length of the pipeline. In the underfloor heating system, it is the most dangerous, since here the pipes are folded into a very large length. Water hammer is also dangerous if a thermostat is installed at the outlet of the heating system. Structurally, it can withstand pressure up to 4 atmospheres, in this case no knocks are observed.

This figure shows the water pressure in the system and the cause of the water hammer.

Appliances are noisy when heating water

Modern boilers work quietly, so vibration, noise, extraneous sounds should alert you. What can serve as an indirect reason:

- Incorrect installation, connection.

- Incorrect setting.

- Wear of knots.

There are also very specific reasons why the boiler is humming.

High oxygen content

The water in the pipes is oversaturated with oxygen, which is why bubbles are released when heated. This effect leads to increased noise and vibration not only of the device, but also of the batteries.

Air accumulation in the system

If the boiler knocks and puffs, it is necessary to release the air in the pipes. Taps are installed on modern radiators. By unscrewing them, accumulated air can be removed.

Scale formation

The high salt content in the water leads to their deposition on the walls of the heat exchanger. Therefore, when heated, the unit will hiss. In addition, the heating rate and heat transfer are reduced. It is recommended to clean the radiator once a year. For this, a pump with a reagent is prepared, a cleaning liquid is pumped through the hoses.

Fan problems

The fan works in models with a closed chamber and forced removal of combustion products. Why does it make strange sounds when rotating, whistle:

The grease in the bearings has dried due to being positioned over the torch. When exposed to high temperatures, the grease dries quickly, which leads to bearing wear. The part is disassembled and lubricated.

Blade imbalance, accumulation of dirt and dust. The blades are cleaned, adjusted from rotation.

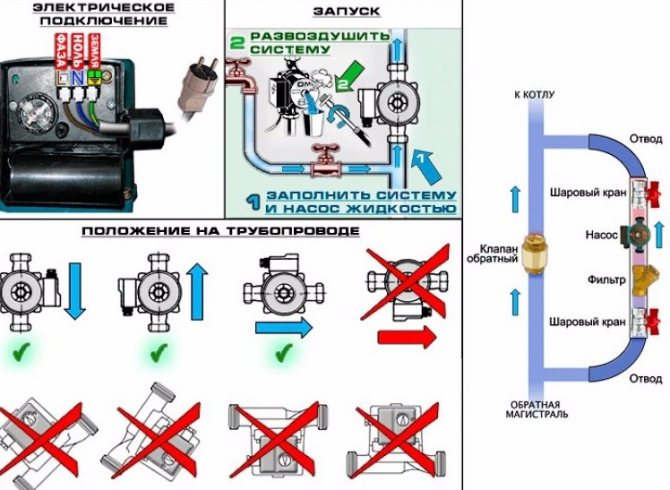

Overpressure in the heating pump

The pump is delivering high pressure, you need to adjust its settings. Too high pressure in the system can lead to an emergency. The values can be adjusted by switching the white lever on the terminal box.

A lack of water in the system leads to serious overheating. First of all, check the thermostat values, set lower values. Measure the pressure, top up the coolant if necessary.

As well as:

- If the boiler howls, the matter is in the wrong setting of the gas valve or bypass (jumper pipes).

- When operating at high power, the gas meter may thunder.

- A worn valve makes rattling sounds.