Home / Gas boilers

Back to

Published: 14.06.2019

Reading time: 5 min

0

635

Heating with gas is considered the most affordable and efficient solution, since natural raw materials are cheap and have a high thermal potential.

To equip the heating system in the room, you can install a single-circuit wall-mounted gas boiler. Such a unit takes up little space and demonstrates good efficiency indicators.

- 1 Varieties 1.1 Differences by type of management

- 1.2 Type of ignition

- 2.1 Is it possible to make DHW with a single-circuit boiler

What are single-circuit wall-mounted gas boilers

A gas hinged single-circuit boiler is the central element of a local heating system, designed exclusively for heating rooms.

Single-circuit wall models have compact dimensions, stylish design and a minimum of communications around, they fit almost any interior (Vaillant EcoTEC model in the photo).

Among analogs, it stands out for its reduced size - from 55 to 90 cm in height and from 40 to 45 cm in width, as well as in weight - from 30 to 75 kg, which allows it to be mounted directly on the wall. Such a unit fits well into almost any environment, be it a pantry, a bathroom, a kitchen, an attic or even an attic.

The rated thermal power of wall-mounted gas boilers is significantly inferior to floor-standing ones: household - from 10 to 42 kW, industrial - from 46 to 100 kW. Nevertheless, this is quite enough for heating most of both residential and industrial facilities of an average area - from 60 to 800 m2.

If this is not enough, several compatible models can be cascaded to expand the power range - from 50 to 1000 kW.

Device and principle of operation

The wall-mounted boiler in many ways resembles a column, with the difference that it heats not running water, but a coolant circulating in a closed circuit.

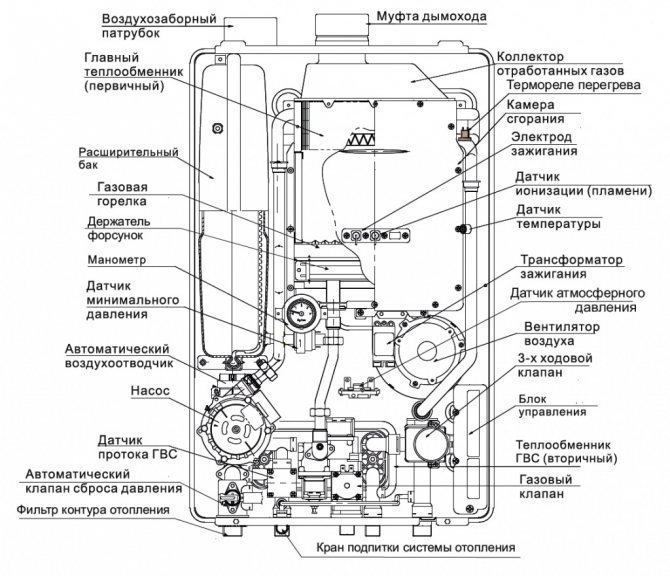

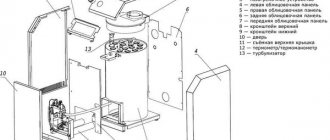

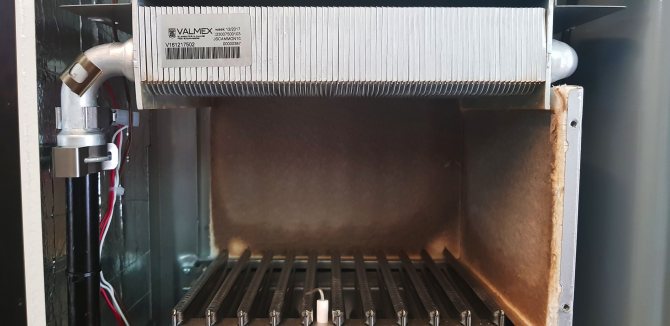

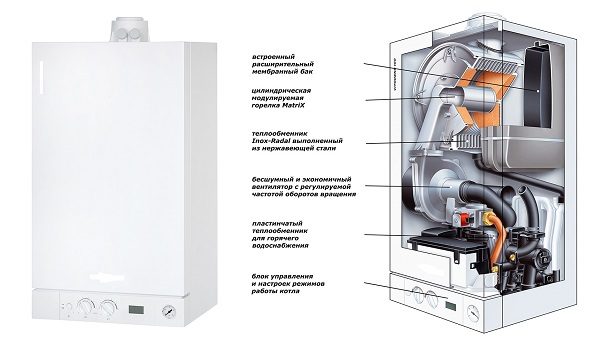

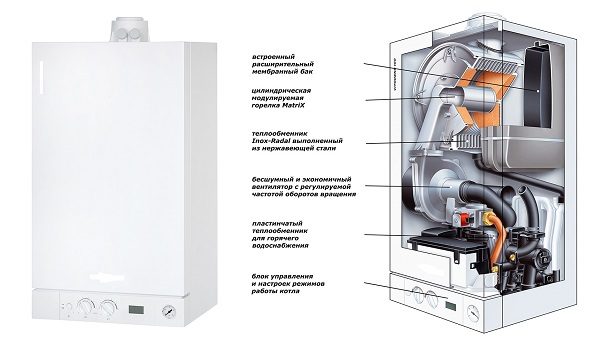

The device of wall-mounted single-circuit models by the example of Buderus Logamax U072-24.

Each single-circuit boiler includes at least four working units:

- combustion chamber (firebox) equipped with a burner;

- plate-type primary heat exchanger;

- exhaust gas (smoke) removal system;

- mechanical / electronic control unit.

The exhaust of gases in the mounted models is carried out through a coaxial (side) chimney, usually it is already included in the basic kit. Modern units, in addition to these components, have a circulation pump, a built-in expansion tank, multifunctional automation, etc.

Regardless of the modifications, all gas boilers work according to the same scheme:

- The burner metered the air-gas mixture into the furnace for combustion.

- The released energy is transferred to the coolant through the heat exchanger.

- The circulating liquid (water, antifreeze) carries heat to the radiators.

- In the cooled state, it returns to the boiler - the cycle repeats again.

So, despite the compact case, single-circuit wall models "by default" have everything you need to connect to a common heating system. But in order to fully provide the house with hot water with their help, you will additionally need to install a storage water heater (boiler).

Organization of an autonomous hot water supply system (DHW)

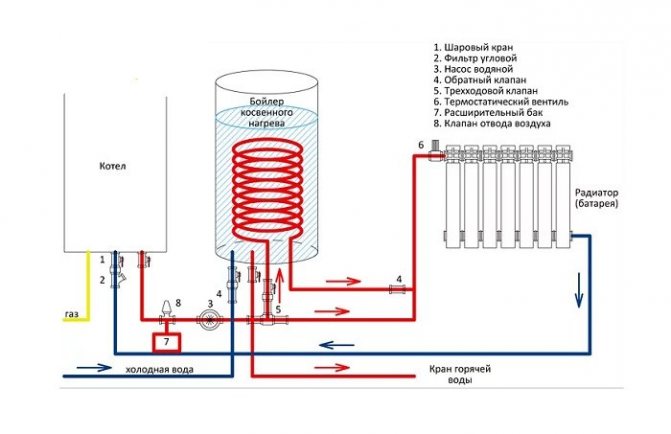

An example of organizing a circuit using an indirect heating boiler.

An indirect heating boiler is a thermal tank that takes up part of the thermal energy from a third-party source to prepare hot water.

The peculiarity of wall-mounted boilers is that, for the most part, they are initially designed to work together with a boiler and have appropriate branch pipes for connecting it. Many models have special decorative panels, thanks to which one unit can be stacked on top of another without being attached to the wall.

The second circuit is connected in the standard way - parallel to the heating one, but in boilers with a boiler (as opposed to two-circuit analogs), DHW priority is given only during primary heating, and then the coolant is distributed so evenly that the change in heating power is imperceptible to the inhabitants of the house.

How to choose a room thermostat and save up to 30% per month on heating

Pluses of a wall-mounted boiler

The advantages of a wall-mounted unit over a floor-standing unit are compactness and lightness (an overview of the types of gas heating boilers for a private house). The boiler can be hung directly in the kitchen, there is no need to allocate a separate room. Finding an "extra" room for a boiler room in a small house is problematic, in a small city apartment it is impossible.

The power of a wall-mounted unit for heating a small area is quite enough: when calculating, they usually proceed from the ratio of 1 kW per square meter of living space with ceilings up to three meters (subject to high-quality insulation of the house).

The power of wall-hung boilers is up to 35 kW. Theoretically, it is possible to heat up to 350 squares (which determines the gas consumption in gas heating boilers). Practically - less: the figure 1 to 10 applies to regions of a temperate climate, for cold ones, a correction factor of up to 2 is introduced.

In any region, when drafting a system, it is necessary to lay a power reserve of 10-15%: if the gas pressure in the pipeline is low (this often happens in rural areas), a boiler with insufficient power may not cope with the load.

The wall model is cheaper than the floor model (what are floor-standing double-circuit gas boilers for heating a private house) due to the lower power. The rest of the pricing factors depend on a specific model, brand, design features, additional functionality.

Reviews of the owners of mounted heating boilers: the main pros and cons

It is no secret that advertising articles and the opinions of consultants in the store can be biased, so you need to carefully study the experience of the real owners.

| Advantages | disadvantages |

| low cost - single-circuit wall models are considered the cheapest type of gas boiler | fragility - the unit is made of lightweight metals, therefore it is not designed for a long service for more than 15 years |

| reliability - unification of the technical component guarantees the absence of serious malfunctions and breakdowns. In practice, the number of calls to the service department of the owners of the mounted models is approximately equal to the number of calls to the owners of the floor speakers | complexity of service - compact assembly makes it difficult to access the units during routine inspection and repair |

| safety - all mounted units are equipped to varying degrees with elements of automatic control and protection (against overheating, freezing of the system, stopping the circulation pump) | volatility - in view of the presence of a circulation pump, complex automation, often - turbines, mounted models require connection to the mains. There are no non-volatile options today |

| free placement - such boilers can be installed in the vicinity of furniture and appliances, including stoves | |

| higher efficiency - despite the more compact dimensions, technologies, used alloys and more advanced automation allow to achieve an average of 2-5% higher efficiency in comparison with floor-standing counterparts |

Before installation, it is required to complete the accompanying documents and obtain permission from GazTechnadzor It is also important to note that any gas boilers cannot be placed in corridors, bathrooms, basements, on balconies and in rooms without ventilation, when supplied with liquefied gas (LPG) - on basements.

Actual requirements for installing a gas boiler in a private house

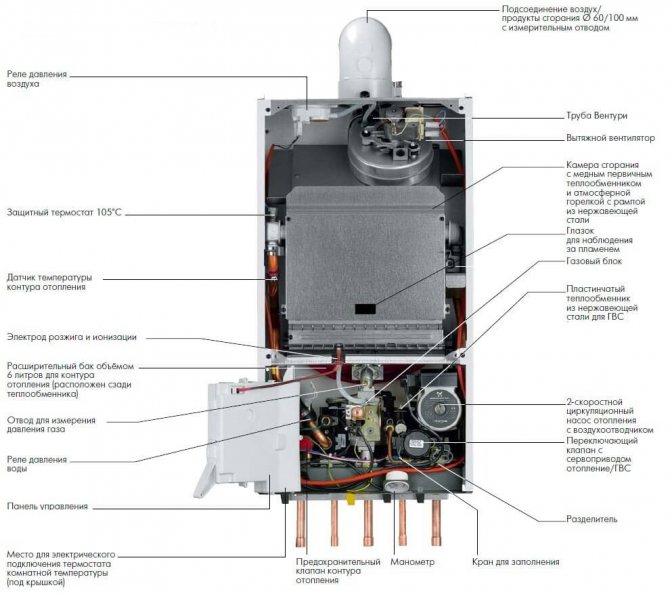

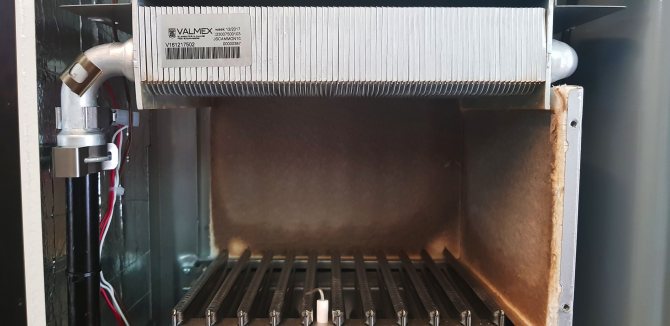

Hydraulic system of gas boilers BAXI LUNA 3 series

Electronic flow meter for hot water gontura;

Energy saving circulation pump with automatic air vent;

Primary copper heat exchanger, coated with a special compound for additional corrosion protection;

Secondary stainless steel plate heat exchanger;

Electrically actuated brass 3-way valve (on dual-circuit models);

High-speed circulation pump with built-in automatic air vent;

Pressure gauge;

Automatic bypass;

Post-circulation pump;

Cold water inlet filter;

Built-in 3-way valve for boiler (without servo drive) in single-circuit models.

How to choose a gas wall-mounted single-circuit boiler for a private house

The range of wall-mounted gas boilers for heating is very wide. To narrow down the search for the best option, it is absolutely not necessary to thoroughly understand all the nuances of the operation of the equipment - it is enough just to understand what this or that engineering solution gives in practice.

Convection, low temperature or condensing

The efficiency of a single-circuit hinged gas boiler depends on the method of use, the thermal energy released during the combustion of fuel. On this basis, all units are classified into three groups:

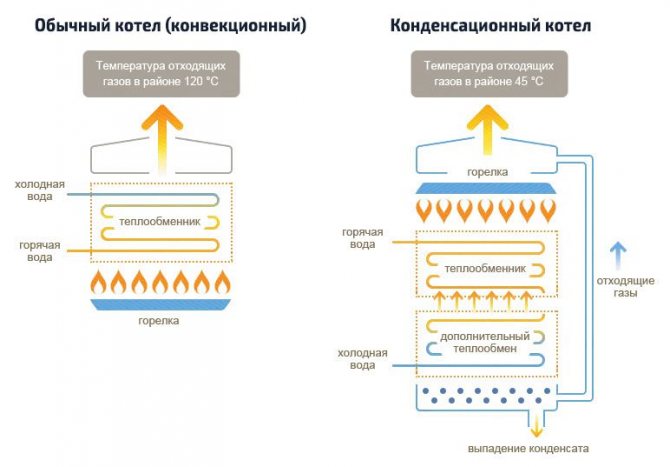

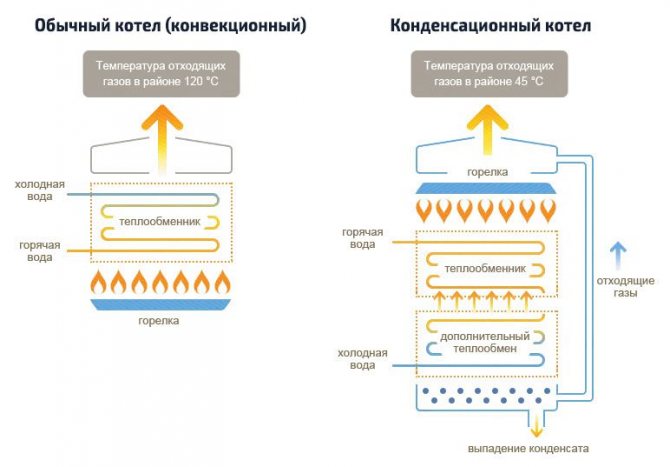

- convection - standard models that receive energy only from direct combustion of gas, while they constantly heat the coolant to high (70-80 ° C) temperatures, regardless of how much heat is needed at the moment, so most of it remains unclaimed and goes away along with the hot (130–160 ° C) smoke;

- low temperature - have the same design as traditional boilers, but they eliminate contact between the cold walls of convective pipes (by shielding) and exhaust combustion products (100–120 ° C), therefore, water cooling is allowed in them (20–40 ° C) , without the risk of condensation;

- condensing - work best when the water temperature in the heating system is below the "dew point" of the gas (10-50 ° C), they are equipped with an auxiliary heat exchanger (economizer), which accumulates the heat of water vapor, not allowing it to come out with smoke, which is why the latter cools down (70–80 ° C).

The principle of operation of conventional convection (efficiency 88-92%) and condensing (efficiency 104-116%) gas boilers.

It is clear that newer models are more expensive than the usual convection ones, but their operation is more profitable: low-temperature boilers are on average 15–20% more economical, and condensing boilers are 25–40% more economical. In addition, the colder the exhaust smoke, the less harmful the unit itself has on the environment.

Differences and selection criteria for condensing gas boilers

Primary (high temperature) heat exchanger material

The primary (high temperature) heat exchanger performs the function of transferring heat from the burner to the heating medium. All wall-mounted boilers are equipped with heat exchangers made of thin and light metals - steel (enameled, stainless) and copper. But the popular durable cast iron is too heavy for this type of equipment.

Conventional heat exchangers are not used to collect steam: it, mixing with smoke, turns into acid and corrodes the walls. Therefore, in condensing boilers, the second (cold) heat exchanger is made of a metal resistant to the aggressive effects of acids, for example, silumin, an aluminum-silicon alloy.

There is no definite answer which heat exchanger is more suitable for the boiler: it all depends on the quality of the metal, its thickness, processing method, etc.

With copper heat exchanger

Copper is considered the most suitable material for wall-hung boilers - it is lightweight, ductile and corrosion-resistant (does not rust). Due to the low inertia, copper heat exchangers quickly warm up, but if they are used for a long time under conditions of intense heating, they can start to burn out.

Thus, boilers with a copper heat exchanger have more advantages than disadvantages, but due to the relative high cost, they can often be found in imported models, while domestic manufacturers prefer to make their heat exchangers from more democratic steel. The service life of copper heat exchangers is 14-16 years.

With steel heat exchanger

Steel is more resistant to influences of both thermal and physical nature, for example, pressure surges and shocks during transportation. Heat exchangers made of it are easy to manufacture, which, not least of all, determines the final, lower price of the unit.

At the same time, the efficiency of steel heat exchangers is lower, because a considerable part of the energy is given simply to warm up the walls. They are more susceptible to corrosion; their service life is often no more than 12-14 years. To extend it, manufacturers go for a trick: they cover the steel with copper, and on top they apply a layer of durable heat-resistant enamel.

Combustion chamber type and exhaust gas removal system

The operation of all boiler units is accompanied by the supply of the required volume of air to the furnace and the subsequent disposal of waste flue products.

In gas units, these processes are carried out in two ways:

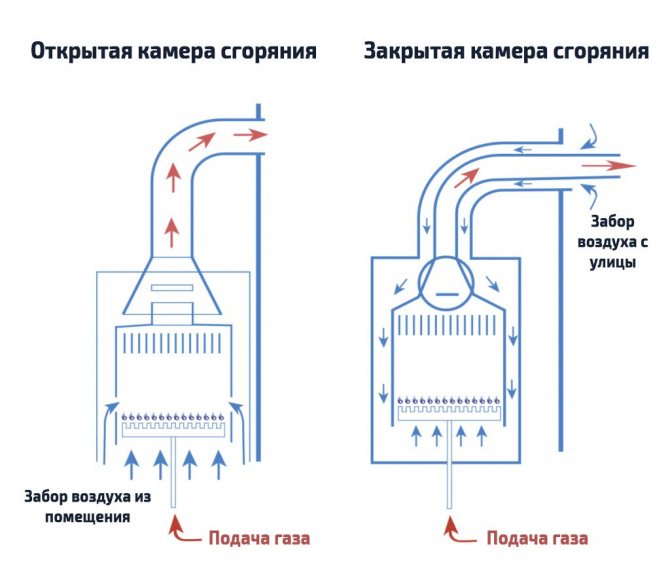

- atmospheric model - equipped with an open combustion chamber, air intake and smoke removal is carried out through vertical channels (natural draft);

- turbocharged model - has a closed combustion chamber, air intake and smoke removal is due to a powerful fan (forced draft).

Open combustion chamber and natural draft

The atmospheric gas boiler with an open combustion chamber is a classic unit that consumes oxygen from the room in which it is located. Therefore, the first - to maintain stable operation, it will be necessary to regularly ventilate the room or install a ventilation system in it.

Of the positive aspects, it is worth highlighting its budgetary cost and silent operation: you can only hear the flame "buzzing" and water flows.

Closed combustion chamber and forced draft (coaxial chimney)

More advanced models, accounting for over 90% of the market. A turbocharged boiler with a closed combustion chamber has a different principle of operation: it absorbs oxygen from the street, through a coaxial chimney (outer pipe), and smoke through it (inner pipe) is removed to the outside - this completely excludes air intake from the room, which allows you not to worry about ventilation.

This design guarantees the impossibility of fuel leakage and other emergencies, since in it the combustion chamber is separated from the room and connected only to the chimney itself, and the sealed casing does not allow the heated parts to come into contact with the gas. Cons - additional noise from the fan.

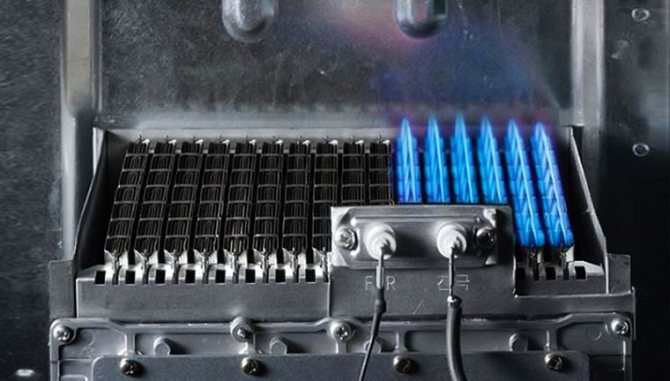

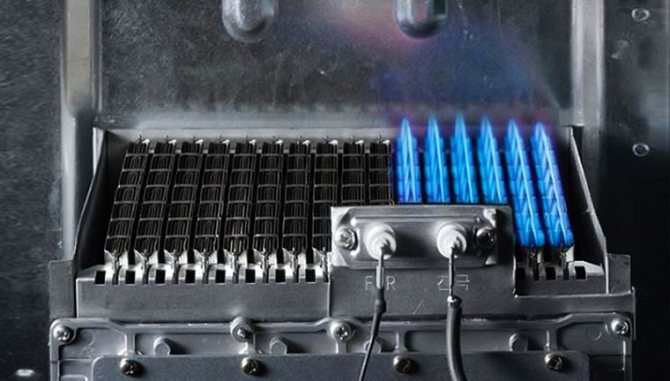

Most forced draft units have a closed combustion chamber, while those with natural draft have an open one. But there are exceptions. So, among the boilers with an open combustion chamber, there are unusual models from the Japanese company Rinnai, which are equipped with a fan at the inlet to remove exhaust smoke.

Varieties of gas burners according to the degree of flame regulation

A gas burner is the "heart" of any gas boiler: it is she who is responsible for igniting and maintaining the process of fuel combustion, regulating its intensity. In total, according to the degree of flame regulation, there are three types of burners:

- single stage - always work in one position at 100% power, maintain the coolant temperature at a fixed level due to periodic switching on and off.

- two-stage - they operate in two modes at 30/50% (depending on the model) and at 100% power, they are powered by electric ignition and never turn off, therefore, when the water temperature reaches the set value, the boiler switches to economic mode (until partial cooling) ;

- modulated - precisely adjust the desired power by 10–100%, their operation is controlled by sophisticated microprocessor automation, while the modes change, depending on the current parameters of the heating system: changes in pressure in the main pipeline, coolant temperature and others.

The most efficient and economical are simulated burners. They automatically select the optimal amount of fuel (including liquefied fuel) and smoothly regulate the heating of the coolant - this helps not only to reduce gas consumption, but also to ensure a minimum percentage of empty undercooling.

An example of the operation of a modulating burner. The ideal mode of operation is always considered to be continuous combustion at the lowest possible power.

Coefficient of performance (COP)

It is believed that the higher the efficiency indicator, the more efficient the operation of the boiler and, accordingly, it consumes gas more economically, but in the case of wall-mounted models this is not entirely true. For modern units, the real efficiency has long been approximately at the same level: standard 91–95%, condensing 103–109%. However, a difference of a few percent in efficiency still cannot be the main selection criterion, especially when heating small houses up to 100 m2.

In this regard, it is better to focus not on its efficiency, but on the estimated fuel consumption, which the manufacturer indicates in the technical passport. For domestic boilers 10–20 kW, the optimal maximum flow rate is 0.9–2.1 m3 of natural gas or 0.7–1.9 kg of LPG per hour.

Minimum required power

The required power can be calculated using a simplified formula:

Q = S × 0.1where

- Q - required power (kW),

- S - area of the heated dwelling (m2),

- 0,1 - the rate of power per unit area for an average house with 2 bricks and a ceiling height of 2.7 meters, located in the climatic zone of the Moscow region.

For example, for a residential building of 120 m², Q = 120 × 0.1 = 12 kW, we also recommend making a reserve of 15–20% for possible frosts, therefore for the same object Q≈14 kW.

When installing an indirect heating boiler, you must immediately take into account that its energy demand should not exceed 45-50% of the total boiler power.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

Additional criteria

In addition to the listed differences, you can consider other parameters that affect the comfort and safety of operation:

- automation functionality - ideally, the control module controls all processes by itself, from starting and changing modes to blocking in the event of a breakdown;

- security level - each sold boiler a priori complies with the standards, but some have a more complex multi-stage protection system;

- degree of heat and sound insulation - dense casing prevents heat loss (increases the efficiency of the device), and also reduces noise from the fan and burner;

- the possibility of using antifreeze - for filling chemical. Only special aggregates resistant to aggressive effects are suitable for use with substances.

Classification of single-circuit wall heaters

Single-circuit wall gas appliances are classified according to many design features that determine the performance and cost of heating appliances.

By type of heat exchanger

It is an important element of the boiler for transferring heat from a gas burner to a liquid.The average price, efficiency and service life of a wall-mounted single-circuit heater are significantly influenced by the material from which the heat exchanger is made. It is also important how high quality a particular metal is.

For the manufacture of heat exchangers, three types of basic materials are used:

- Cast iron. Does not burn out and does not corrode. The disadvantages of cast iron products are their high weight and high fragility. Therefore, they are mainly used in floor-standing models of gas heaters.

- Copper. The best material for wall heaters heat exchangers, lightweight, non-corrosive. Such devices have the highest heat transfer efficiency. But boilers with copper heat exchangers are the most expensive ones.

- Steel. This material is much lighter than cast iron, but heavier than copper. Steel heat exchangers withstand mechanical stress well, but are susceptible to rapid burnout and corrosion when condensation appears on them. The use of stainless steel devices prevents oxidation processes, increases the service life of the boiler, but also increases its cost.

By type of control

All heating gas boilers are equipped with automatic control and monitoring devices and devices for safety reasons.

By functionality and design features, the following types of automation are distinguished:

- mechanical or electrical energy independent devices;

- electronic or volatile devices.

Mechanical automation is the easiest to operate. In this case, the equipment is set up by manually adjusting the mechanical rotary toggle switches. The main element of the system is a thermostat, which maintains the coolant temperature within the specified parameters and protects the boiler from overheating.

The non-volatile control has sensitive draft and flame sensors. If the gas pressure suddenly drops or the draft in the chimney drops, the boiler shuts down. With the help of a safety valve, the system determines the amount of heat carrier in the heating circuit.

Volatile automation is an interconnected complex of electromechanical devices and electronic elements that functions only when there is voltage in the network.

Allows to solve the following functions of the heating technological process:

- Gas supply control.

- Automatic start-up of the heat supply system.

- Adjustment of the burner power (thanks to the use of a thermostat).

- Shutdown of equipment both in the event of a given technological mode, and in the event of an emergency.

- Display of data on the operation of the boiler on the display.

Gas heating equipment has a wide range of models with both mechanical and electronic control, which allows the consumer to choose an acceptable model for himself.

The best known manufacturers and models: characteristics and prices

BAXI ECO Four 1.24

The famous Italian boiler with an open combustion chamber from the popular BAXI ECO line, stands out for its special reliability and durability (even among other European models) at an extremely affordable price.

Its hydraulic unit is equipped with a pressure gauge, an automatic bypass and a heating medium filter, and the integrated control unit has weather-compensated regulation and self-diagnostic options. With a power of 24 kW, it consumes 2.7 m3 / h (LPG 2.0 kg / h). The primary heat exchanger is made of copper.

Cost: 32 210 - 35 750 rubles.

Protherm Panther 25 KTO

This model belongs to the equipment of the middle class (increased comfort) - it is convenient both in connection and in everyday use.

The turbocharged unit has a closed combustion chamber. The heat exchanger, internal wiring and inlet / outlet pipes are made of copper. A burner with a modulation depth of up to 25 kW burns 2.8 m3 / h (LPG 2.1 kg / h) of gas at maximum capacity.

Cost: 43 150 - 47 620 rubles.

Vaillant turbo TEC plus VU 242 5-5

This 24 kW German reference gas boiler has long been recognized by the craftsmen as the leader among all turbocharged units in terms of reliability and build quality.

German models are always distinguished by extreme reliability and resistance to any operating conditions, which is ensured by the use of modern alloys and technologies. It has an alphanumeric display with an extended list of information codes, a circulation pump with auto-switching, a copper heat exchanger and a burner made of chromium-nickel steel, which is not subject to burnout. Maximum fuel consumption 2.9 m3 / h (LPG 2.2 kg / h).

The only drawback is vulnerability to voltage surges (it is advisable to connect to the network through a stabilizer).

Cost: 54 920 - 59 670 rubles.

The best German gas boilers The most efficient, reliable and functional models on the market

Viessmann Vitopend 100-W A1HB002

Another reference German representative, the low-temperature unit is one of the best gas wall-mounted single-circuit boilers for heating a private house, especially popular in the EU.

It has a copper heat exchanger and a “smart” controller with a self-tuning function, which protects the automation system from fluctuations in the gas and electric network. This allows him to adapt to the most extreme situations. For a power of 30 kW, it is quite economical - 3.4 m3 / h (LPG 2.5 kg / h).

According to the practice of operation and feedback from the owners, all models have been working without problems for more than 6 years.

Cost: 39 650 - 46 180 rubles.

Buderus Logamax U072-18

An inexpensive 18 kW unit with a copper heat exchanger was designed specifically for operation in typical Russian conditions, including freezing.

Its advantage is low price, excellent design and economy. The Buderus service structure is highly developed in Russia and is known for the presence of competent specialists in almost all regions. The maximum consumption is 2.0 m3 / h (LPG 2.8 kg / h) of fuel.

Cost: 28 250 - 36 180 rubles.

Rinnai BR-UE30

The well-known Japanese model, despite its ultra-compact size, has a rather impressive power of 29 kW. It also has a copper heat exchanger.

As in all Asian boilers, it pays special attention to the comfort of the owner, therefore it includes a set of side modules: a voice navigator, remote access (remote control, Wi-Fi) and weather-dependent automation. Precise temperature control helps to minimize gas consumption - 2.8 m3 / h (LPG 2.5 kg / h).

Cost: 55 300 - 61 900 rubles.

Varieties

Various single-circuit wall-hung boilers are available for sale, which differ in both performance characteristics and the principle of operation and cost. In order not to be mistaken with the choice, it is necessary to familiarize yourself with the existing types and their classification. Modern installations are classified according to:

- The method of heating the coolant.

- Gas burner type.

- The way of control.

- Additional functionality.

The principle of operation of a single-circuit unit is based on schemes with open and closed types of combustion. The first type is in great demand and uses traditional gas burners in its work. The combustion is carried out by natural circulation, and the waste products are discharged through the chimney. Among the advantages of such equipment are:

- Ease of manufacture. The design of the boiler is made up of fewer parts, which reduces the frequency of damage.

- Low noise.

- Affordable price.

Of the minuses, they highlight the need for arranging effective ventilation and insufficiently high efficiency.

Units with the "turbo" attachment appeared on the market relatively recently. They are an advanced system based on closed combustion chambers. Gas combustion takes place in a hermetically sealed tank with forced smoke extraction and air circulation.

Differences by type of control

According to the control method, boilers are mechanical and electronic. The first variety is equipped with primitive temperature control and valve position changes. When the temperature indicators drop below the set value, gas is supplied and the temperature rises. After the restoration of normal operation, the automation will cut off the gas supply.

Photo source: koffkindom.ru

The electronic type has an improved structure and additional functions. Such units maintain the optimal temperature, are able to select the intensity of heating, taking into account the climatic conditions on the street or user preferences. Still similar boilers can control external equipment. Their key disadvantage is their high cost.

Ignition type

A wall-mounted single-circuit boiler can have two types of ignition:

- Piezoelectric - a gas igniter is installed on board, which is ignited by a special piezoelectric element.

- Electric - equipped with a high-voltage generator, which creates a spark between the electrodes.

The second type is characterized by an increased degree of safety and economy.

Prices: summary table

Comparative rating of wall-mounted single-circuit gas boilers:

| Boiler name | Efficiency,% | power, kWt | Gas consumption, m3 / h | price, rub. |

| BAXI ECO Four 1.24 | 91,2 | 24 | 2,7–2,0 | 34 000 |

| Protherm Panther 25 KTO | 92,8 | 25 | 2,8–2,1 | 45 000 |

| Vaillant TEC VU 242 5-5 | 91,9 | 24 | 2,9–2,2 | 57 500 |

| Viessmann Vitopend 100 W | 93,0 | 30 | 3,4–2,5 | 43 000 |

| Buderus Logamax U072-18 | 92,1 | 18 | 2,0–2,8 | 32 000 |

| Rinnai BR-UE30 | 92,8 | 29 | 2,7–2,5 | 58 500 |

Differences by type of control

The simplest single-circuit wall-mounted gas boilers are equipped with mechanical control systems. Here, the simplest circuit temperature control circuit is used, which controls the gas valve. As soon as the temperature in the heating system falls below the set level, the gas supply opens and the temperature rise begins. As soon as the set value is reached, the automatics will turn off the fuel supply.

Electronic control systems in gas wall-mounted single-circuit boilers provide more advanced functionality of the equipment - it more accurately withstands a given temperature, can be guided by the weather outside, can work according to a given program and even control external equipment. The disadvantage of such boilers is their higher cost.

The vast majority of modern wall-mounted gas boilers operate on the basis of electronic control. Mechanical assemblies are rare.

Calculation of the power of a 1-circuit gas boiler

To approximately calculate the power of single-circuit gas boilers required for heating a particular room, one should start from a simple relationship: 100 W of thermal energy is needed for each square meter. In other words, for example, for a dwelling with a total area of 400 sq.m. you will need equipment capable of delivering a thermal power of 40 kW.

In the above example, it is preferable to have a floor-standing boiler, since an additional 15-20% of power should be added to the reserve, which will manifest its need in case of severe frosts. In general, such a simple calculation can be used for buildings with good thermal insulation and low ceilings, that is, up to 2.7 m high. The fact is that it is not the area that is heated, but the volume of the dwelling.

To more accurately determine which gas heat generator is best purchased for specific conditions of use, the following points are taken into account:

- Heat loss through walls. Here, the features of the materials of each wall layer are taken into account.

- Heat loss through windows and doors. Both the total number of openings and the characteristics of each of them affect.

- Heat loss through the floor and ceiling.

- Climatic features of the region.

Without taking into account the above parameters, it is impossible to determine exactly which single-circuit boiler is better to use. For a detailed power calculation, you should use the services of a professional in the field or one of the many special calculators.