Varieties of solid fuel boilers

As you know, one of the main properties of a heating boiler for a summer residence, which must be taken into account when choosing a particular model, is the efficiency of work (in more detail: "How and which solid fuel boiler to choose: selection and comparison"). This parameter directly depends on what type of solid fuel boiler is planned to be operated, since the fuel burns out in completely different ways in different designs. Therefore, we should dwell in more detail on the types of TTK.

Choosing a boiler for a summer residence

Main varieties

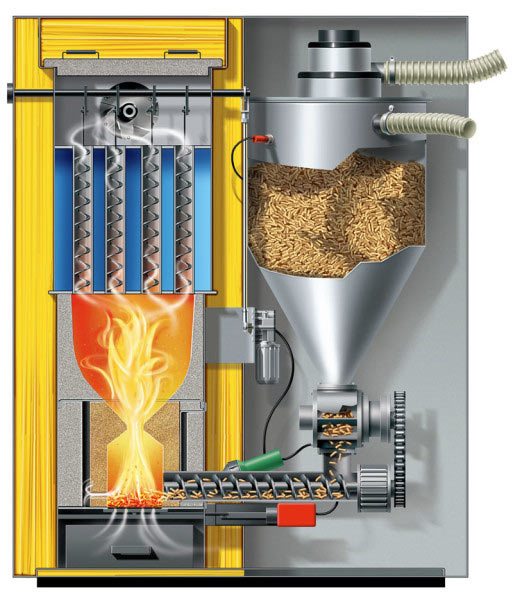

Pellet model

As a rule, solid fuel heating boilers for summer cottages are classified according to the type of fuel used. To make it easier for you to analyze the options, basic information has been collected in the form of a table:

| Variety | Features of the |

| Coal |

|

| Wood and pellet |

|

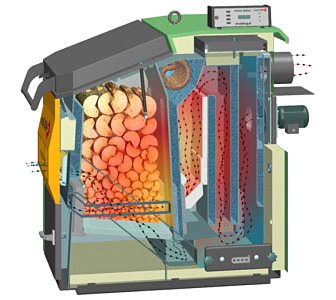

| Pyrolysis |

|

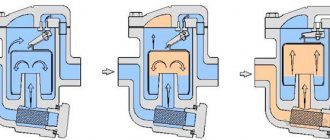

Heat flow diagram in a pyrolysis boiler

When approaching the choice of technology from a practical point of view, the most important factor will be the factor of accessibility. If logging is underway in your region, then it is best to purchase a wood-burning model. In regions with a developed mining industry, there is usually no shortage of coal, therefore its cost will be lower - accordingly, the operation of the coal model will be cheaper.

Unit selection parameters

If we have decided on the fuel, then further instructions for selecting a boiler for a summer residence will relate to the features of its functioning:

For a large summer cottage, you need to purchase powerful heating equipment

- Equipment power. This parameter is key, since it will depend on whether the heating equipment can cope with heating the room in the cold season. So, if you plan to use the heater in winter, then its performance must be calculated according to the ratio of 1 kW * h per 10 m2.

Note! This value is valid for houses with standard thermal insulation and ceilings no higher than 3 m, located in the middle zone of the Russian Federation. It is better to entrust the calculation of boiler performance for the northern regions, as well as for buildings with additional heat-insulating circuits.

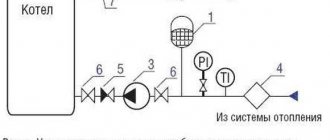

- Volatility. For the efficient use of heating equipment during a power outage, we will have to purchase an expensive generator. That is why boilers with a simple regulating mechanism are usually bought for summer cottages, the operation of which does not depend on the presence of voltage in the network.

- Fuel loading volume.Everything is simple here: the larger the bunker, the less often we will have to approach the apparatus and add fuel to the furnace. If you use the dacha only occasionally, then you can purchase models with one firebox and lay a portion of firewood 5-6 times a day. But for a permanent stay, it is better to overpay a little for the auto-feed system.

The larger the bunker, the less worries!

- The presence of a second circuit. If the boiler is to be used as the main source of heat, then it would be quite logical to install a model with a hot water tank. So we will not only provide a comfortable microclimate in the house, but also get a hot water source for shower and household needs.

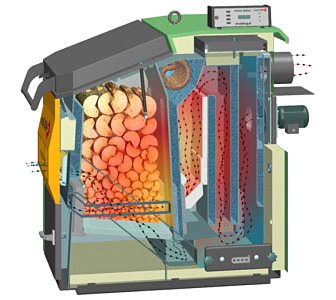

Solid fuel boilers for long and direct combustion

- In mechanisms operating by means of direct combustion, the process of heat transfer occurs during the combustion of the consumable, which explains the need to constantly maintain combustion. In these devices, fuel consumption is high, while the performance ratio is far from ideal. Moreover, these boilers are not automated.

- Direct fired boilers transfer heat while the fuel is smoldering and not directly from the flame. Thanks to the top burning method, this equipment is able to provide a room with constant heat. The method of supplying material for combustion is manual, and the time for warming up such devices is long.

TT boilers with tubular heating elements what you need to know

The main requirements that the owners of modern cottages make to the projected heating systems of their home are reliability, uninterrupted operation and economy. In most cases, the fulfillment of these conditions depends on the type of fuel used for heat generation.

It is known that network gas is considered the most efficient type of fuel. However, what to do if the gas pipeline has not yet been connected to the section where the house is supposed to be or has already been erected? In this case, a universal boiler is often installed, which will work from several energy sources at once.

Boilers of pyrolysis and pellet type

- The efficiency coefficient of the TTK pyrolysis combustion is very high. It functions by releasing a combustible gas produced when heated at high temperatures. These gases enter a special part of the boiler, where they are burned. It should be noted that such solid fuel boilers for heating summer cottages and other living quarters work in such a way that the fuel burns out almost without residue, while it is not necessary to equip a complex chimney system, since the combustion products are removed by means of a blower fan. Among the disadvantages of pyrolysis equipment is the high cost, as well as the need to use extremely well-dried fuel. In this case, the moisture content for wood should not exceed 20%, otherwise the boiler performance will significantly decrease.

- The most functional is the pellet boiler system, where the heat source is special fuel pellets (pellets). There is practically no need to control the operation of this mechanism, since the fuel supply and ignition to them are automatic. Only the fuel material needs to be added periodically. Moreover, the efficiency of such boilers is very high, which is explained by the afterburning of gases in the system and the use of additional heat.

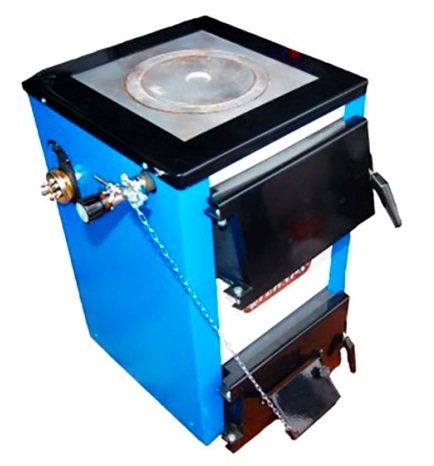

Solid fuel boiler with electric heating element

A solid fuel boiler with an electric heating element is optimal for use in regions where there is no centralized gas supply. The main advantage of the equipment is the ability to use two alternative types of energy. Heating units operate both on solid fuel and heat the room using built-in electric heaters.

Design features

The basis of the mechanism is a combustion chamber for solid fuel, which can be used as:

- Coal.

- Firewood.

- Peat briquettes.

- Wood sawdust.

Today you can buy heating equipment in various modifications. In some models, the water circuit can be located on top of the firebox, in others around it. The efficiency for both options is high. This criterion does not affect the price of the equipment.

Ash, which is formed as a result of the combustion of solid fuel, in most units is poured through the grate into the ash pan. From there, it is easily removed as the container is filled.

The electric heater, powered by the network, is automatically turned on in case of a decrease in heat transfer from the combustion chamber. Most modern models are equipped with automatic control that allows you to set different temperature conditions, depending on the accompanying conditions.

Equipment advantages

The main advantages of a solid fuel boiler with an electric heating element include:

- High strength characteristics. Boilers are made of extra strong materials - heat-resistant steel, cast iron.

- Ability to work from two independent energy sources. In the absence of one, the equipment automatically switches to the other and continues to heat the room within the specified temperature parameters.

- Simple controls. Many affordable models have a remote control. The temperature regime of the water circuit is set using the heating element control panel.

- Possibility of connecting up to several systems to the boiler at the same time. This allows using one unit to heat several independent premises (house, garage, sauna, etc.).

- Profitability. After the optimum temperature in the room is reached with the help of solid fuel, the included heating element will allow you to maintain heat in the specified parameters. This allows you to optimally use the energy resources used.

In our online store there is a wide selection of solid fuel boilers equipped with an electric heater. It is easy to choose and buy a suitable unit among a wide range of products.

Steel boilers

Steel TTK, as a rule, have obvious advantages, such as an affordable price and low weight. But at the same time, long-burning solid fuel boilers have one big drawback - a short service life. In addition, if such units are installed in open heating systems, this also contributes to faster wear of the equipment.

This is explained by the fact that the coolant contains oxygen, which, as you know, is one of the reasons for the appearance of corrosion on the mechanism. All these factors, negatively affecting the operation process, reduce the service life of the boilers to 10 years.

But in those devices in which circulation is forced, active oxygen does not appear. Thanks to this, their service life is increased and is approximately 20 years.

Solid fuel boiler and electricity specific device

Initially, the title of the publication looks contradictory (curious), as if they want to associate the Stone Age with the scientific and technological revolution of the 20th century. But the problem faced by homeowners who heat their home or house in the country, resorting to burning solid fuel, forces them to improve ordinary boilers and create their modified hybrids - electro TT boilers.

The first task pursued in these units is to prevent the defrosting process of heating systems at low temperatures. When the boiler is not in operation for a very long time, and the heat carrier is in the heating circuit. You can solve this issue by changing with a heat carrier.For example, by replacing the water in the system with antifreeze or adding additives that reduce the cryogenic freezing threshold for the heat carrier. These options solve the established problem, however, the cost of these steps to get out of the situation is very high.

Unit design features

Externally, the device of an electric-wood boiler practically does not differ from a traditional solid fuel heat generator. Only in one place, where the unit's water jacket is located under the casing and thermal insulation, is there a special hole from which the contacts for connecting electrical wires are visible. In reality, the combi plant has a combustion chamber for loading solid fuels, an ash chamber with a damper through which combustion air passes, and a grate.

Household combined boilers for wood and electricity can be equipped with both a water-tube heat exchanger and smoke tubes. Some models are also equipped with hobs located in the upper part of the combustion chamber. That is, these are full-fledged solid fuel plants with an efficiency of 75-85%. But they have one design feature: one of the walls of the firebox, which is the inner lining of the water jacket, has a complex profile, made using cold stamping. Thanks to this profile, one or more heating elements are placed in the space between the inner and outer skin of the shirt. This is a special case of the scheme according to which electric-wood heating boilers are made, heating elements can be built into the boiler tank in other ways.

When, for any reason, the boiler cannot operate on the main fuel - wood, it automatically switches to electricity and vice versa, when the furnace is ignited, the electric heaters are turned off.

Boiler operation description

The heating elements are controlled by the electric unit, and the intensity of solid fuel combustion is regulated by the air supply thermostat, opening the ash chamber flap with a chain at a certain angle. That is, the control functions of the electric and solid fuel parts of the heater are separate. If the air is supplied to the furnace forcibly by a fan, then both parts are controlled by the automatics for the wood boiler. In the first case, the operation algorithm is as follows:

After connecting the heat generator to the network, the electric heater turns on. The temperature of the coolant is set on the control panel and the heating element begins to heat the water in automatic mode. It is better to set the temperature 10-15 ºС below the working temperature.

At this time, fuel is loaded into the combustion chamber and ignited. From this moment, the heating of the coolant occurs jointly, if the electric heaters are not forcibly turned off.

Having reached the water temperature set on the control panel, the heating elements are turned off and the coolant is heated with wood until the operating temperature. The intensity of combustion is controlled by a chain-driven thermostat, and as soon as the water reaches the operating temperature, it shuts off the air supply.

When the combi boiler burns its main fuel and there is no new load, the coolant will start to cool down and at a certain moment the sensor of the electric unit will work and it will turn on the heaters that will maintain the water temperature until the next firewood is loaded.

The algorithm for working with an air supply fan and a single electronic unit is similar to that described above, only the process of setting up the equipment is simplified. In this case, the non-volatility of the solid fuel part of the unit is lost.

Due to their design and principle of operation, electric-wood heating boilers for a private house acquire some advantages that are unusual for conventional solid fuel units:

- Condensation does not form on the inner walls of the furnace due to the flow of cold water from the return pipeline, since the boiler tank is constantly heated by the heating element.

- As a result, the building heating system can be connected directly to the heat source, without the organization of a small circuit and a mixing unit with a three-way valve.

- Theoretically, the efficiency of the combined water heater increases to 97-99% while the electric heating is in effect and the main firebox is not functioning.

At the same time, the versatility of the unit does not eliminate the disadvantages inherent in both types of heaters separately. This is inertia, which is expressed in the inability to immediately stop heating the coolant when the maximum temperature is reached.

Another drawback is the relatively low power of the electrical part, the device of a water jacket will not significantly increase it, it is impossible to build many electric heaters into it. For this reason, the power of electric heaters is equal to the power of a wood-burning combustion chamber in the range of 6-25 kW. If a higher indicator is required, then the electricity will serve only as heating and will be able to maintain the temperature of the coolant at a certain level.

Solid fuels and electricity - the background to this combination

We are all familiar with the situations that arise during the operation of boiler equipment in a private house. With a centralized gas supply, the human factor is reduced to almost zero, while the operation of heating equipment on solid fuels requires constant attention. It will not be possible to solve the problem by installing only one automation.

Excellent technological capabilities, efficiency and practicality in operation, characteristics that today can deservedly be given to solid fuel heating units. Everything would be fine. However, there is one major drawback that can cloud the idyll and comfort of your home. The fuel supply has run out, the firewood in the firebox has burned out, and what? The boiler is forced to stop involuntarily. If there is a heat accumulator, the situation is not so catastrophic. The hot water accumulated in the tank will disperse through the heating system, maintaining the required temperature in the house for some time.

And if we are talking about a country house, where a lot of time passes between the visits of the owners. A stopped boiler, wasted coolant from the storage tank will put the entire system into a technological collapse. In winter, such a situation is fraught with defrosting of the entire heating system - an emergency, the consequences of which cannot be eliminated in a short time. Whatever this happens, a backup option for heating the coolant in the system is used. The role of the fuse in this case is best entrusted to electric heating devices. Electricity in the network is almost always available, regardless of whether the owners are at home or not.

Important! A solid fuel boiler performs the main work on heating the coolant, providing the inhabitants of the house with hot water. The results obtained are achieved due to the high power of the equipment and the peculiarities of the piping of solid fuel units. Electricity in this case is assigned a supporting role. The electrical part has limited power.

Electric heating elements are able to maintain the performance of the heating system at an optimal level. We ran out of firewood in the firebox, the system itself switches to power supply. It is not uncommon for both heating sources to work in tandem, taking turns replacing each other. We are well aware of the situation when the next firewood burns out during the night, and by morning the house begins to cool down and the hot water in the tap is barely warm.