Heating equipment on the modern market is represented by a huge number of models. Of these, the most common are gas-powered units. This fact can be explained quite simply: the described fuel is one of the available energy products, with the help of which the systems operate in an autonomous mode. The principle of operation and the advantages of double-circuit floor boilers are known not only to specialists, but also to many owners of private real estate.

If you also decided to equip a heating system in your house, then you should know how a wall-mounted double-circuit unit with an open combustion chamber differs from a floor version, in which the chamber is closed. It will also be useful to know where the double-circuit systems are used, as well as what their structure and principle of operation are. Gas boiler models can be classified into single-circuit and double-circuit.

The first ones have a coil, which only provides the possibility of heating in the house. Double-circuit boilers have two coils or circuits, one of them is intended for heating, while the other is for water, which is usually used for sanitary needs.

What it is

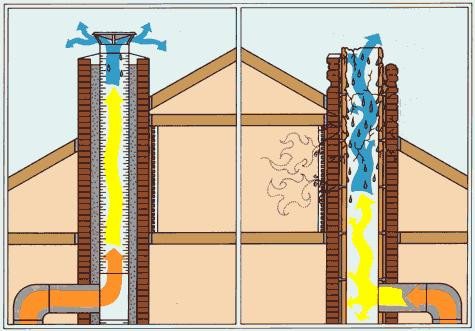

When burning any fuel - gas, coal, peat, coke and others, in addition to heat, steam is also released. As it rises, it cools on contact with air of a lower temperature, and part of it turns into condensate in the smoke channel, that is, into moisture that flows down the walls. This is a natural, but negative and even dangerous physical phenomenon that can turn into the most harmful consequences for the entire heating system (below, in a separate section, we will tell you which ones).

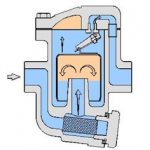

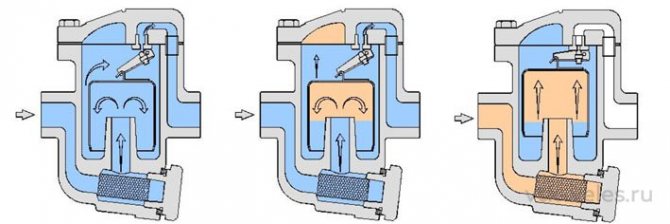

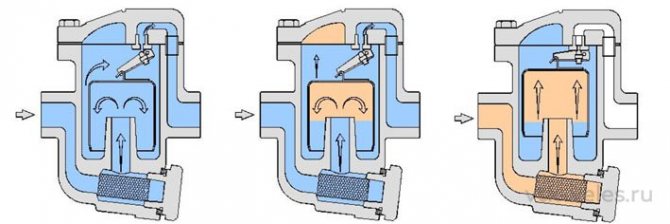

Inverted Bowl Steam Traps

This type of steam trap works on the principle of a glass of gas placed upside down in the water. When filled with steam, it tends to rise, filled with condensate goes down. Such an inverted glass is connected to a valve that opens when it is lowered and closes when it is raised. The inverted bowl design is insensitive to water hammer and steam locks, can operate at high pressure drops and allows for a constant drainage of gases and air.

Causes and factors affecting the formation of condensation

Immediately, we note that they are listed in no particular order, and not according to their degree of importance. So this:

- The temperature of the steam (waste gas leaving the furnace head) does not exceed 100 ° C. This is a typical disadvantage for a significant part of modern heating units.

- The pipe is too long - the smoke cools quickly and strongly in the upper part.

- The selected fuel is either damp (saturated with moisture during storage), or simply poorly suited (initially contains a large percentage of water).

- The hog's clearance has narrowed due to a decrease in thrust caused by the accumulation of soot deposits.

- The piping is not sufficiently insulated and / or made of the wrong material (for example, zinc in one layer).

- The air outside is much colder than the outgoing steam and, due to the serious temperature difference, condensation in the chimney of a private house collects quickly and in large volumes.

- The exhaust gas is trapped by the rough walls.

- There is no or insufficient supply of fresh air to the stove, as a result of which the draft is too low, the fuel burns slowly and is not completely burned.

- The outlet channel already contains some amount of liquid that got there due to precipitation or for some other reason.

- The pipe has defects and / or design flaws - it has too inclined or even horizontal sections, its cross-sectional area differs from the design one (up or down), and the like.

- Poor draft - the faster the gas leaves the system, the better, the less time is left for cooling and moisture formation.

- The stove is folded incorrectly - a significant part of the released energy is spent on heating it (and not on heating the room). This leads to a low outgoing steam temperature, and what this threatens, we have already sorted out above.

All these factors provoke the appearance of fluid, but they act to varying degrees: some are stronger, others are weaker.

Influence of material on the formation of condensation

A gas boiler differs from an electric or solid fuel gas boiler in that it operates in such a way that a certain amount of moisture is always formed in the system. Therefore, when buying and installing it, it is especially important to think over the issue of insulation and decide what the chimney will be made of. The term and safety of operation of heating equipment depends on the correct choice.

Brick

Well assembled (without cracks and cracks), it will be able to effectively retain heat, which will allow its walls to stay cool for a long time, which means it will help maintain normal traction. On the other hand, it needs to be heated up for a long time, and as long as the temperature remains low, the liquid accumulates relatively actively.

Note also that the brick is easily destroyed by contact with acid solutions and temperature extremes. So it is classic and expensive (if made with good bricks), but not the best choice.

Stainless steel pipes

The material itself, the surface of which is perfectly smooth, is resistant to corrosion and aggressive media. Now about the constructive solution.

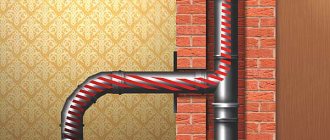

In order not to see how the condensate flows from the chimney, it is necessary to use double-walled, not single-walled. The sandwich manufacturing technology implies double rings of different diameters, between which there is a layer of insulation made of non-flammable basalt fiber. With such an additional insulation, the stainless steel will not only warm up quickly, but also cool down for a long time. And this is without the accumulation of moisture and soot inside.

Ceramic pipes

They are quite durable and have the following advantages:

- warm up quickly and cool down slowly, which means they effectively retain heat;

- universal, do not depend on the type of fuel of the stoves;

- easy to maintain and therefore have been in operation for decades;

- fireproof - they are not afraid of soot fires.

There are also disadvantages, they lie in the large weight of the structure, which can lead to difficulties in installation and high cost.

Furanflex chimneys

You can also consider this composite material so as not to think that condensation from the pipe of a gas boiler or stove can damage the heating system. Moisture will not collect on the channel walls, as they will be made of polymer resin reinforced with fiberglass.

The finished furanflex sleeve can be of any length, diameter and, if properly installed, will be completely sealed. Say a categorical "no" to leaks and a confident "yes" to consistently powerful traction. Installation is quick and clean, without demolition of walls, ceilings, roof parts, supporting structures, and is easy to perform even after finishing work. The material is not damaged even when the steam temperature reaches 250 ° C.

The main disadvantages of furanflex are its high price (2-3 times higher than stainless steel chimneys), expensive installation. In case of damage to the sleeve, it is difficult to access the element, and the purchase of the entire system can significantly hit the pocket.

Asbestos-cement chimneys

Previously, they were used everywhere, today, with the development of technology, they are considered morally obsolete.Choosing this option, you will think not only about why condensation forms in the chimney, but also how to eliminate the consequences of inhaling asbestos dust. And it will be released during the heating process (when the acids contained in the flue gases begin to destroy the channel), settle in the room, and then get into your lungs when you inhale.

This material has other disadvantages: it is not tight enough, does not retain heat well, and absorbs liquids relatively actively. Add to this the roughness of the surface (which, as we found out above, is bad), high porosity and a tendency to cracking under the influence of high temperatures, a threshold of 300 ° C, above which there is a threat of explosion.

Steel and galvanized pipes (single wall)

They are lightweight and inexpensive - the sleeve will come out 50-80% cheaper than the brick sleeve, not to mention the rest. But at the same time, there are drawbacks, and the main one is that the channel burns out quickly. This is due to the inability to withstand the effects of condensation and high temperatures. Steel can rust as it has poor corrosion resistance. And zinc, when heated above 419 ° C, emits toxic substances, therefore, rolled metal products from it can only be used at a low temperature of exhaust gases.

Thus, we recommend opting for insulated stainless steel chimneys.

In addition to choosing a suitable material, it is necessary to install according to the instructions. Failure to assemble the pipe can lead to condensation and soot settling.

Our production

Single wall chimneys

Double-walled chimneys

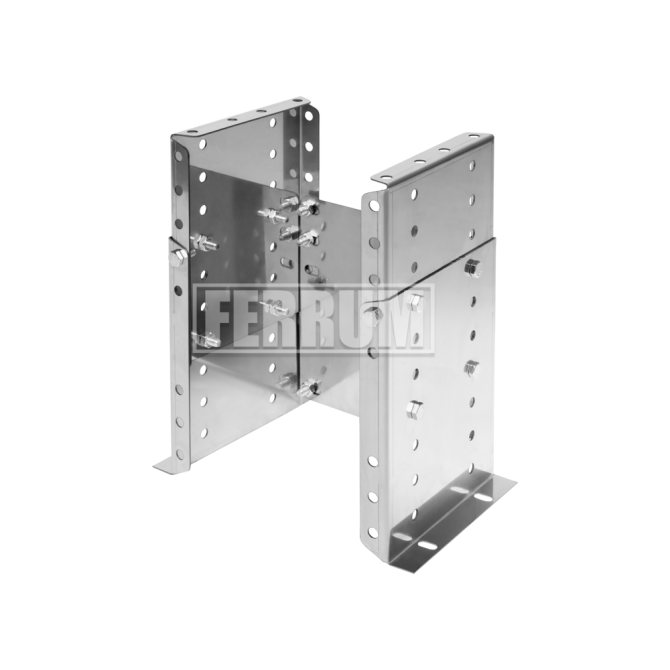

Mounting elements

Bimetallic steam traps

Here, the valve stem acts as a working element, on which bimetallic plates with different expansion coefficients are fixed.

The elements are selected in such a way that in the cold state the plates are a flat disc that allows air and condensate to pass through. When heated, the plates expand and bend unevenly, moving the stem to close and preventing steam from escaping. As a result, the bimetallic steam trap can be used as an air vent. In addition, this type is suitable for installation on superheated steam lines, since the element is structurally composed of materials that can withstand high temperatures.

You can purchase any of the listed types of steam traps in ours. Our assortment includes all types from leading manufacturers at affordable prices. When ordering a steam trap, keep in mind that there is no universal option. In each case, you need to select an element taking into account the parameters of your steam condensate system. If you have any difficulties, please contact our specialists - we will help you with the choice of equipment. You can contact us in any way convenient for you.

The appearance of moisture in double-circuit boilers

In addition to the chimney, condensation can occur in the water pipes of 2-circuit gas boilers. It's all about the temperature difference, due to which the pipe can rust and fail.

The problem can manifest itself for one of the following reasons:

- The ventilation is not working properly (the extraction power is insufficient).

- The indoor climate is unfavorable - the humidity level is consistently exceeded.

- The equipment is operating in the wrong (erroneously calculated) mode.

Unfortunately, the boiler's features do not allow to completely get rid of condensate, but pipe insulation and chimney insulation can reduce the rate of moisture accumulation.

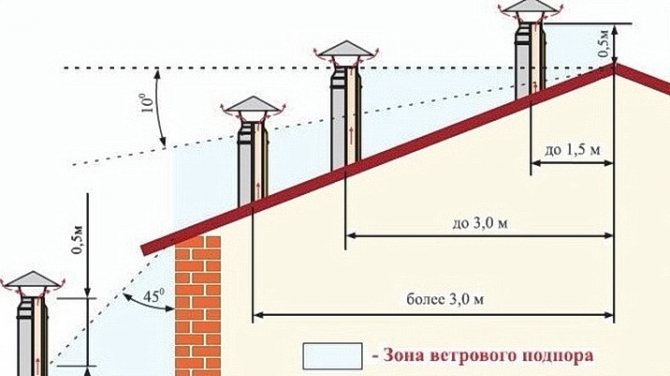

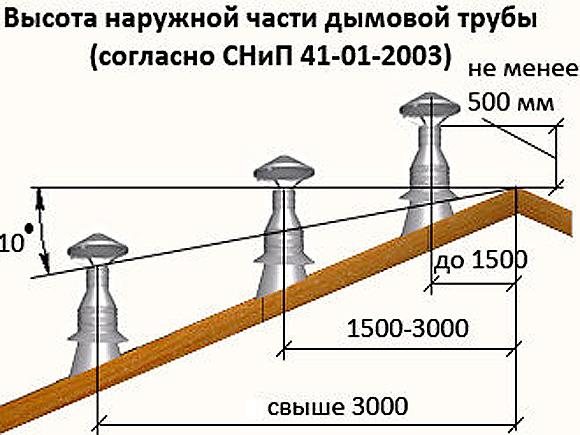

Chimney design requirements

They are stipulated by the provisions of SNiP 41-01-2003 and boil down to the following:

- channel height at least 5 m;

- the pipe rises above the flat roof by at least 1 m, above the pitched one - depending on the distance between the ridge and the head (by 0.5 mm, flush or at an angle up to 10 0);

- horizontal sleeve no more than 1 m long;

- the sum of the projections of the inclined and horizontal zones is strictly up to 2 m, and the vertical sections also increase by the same length.

We have figured out why condensation is collecting in the chimney, and now let's see how to prevent it. First of all, correct installation of the pipe helps to prevent the appearance of excess moisture.

Installation rules

It is important to make the system airtight, insulated, waterproof, protected from the destructive action of aggressive media. To do this, it is necessary to select suitable materials for arrangement and insulation, and then be guided by the following principles:

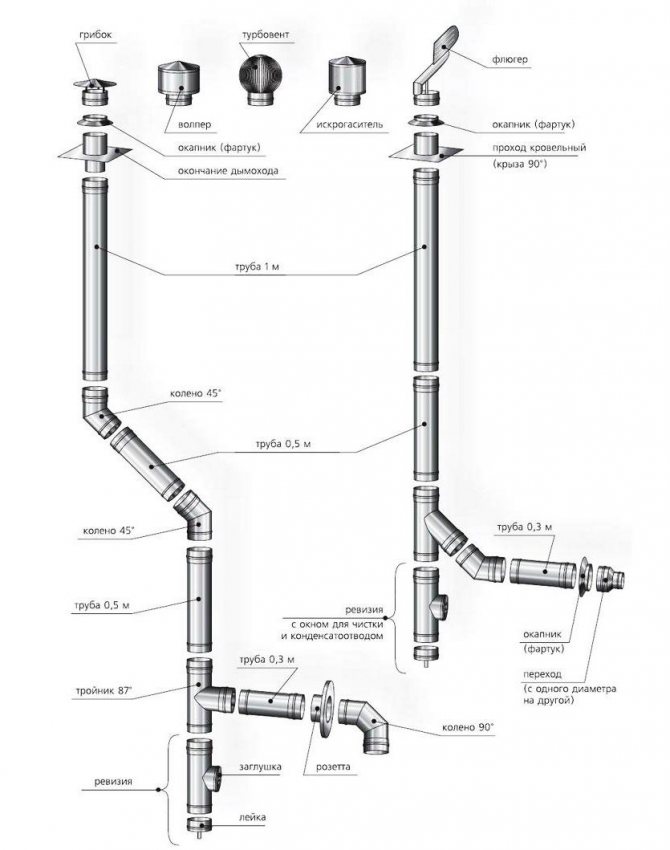

- The chimney assembly must pass through “condensate” and not through “smoke”. For single-walled chimneys, when assembling "by condensate", the upper end is inserted into the lower one. For sandwich insulated structures, this rule applies to internal assembly. In this case, the outer part is assembled "by smoke".

- Treat each joint with a sealing compound.

- Do not deviate from the vertical by more than 30% (less serious deviations are acceptable).

- Make horizontal sections no longer than 1 m.

- Use accessories of the same cross-section (throughout the channel).

The installation must be carried out in compliance with the technologies and competently choosing the pipe material. Avoid using obsolete and hazardous materials (asbestos) or difficult to build materials (such as bricks). It is better to use ready-made chimney kits, which are presented on the website feflues.ru. The prices can be found in the price list.

Float steam traps (mechanical), principle of operation:

| 45s99nzh | 45h13nzh | RKPM-RN | RCP |

Operating principle (operating principle) float steam traps based on the difference in density between steam and condensate. The actuator is a ball float or an inverted glass float. The float is connected to the outlet valve by means of a lever. Condensate enters the trap body and, filling it, raises the float, while opening the drain valve. When the system is started up, air enters the condensate drain, which is easily removed into the condensate line. These traps provide continuous drainage of condensate and are most suitable for systems with large heat transfer surfaces and large volumes of condensate.

The advantages of float steam traps:

- Stable operation at low loads;

- Resistant to sudden pressure fluctuations;

- High productivity (up to 150 tons of condensate per hour!);

- Reliable in operation, resistant to water hammer;

Disadvantages of float steam traps:

- Low resistance to dirt;

- If the float breaks, the valve will be constantly closed, which can lead to rupture of the pipeline;

- Possible frost damage;

During operation, the body of the float steam trap must always contain water (water seal). Loss of this water seal can result in unimpeded steam escaping through the steam trap. This can happen with a sharp drop in steam pressure and, as a result, condensate boiling. To avoid this, in systems where pressure fluctuations are possible, a check valve is installed upstream of the steam trap. The float steam trap can be damaged by freezing. When installing the float trap outdoors, it is necessary to use thermal insulation on the casing.

What to do if the chimney is leaking

Yes, it will not be possible to completely protect against moisture on the walls of the channel, but at least the volume of its appearance can be reduced, however, at the stage of building a building and arranging the roof.But what if the house is not new (for example, you bought it from someone), has been in operation for a long time and already has this problem.

There are effective measures, and it is quite possible to take them even on your own. Below we will tell you several ways, but first, answer a simple question: what are you going to use to heat?

Focus not only on the price of the combustible material, but also on its environmental friendliness (after all, the health of yours and those of your loved ones depends on it), the economy of consumption and, attention, on its natural humidity. Indeed, in the same fuel oil or gas there is a lower percentage of water than in wood. Also, consider how easily the fuel absorbs liquid. Any tree must be dried before use, peat or coal is strictly forbidden to wet.

Now let's move on to how to fix the problem.

Pipe cleaning

How to avoid excess moisture and deal with condensation in the chimney? Remove soot in a timely manner. Because it settles on the walls of the channel, making the surface rough, and thereby impairs the draft - the flue gases are trapped in artificially created "cavities".

The amount of soot depends on the fuel used and the system installed. With a coal stove, there will be a lot of it, with a gas boiler - not enough. But she will still be. Therefore, it is important to clean the inside of the canal at least twice, and preferably three times a year. Choose any convenient method, mechanical or chemical, only in the first case, act carefully so as not to damage the walls, and in the second, use environmentally friendly and not too aggressive compounds.

Warming

It is important to prevent the formation of excess condensation in the chimney even at the stage of building a house or bath. For these purposes, it is necessary to use an insulated structure, namely:

- single-walled chimney in an insulated shaft;

- double-walled chimney.

How to get rid of condensation in the chimney chimney if it is constantly cold? It is necessary to insulate it with modern thermal insulation materials. If you have a brick chimney, the best option to prevent condensation is to use a stainless steel sandwich.

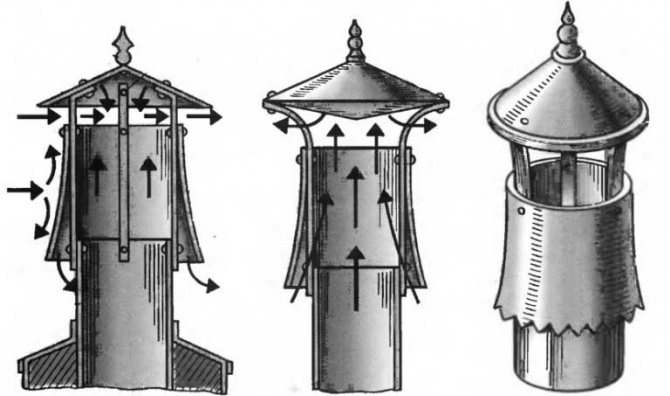

Protection of the channel from precipitation

Achieved by installing accessories - you need to install:

- chimney condensate drain - a container for collecting condensate, usually made of stainless steel; place such an element below the nozzle so that, if necessary, it can be easily emptied;

- deflector (umbrella with wind protection) - installed at the end of the chimney (a cone is previously attached to the sandwich), prevents precipitation from falling into the pipe;

- visor - with or without a weather vane, in the form of a fungus (four-pitched roof), with an opening lid or not; but in any case, it will protect against direct precipitation - raindrops and snowflakes.

These elements stabilize traction, eliminate the possibility of blowing out and make the appearance of the roof more modern and aesthetic.

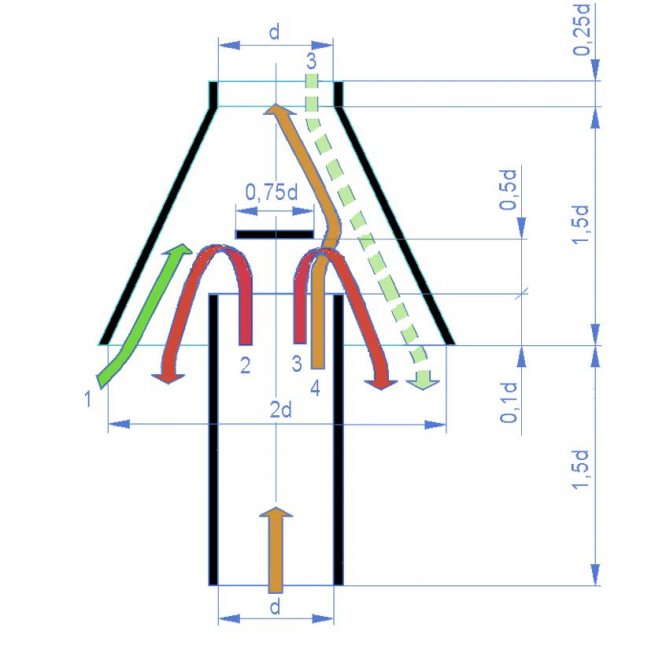

Installation of a through-feed collector

In the chimneys of gas boilers, condensate often forms in horizontal pipe sections. In order to solve this problem, a collector is installed as a pipe segment, to which an angle of 90 ° is attached so that the chimney is tilted towards the boiler. This is done so that moisture can flow down into the condensate trap.

Is it possible to calculate the probability of condensation

Yes, if it appears due to overheating of the walls due to too much steam emission. In this case, it is realistic to determine what the power of the operating equipment should be.

In general, the rate of heat release (per 10 m2 of room area) is 1 kW. If the ceilings in the room are not higher than 3 meters, the formula is as follows:

MK = S * UMK / 10, where

MK is the calculated power of the boiler in kW; S is the area of the room in which the heating unit operates; UMK is a specific indicator that depends on the climatic zone of residence and is equal to:

- 0.9 - for the south;

- 1.2 - for the middle band;

- 2 - for northern latitudes.

If a double-circuit boiler is used, the resulting MK figure must be multiplied by 0.25 (additional factor).

Benefits of gas boilers

The main advantages are:

- There is no need to store fuel. This saves time and money.

- Cleanliness in use. There is no need to constantly clean up garbage, soot and soot.

- Efficiency. A properly selected boiler heats up the steam room in less than 1 hour.

It's important to know! The calculation of the power of a gas burner is based on a proportion of 252 kcal per 0.4 m3. Calculation example: a steam room has dimensions of 2x1 5 x 1.7 meters. The volume is 5.1 m3. 5.1 / 0.4 * 252 = 3213 kcal.

To convert kcal to kW, we use the coefficient 0, 001163.3,213 kcal x 0.001163 = 3.7 kW.

It is better that the power of the selected boiler exceeds the calculated one. This will increase its service life. The required power of a gas burner can depend on a number of other variable factors.

A gas specialist will help determine the capacity based on these factors:

- Profitability. Natural gas is a cheaper fuel than diesel or wood.

- Easy to operate.

- Safety. Modern gas equipment is equipped with a gas control system. If the burner goes out, the gas supply will shut off automatically.

And so you came to the store to buy a gas boiler for a bath. The store manager will give advice, talk about the disadvantages and advantages of different options. Basic knowledge will help you understand the information and choose the most suitable model.

Consequences of the formation of condensation inside the chimney

Moisture is not simply collected, but mixed with combustion products - aggressive acids (nitric, carbonic, sulfuric). By settling on the walls, these harmful compounds gradually destroy the channel (if it is made of brick, plain steel or other material with low corrosion resistance). Excessive condensation leads to the formation of soot, which clogs the hose, impairing draft, resulting in the risk of chimney fire and back draft.

Preventive measures

We will tell you how to get rid of the cause of condensation in the chimney. It's simple: you need to prevent the appearance and development of moisture formation factors. This requires:

- competently design a heating system and equip it strictly according to the drawings;

- correctly mount the flue gas vent made of material resistant to aggressive environments and high temperatures;

- provide high-quality thermal insulation;

- to maximize thrust - by installing deflectors, visors, rotary turbines;

- use suitable and dry fuel;

- carry out regular cleaning of the inner surfaces of the sleeve.

Now that you know why condensation forms in the chimney of a flue boiler and how to eliminate it, you can extend the life of the heating system, as well as increase the convenience and efficiency of using it.

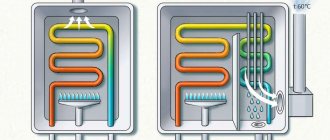

What is a condensing boiler and what does it work on

To understand the high fuel economy characteristics of a condensing boiler, let's remember how any heating boiler works.

In any heating boiler, various types of fuel are burned, the energy from the combustion of which is transferred into the heat of the coolant. But not all heat goes to the coolant. Part of the heat is given to the boiler body, part of the heat is removed with water vapor contained in the combustion products.

The device of a condensing boiler allows condensation of water vapor from combustion products. The physical process of condensation is accompanied by the release of heat, which is returned to the heating system. This allows you to achieve 10-15% heat savings in comparison with conventional boilers, as a result, to reduce fuel consumption.

Note: The main fuel for condensing boilers is gas.